8

Drain hose

How to remove the drain hose

• The drain hose can be removed by removing the

screw securing the drain hose and then pulling out

the drain hose.

sharp edges of steel plate. The edges can injuries.

How to remove the drain cap

pliers and pull out.

How to x the drain cap

1) Insert hexagon wrench (4 mm)

in a center head.

No gap Insert a hexagon wrench

(4 mm).

Do not apply lubricating oil

(refrigerant machine oil)

when inserting the drain

cap. Application causes

deterioration and drain

leakage of the plug.

2) Firmly insert the drain cap.

CAUTION

Information

due to the condition of piping and you

9screws provided

Slit

Slit

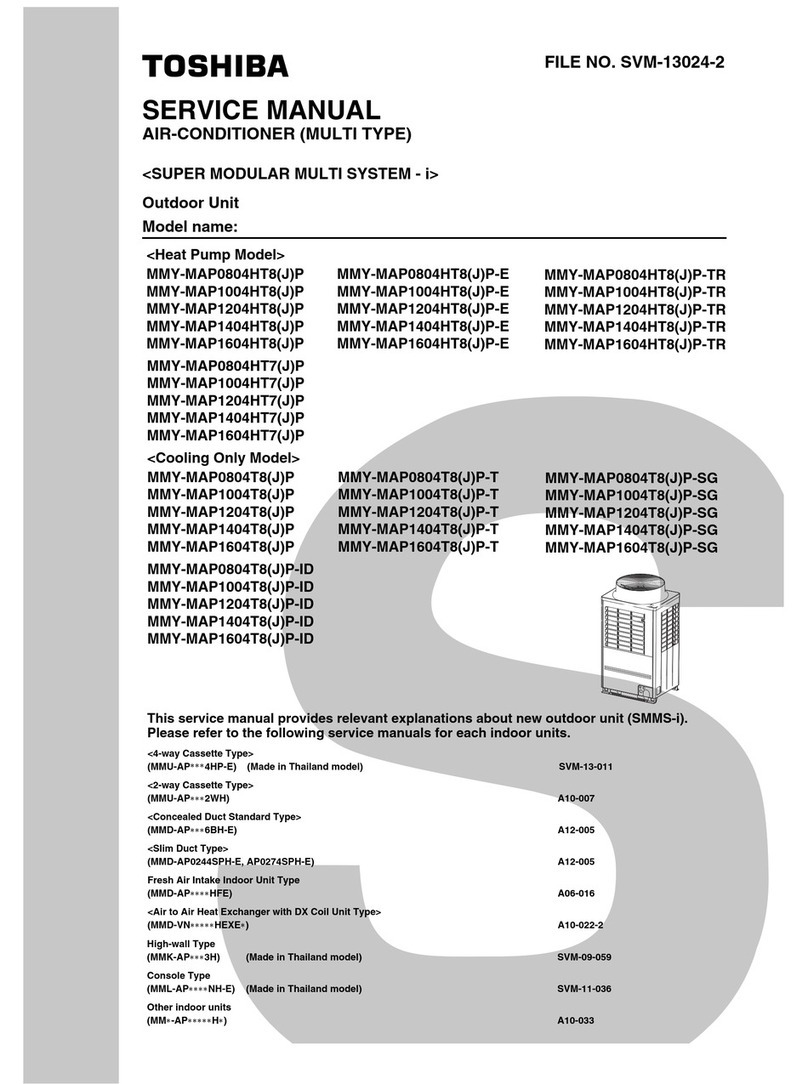

In case of right or left piping

In case of bottom right or bottom left piping

• After scribing slits of the front panel

them with a pair of nippers or an

equivalent tool.

• After scribing slits of the front panel

them with a pair of nippers or an

equivalent tool.

Left-hand connection with piping

surface. If the connecting pipe is laid exceeding 43 mm above the wall

as not to crush the pipe.

Bend the connecting pipe within a radius of 30 mm.

Gas side

Liquid side

520 mm

43 mm

420 mm

Outward form of indoor unit

R 30 mm (Use polisin (polyethylene)

core or the like for bending pipe.)

connecting pipes to the auxiliary pipes and wrap the facing tape around

them.

CAUTION

auxiliary pipes (two) only with facing tape.

• Carefully arrange pipes so that any pipe does not stick out of the rear

plate of the indoor unit.

• Carefully connect the auxiliary pipes and connecting pipes to one

connecting pipes. (Use polyethylene foam as insulating material.)

Indoor unit

Connecting cable

Auxiliary pipes

Installation plate

Indoor Unit Fixing

1. Pass the pipe through the hole in the wall and hook the indoor unit on the

installation plate at the upper hook.

on the installation plate.

hooked up on the installation plate.

Hook here.

Hook Press

(unhook)

Installation plate

1

• For detaching the indoor unit

pull the indoor unit toward

you while pushing its bottom

Push Push

9Screw 9Screw

1120650172-00_S01_182x257_36p_S_p70_181219.indd 8 6/2/2562 16:25:45