TOSOH BIOSCIENCE TSKgel NH2-100 3mm User manual

Packed Columns for

Normal Phase Chromatography

TSKgel NH2

-

100 3μm

INSTRUCTION

MANUAL

Rev. CO067000

To help protect you and/or your property from potential damage, please read

this manual thoroughly before using the product.

Safety Precautions

[Notation Conventions]

Notation

WARNING

CAUTION

!

!

Explanation

!WARNING

Keep away from fire

Not taking proper precautions when using flammable solvents could result in

fire, explosion, or poisoning.

!CAUTION

Use only in well-ventilated areas

In case of insufficient ventilation, flammable and toxic solvents can cause fire,

explosion, or poisoning.

Do not spill solvents

Spillage and leakage can cause fire, electric shock, poisoning, injury, and

corrosion.

Wear appropriate protective gear when cleaning up a spill.

Wear protective eye gear and gloves

Organic solvents and acids should not come in direct contact with the skin.

Handle the package with care

Inappropriate handling may cause rupturing and/or splattering of the product.

Only use this product as intended

This product is for separation and purification. Do not use for any other

purpose.

Make sure compounds are safe

Check that obtained compounds and solutions after separation and purification

are safe.

Proper disposal

Dispose in accordance with local laws and regulations.

NOTE

Keep this manual with the product for future reference.

Indicates a hazardwith a medium level of risk which, if

not avoided, could result in death or serious injury.

Indicates a hazardwith a low level of risk which, if not

avoided, could result in minor or moderate injury.

Precautions: Shipping Solvents

Shipping solvent : CH

3

CN/H

2

O=85/15

First Aid

Handling

and

Storage

Waste

Disposal

Inhalation

Skin exposure

Eye exposure

Ingestion

Ventilation

Container

handling

Wear

appropriate

protective

equipment

Hazardous

substance

storage

Disposal

methods

General

considerations

Disposal

precautions

•Move the person to an area with fresh air.

Rinse the mouth with plenty of water.

•Call for medical attention immediately.

•Wash exposed area with plenty of soap and water.

•

Open eyes as wide as possible and rinse with clean

water for at least 15 minutes.

•Call for medical attention immediately.

•Rinse the mouth with plenty of water and call for

medical attention immediately.

•Provide adequate air ventilation to keep organic

vapor concentrations below approved level.

•Container may break if not handled with care.

•

Use solvent-resistant gloves and protective eye gear

when using this product. Use of gas mask, additional

protective clothing or rubber boots could be

appropriate when handling this product.

•If any flammable solvents are used for shipping or

storage, keep away from fire and open heat.

•

Follow local guidelines for disposal. This product can

be incinerated safely.

•Please pay attention to all safety precautions with

respect to the handling and storage of this product.

•

Assure that appropriate countermeasures are taken

when incinerating solvents that contain acetonitrile.

Fumes produced during incineration may contain

nitrogen oxides.

Precautions: Packing Material

First Aid

Handling

and

Storage

Waste

Disposal

Inhalation

Skin exposure

Eye exposure

Ingestion

Ventilation

Container

handling

Wear

appropriate

protective

equipment

Hazardous

substance

storage

Disposal

methods

General

considerations

Disposal

precautions

•Move the person to an area with fresh air.

Rinse the mouth with plenty of water.

•Call for medical attention immediately.

•Wash exposed area with plenty of soap and water.

•

Open eyes as wide as possible and rinse with clean

water for at least 15 minutes.

•Call for medical attention immediately.

•Rinse the mouth with plenty of water and call for

medical attention immediately.

•

Provide adequate air ventilation to keep organi

c

vapor concentrations below approved level.

•Container may break if not handled with care.

•

Use solvent-resistant gloves and protective eye gear

when using this product. Use of gas mask, additional

protective clothing or rubber boots could be

appropriate when handling this product.

•If any flammable solvents are used for shipping or

storage, keep away from fire and open heat.

•

Dispose in accordance with local laws and regulations.

•Please pay attention to all safety precautions with

respect to the handling and storage of this product.

•Fumes produced during incineration may contain

nitrogen oxides.

Aminoalkyl group functionalized silica gel

Table of Contents

01. General Information ……………………………………………………… 1

02. Unpacking …………………………………………………………………… 1

03. Column Parts ……………………………………………………………… 1

04. Column Installation ………………………………………………………… 2

05. Column Maintenance ……………………………………………………… 3

06. Solvent Selection and Preparation ……………………………………… 3

07. Flow Rate …………………………………………………………………… 4

08. Temperature ………………………………………………………………… 5

09. Sample Preparation ……………………………………………………… 5

10. Measurement of Number of Theoretical Plates

and Asymmetry Factor …………………………………………………… 5

11. Guard Column ……………………………………………………………… 6

12. Troubleshooting …………………………………………………………… 8

13. Quality Specification and Warranty ……………………………………… 8

14. Column Cleaning Solutions ……………………………………………… 9

−1−

Published, February 2009

1. General Information

TSKgel NH2-100 3μm packed columns have been optimized for high performance

NPC and HILIC. Please read this INSTRUCTION MANUAL carefully and use the

column as recommended in order to make effective use of its high performance.

2. Unpacking

Check that there is no visible damage to the outer package or the column.

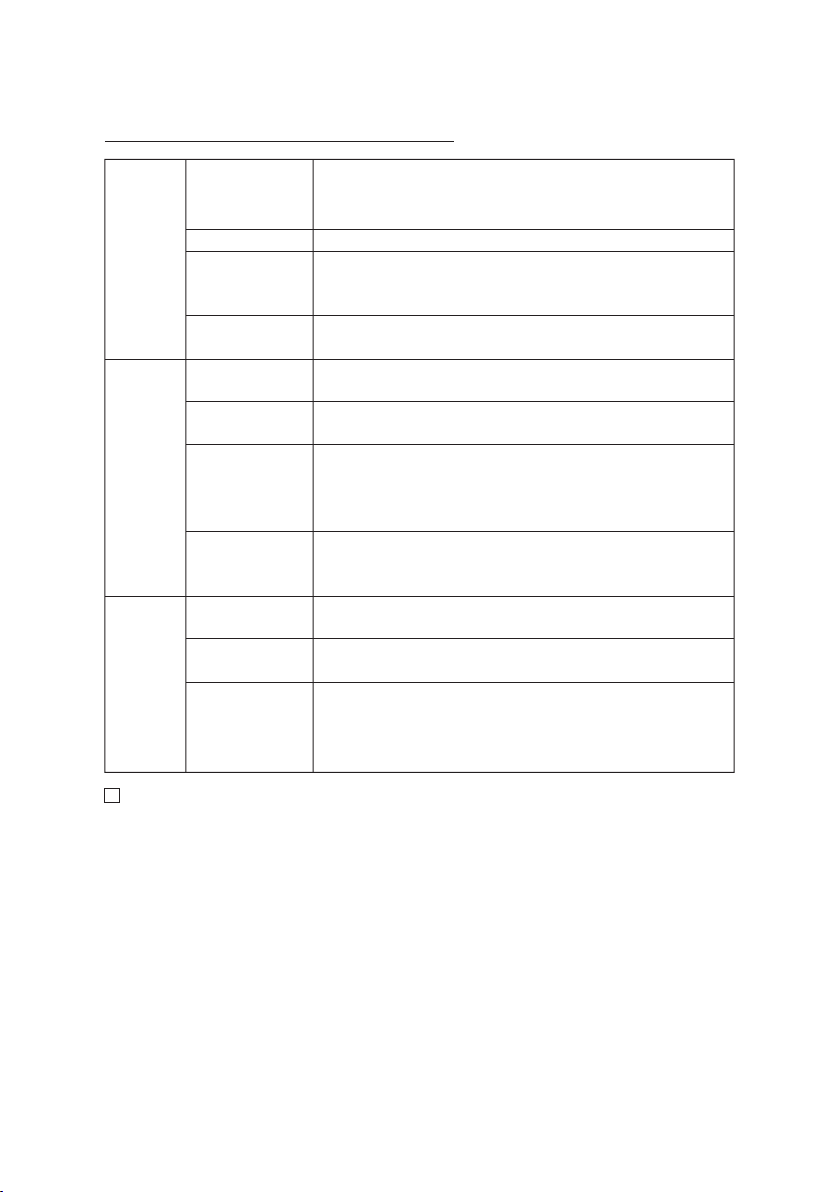

Figure 1 Appearance of the Package

Check that the following documents are shipped with the column.

1) INSTRUCTION MANUAL

1 copy

2) INSPECTION DATA 1 copy

3. Column Parts

1) Analysis column

Figure 2 Column Parts (1)

Inlet Outlet

Name Plate

End Fitting

End Plug

FLOW

−2−

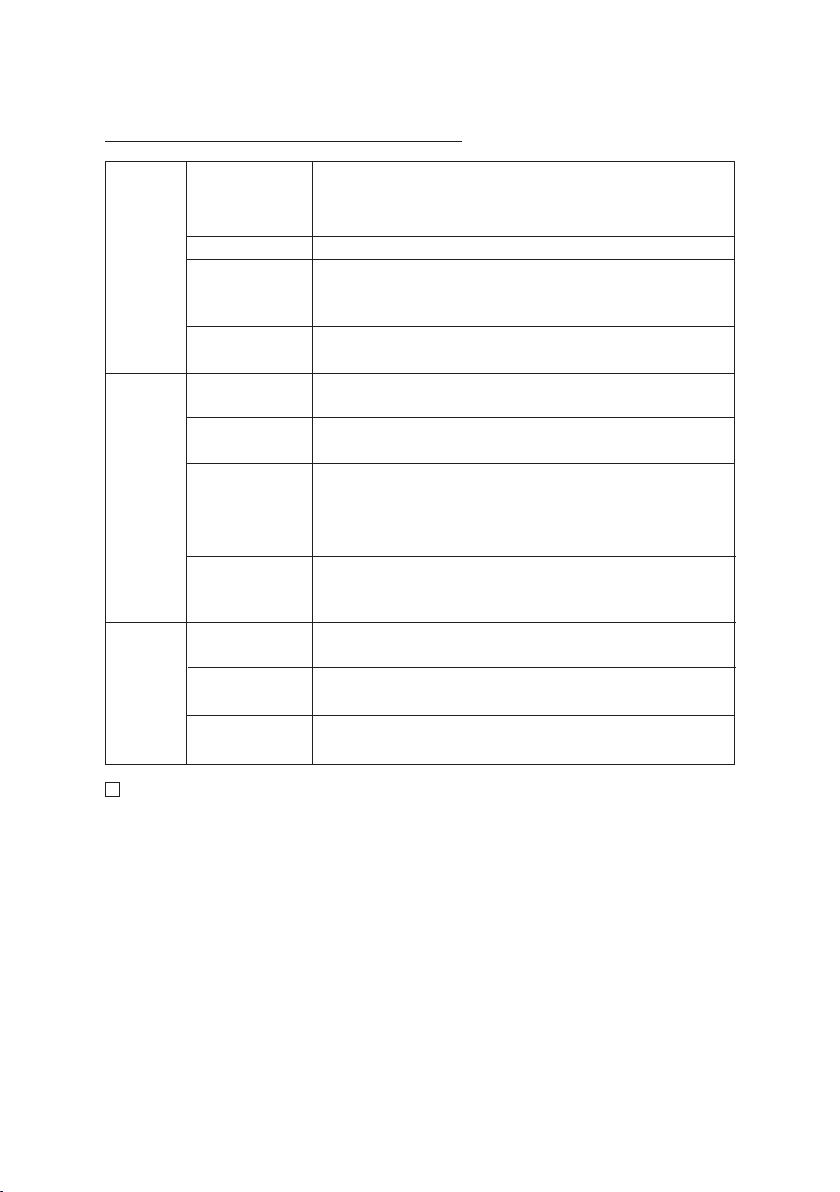

2) Guard column

4. Column Installation

(1) Confirm the correct product name is listed on the column label.

(2) Each column is equipped with a union nut enabling a connection to a 1/16,, O.D.

capillary tubing. The union nut is designed for American standard compression

plugs and ferrules.

(3) Confirm the flow direction on the column label or on etched onto the column as

shown in Figure 2. Solvent should flow only into the column from the inlet side.

The columns are designed so that optimal resolution is obtained when the flow

direction is as indicated on the column.

(4) Purge all air out of the tubing using the mobile phase. This helps to prevent any

air from entering the column. Any air in the tubing causes serious deterioration

of column efficiency.

(5) Initially set the solvent flow rate at one-half of the intended flow rate. Make sure

that the solvent is flowing freely out of the end of the tubing from the injector.

(6) Remove the end plugs from the column and connect the inlet of the column to

the tubing from the injector. Make sure that the tubing is fully inserted into the

compression fittings before tightening in order to minimize dead volume. Always

keep dead volume to the absolute minimum throughout the entire system.

(7) After the solvent flows from the outlet of the column, connect the column to the

detector.

Cartridge holder (Inlet) Column-extracting toolGuard column Cartridge holder (Outlet)

Cartridge holder (Inlet) Guard column Cartridge holder (Outlet)

Figure 3 Column Parts (2)

3.2 mm(I.D.)× 1.5 cm(L)

2.0 mm(I.D.)× 1 cm(L)

−3−

(8) Start pumping the solvent at a flow rate less than one-half of the final flow rate.

Avoid a sudden pressure surge to the column.

(9) The columns are very sensitive to pressure pulsing. A pulseless pumping system

should be used.

(10) The columns should be equilibrated before use by allowing at least 10 column

volumes of solvent to pass through the column.

(11) If a mixture of water or aqueous acetate solution with water-soluble organic

solvent (e.g., acetonitrile) is used as a mobile phase, install a guard column and

routinely clean the main analytical column in order to prevent the accumulation

of impurities on the column. Replacing the guard column and cleaning the

analytical column are described in section 11-3 Guard Column Replacement.

(12) Elution times depend on the counter-anion associated with the amino group on

the packing material. Take care so that the counter-anion is sufficiently

exchanged when the mobile phase is changed, especially when used for LC/

MS. The procedure for exchanging the counter-anion is described in section 6

Solvent Selection and Preparation.

5. Column Maintenance

(1) If the column is used in routine daily operation, it is permissible to leave the

mobile phase in the column overnight if the mobile phase is not corrosive. If

halides are included in the mobile phase, it is better to replace the mobile phase

with a suitable solvent (for example "packed solvent" shown in the INSPECTION

DATA sheet) even for one night.

(2) If the column will not be used for several days, it should be stored as follows:

a) Purge the system with the "packed solvent" shown in the INSPECTION DATA

sheet at a flow rate one-half of the operating flow rate as shown in Table 1

(purge the system with distilled or ion-exchanged water if you have used a

buffer solution, as a mobile phase, which contains salt in considerably high

concentrations).

b) Remove the column from the system and keep the ends of the column tightly

capped with the end plugs supplied with the column.

c) Store the column at a relatively constant temperature in its original shipping

container. Take care not to allow the column to freeze during storage.

(3) The performance of the cartridge column may be decreased by repeated

removal from the cartridge holder. TOSOH recommends that the cartridge

column is kept in the cartridge holder with the both ends capped with end plugs.

6. Solvent Selection and Preparation

(1) The shipping solvent is 85 % acetonitrile in water. Before using the column, the

−4−

solvent should be replaced with an appropriate mobile phase for analysis. When

salt-containing buffers are used as a mobile phase, purge the column for at least

1 h with salt solution containing 5 % of a water-soluble organic solvent (e.g., 200

mmol/L ammonium formate/ acetonitrile= 95/5, v/v) to exchange the counter-

anion associated with the amino group on the packing material. When used for

LC/MS, special care must be taken so that the counter-anion is sufficiently

exchenged. Solvent replacement should be performed at a flow rate one-half of

the normal operating flow rate, or at a pressure below the maximum pressure

shown in Table 1. Note that a drastic change of solvent composition or frequent

solvent replacements may shorten the lifetime of the column.

(2) pH range : 2.0-7.5

The pH range should be selected based on the stability of both the packing

material and the column itself. At a pH below pH 2.0, the ligand binding sites on

the silica-based support are subject to hydrolysis by acidic solutions. Above pH

7.5, the silica backbone may dissolve, leading to rapid column failure.

Additionally, the stainless steel of the column is subject to corrosion at a low pH

particularly when using halides.

(3) The solvent should be filtered through a 0.5μm filter in order to prevent the

accumulation of small particles. The performance of semi-micro columns quickly

deteriorates when exposed to small-particle contamination. Thus, it is highly

recommended that an in-line filter containing a membrane of 0.2 〜0.5μm pore

size is inserted between the pump and the sample injector.

Line filter

Part No. 0014594 Filter assembly

Part No. 0006280 Fluoropore filter (0.45μm, package of 100)

(4) Solvents should be degassed to ensure optimal flow through the system.

7. Flow Rate

The flow rate should be selected based on the desired resolution, column life and

assay time. Although the TSKgel NH2-100 3μm is designed for high-speed analysis,

TOSOH recommends that this column is operated at a rather low flow rate because

better resolution and extended column life can be expected. A suitable flow rate and

the maximum flow rate depend on the organic solvent in the mobile phase. When

using the TSKgel NH2-100 3μm for the first time, the flow rate should be set at a

linear velocity of 6 cm/min (0.20 mL/min for 2.0 mm(I.D.) and 1.00 mL/min for 4.6

mm(I.D.)). The column life may be reduced if the column is operated near the

maximum pressure. The maximum pressure for the TSKgel NH2-100 3μm is shown

in Table 1. The viscosity of the solvent must be considered when selecting the flow

rate, too.

8. Temperature

The column should be operated in a temperature range of 10 - 50 ℃.

9. Sample Preparation

(1) Preparation of Sample Solution

Prepare the sample solution immediately prior to injection by dissolving the

sample into the solvent that is used as an eluent. The eluent should be

optimized by adjusting the pH, salt concentration, etc. so that the sample is

completely dissolved, otherwise the column lifetime may be reduced by

unexpected precipitation of sample on the column.

(2) Filtration of Insoluble Particles

The sample solution should be filtered with a micropore-filter (0.5μm). Even

though no particles can be detected by the naked eye, insoluble particles may

exist in the sample.

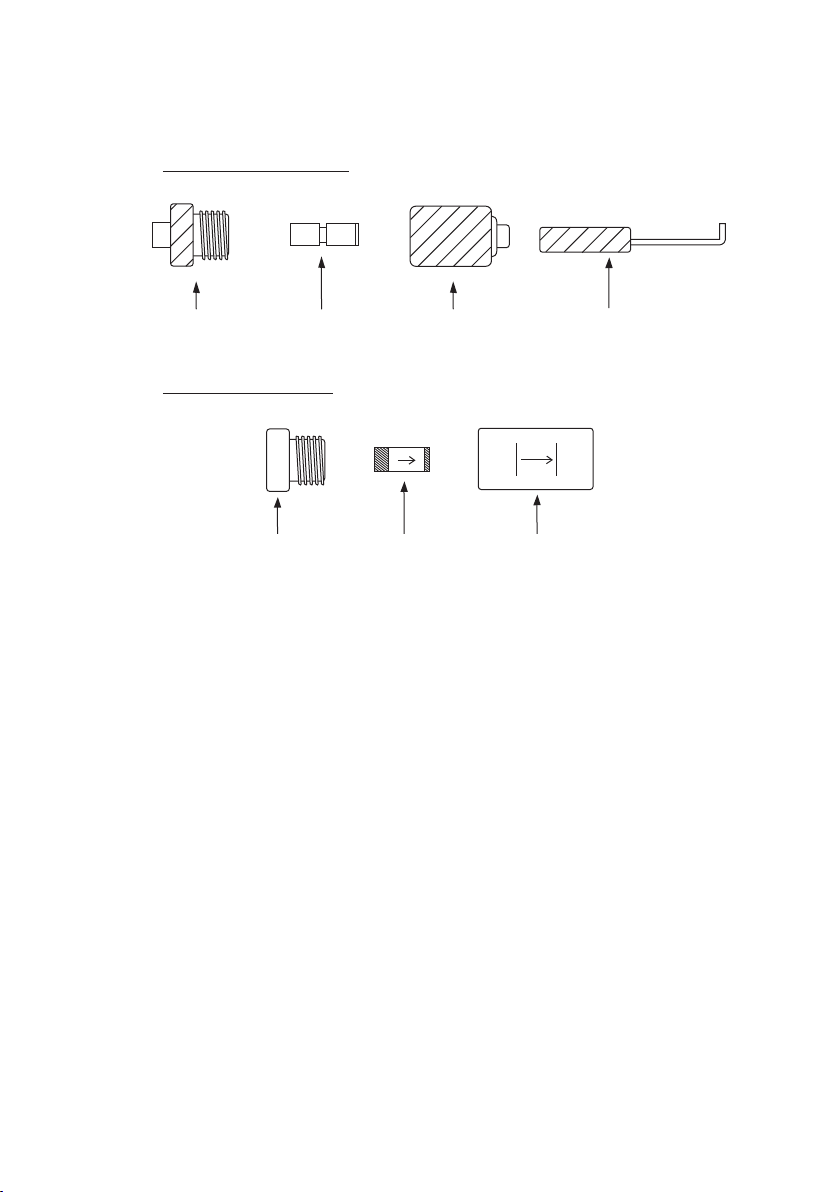

10. Measurement of Number of Theoretical Plates

and Asymmetry Factor

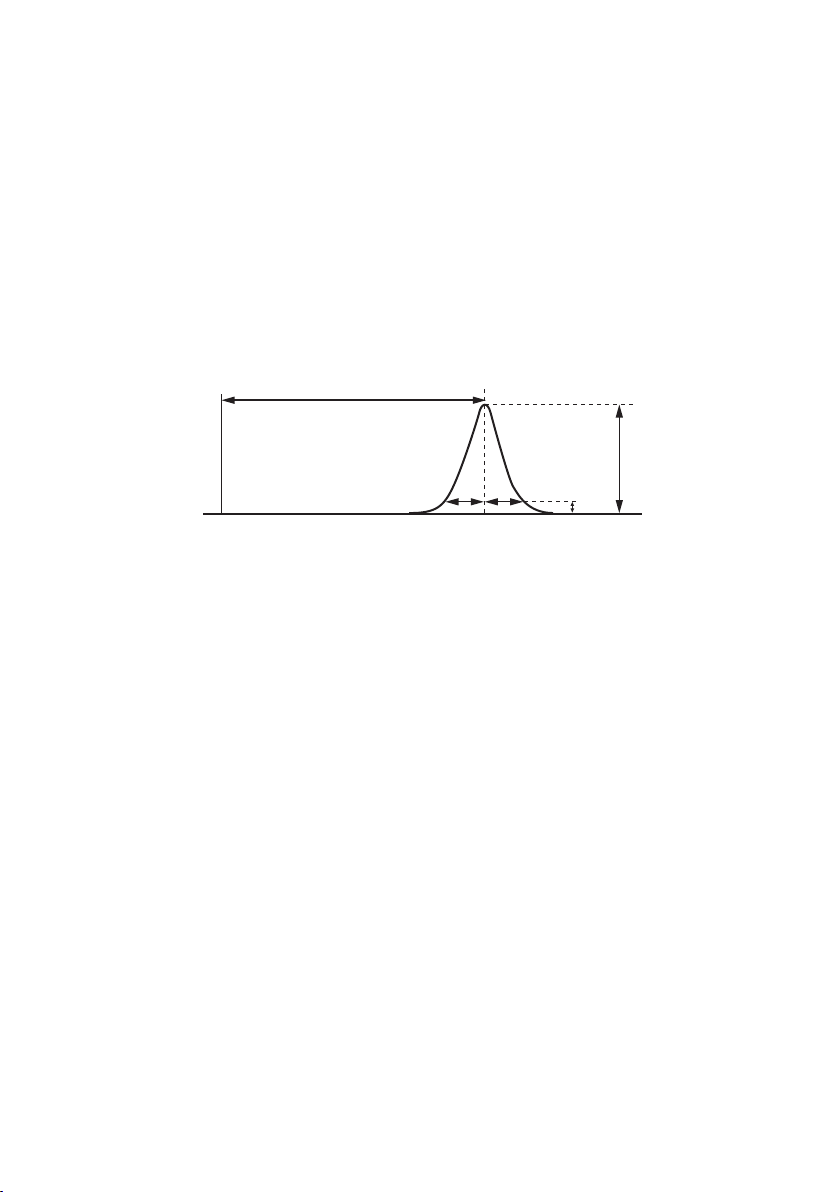

(1) Number of theoretical plates (N)

The N is calculated using an unretained molecule by the half-peak width method

as shown in Figure 3 and the following equation:

Figure 3 Calculation of Number of Theoretical Plates

−5−

Ve

h

W

Injection

1/2 1/2h

Table 1 Maximum Pressure

Part No.

0021967

0021968

0021969

0021970

2.0×5

2.0×15

4.6×5

4.6×15

15

20

5

15

TSKgel NH2-100 3μm

〃

〃

〃

Maximum

Pressure

(MPa)

Column Size

mm(I.D.)×cm(L)

Type

−6−

N=5.54(Ve/W1/2)2

where:

Ve

: Elution time

W1/2 : Width of peak at half-height

h

: Peak height

N : Number of theoretical plates/column

(2) Asymmetry factor (As)

The asymmetry factor is calculated according to Figure 4 and the following

equation:

Figure 4 Calculation of Asymmetry Factor

As=b/a

(3) The N and As should be measured with an instrument with small dead volume.

(4) The N and As are mentioned in the INSPECTION DATA sheet together with the

experimental conditions.

11. Guard Column

Fundamental keys to prevent problems have been outlined in Section 4 to 9. When

impurities that tend to adsorb onto the packing material are present in a sample,

they are typically adsorbed at the inlet side of the column and gradually accumulate

causing a reduction in the number of theoretical plates and a decrease in column

performance.

In such cases the original column performance can be maintained by connecting a

guard column between the injection valve and the analytical column. The guard

column should be replaced when the performance deteriorates as a result of the

adsorption of such a material to the guard column. A guard column can not be used

in place of analytical column.

The use of a guard column will not improve the resolution obtained on the analytical

column.

Ve

h

a b

Injection

1/10h

11-1 Effect of Guard Column Installation

(1) Contamination of the analytical column can be prevented by the removal of

adsorptive or insoluble materials in the sample.

(2) Pressure shock, due to pump pulsation, to the analytical column should be

avoided.

11-2 Type and Selection of Guard Columns

Guard columns specifications are shown in Table 2.

Cartridge holders are shown in Table 3.

11-3 Guard Column Replacement

Since the guard column has limited adsorbtion capacity, it has a finite lifetime.

The guard column must be replaced before contamination extends to the main

analytical column.

The frequency of the guard column replacement can not be standardized because it

depends on various factors such as application, sample properties (properties of

principal components, properties and concentrations of impurities, etc.), sample

loading, solvents, flow rate, etc.

Since an increase in the system pressure during operation could indicate clogging

at the end fitting of the guard column or contamination of the gel, it is a good idea to

replace the guard column when the pressure has increased.

In general, when changes in the results are observed, the guard column should be

replaced immediately.

−7−

Table 3 Cartridge Holder

Part No.

0019308

0019018

2.0×1

3.2×1.5

Cartridge holder (2.0×1)

Cartridge holder (3.2×1.5)

Column Size

mm(I.D.)×cm(L)

Type

Note : Two nuts, two ferrules and two small pieces of tubing are attached to the cartridge

holder as accessories.

In addition, column-extracting tool is attached to Part No. 0019018

Table 2 Cartridge Column

Part No.

0021971

0021972

2.0×1

3.2×1.5

TSKgel NH2-100 3μm

(2.0×5, 2.0×15)

TSKgel NH2-100 3μm

(4.6×5, 4.6×15)

TSKguardgel NH2-100 3μm

TSKguardgel NH2-100 3μm

Applied Column

mm(I.D.)×cm(L)

Column Size

mm(I.D.)×cm(L)

Type

Note : Three cartridge columns are packed in a box.

−8−

If a mixture of water or aqueous acetate solution with water-soluble organic

solvents (e.g., acetonitrile) are used as a mobile phase, the guard column should

be replaced after approximately 70 h of usage (for 4.6 mm(I.D.) columns) or 40 h of

usage (for 2.0 mm(I.D.) columns). Additionally, the main analytical column should

be cleaned when the guard column is replaced (for 4.6 mm(I.D.) columns) or every

20 h of usage (for 2.0 mm(I.D.) columns). Cleaning should be done by purging the

column for 0.5 h with a 5% water-soluble organic solvent (e.g., 5% acetonitrile in

water) at a flow rate of one-half the operating flow rate, or at a pressure below the

maximum pressure as shown in Table 1.

12. Troubleshooting

(1) Clogging of the inlet filter

Increased pressure or decreased flow rate are indicative of a clogged inlet filter.

In this case, clean the end fitting by reversing the flow direction through the

column (The flow rate must be kept below one-half of the operating flow rate as

shown in Table 1).

(2) Contamination

Continuous column operation may lead to gradual accumulation of strongly ionic

compounds or hydrophobic compounds.

This is demonstrated by changes in chromatographic behavior and loss of

resolution. Adsorbed materials may be removed from the column by injections of

solvent with a different polarity from the operating mobile phase.

(3) Bed Compression

Failure to properly clean the analytical column may result in the formation of a

void at the column head due to bed compression.

This failure can be confirmed by carefully removing the column end and

inspecting the bed.

13. Quality Specification and Warranty

13-1 INSPECTION DATA

The inspection conditions and the results of each individual column are shown on

the INSPECTON DATA sheet. The number of theoretical plates is expressed as the

number per column.

The inspection results are different for each column.

13-2 Quality Specifications

TSKgel NH2-100 3μm are delivered according to the specifications as shown in

Table 4.

13-3 Warranty

Upon receiving the column, check that the column is not damaged and test the

performance according to Section 10. If the guaranteed specifications in Table 4

can not be obtained, contact a local TOSOH representative within 30 days. Note

that the column lifetime is not guaranteed.

14. Column Cleaning Solutions

(1) Sample property : Hydrophobic compounds

Water soluble organic solvents such as 70-95 % acetonitrile and methanol in

aqueous buffer

(2) Sample property : Hydrophilic compounds

Water soluble organic solvents such as 5-10 % acetonitrile and methanol in

aqueous buffer

−9−

Table 4 Guaranteed Specifications

Part No.

0021967

0021968

0021969

0021970

2.0×5

2.0×15

4.6×5

4.6×15

4,000

15,000

6,000

18,000

0.90-1.35

0.90-1.35

0.90-1.30

0.90-1.30

TSKgel NH2-100 3μm

〃

〃

〃

Number of

theoretical plates

(TP/Column)

Column Size

mm(I.D.)×cm(L)

Asymmetry

factor

Type

HLC, TSK-GEL, TSKgel, TSKgel SuperMultipore, BioAssist, Enantio, PStQuick, Enviropak,

TOYOPEARL, ToyoScreen, TOYOPEARL GigaCap, TOYOPEARL MegaCap, TOYOPEARLPAK

and TOYOPAK are registered trademarks of TOSOH CORPORATION in Japan and other countries.

This manual may not be reprinted or copied in whole or in part without written consent of TOSOH

CORPORATION. The contents of the manual are subject to change without notice.

Printed in Japan

TOSOH CORPORATION

BIOSCIENCE DIVISION

Shiba-Koen First Bldg.

3-8-2 Shiba, Minato-ku, Tokyo 105-8623, Japan

Phone: +81-3-5427-5180 Fax: +81-3-5427-5220

Web site: http://www.separations.asia.tosohbioscience.com/

HPLC database: www2.tosoh.co.jp/hlc/hlcdb.nsf/StartE?OpenForm

TOSOH BIOSCIENCE GmbH

Zettachring 6, 70567 Stuttgart, Germany

Phone: +49-711-132570 Fax: +49-711-1325789

E-mail: [email protected]

Web site: http://www.tosohbioscience.com/

TOSOH BIOSCIENCE

SHANGHAI CO., LTD.

Room 301, Plaza B, No.1289 Yi Shan Road,

Xu Hui District, Shanghai 200233, China

Phone: +86-21-3461-0856 Fax: +86-21-3461-0858

E-mail: [email protected]

Web site: http://www.separations.asia.tosohbioscience.com/

TOSOH ASIA PTE. LTD.

63 Market Street #10-03 Singapore 048942

Phone: +65-6226-5106 Fax: +65-6226-5215

E-mail: [email protected]

Web site: http://www.separations.asia.tosohbioscience.com/

TOSOH BIOSCIENCE LLC

3604 Horizon Drive Suite 100,

King of Prussia, PA 19406, USA

Phone: +1-800-366-4875 Fax: +1-610-272-3028

E-mail: [email protected]

Web site: http://www.tosohbioscience.com/

Packed Columns for Aqueous

Size Exclusion Chromatography

TSKgel SuperMultiporePW-N

TSKgel SuperMultiporePW-M

TSKgel SuperMultiporePW-H

TSKgel SuperOligoPW

INSTRUCTION

MANUAL

Rev. CO073003

Rev. CO067000A0

Published in February, 2010

Supplemental Information related to TSKgel NH2-100 3μm columns

INSTRUCTION MANUAL for TSKgel NH2-100 DC 3μm (4.6 mm(I.D.), 5 cm(L))

To help protect you and/or your property from potential damage and ensure personal safety,

please read the “Precautions” which are printed in the beginning of the “TSKgel NH2-100

3μm” INSTRUCTION MANUAL thoroughly before using the above TSKgel NH2-100 DC

3μm column.

For this TSKgel NH2-100 DC 3μm column, please read section 1, section 3 (1), section 7

(Table 1), and section 13 (Table 4) on this supplemental information sheet instead of the

corresponding sections you find on the “TSKgel NH2-100 3μm” INSTRUCTION MANUAL.

Please read section 4 (13) in addition to those in each section on the “TSKgel NH2-100

3μm” INSTRUCTION MANUAL.

1. General Information

This TSKgel NH2-100 DC 3μm column has the outlet end fitting with an external male

connector so that it can be easily connected to another HPLC column.

In this supplemental information sheet, only those instructions different from the other

TSKgel NH2-100 3μm columns are included. Please refer to the “TSKgel NH2-100 3μm”

INSTRUCTION MANUAL regarding instructions which are not mentioned in these

document.

3. Column Parts

1) Analysis column

Figure 2 Column Parts

Inlet Outlet

End Plug (Inlet)

End Fitting (Inlet)

Name Plate Spacer Ring

End Fitting (Outlet) End Plug (Outlet)

FLOW

Inlet Outlet

End Plug (Inlet)

End Fitting (Inlet)

Name Plate Spacer Ring

End Fitting (Outlet) End Plug (Outlet)

FLOWFLOW

4. Column Installation

(13) To directly connect the TSKgel NH2-100 DC 3μm column to another HPLC column,

finger-tighten the connection between the outlet of the TSKgel NH2-100 DC 3μm

column and the inlet of the second column, and then tighten with appropriate

wrenches until you feel some resistance. Check for solvent leaks from the connection.

The following operations may cause permanent deterioration in column efficiency.

a) Damage to the tip of the outlet end fitting caused by mechanical force such as

accidentally dropping the column.

b) Tightening the connection between the two columns to more than 2.0 Nm of

torque (more than about 30 degrees).

c) Repeated connections and disconnections of the two columns. It is recommended

that the two columns are kept connected during storage.

d) Connection to other companies’ columns not compatible with TOSOH’s.

7. Flow Rate

Table 1 Maximum Pressure

Part No. Type Column Size

mm(I.D.)×cm(L)

Maximum

Pressure

(MPa)

0021999 TSKgel NH2-100 DC 3μm 4.6×5 5

11. Guard Column

11-2 Type and Selection of Guard Columns

Table 2 Cartridge Column

Part No. Type Column Size

mm(I.D.)×cm(L)

Applied Column

mm(I.D.)×cm(L)

0021972 TSKguardgel NH2-100 3μm3.2×1.5 TSKgel NH2-100 DC 3μm

(4.6×5)

Note: Three cartridge columns are packed in a box.

13. Quality Specification and Warranty

13-3 Warranty

Table 4 Guaranteed Specifications

Part No. Type Column Size

mm(I.D.)

×

cm(L)

Number of

Theoretical plates

(TP/Column)

Asymmetry

factor

0021999 TSKgel NH2-100 DC 3μm4.6×5 6,000 0.90~1.30

TOSOH CORPORATION

BIOSCIENCE DIVISION

Table of contents

Other TOSOH BIOSCIENCE Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific AI 1310 user guide

PRO Scientific

PRO Scientific P Series Operator's manual

BD

BD BACTEC FX user manual

Fritsch

Fritsch premium PULVERISETTE 14 operating instructions

Hitachi

Hitachi S-3400N quick start guide

Miele professional

Miele professional A 620 operating instructions

BioLAB

BioLAB BBWA-100 Operation manual

Deltec

Deltec 1500 Series operating instructions

Tecno-gaz

Tecno-gaz Multisteril Fast Technical manual

Integra

Integra Evolve 3011 operating instructions

Peak Scientific

Peak Scientific Precision Zero Air Series user manual

Sensorex

Sensorex 8000 Series Product Instruction Sheet