EN

PRECAUTIONS FOR SAFETY ..............................................1

ACCESSORY PARTS ............................................................4

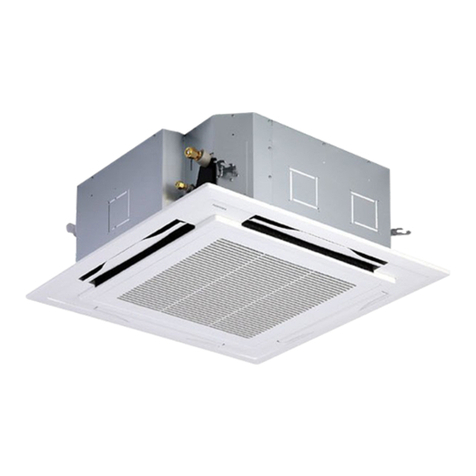

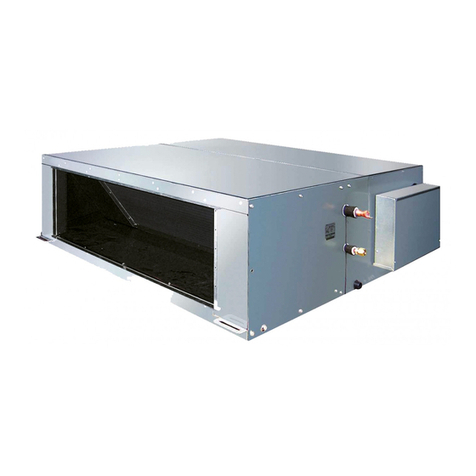

INSTALLATION DIAGRAM OF INDOOR AND

OUTDOOR UNITS ..................................................................5

Optional Installation Parts .................................................5

INDOOR UNIT ........................................................................6

Installation Place ...............................................................6

CuttingaHoleandMountingInstallationPlate.................6

PipingandDrainHoseInstallation....................................6

IndoorUnitFixing..............................................................7

Drainage ...........................................................................7

OUTDOOR UNIT ....................................................................8

Installation Place ...............................................................8

PrecautionsaboutInstallationinRegionswithSnowfall

andColdTemperatures.....................................................8

DrainingtheWater............................................................9

RefrigerantPipingConnection..........................................9

Evacuating.......................................................................10

ELECTRICAL WORKS ........................................................11

WiringConnection...........................................................11

PowerSupplyandConnectingCableConnection..........12

PowerSupplyInputWiringDiagram...............................13

OTHERS ...............................................................................14

GasLeakTest.................................................................14

RemoteControlA-BSelection........................................14

TestOperation.................................................................14

AutoRestartSetting........................................................14

APPENDIX ...........................................................................15

RU

MEPЫ БEЗOПACHOCTИ .....................................................1

ДОПОЛНИТЕЛЬНЫЕ ДЕТАЛИ ............................................5

СХЕМА УСТАНОВКИ ВНУТРЕННЕГО И НАРУЖНОГО

БЛОКОВ .................................................................................6

OпционaльныeУcтaновочныeЧacти.............................6

BHУTPEHHИЙ БЛOК ............................................................7

MecтоУcтaновки .............................................................7

ПpоpeзaниeОтвepcтияиМонтaжУcтaновочной

Плacтины

..........................................................................

7

УcтaновкaTpyбопpоводовиДpeнaжнойTpyбки...........8

УcтaновкaBнyтpeннeгоБлокa........................................9

Дpeнaж..............................................................................9

HAPУЖHЫЙ БЛOК ...............................................................9

MecтоУcтaновки..............................................................9

Мерыбезопасностиприустановкеврегионах,

вкоторыхвозможновыпадениеснегаинизкие

температуры....................................................................9

Сливводы.......................................................................10

ПодcоeдинeниeTpyбопpоводaдляXлaдaгeнтa..........10

УдaлeниeВоздyxa..........................................................11

ЭЛEКТPОМОНТAЖНЫE РAБОТЫ ...................................12

ЭлeктpичecкиeCоeдинeния.........................................12

Подключениеисточникапитанияисоединительного

кабеля

............................................................................

13

Схемаэлектрическихсоединений...............................14

ДPУГИE ................................................................................15

ПpовepкaОтcyтcтвияУтeчкиГaзa...............................15

ВыборА-ВнапультеДУ.................................................15

ПpобнaяЭкcплyaтaция..................................................15

УcтaновкaAвтомaтичecкогоПовтоpногоПycкa...........15

ПРИЛОЖЕНИЕ ....................................................................16

TR

GÜVENLİK ÖNLEMLERİ .......................................................1

AKSESUAR PARÇALARI ......................................................4

İÇ VE DIŞ ÜNITENIN MONTAJ ŞEMASI ...............................5

İsteğeBağlıMontajParçaları............................................5

İÇ ÜNİTE ................................................................................6

MontajYeri........................................................................6

BirDelikAçılmasıveMontajPlakasınınYerleştirilmesi.....6

BorularınBağlanmasıveBoşaltmaHortumununMonte

edilmesi.............................................................................6

İçÜniteninTakılması.........................................................7

SuBoşaltma......................................................................7

DIŞ ÜNİTE ..............................................................................8

MontajYeri........................................................................8

KarlıveSoğukBölgelerdeMontajİleİlgiliÖnlemler.........8

SuTahliyesi.......................................................................9

SoğutmaMaddesiBoruBağlantısı...................................9

Boşaltma..........................................................................10

ELEKTRİK İŞLERİ ...............................................................11

KabloBağlantısı..............................................................11

GüçKaynağıveBağlantıKablosuBağlantısı..................12

GüçKaynağıgirişiKabloŞeması...................................13

DİĞERLERİ ..........................................................................14

GazKaçağıTesti.............................................................14

UzaktanKumandaileA-BSeçimi...................................14

Testİşlemi.......................................................................14

OtomatikYenidenBaşlamaAyarı....................................14

EK .........................................................................................15

1122950109_S04_182x257_52p_S_p70_181217_EN+TR+RU.indd 2 12/25/2018 10:46:49 AM