Toshiba 2000 User manual

Other Toshiba Controllers manuals

Toshiba

Toshiba TS2000 User manual

Toshiba

Toshiba 2000 User manual

Toshiba

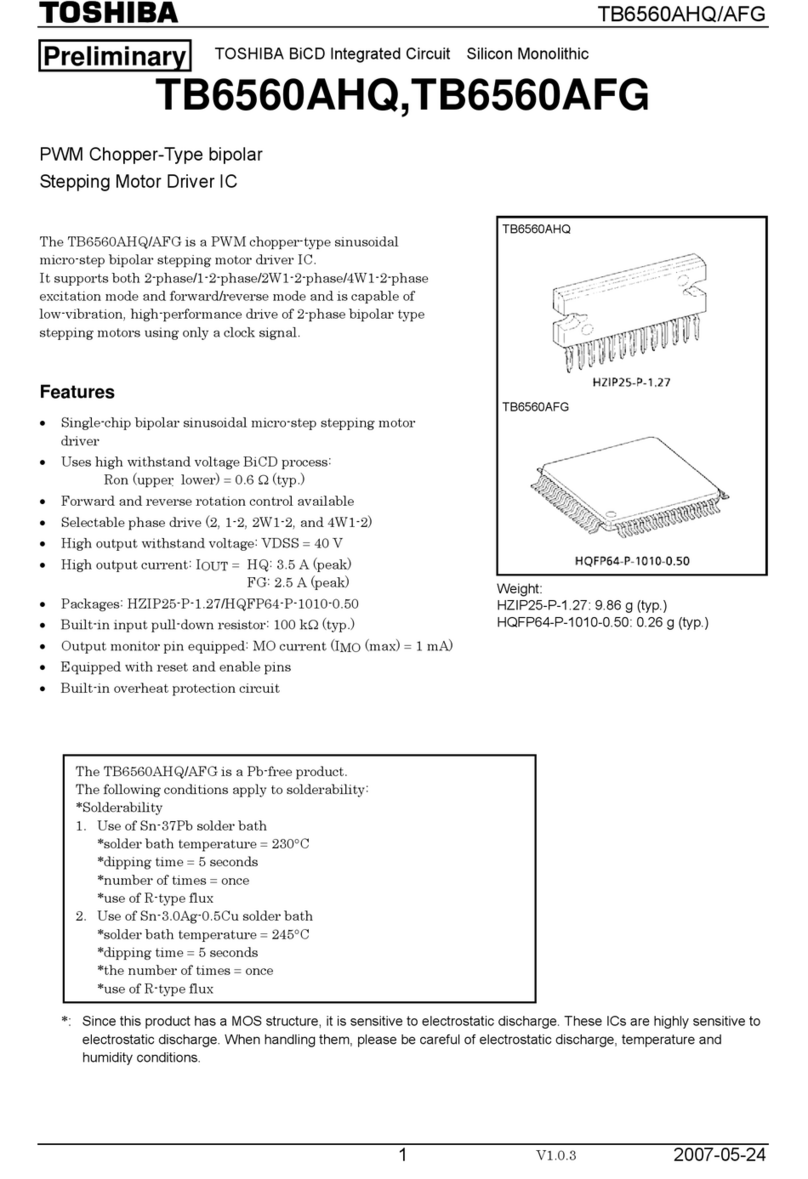

Toshiba Preliminary TB6560AHQ User manual

Toshiba

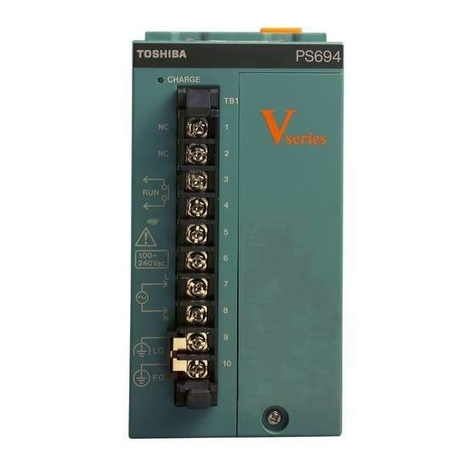

Toshiba V Series User manual

Toshiba

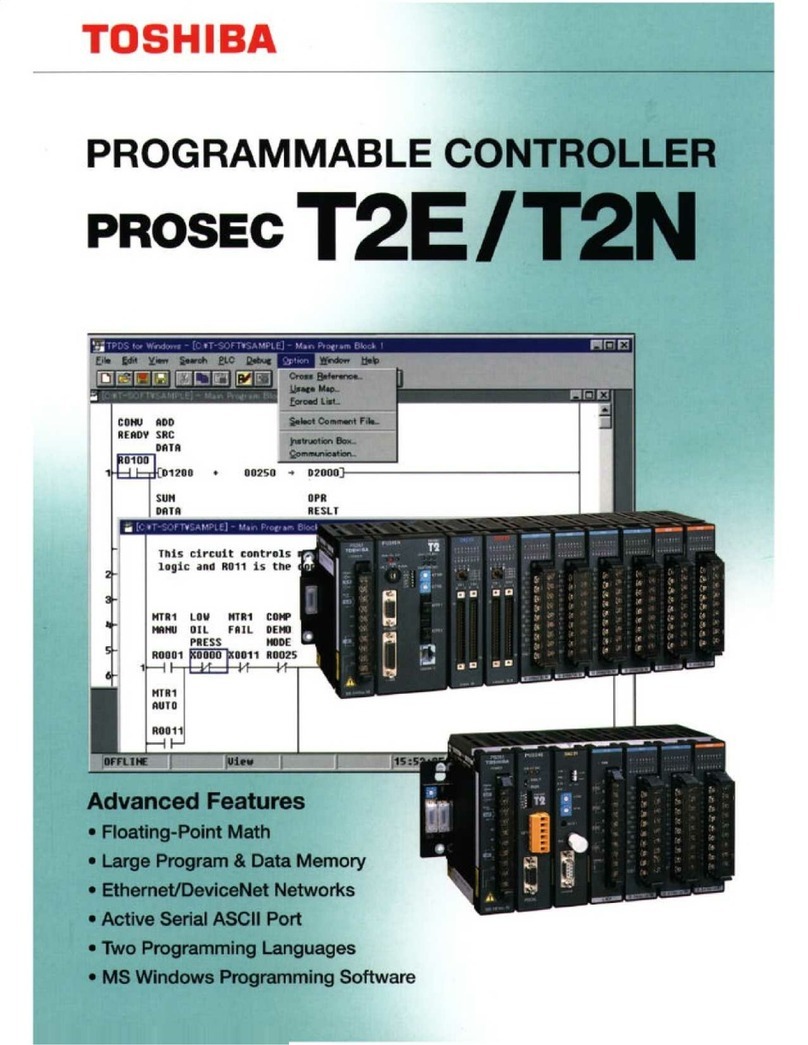

Toshiba T2E User manual

Toshiba

Toshiba S2E21 User manual

Toshiba

Toshiba RB-RXS34-E User manual

Toshiba

Toshiba AS311 User manual

Toshiba

Toshiba nv Series User manual

Toshiba

Toshiba TCB-SC640U User manual

Toshiba

Toshiba TS2000 User manual

Toshiba

Toshiba V Series User manual

Toshiba

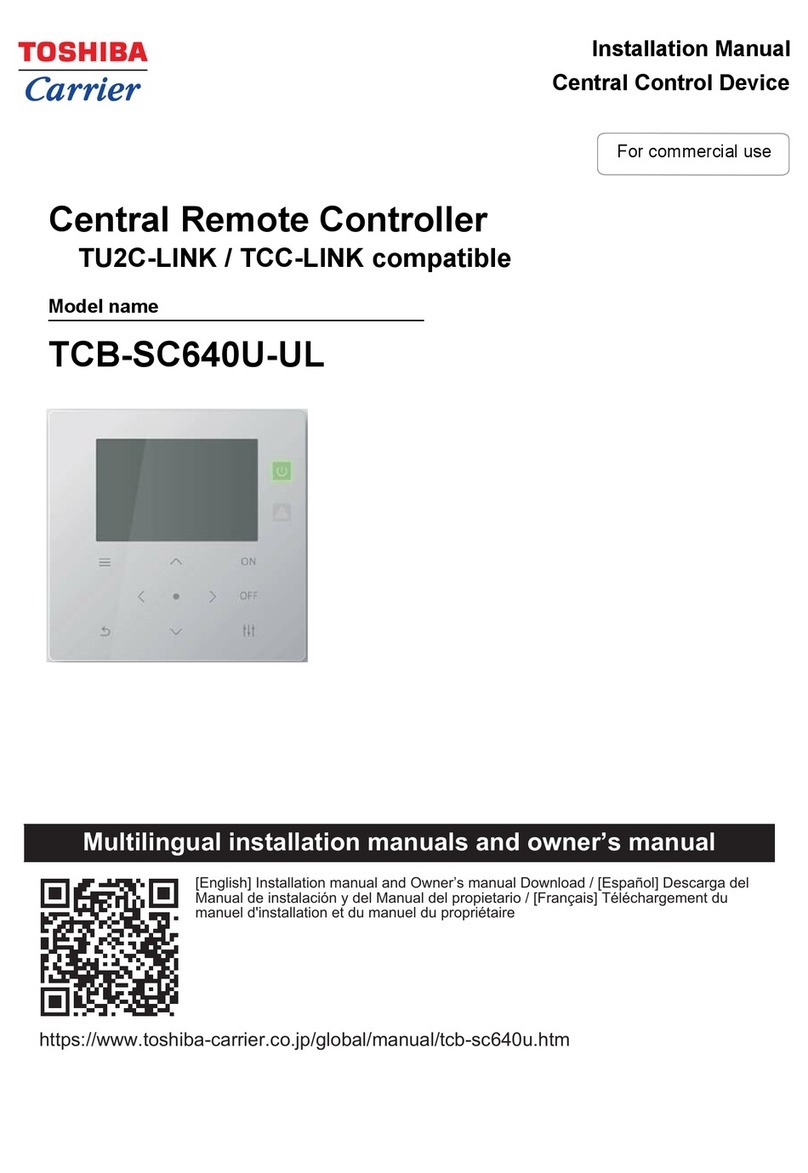

Toshiba TCB-SC640U-UL User manual

Toshiba

Toshiba TSL3000 Use and care manual

Toshiba

Toshiba V Series User manual

Toshiba

Toshiba V Series User manual

Toshiba

Toshiba TSL3000E User manual

Toshiba

Toshiba V Series User manual

Toshiba

Toshiba APOGEE FLN APG001Z Guide

Toshiba

Toshiba TS3000 Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions