Instruction Manual

D103643X012

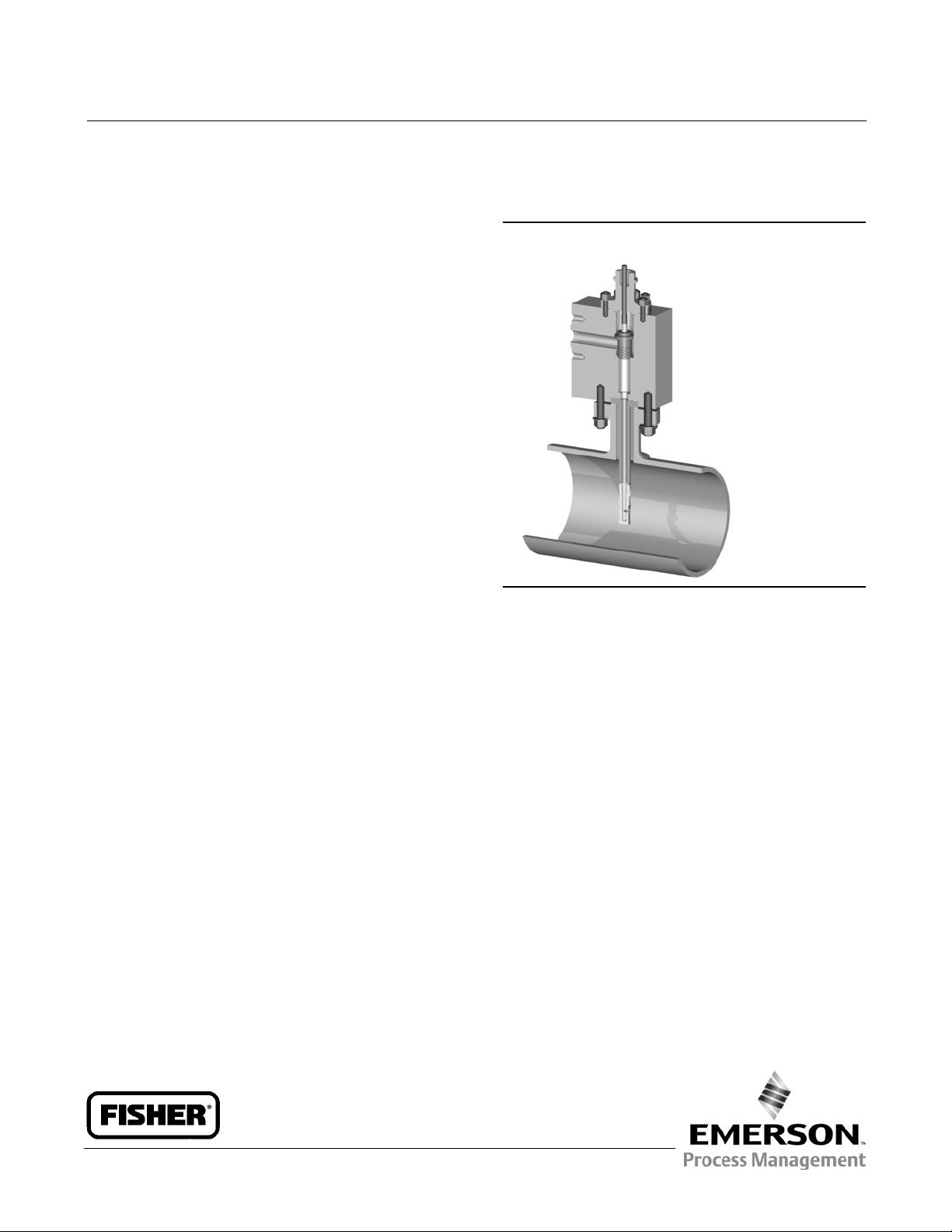

DFA Desuperheater

August 2013

2

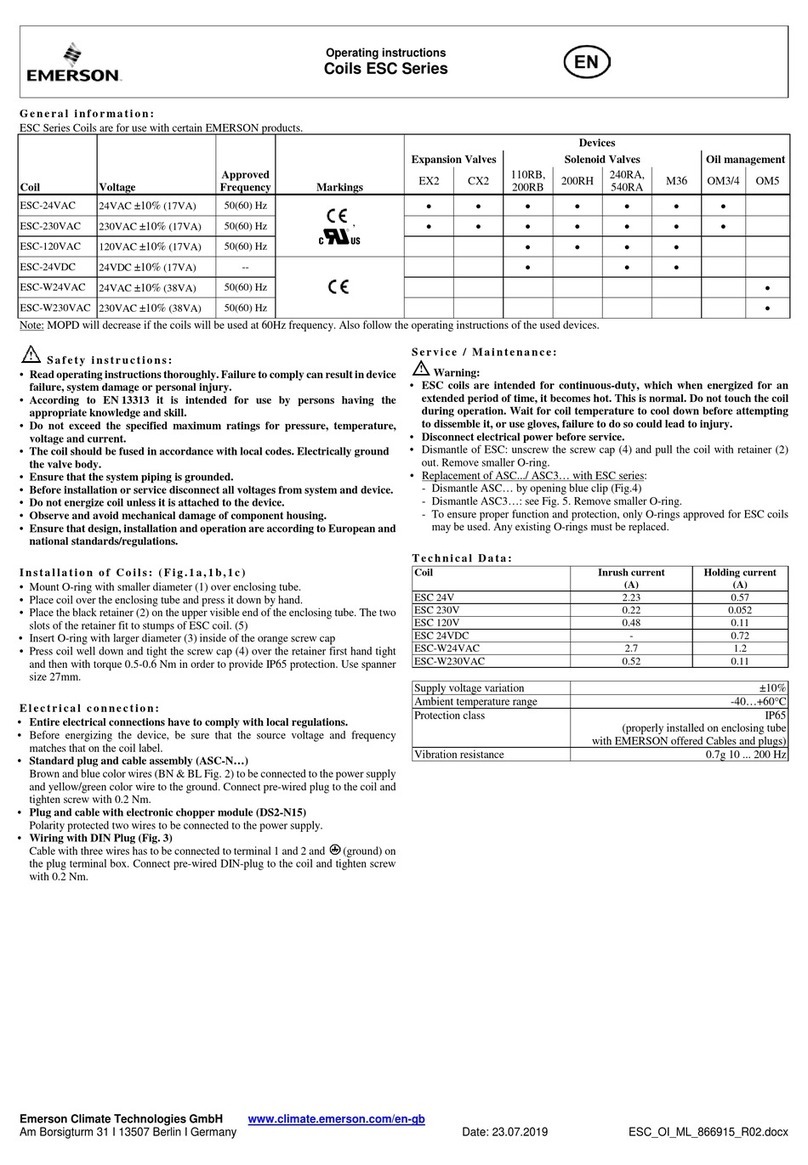

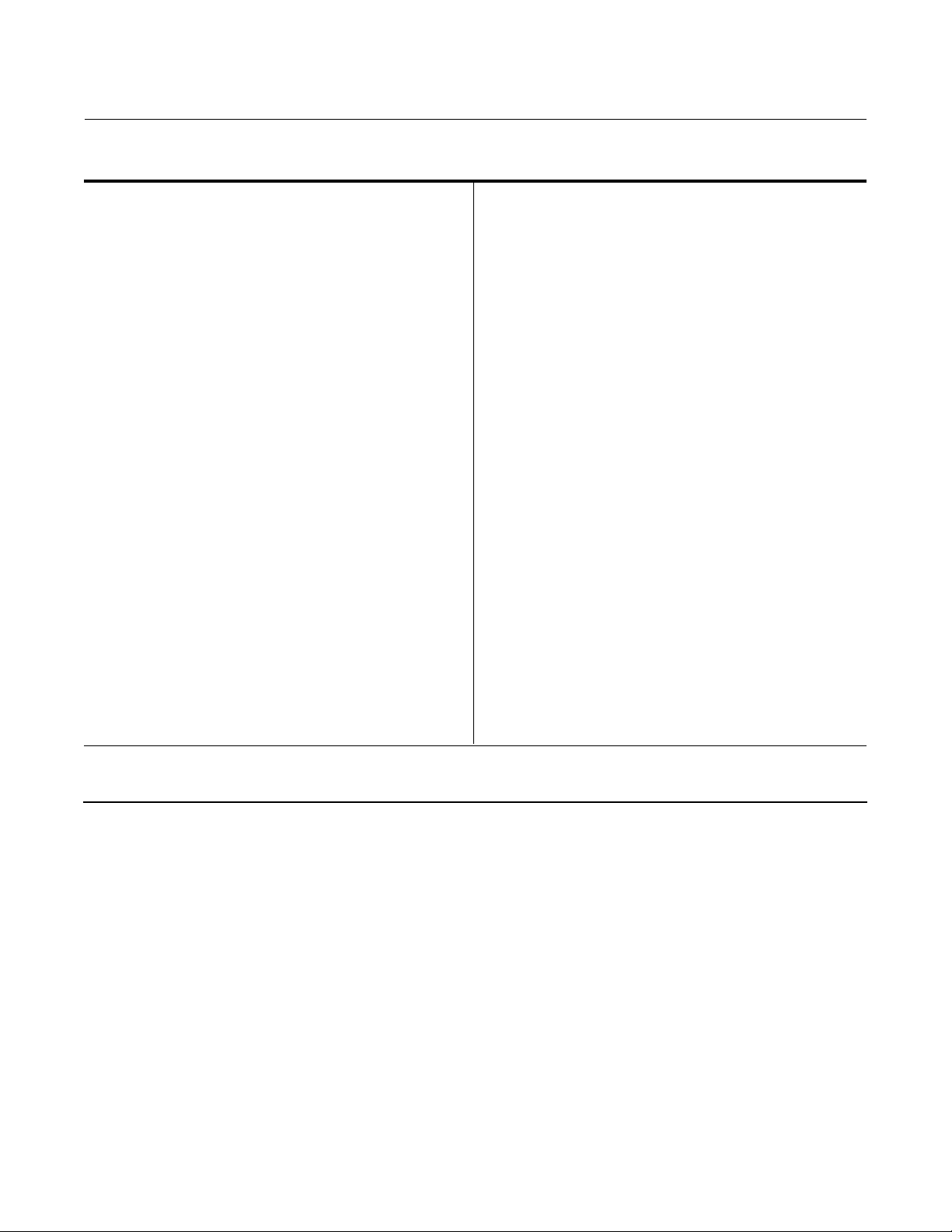

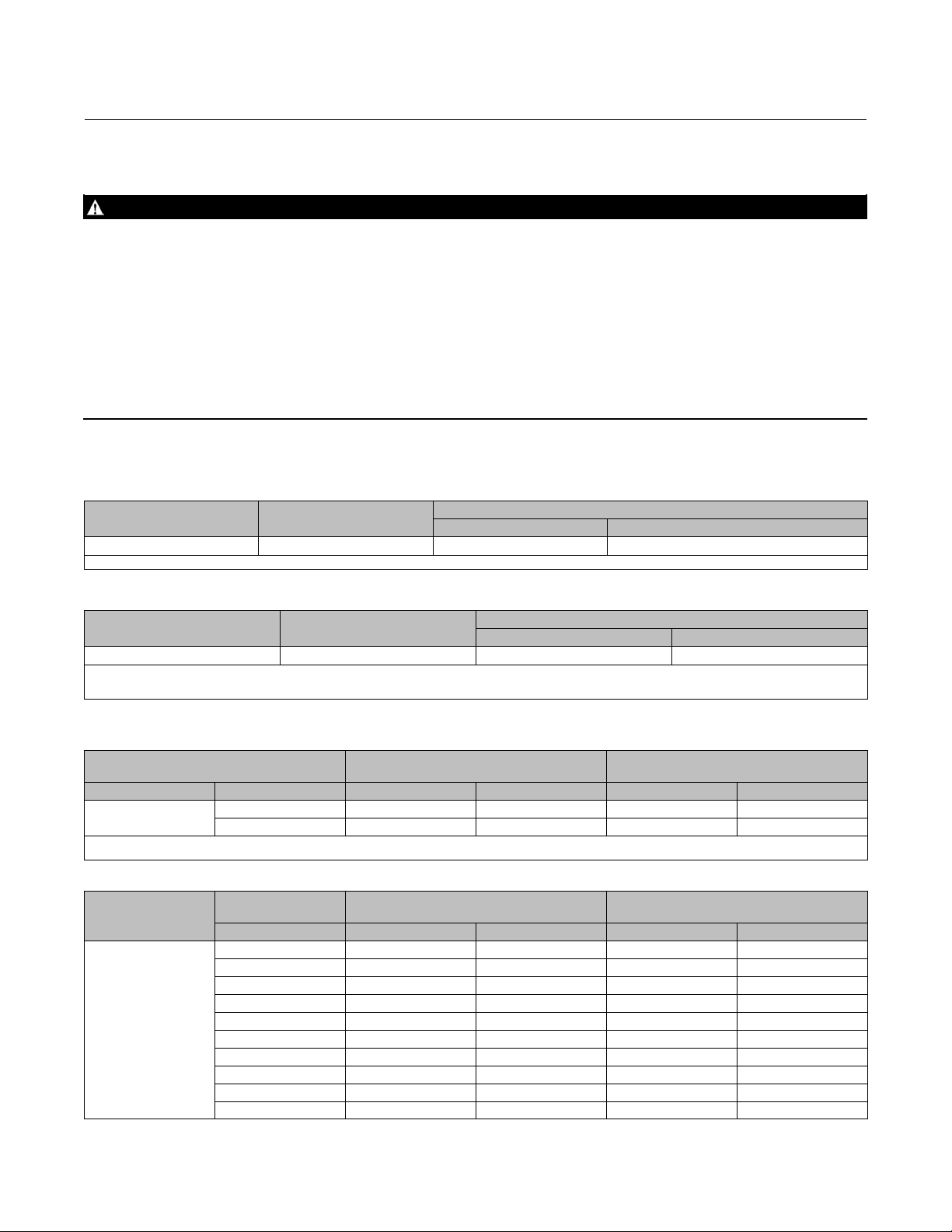

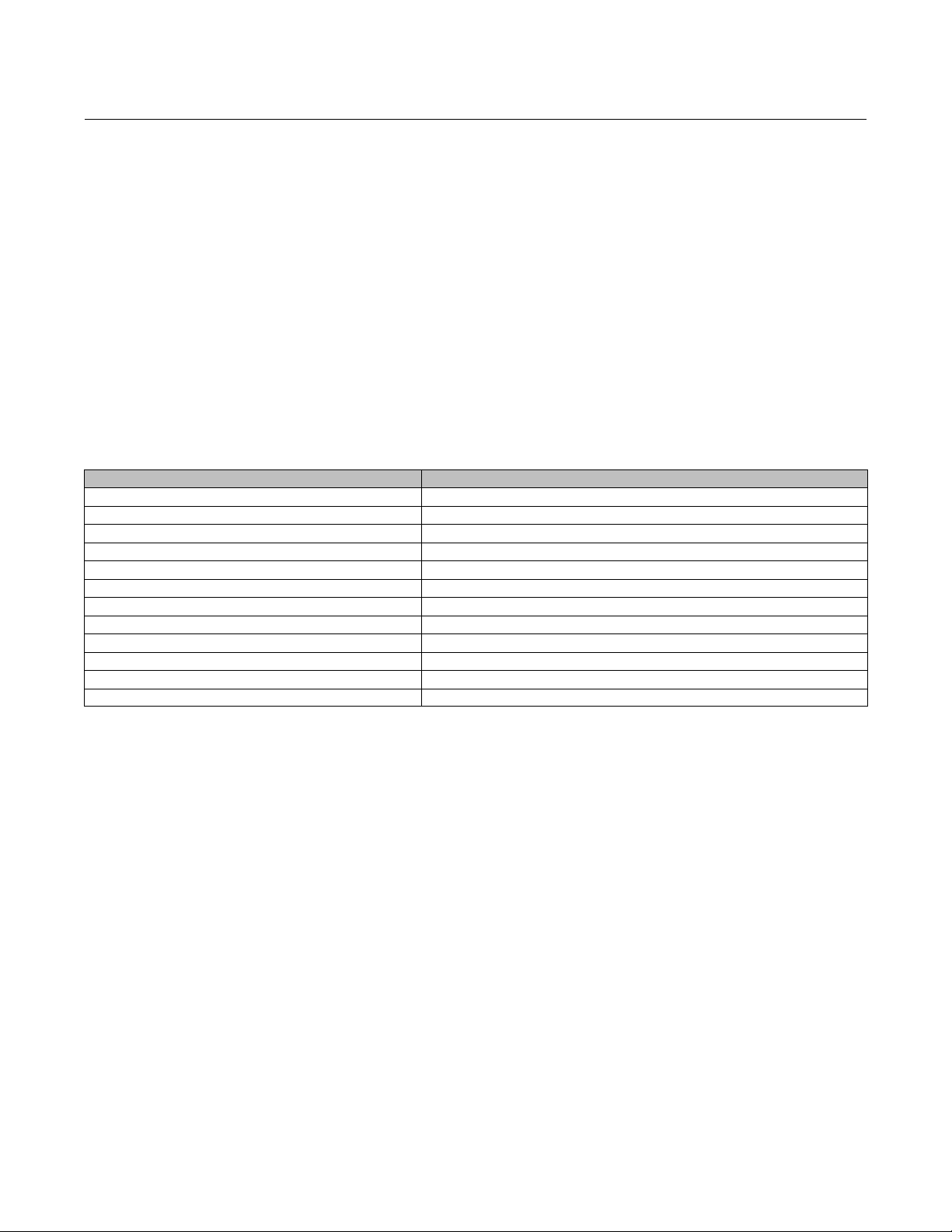

Table 1. Specifications

Available Configurations(1) and Valve Sizes

JDFA valve body style: Angle

Common Characteristics: Designed according to ASME

B16.34 Valve-Flanges, Threaded and Welding End

End Connections Styles(1)

See tables 2 and 3

Maximum Inlet Pressure and Temperature(1,2)

Flanged, Socketwelding, or Buttwelding: Consistent

with CL150, 300, 600, 900, 1500, and 2500 according

to ASME B16.34, unless limited by maximum pressure

drop or material temperature capabilities

Maximum Pressure Drop(1)

Valve with Cavitrol™ III Cage: 149 bar (2160 psi) for

two-stage and 207 bar (3000 psi) for three-stage cage.

Consult Fisher Bulletin 80.2:030, Cavitrol III One-,Two-,

and Three-Stage trims,for more information

Anti-cavitation MicroFlat: <51.7 bard (<750 psid)

Inherent Rangeability

Up to 50:1. The ratio of maximum to minimum

controllable Cvis dependent upon the available water

pressure differential

Spray Water Pressure Required(3)

6.9 bar (100 psi) or larger is acceptable

Shutoff Classifications per ANSI/FCI 70-2 and IEC

60534-4

Class V only

Material Temperature Capabilities(1)

Up to 593_C (1100_F) depending on construction

Flow Characteristics(4)

Standard Cages: JLinear, Jequal percentage,

Jmodified equal percentage(5)

Cavitrol III: Linear

Micro-Flat: Linear

Flow Direction

Standard Cage (Micro-Flat):Flowdown

Cavitrol III Cage: Flow down

Bonnet Style and Mounting(1)

Standard Bonnet

Yoke Temperature Limit: Standard bonnet with cast iron

yoke is limited to 537_C (1000_F)

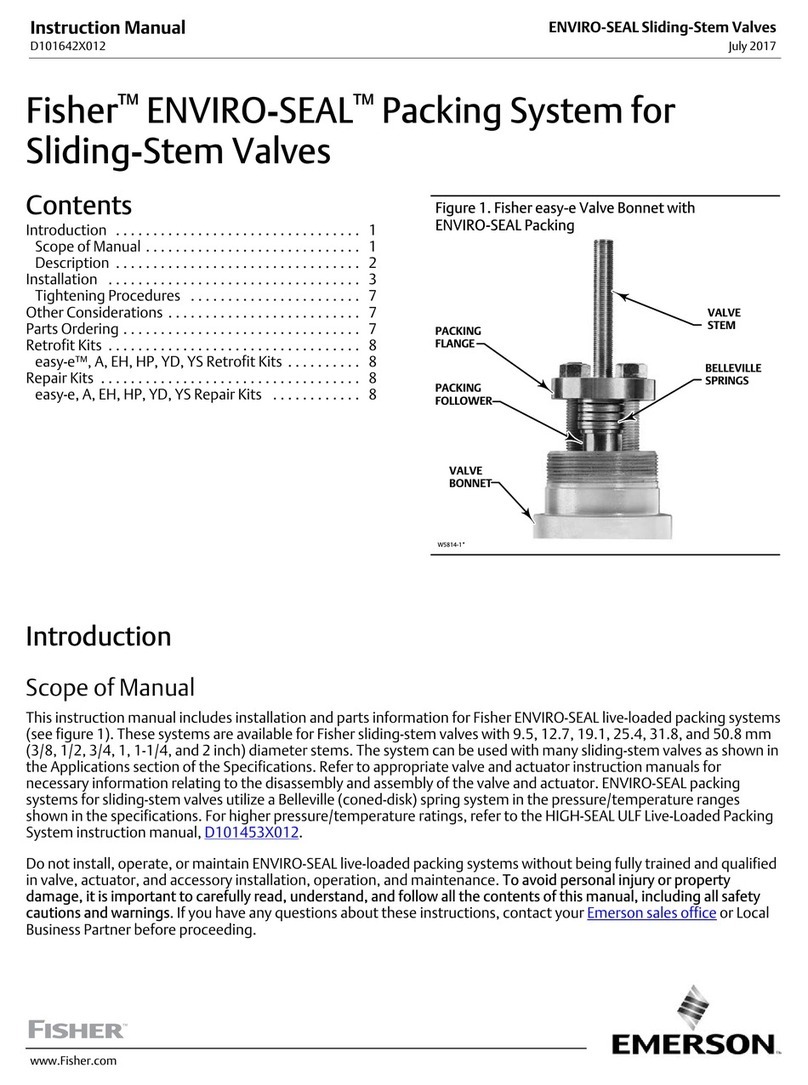

Packing Arrangements

JSingle, JDouble, and JLeakoff standard graphite

packing, or optional JENVIRO-SEAL™ and

JHIGH-SEAL packing systems. See bulletin 59.1:061,

ENVIRO-SEAL and HIGH-SEAL Packing System for

Sliding-Stem Valves

Approximate Weight

See table 12

1. Do not exceed the pressure or temperature limits in this bulletin, nor any applicable code or standard limitations.

2. EN (or other valve body material) ratings and end connections can usually be supplied; consult your Emerson Process Management sales office.

3. A function of required turndown and equipment selection.

4. Special characterized cages are available. Contact your Emerson Process Management sales office.

5. Modified equal percentage characteristic is equal percentage for the first 75% of travel, then opens quickly for additional capacity.

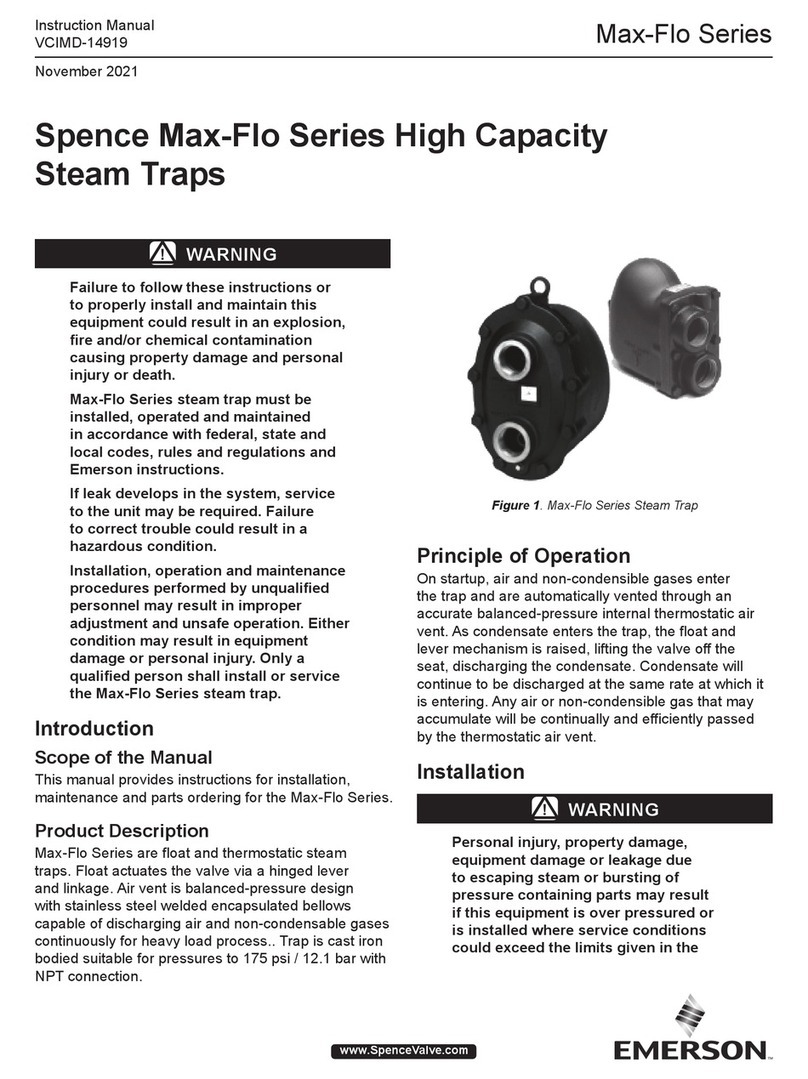

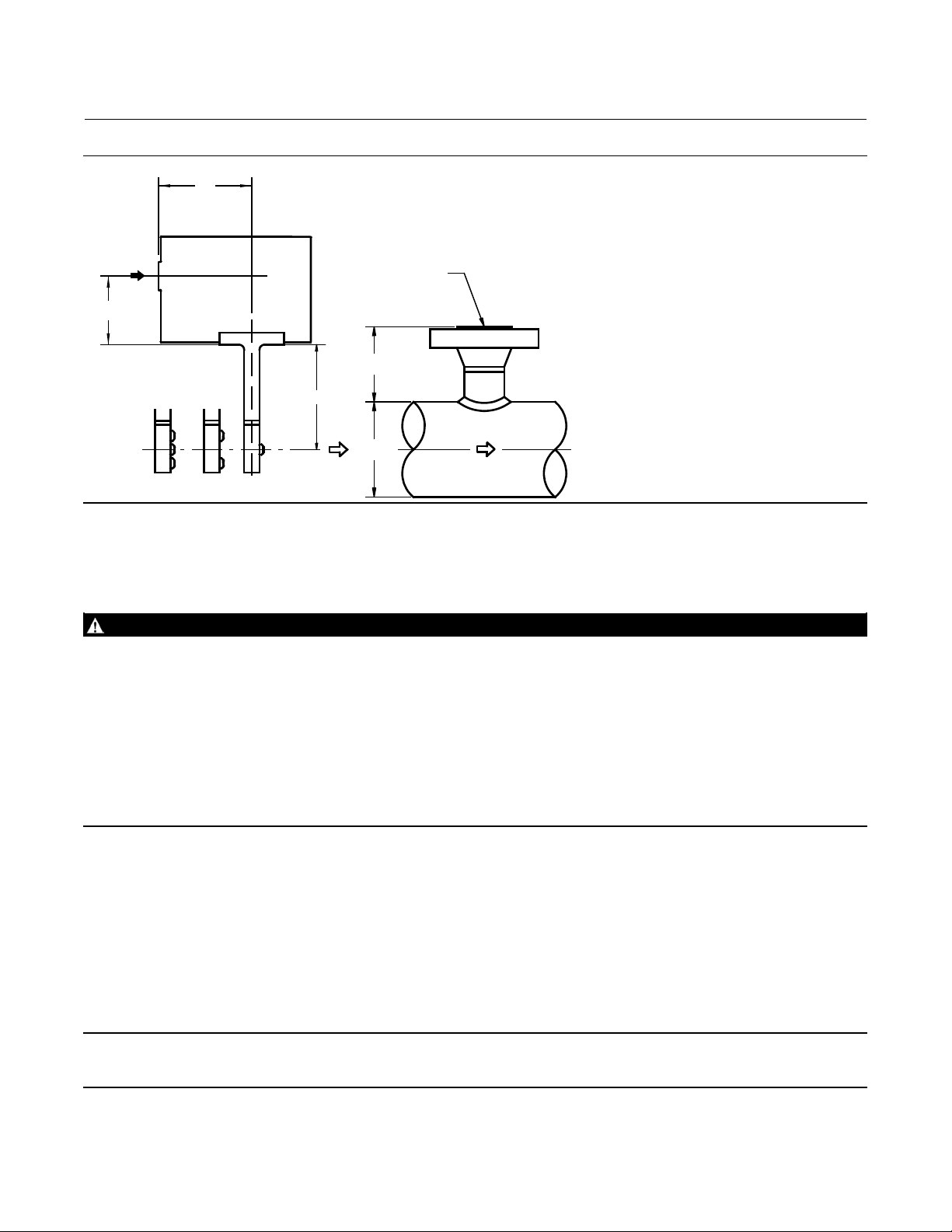

The DFA features:

1. Fine atomization over a wide range of operating conditions helping to assure rapid and complete vaporization of

injected water.

2. Available with a wide range of standard and anti-cavitation trim styles.

3. Designminimizesaffectsofthermalcycling.

4. High turndown capability.

5. Flexible architecture with multiple valve trim combinations and face-to-face dimensions available.