2

English-4English-3

WARNING

• Ask an authorized dealer or qualified installation professional to install/maintain the air conditioner.

Inappropriate installation may result in water leakage, electric shock or fire.

• Turn off the main power supply switch or breaker before attempting any electrical work.

Make sure all power switches are off. Failure to do so may cause electric shock.

• Connect the connecting wire correctly.

If the connecting wire is connected in a wrong way, electric parts may be damaged.

• When moving the air conditioner for the installation into another place, be very careful not to enter any

gaseous matter other than the specified refrigerant into the refrigeration cycle.

If air or any other gas is mixed in the refrigerant, the gas pressure in the refrigeration cycle becomes abnormally high

and it as a result causes pipe burst and injuries on persons.

• Do not modify this unit by removing any of the safety guards or by by-passing any of the safety interlock

switches.

• Exposure of unit to water or other moisture before installation may cause a short-circuit of electrical

parts.

Do not store it in a wet basement or expose to rain or water.

• After unpacking the unit, examine it carefully if there is possible damage.

• Do not install in a place that might increase the vibration of the unit.

• To avoid personal injury (with sharp edges), be careful when handling parts.

• Perform installation work properly according to the Installation Manual.

Inappropriate installation may result in water leakage, electric shock or fire.

• When the air conditioner is installed in a small room, provide appropriate measures to ensure that the

concentration of refrigerant leakage occur in the room does not exceed the critical level.

• Install the air conditioner securely in a location where the base can sustain the weight adequately.

• Perform the specified installation work to guard against an earthquake.

If the air conditioner is not installed appropriately, accidents may occur due to the falling unit.

• If refrigerant gas has leaked during the installation work, ventilate the room immediately.

If the leaked refrigerant gas comes in contact with fire, noxious gas may generate.

• After the installation work, confirm that refrigerant gas does not leak.

If refrigerant gas leaks into the room and flows near a fire source, such as a cooking range, noxious gas might

generate.

• Electrical work must be performed by a qualified electrician in accordance with the Installation Manual.

Make sure the air conditioner uses an exclusive power supply.

An insufficient power supply capacity or inappropriate installation may cause fire.

• Use the specified wires for wiring connect the terminals securely fix.

To prevent external forces applied to the terminals from affecting the terminals.

• Conform to the regulations of the local electric company when wiring the power supply.

Inappropriate grounding may cause electric shock.

• Do not install the air conditioner in a location subject to a risk of exposure to a combustible gas.

If a combustible gas leaks, and stays around the unit, a fire may occur.

2INSTALLATION OF NEW REFRIGERANT

AIR CONDITIONER

This air conditioner adopts the new HFC refrigerant (R410A) which does not deplete the ozone layer.

• R410A refrigerant is apt to be affected by impurity such as water, oxidizing membrane, or oils because the

pressure of R410A refrigerant is higher than that of the former refrigerant by approx. 1.6 times.

Accompanied with adoption of the new refrigerant, refrigerating oil has been also changed.

Therefore pay attention so that water, dust, former refrigerant, or refrigerating oil does not enter into the refriger-

ating cycle of the new refrigerant air conditioner during installation work.

• To prevent from mixing of refrigerant or refrigerating oil, the size of charge port of the main unit or connecting

section of installation tool differs from that of the air conditioner for the former refrigerant.

Accordingly the exclusive tools are required for the new refrigerant (R410A) as shown below.

• For connecting pipes, use the new and clean piping materials so that water or dust does not enter.

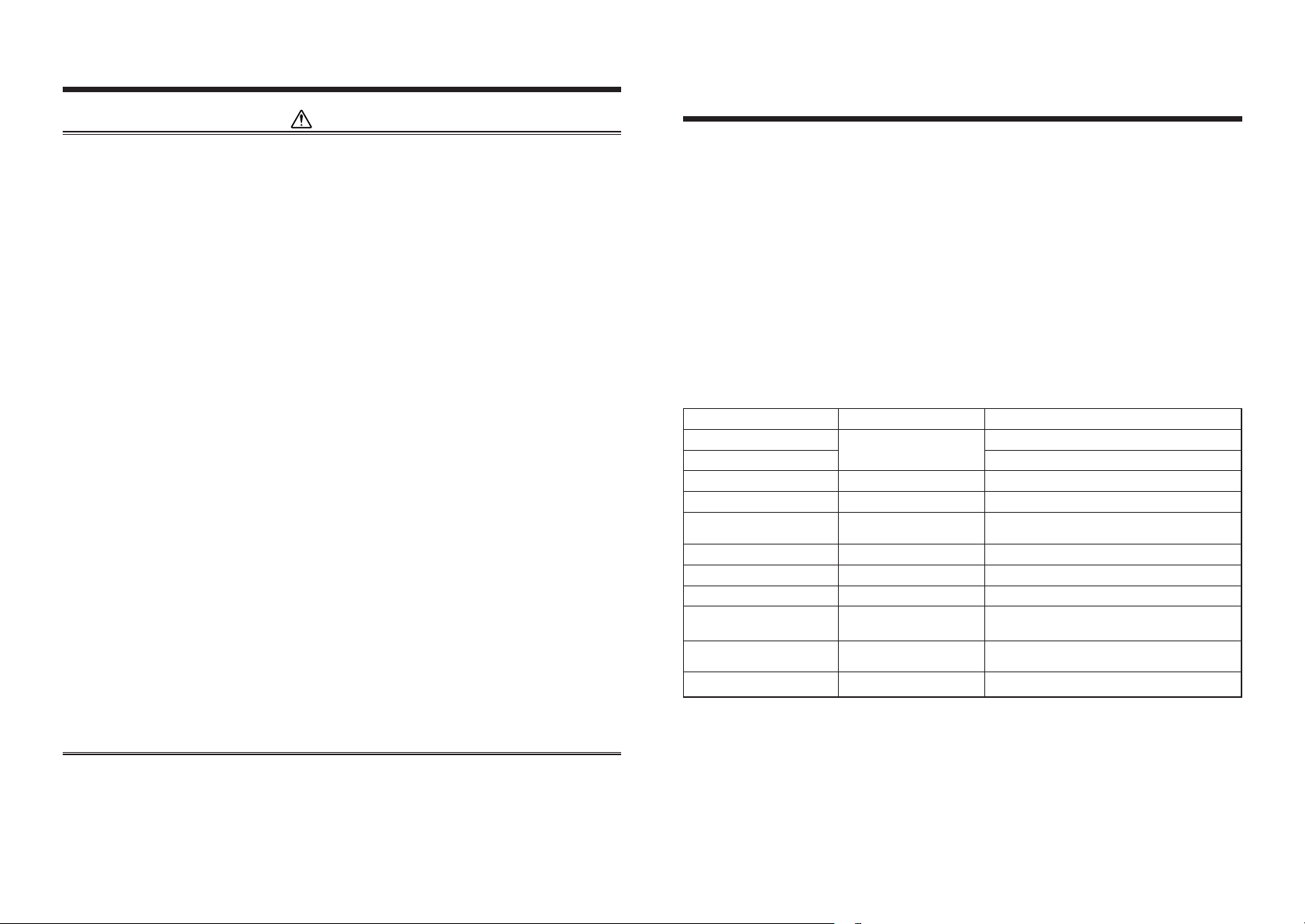

Required tools and cautions on handling

It is necessary to prepare the tools and parts as described below for the installation work.

The tools and parts which will be newly prepared in the following items should be restricted to the exclusive use.

Explanation of symbols

z: Newly prepared (It is necessary to use it properly exclusive to R410A separated from those for R22 or R407C.)

{: Former tool is available.

Refrigerant piping

• Piping material used for the conventional refrigerant cannot be used.

• Use copper pipe with 0.8mm or more thickness for Ø6.4, Ø9.5, Ø12.7mm.

Use copper pipe with 1.0mm or more thickness for Ø15.9mm, Ø19.1mm, Ø22.2mm or more.

• Use clean and new pipes for the refrigerant pipes and perform piping work so that water or dust does not

contaminate the refrigerant.

Used tools

Gauge manifold

Charging hose

Gas leak detector

Vacuum pump

Vacuum pump with counter-flow

preventive adapter

Bender

Refrigerant recovery device

Pipe cutter

Refrigerant cylinder

Welding machine/

Nitrogen gas cylinder

Refrigerant charging balance

Usage

Vacuuming or charging of

refrigerant and operation check

Checks gas leak

Vacuum drying

Vacuum drying

Bending processing of pipes

Recovers refrigerant

Cuts pipes

Charges refrigerant

Welding of pipes

Charges refrigerant

Proper use of tools/parts

zNewly prepared, Exclusive to R410A

zNewly prepared, Exclusive to R410A

zNewly prepared

Usable if a counter-flow preventive adapter is attached

{: R22 (Existing article)

{: R22 (Existing article)

zExclusive to R410A

{: R22 (Existing article)

zExclusive to R410A

ID : Refrigerant name entered

{: R22 (Existing article)

{: R22 (Existing article)