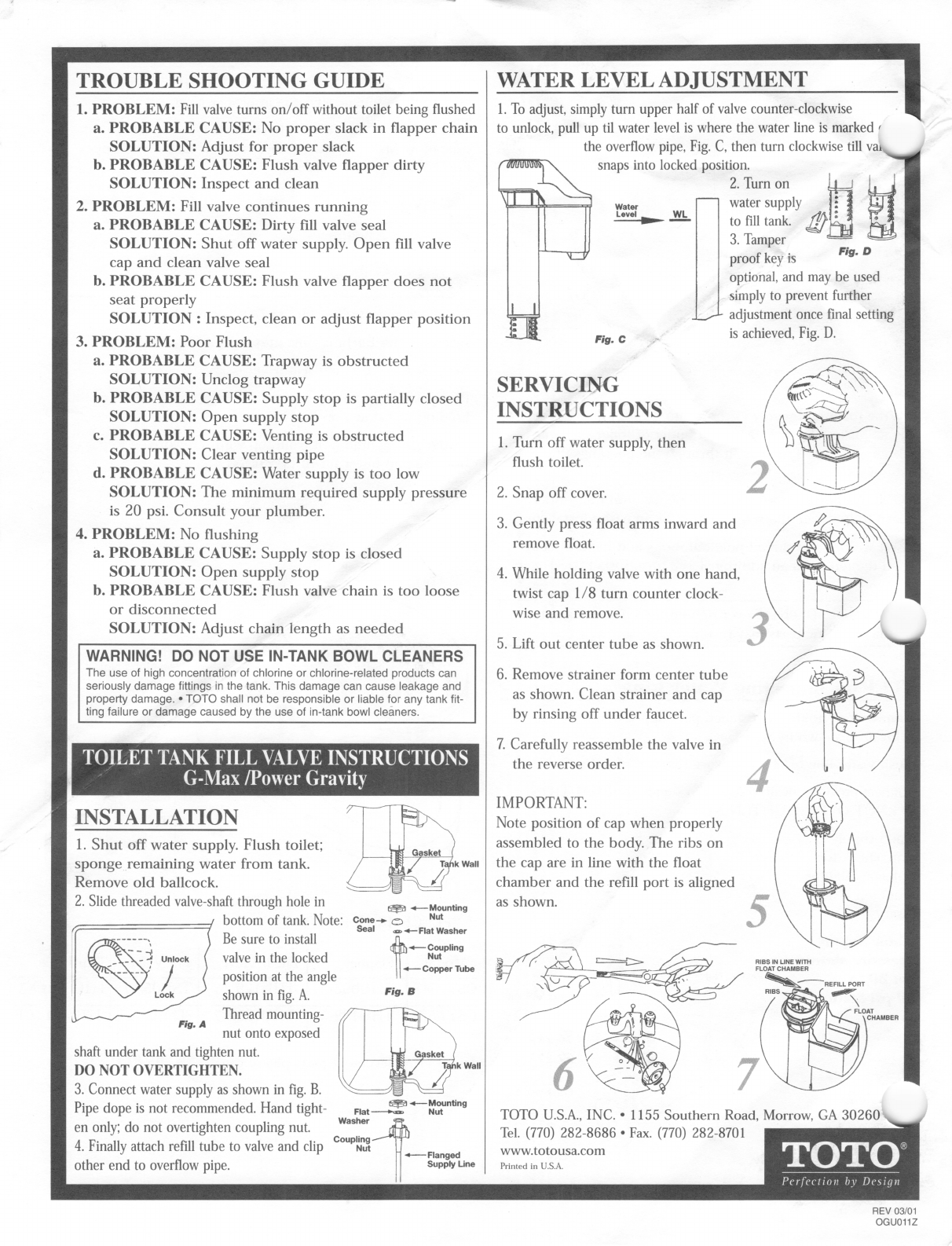

WATER LEVEL ADJUSTMENT

T R O U B L E S H O O T I N G G U I D E

1. PROBLEM: Fill valve turns on/off without toilet being flushed

a. PROBABLE CAUSE: No proper slack in flapper chain

SOLUTION: Adjust for proper slack

b. PROBABLE CAUSE: Flush valve flapper dirty

SOLUTION: Inspect and clean

2. PROBLEM: Fill valve continues running

a. PROBABLE CAUSE: Dirty fill valve seal

SOLUTION: Shut off water supply. Open fill valve

cap and clean valve seal

b. PROBABLE CAUSE: Flush valve flapper does not

seat properly

SOLUTION :Inspect, clean or adjust flapper position

3 . P R O B L E M : P o o r F l u s h

a. PROBABLE CAUSE: Trapway is obstructed

SOLUTION: Unclog trapway

b. PROBABLE CAUSE: Supply stop is partially closed

SOLUTION: Open supply stop

c. PROBABLE CAUSE: Venting is obstructed

SOLUTION: Clear venting pipe

d. PROBABLE CAUSE: Water supply is too low

SOLUTION: The minimum required supply pressure

is 20 psi. Consult your plumber.

4. PROBLEM: No flushing

a. PROBABLE CAUSE: Supply stop is closed

SOLUTION: Open supply stop

b . P R O B A B L E C A U S E : F l u s h v a l v e c h a i n i s t o o l o o s e

or disconnected

SOLUTION: Adjust chain length as needed

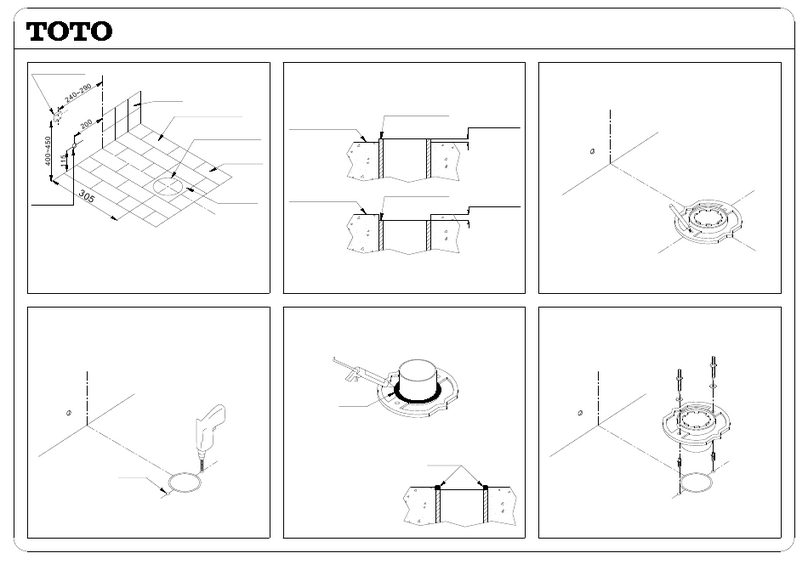

1. To adjust, simply turn upper half of valve counter-clockwise H

to unlock, pull up til water level is where the water line is marked '

theoverflowpipe.Fig.C,thenturnclockwisetillvai^^^v

'(fWiiliwRj \snaps into locked position.

2. Turn on 4

water supply

to fill tank.

3. Tamper

proof key is

optional, and may be used

simply to prevent further

adjustment once final setting

is achieved. Fig. D.

Water

Level WL

Fig. D

Fig. C

SERVICING

INSTRUCTIONS

1. Turn off water supply, then

flush toilet.

2. Snap off cover.

3. Gently press float arms inward and

remove float.

4. While holding valve with one hand,

twist cap 1/8 turn counter clock¬

wise and remove.

5. Lift out center tube as shown.

W A R N I N G ! D O N O T U S E I N - T A N K B O W L C L E A N E R S

The use of high concentration of chlorine or ohiorine-reiated products can

seriously damage fittings in the tank. This damage can cause leakage and

property damage. ●TOTO shall not be responsible or liable for any tank fit¬

ting failure or damage caused by the use of in-tank bowl cleaners.

6. Remov e s train e r form cen ter tube

as shown. Clean strainer and cap

by rinsing off under faucet.

7. Carefully reassemble the valve in

the reverse order.

TO ILE T TAN K FIL L VALVE INS TRU CTI ONS

G-Max /Power Gravity

IMPORTANT:

INSTALLATION Note position of cap when properly

assembled to the body. The ribs on

the cap are in line with the float

chamber and the refill port is aligned

1. Shut off water supply. Flush toilet;

sponge remaining water from tank.

Remove old ballcock.

2. Slide threaded valve-shaft through hole in

bottom of tank. Note: cone-* o

Be sure to install

valve in the locked

a s s h o w n .

—Mounting

Nut

Seal «.**-Rat Washer

^—Coupling

Nut RIBS IN LINE WITH

^— Copper Tube FLOATCHAURFR

position at the angle

shown in fig. A.

Thread mounting- ^

nut onto exposed

REFILL PORT

Fig. B

\

FLOAT

CHAMBER

shaft under tank and tighten nut.

DO NOT OVERTIGHTEN.

Gasket

7Wall

3. Connect water supply as shown in fig. B.

Pipe dope is not recommended. Hand tight¬

en only; do not overtighten coupling nut.

4. Finally attach refill tube to valve and clip

other end to overflow pipe.

^—Mounting

Flat Nut TOTO U.S.A., INC. ●1155 Southern Road, Morrow, GA 30260

Tel. (770) 282-8686 ●Fax. (770) 282-8701

Washer,.J0b

Coupling

TOTO

Nut www.totousa.com

Printed in U.S.A.

Flanged

Supply Une

P e r f e c t i o n b y D e s i g n

R E V 0 3 / 0 1

OGU011Z