Toshiba G1IF4 User manual

Other Toshiba Recording Equipment manuals

Toshiba

Toshiba NV Series User manual

Toshiba

Toshiba Strata DK Backup User manual

Toshiba

Toshiba RBM-Y0384FUL User manual

Toshiba

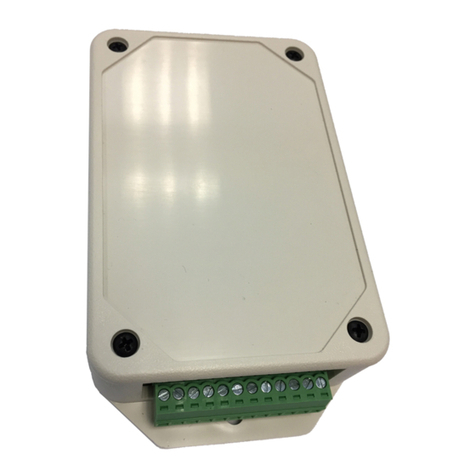

Toshiba BMS-IFMB1280U-E User manual

Toshiba

Toshiba BMS-IFWH4E2 User manual

Toshiba

Toshiba BMS-IFBN1280U-E User manual

Toshiba

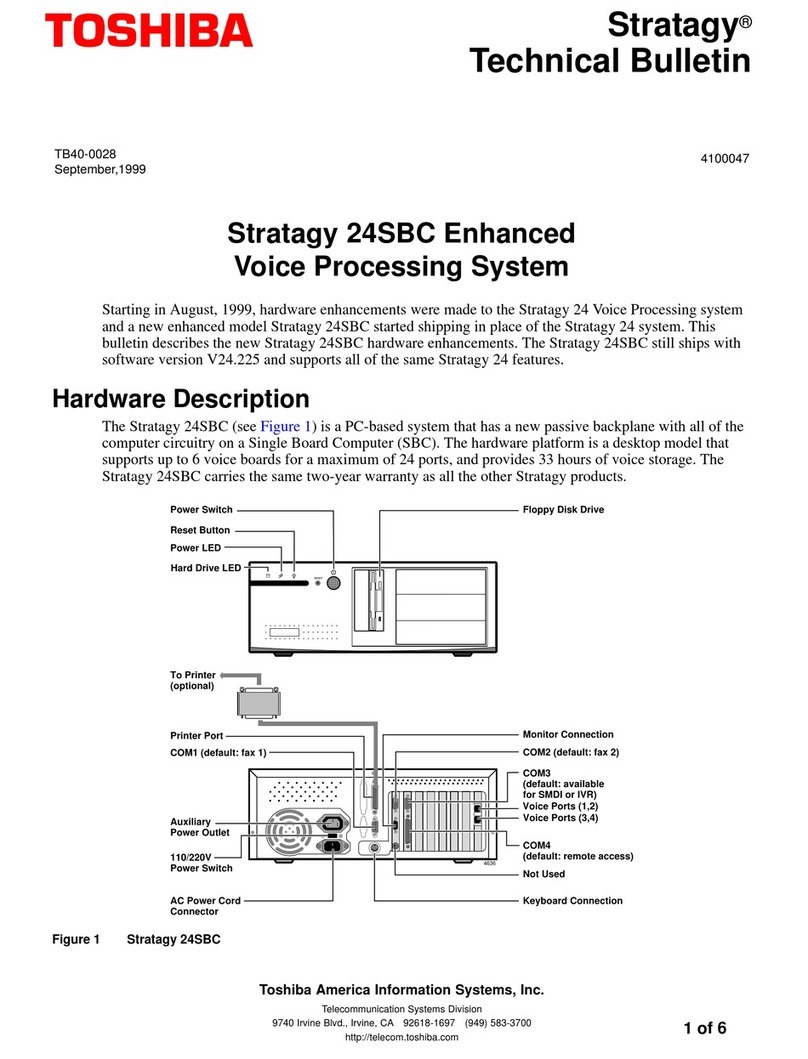

Toshiba Stratagy 24SBC Service manual

Toshiba

Toshiba TCB-IFMB641TLE User manual

Toshiba

Toshiba BMS-IFMB0AWR-E User manual

Toshiba

Toshiba Black Pear User manual

Toshiba

Toshiba TCB-IFGSM1E User manual

Toshiba

Toshiba TCS-NET User instructions

Toshiba

Toshiba Surveillix EAV Series User manual

Toshiba

Toshiba LonWorks TCB-IFLN642TLUL User manual

Toshiba

Toshiba RAV-DXC010 User manual

Toshiba

Toshiba HWS-IFAIP01U-E 0-10V User manual

Toshiba

Toshiba OIS PLUS Series User manual

Toshiba

Toshiba W-705 User manual

Toshiba

Toshiba TCB-IFGSM1E User manual

Toshiba

Toshiba TCB-IFDMX01UP-E User manual