TOYODenki VF66 User manual

TOYO INTELLIGENT INVERTER

EIP66-Z Communication

Protocol Manual

3

Preface

Thank you very much for choosing our inverter optional board.

This manual describes the communication protocol of the optional board EIP66-Z designed for VF66 inverter.

Please read this manual thoroughly to use the EIP66-Z communication function properly.

This manual describes the EIP66-Z EtherNet/IP communication function. For the terminal block functions of

EIP66-Z board, wiring, switch settings and VF66 inverter settings, refer to "EIP66-Z Operating Instructions."

To use various functions according to intended use as well as the VF66 inverter functions, read the operating

instructions of VF66 inverter main unit or dedicated manual thoroughly before use.

The following shows the EtherNet/IP specification versions used by EIP66-Z.

Volume1:Edition 3.15 November 2013

Volume2:Edition 1.16 November 2013

4

Be Sure To Read This Before Use

Safety Notice

To use the EIP66-Z correctly, be sure to completely read this manual and all other attached documents before

installation, operation, maintenance, and inspection. You need to have a good knowledge of equipment, safety

information, and all notices before using the EIP66-Z. Read also the operating instructions of VF66 inverter

main unit thoroughly before use for safe operations.

In this manual, safety notices are ranked as "Danger," "Warning," and "Caution."

WARNING

When improper use may cause a dangerous situation, and death or serious

injury may result.

CAUTION

When improper use may cause a dangerous situation, medium-level or minor

injury may result, and only physical damage may result. However, it can

cause serious results depending on the situation. Cautions described in

this manual are all important. Be sure to observe them.

CAUTION [Installation]

Do not use the product if it is found damaged or deformed in unpacking.

It may cause failure/malfunction.

Do not put a flammable material near the product.

It may catch fire.

Do not give a shock to the product by dropping or toppling it.

It may cause failure/damage to the product.

Do not install an optional board with damage or missing part to perform operations.

It may cause injury.

WARNING [Wiring]

Check that the input power is turned off before wiring.

Otherwise, electric shock/fire may result.

After turning off the power, wait at least ten minutes before opening the inverter front cover.

Be sure to connect a ground wire.

Otherwise, electric shock/fire may result.

Let an electrical engineering technician do the wiring work.

Otherwise, electric shock/fire may result.

Be sure to install the main unit before wiring.

Otherwise, electric shock/fire may result.

5

CAUTION [Wiring]

Be sure to attach and lock the communication cable and connector.

Otherwise, failure/malfunction may result.

WARNING [Operation]

Be sure to attach the inverter front cover before turning on the input power.

Do not remove the cover while the inverter is energized.

Ignoring this may cause electric shock.

Do not operate the switch with wet hands.

Ignoring this may cause electric shock.

While the inverter is energized, do not touch the inverter terminal even when the inverter is stopped.

Ignoring this may cause electric shock.

Resetting an alarm with the operation signal input causes a sudden restart.

Perform resetting after making sure that the operation signal is off.

Otherwise, you may be injured.

The inverter operation setting is available from low to high speed. Check the allowable range of motor

or machine carefully before starting operation.

Otherwise, injury/failure/damage may result.

CAUTION [Operation]

Do not touch the inverter radiation fin or discharge resistor because it can be very hot.

Ignoring this may cause burn injury.

WARNING [Maintenance/inspection and part replacement]

Be sure to turn off the power before performing inspection.

Otherwise, electric shock/injury/fire may result.

Only the specified person must perform maintenance/inspection and part replacement.

Use an insulated tool for maintenance/inspection.

Otherwise, electric shock/injury may result.

CAUTION [Others]

Never modify the product.

Otherwise, electric shock/injury may result.

CAUTION [General cautions]

Some figures in this manual are shown with the cover or safety shield removed for the purpose of detailed

descriptions. However, for actual operations, be sure to attach the specified cover or safety shield and

follow the instructions in this manual.

Note that these safety precautions and specifications described in each manual are subject to change without

notice.

6

Contents

Be Sure To Read This Before Use ................................................................................................................................. 4

Safety Notice........................................................................................................................................................... 4

CHAPTER 1 Function Overview......................................................................................................................................... 7

CHAPTER 2 Function Specifications.............................................................................................................................. 8

2. 1 EtherNet/IP Communication Function Connector/Terminal Specifications.......................................... 8

2. 2 EtherNet/IP Communication Specifications............................................................................................... 8

2. 3 Device Profile................................................................................................................................................ 9

2. 4 Others................................................................................................................................................................ 9

CHAPTER 3 Communication Function Description....................................................................................................... 10

3. 1 Parameter Setting........................................................................................................................................ 10

3. 2 Speed Commanding Place Setting ............................................................................................................... 12

3. 3 I/O Assembly Instance Number Setting.................................................................................................... 13

CHAPTER 4 I/O Assembly ................................................................................................................................................ 14

4. 1 Standard I/O Assembly Data Attribute Format....................................................................................... 14

4. 2 Expanded I/O Assembly Data Attribute Format....................................................................................... 16

CHAPTER 5 Object............................................................................................................................................................ 23

5. 1 Identity Object (Class Code: 0x01)......................................................................................................... 24

5. 2 Message Router Object (Class Code: 0x02)............................................................................................. 26

5. 3 Assembly Object (Class Code: 0x04)........................................................................................................ 26

5. 4 Connection Manager Object (Class Code: 0x06)..................................................................................... 27

5. 5 Motor Data Object (Class Code: 0x28).................................................................................................... 28

5. 6 Control Supervisor Object (Class Code: 0x29)..................................................................................... 29

5. 7 AC/DC Drive Object (Class Code: 0x2A).................................................................................................. 31

5. 8 TCP/IP Interface Object (Class Code: 0xF5)......................................................................................... 32

5. 9 Ethernet Link Object (Class Code: 0xF6) .............................................................................................. 34

5. 10 VF66 Parameter Table Object (Class Code: 0x67) ............................................................................... 35

5. 11 VF66 Traceback Data Object (Class Code: 0x68)................................................................................. 36

5. 12 VF66 Protection History Object (Class Code: 0x69).......................................................................... 37

5. 13 VF66 Monitor Data Object (Class Code: 0x6A)..................................................................................... 40

CHAPTER 6 Status Code .................................................................................................................................................. 42

7

CHAPTER 1 Function Overview

EIP66-Z is attached to the connector of the board (VFC66-Z) inside the VF66 inverter to use. EIP66-Z is equipped

with the EtherNet/IP adapter function (slave station), analog input/output function, multifunction input and

PG input/output function.

EtherNet/IP is a public network standard, and the specification and protocol are made public by ODVA (Open

DeviceNet Vendor Association, Inc.) to provide mutual compatibility between the devices of the same type by

multiple vendors.

The EIP66-Z EtherNet/IP communication function allows users to input a command related to operation, speed,

torque, etc. to the VF66 inverter or monitor the situations including the inverter operation/protection status,

current and voltage. In addition, reading/rewriting of inverter settings and reading of traceback data,

protection history and monitoring data are available. This function can also be used as an input/output signal

of the internal PLC function of the VF66 inverter. For the internal PLC function, refer to the VF66 PC Tool

manual.

CAUTION [Safety precautions]

Read this manual thoroughly before use for proper handling.

Our inverter is not designed/manufactured for the devices or systems used in a life-threatening

situation.

Do not use this inverter for special use, such as riding mobile object, medical care, aerospace,

nuclear power control, submarine repeater/system, etc.

This inverter is manufactured under stringent quality control; however, install safety equipment

to avoid a serious accident for the important facility which may put human lives in danger by failure

of the inverter

or the facility to which a serious loss is caused by failure of the inverter.

Contact us to use this product for the load other than three-phase AC motors.

Electrical work is required for this inverter. Let an electrical engineering technician do the work.

8

CHAPTER 2 Function Specifications

2. 1 EtherNet/IP Communication Function Connector/Terminal Specifications

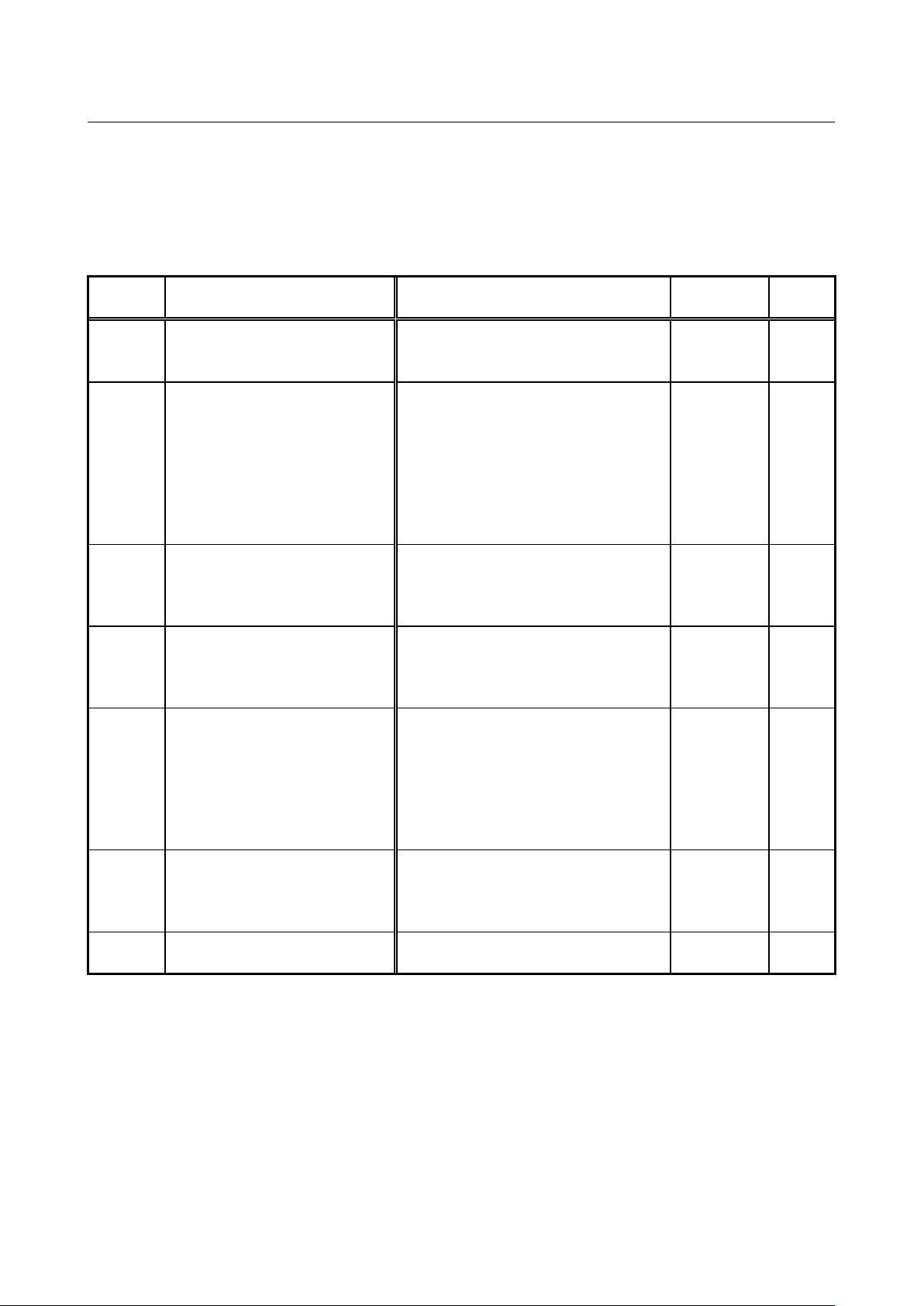

Table 2.1 Communication function connector specifications (RJ-45 8 poles)

EIP66-Z connector CN3/4

Pin No.

Usage

Description

1

TX+

Transmission signal line (+)

2

TX-

Transmission signal line (-)

3

RX+

Reception signal line (+)

4

-

Unused

5

-

6

RX-

Reception signal line (-)

7

-

Unused

8

-

Table 2.2 Communication function terminal specifications

EIP66-Z terminal block

TB3

Terminal name

Usage

Description

FG

Safety ground terminal

Shielded terminal (M4) for CN3/CN4

2. 2 EtherNet/IP Communication Specifications

Table 2.3 EtherNet/IP communication specifications

Ethernet

Compliance standard

IEEE802.3i (10BASE-T)/IEEE802.3u (100BASE-TX)

Transmission speed

10/100 Mbps (automatic switching)

Communication mode

Full-duplex/half-duplex (automatic switching)

Connection type

Star/daisy chain connection

Interface

RJ-45 connector

Transmission distance

(between nodes or node and hub)

Within 100 m (depends on the specification of used cable)

Connected cable

Shielded twisted pair cable (STP): Category 5 or higher

Straight, cross (automatic switching)

EtherNet/IP

IP address setting

Set by the setting parameter of VF66 inverter main unit.

Communication function

Cyclic communication (Implicit message)

Message communication (Explicit message)

Vendor ID

178

Product Code

13

Device Type

AC Drive Profile

Product Name

EIP66 Series

ACD function (Address Conflict Detection)

Supported

Conformance test

EtherNet/IP CT-11

EDS file

EIP66 Series 1_0.eds

9

2. 3 Device Profile

An ODVA certified AC drive profile and Toyo original profile that works as a vendor-specific expanded

profile are available for EIP66-Z.

Standard profile

AC drive profile

Expanded profile

Toyo original profile

Select a profile to use using the inverter setting parameter. (Refer to Section 3.3.)

2. 4 Others

For the terminal block and other specifications, refer to "EIP66-Z Operating Instructions."

WARNING [Wiring]

Check that the input power is turned off before wiring.

Otherwise, electric shock/fire may result.

CAUTION [Wiring]

Never connect the G and G2 terminals to a ground.

Ignoring this may cause failure/damage.

Do not bring the PS and G terminals into contact or connect them.

Ignoring this may cause failure/damage.

10

CHAPTER 3 Communication Function Description

3. 1 Parameter Setting

The EIP66-Z EtherNet/IP communication function allows users to input a command related to operation, speed,

torque, etc. to the VF66 inverter or monitor the situations including the inverter operation/protection status,

current and voltage. In addition, reading/rewriting of inverter setting parameters and reading of traceback data,

protection history and monitoring data are available. This function can also be used as an input/output signal

of the internal PLC function of the VF66 inverter. For the internal PLC function, refer to the VF66 PC Tool manual.

To communicate with the EtherNet/IP scanner (master), the following VF66 inverter setting parameters need to

be set. Read also "EIP66-Z Operating Instructions" and operating instructions of VF66 inverter main unit and

scanner to use.

As for the direction of EtherNet/IP communication in this chapter, "Input" indicates the direction of input

from EIP66-Z to the network, and "Output" indicates the direction of output from the network to EIP66-Z. This

does not apply to the descriptions of the internal PLC function and multifunction input.

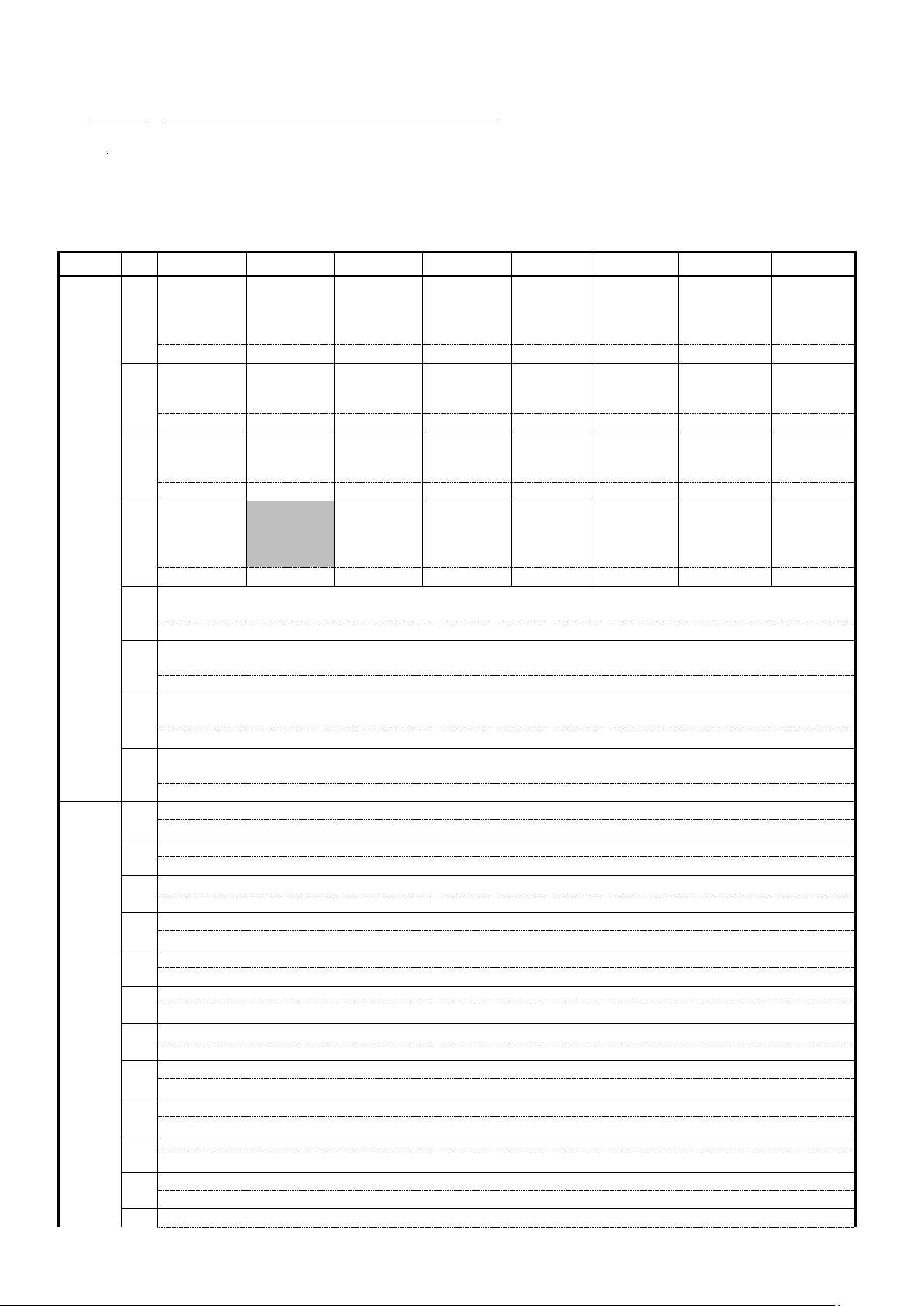

Table 3.1.1 EtherNet/IP communication related settings

Display

Item

Setting band (selection item)

Default

Driving

ReWrite

J-00

1: Digital communication option selection

0: Communication option not used

8: Use EIP66-Z

1 to 7: Set to use other options

0

x

J-07

IP address setting (high-order 2 bytes)

Set an IP address in hexadecimal

notation.

For the case of 192. 168. 100. 1,

0

x

J-08

IP address setting (low-order 2 bytes)

set J-07 to C0A8, and

J-08 to 6401.

0

x

J-09

Output Assembly

Instance number setting

0: Instance No. 20 (standard profile)

2: Instance No. 100 (expanded profile)

10: Instance No. 108 (expanded profile)

(refer to Section 3.3)

0

x

J-10

Input Assembly

Instance number setting

0: Instance No. 70 (standard profile)

14: Instance No. 132 (expanded profile)

15: Instance No. 140 (expanded profile)

(refer to Section 3.3)

0

x

J-11

SpeedScale setting

-126 to 127

3

x

J-12

MonitorDataNo. setting

0 to 119

3

○

J-16

Subnet mask setting (high-order 2 bytes)

Set a subnet mask in hexadecimal notation.

0

x

J-17

Subnet mask setting (low-order 2 bytes)

0

x

J-18

Default gateway setting (high-order 2 bytes)

Set a default gateway in hexadecimal

notation.

0

x

J-19

Default gateway setting (low-order 2 bytes)

0

x

11

* When a change is made in these settings, turn off the inverter power and then turn it on again.

・"J-11" is used to set the speed scaling coefficient (AC/DC Drive object attribute 22 "SpeedScale") used by

the standard profile (AC drive). This speed scaling coefficient determines the resolution of speed detection

value (SpeedActual) and speed setting value (SpeedRef).

Resolution = r/min/2SpeedScale

With the default value (= 3), the resolution becomes 0.125 r/min.

・"J-12" is used to set MonitorDataNo. used by the instance 140.

For more information about the setting value, refer to Section 4.2.4.

EIP66-Z allows the use of internal PLC function when the expanded profile is selected. Whether to use the internal

PLC function can be set using the VF66 inverter setting parameters (area i) as shown in the following table.

For more information, refer to the operating instructions of VF66 inverter main unit.

Table 3.1.2 Selecting use of internal PLC function

Display

Item

Selection item

Default

Driving

ReWrite

i-00

PLC-L function usage selection

off: Unused

on: Used

off

x

i-01

PLC-H function usage selection

0: Unused

1: Used

2: Used (PLCH output recognized as

speed command input)

0

x

・Use the internal PLC function when "J-09" and "J-10" are set to 2 or more (expanded profile).

・For the internal PLC function, refer to the VF66 PC Tool manual.

* In using the PLC-L function, each bit of the first and second words does not function as an operation control

or multifunction input signal. In this case, create a sequence to operate the operation control signal by

the internal PLC function.

12

3. 2 Speed Commanding Place Setting

To enable various commands on the VF66 inverter via communication, the following inverter setting parameters

need to be set appropriately. To enable the operation control signal of first word, turn on the forward operation

terminal "ST-F" on the terminal block TB1 of VF66 inverter control board VFC66-Z. For more information, refer

to the operating instructions of VF66 inverter main unit.

Table 3.2 Commanding place selection setting

Display

Item

Setting band (selection item)

Default

Driving

ReWrite

b-09

Commanding place when coupled

0: Terminal block

1: Console (SET66-Z)

2: Digital communication option

1

x

b-10

Speed commanding place

selection(*1)

0: Coupled

1: Analog input (1) (AIN1)

2: Console (SET66-Z)

3: Digital communication option

4: Analog input (2) (AIN2)

5: (For external extension option)

6: Analog input (3) (AIN3)

7: Internal PLC

0

x

b-11

Operation commanding place

selection

0: Coupled

1: Terminal block

2: Console (SET66-Z)

3: Digital communication option

0

x

b-12

JOG commanding place selection

0: Coupled

1: Terminal block

2: Console (SET66-Z)

3: Digital communication option

0

x

i-07

Operation mode selection(*2)

0: Speed control (ASR) mode

1: Torque command negative direction

prioritized

2: Torque command positive direction

prioritized

3: Torque control (ATR) mode

4: Speed/torque control setting change

0

x

i-08

Torque command input place

selection(*2)

1: Analog input (1) (AIN1)

1: Analog input (2) (AIN2)

2: Digital communication option

3: Internal PLC output

1

x

J-14

Date/time data selection from

communication

0: Without date/time data

1: With date/time data

0

x

(*1) This becomes "Frequency commanding place selection" when V/f mode is selected for the inverter mode.

(*2) This cannot be set when V/f mode is selected for the inverter mode.

・To control the inverter via a scanner (master) on the network using the standard profile (AC drive), set

the parameter "b-10" (Speed commanding place selection) to 3 (Digital communication option).

With "b-10" set to 3, EIP66-Z sets the speed commanding place (AC/DC Drive object attribute 4 "NetRef") to

network control at power-on to receive a speed command from a scanner on the network.

With "b-10" set to a value other than 3, EIP66-Z sets the speed commanding place to local control and ignores

a speed command from a scanner.

13

・To control the inverter via a scanner (master) on the network using the standard profile (AC drive), set

the parameter "b-11" (Operation commanding place selection) to 3 (Digital communication option).

With "b-11" set to 3, EIP66-Z sets the operation commanding place (Control Supervisor object attribute 5

"NetCtrl") to network control at power-on to receive an operation command from a scanner on the network.

With "b-11" set to a value other than 3, EIP66-Z sets the operation commanding place to local control and

ignores an operation command from a scanner.

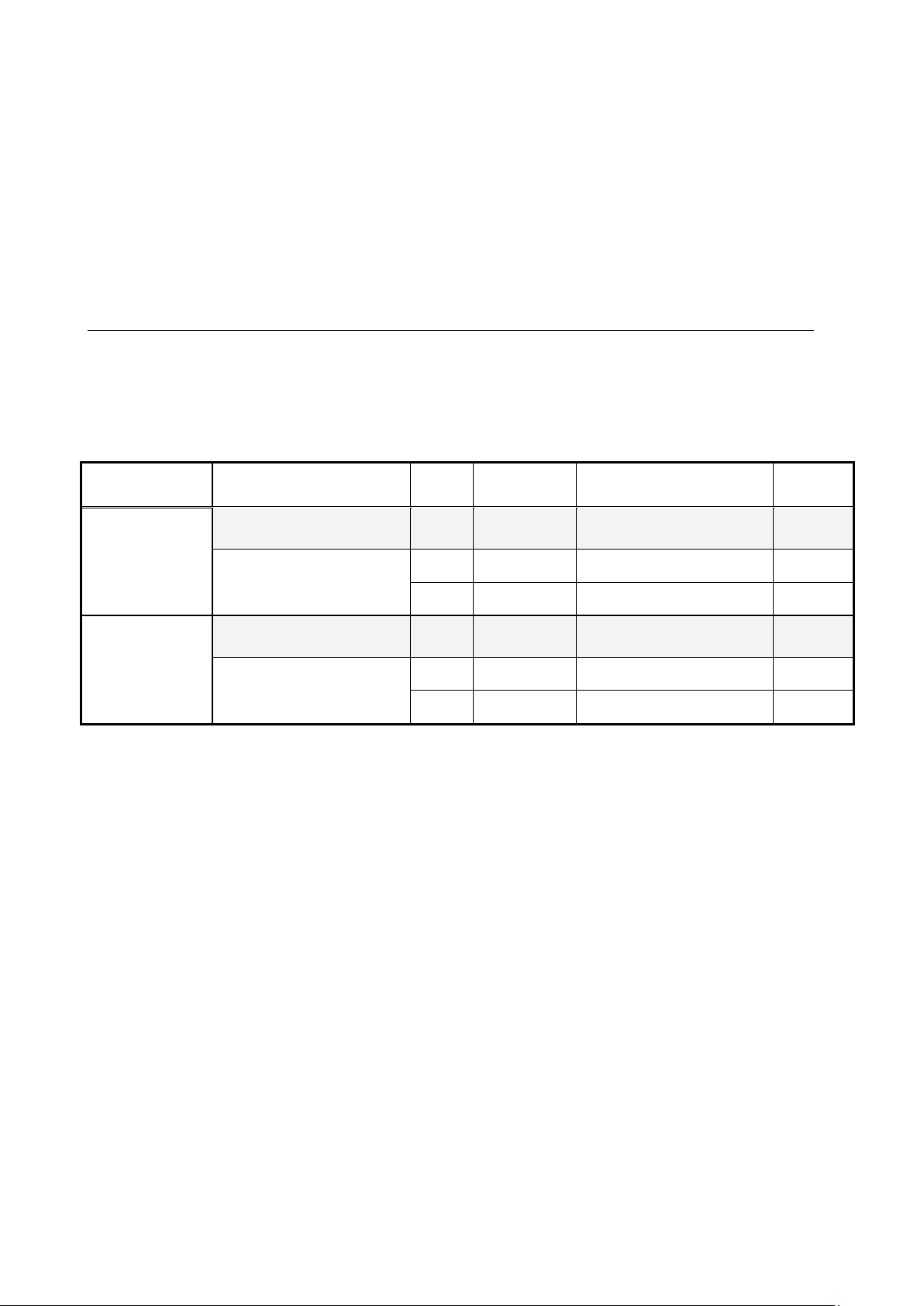

3. 3 I/O Assembly Instance Number Setting

The EIP66-Z I/O Assembly instance number is set by the inverter setting parameters "J-09" (Output Assembly

instance number setting) and "J-10" (Input Assembly instance number setting). These values are set on

EIP66-Z at power-on. The default values are both 0.

Table 3.3

Parameter name

Device profile

Setting

value

Instance

number

Name

Size

(word)

"J-09"

Output Assembly

instance number

setting

Standard profile

(AC drive)

0

20

Basic Speed Control Output

2

Expanded profile

(Toyo original)

2

100

Special 1 Control Output

4

10

108

Special 9 Control Output

12

"J-10"

Input Assembly

instance number

setting

Standard profile

(AC drive)

0

70

Basic Speed Control Input

2

Expanded profile

(Toyo original)

14

132

Special 13 Control Input

18

15

140

Special 14 Control Input

4

・When the "J-09" instance number is set to 20, select 70 for the "J-10" instance number.

When the "J-09" instance number is set to a value other than 20, select a value other than 70 for the

"J-10" instance number.

The standard profile and expanded profile cannot be set together.

・Specifying 1 for "J-09" selects the instance number 20, and specifying any value from 3 to 9 selects

the instance number 108.

・Specifying 1 for "J-10" selects the instance number 70, and specifying any value from 2 to 13 selects

the instance number 132.

14

CHAPTER 4 I/O Assembly

4. 1 Standard I/O Assembly Data Attribute Format

The following shows the data format for the case of selecting the standard profile (AC drive profile).

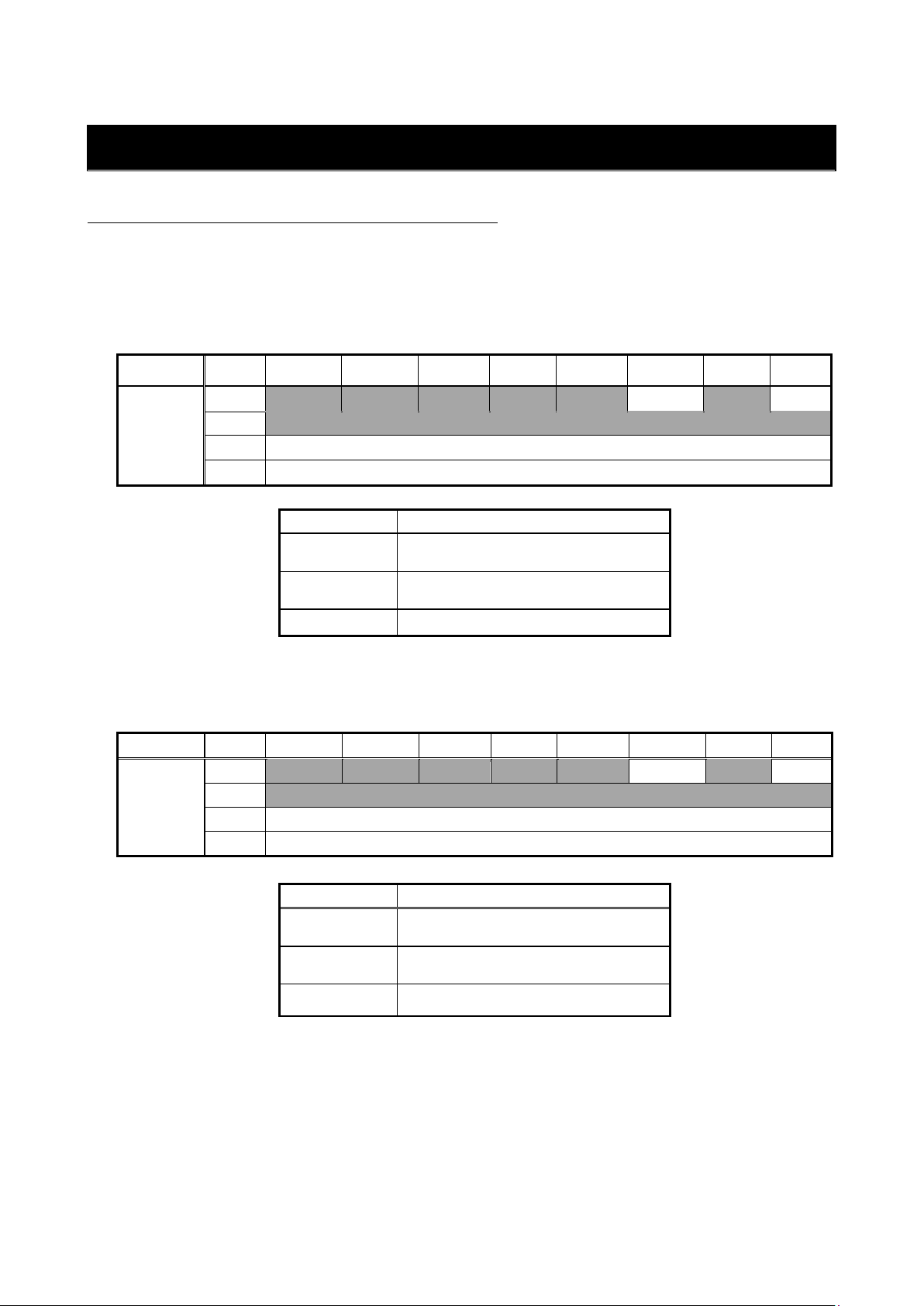

4. 1. 1 Output Assembly Instance

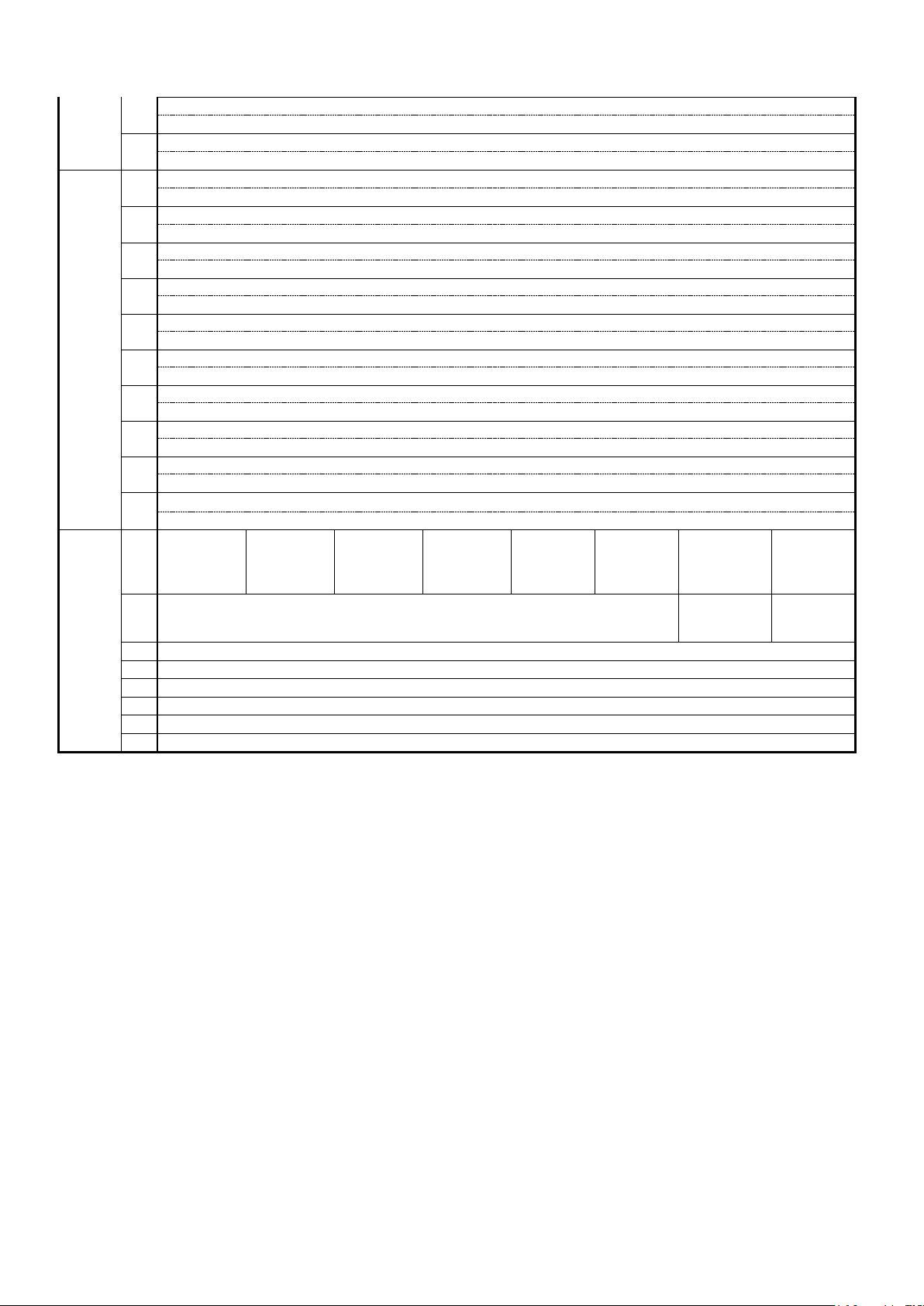

Table 4.1.1

Instance

Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

20

0

Fault Reset

Run Fwd

J-09 = 0

1

(2 words)

2

Speed Reference (low-order byte)

3

Speed Reference (high-order byte)

Name

Description

Run Fwd

Forward operation command

0: Stop, 1: Run

Fault Reset

Fault reset

0 -> 1 = Fault reset

Speed Reference

Speed setting value

4. 1. 2 Input Assembly Instance

Table 4.1.2

Instance

Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

70

0

Running1

Faulted

J-10 = 0

1

(2 words)

2

Speed Actual (low-order byte)

3

Speed Actual (high-order byte)

Name

Description

Faulted

Abnormal

0: Normal, 1: Run

Running1

Running

0: Stop, 1: Running

Speed Actual

Speed detection value

15

4. 1. 3 SpeedRef/SpeedActual Calculation Method

The inverter provides the following three modes, and the calculation method of SpeedRef/SpeedAcutal

varies by the mode.

(1) Induction motor V/f mode

(2) Induction motor vector mode

(3) ED motor vector mode

SpeedRef/SpeedAcutal calculation method in the vector mode

In the vector mode (2 and 3), SpeedRef and SpeedAcutal are calculated using SpeedScale as follows.

SpeedRef (AC/DC Drive object attribute 8)

= Rotational speed command x 2SpeedScale

SpeedActual (AC/DC Drive object attribute 7)

= Motor speed x 2SpeedScale

SpeedRef calculation example in the vector mode

・SpeedRef = 4567

・SpeedScale = 3

Speed command = SpeedRef/2SpeedScale

= 570.875 r/min

SpeedRef/SpeedAcutal calculation method in the V/f mode

In the V/f mode (1), a motor pole number is required as well as SpeedScale to calculate SpeedRef

and SpeedAcutal.

The motor pole number is specified by the inverter setting parameter "A-06."

SpeedRef (AC/DC Drive object attribute 8)

= {(Frequency command x 60)/(Motor pole number/2)} x 2Speedscale

SpeedActual (AC/DC Drive object attribute 7)

= {(Rotational frequency x 60)/(Motor pole number/2)} x 2Speedscale

SpeedRef calculation example in the V/f mode

・Number of motor poles = 4 poles

・Frequency command = 30 Hz

・SpeedScale = 3

SpeedRef = {(30 Hz x 60)/(4 poles/2)} x 23

= 7200

16

4. 2 Expanded I/O Assembly Data Attribute Format

The following shows the data format for the case of selecting the expanded profile (Toyo original

profile).

4. 2. 1 Output Assembly Instance

Table 4.2.1

Instance

Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

100

J-09 = 2

(4 words)

0

Preset2

Preset1

Protection

status reset

Fault Reset2

DC brake command

DC-Brake

Initial

excitation

command

Excit.

Reverse

operation

command

Rev

JOG command

Jog

Operation

command

Start

[I00027]

[I00026]

[I00025]

[I00024]

[I00023]

[I00022]

[I00021]

[I00020]

1

Max-SPD

Reduce

S-ARC off

Speed hold

Spd Hold

MRH deceleration

MRH down

MRH

acceleration

MRH up

Acc/DecSel2

Acc/DecSel1

Preset3

[I0002F]

[I0002E]

[I0002D]

[I0002C]

[I0002B]

[I0002A]

[I00029]

[I00028]

2

Ex-Fail.1

(no 86A)

External failure

4

Ex-Fail.4

External failure

3

Ex-Fail.3

External failure

2

Ex-Fail.2

External

failure 1

Ex-Fail.1

Rev Cmd

ATRMode

Droop control

OFF

Droop off

[I00037]

[I00036]

[I00035]

[I00034]

[I00033]

[I00032]

[I00031]

[I00030]

3

SPD.Ref.

Term

Unused

Emergency stop

(Normally open)

input

EMG.Stop

Second Motor

Trace Trg.

Ex-Fail.4

(no 86A)

Ex-Fail.3

(no 86A)

Ex-Fail.2

(no 86A)

[I0003F]

[I0003E]

[I0003D]

[I0003C]

[I0003B]

[I0003A]

[I00039]

[I00038]

4

Communication speed command: Speed Reference2

(20000/top)

(Low-order byte)

Communication input register 1 [i00010]

(Low-order byte)

5

Communication speed command: Speed Reference2

(20000/top)

(High-order byte)

Communication input register 1 [i00010]

(High-order byte)

6

Communication torque command: Torque Reference

(5000/100 %)

(Low-order byte)

Communication input register 2 [i00011]

(Low-order byte)

7

Communication torque command: Torque Reference

(5000/100 %)

(High-order byte)

Communication input register 2 [i00011]

(High-order byte)

108

J-09 = 10

(12 words)

8

Date

(Low-order byte)

Communication input register 3 [i00012]

(Low-order byte)

9

Month

(High-order byte)

Communication input register 3 [i00012]

(High-order byte)

10

Minute

(Low-order byte)

Communication input register 4 [i00013]

(Low-order byte)

11

Hour

(High-order byte)

Communication input register 4 [i00013]

(High-order byte)

12

(Not specified)

Communication input register 5 [i00014]

(Low-order byte)

13

(Not specified)

Communication input register 5 [i00014]

(High-order byte)

14

(Not specified)

Communication input register 6 [i00015]

(Low-order byte)

15

(Not specified)

Communication input register 6 [i00015]

(High-order byte)

16

(Not specified)

Communication input register 7 [i00016]

(Low-order byte)

17

(Not specified)

Communication input register 7 [i00016]

(High-order byte)

18

(Not specified)

Communication input register 8 [i00017]

(Low-order byte)

19

(Not specified)

17

Communication input register 8 [i00017]

(High-order byte)

20

(Not specified)

Communication input register 9 [i00018]

(Low-order byte)

21

(Not specified)

Communication input register 9 [i00018]

(High-order byte)

22

(Not specified)

Communication input register 10 [i00019]

(Low-order byte)

23

(Not specified)

Communication input register 10 [i00019]

(High-order byte)

・When the instance 100 (J-09 = 2) is used, the Output Assembly data length becomes four words.

・When the instance 108 (J-09 = 10) is used, the Output Assembly data length is 12 words.

When the internal PLC function is not used, the seventh word and the followings will be ignored.

・When the internal PLC function is used, each bit of the first and second words of Output Assembly data

becomes an input relay of the internal PLC function. The third word and the followings become input

registers of the internal PLC function.

For the allocation of Output Assembly data to the input relay/register of the internal PLC function,

see Table 4.2.1.

18

4. 2. 2 Input Assembly Instance

Table 4.2.2

Instance

Byte

Bit 7

Bit 6

Bit 5

Bit 4

Bit 3

Bit 2

Bit 1

Bit 0

132

J-10 = 14

(18 words)

0

Gate driving

Auto measurement

(auto tuning)

in operation

Power failure

DC excitation

Reverse

operation

command

JOG operation

Inverter running

(deceleration

stop included)

Operation/JOG

command input

1

External signal

input 4

External signal

input 3

External signal

input 2

External signal

input 1

Second setting

block selected

External DB

protection

operation or

communication

abnormality

DC brake

Initial

excitation

2

Current sensor

abnormality

Overload

protection

DC part

overvoltage

Gate board

abnormality

Unused

(unspecified)

Unused

(unspecified)

IGBT protection

operation

Overcurrent

protection

3

Optional error

Memory

abnormality

Unit overheat

Overtorque

protection

Insufficient

voltage (power

failure)

Overfrequency

protection

Overspeed

protection

Start delay

4

Open phase

Setting error

FCL operation

Charging

resistance

overheat

Motor overheat

Speed control

error

Communication

timeout error

Sensorless

start error

5

External failure

4

External failure

3

External failure

2

External failure

1

Sensor error

PG error

Fan failure

CPU abnormal

process

6

Setting reached

Speed detection 2

(spd <= detect2)

Speed detection 2

(spd >= detect2)

Speed detection 2

(spd = detect2)

Speed detection

1 (spd <=

detect1)

Speed detection

1 (spd >=

detect1)

Speed detection 1

(spd = detect1)

Unused

(unspecified)

[O00047]

[O00046]

[O00045]

[O00044]

[O00043]

[O00042]

[O00041]

[O00040]

7

Cooling fan

failure

Second setting

block

selected

Reverse

operation

Retry by failure

Overload

pre-alarm

Power failure

detected

Absolute torque

value detection

Torque

detection

[O0004F]

[O0004E]

[O0004D]

[O0004C]

[O0004B]

[O0004A]

[O00049]

[O00048]

8

Motor speed: Speed Actual2 (20000/top)

(Low-order byte)

Communication output register 1 [o00010]

(Low-order byte)

9

Motor speed: Speed Actual2 (20000/top)

(High-order byte)

Communication output register 1 [o00010]

(High-order byte)

10

ARC output: ARC out (20000/top)

(Low-order byte)

Communication output register 2 [o00011]

(Low-order byte)

11

ARC output: ARC out (20000/top)

(High-order byte)

Communication output register 2 [o00011]

(High-order byte)

12

Effective current: RMS Motor Current (10000/100 % [Inv.rated])

(Low-order byte)

Communication output register 3 [o00012]

(Low-order byte)

13

Effective current: RMS Motor Current (10000/100 % [Inv.rated])

(High-order byte)

Communication output register 3 [o00012]

(High-order byte)

14

Torque Command (5000/100 %)

(Low-order byte)

Communication output register 4 [o00013]

(Low-order byte)

15

Torque Command (5000/100 %)

(High-order byte)

Communication output register 4 [o00013]

(High-order byte)

16

DC Voltage (10/1 V [200 V class], 5/1 V [400 V class])

(Low-order byte)

Communication output register 5 [o00014]

(Low-order byte)

17

DC Voltage (10/1 V [200 V class], 5/1 V [400 V class])

(High-order byte)

Communication output register 5 [o00014]

(High-order byte)

18

Output Voltage (20/1 V [200 V class], 10/1 V [400 V class])

(Low-order byte)

Communication output register 6 [o00015]

(Low-order byte)

19

Output Voltage (20/1 V [200 V class], 10/1 V [400 V class])

(High-order byte)

Communication output register 6 [o00015]

(High-order byte)

20

Output Frequency (20000/top)

(Low-order byte)

Communication output register 7 [o00016]

(Low-order byte)

21

Output Frequency (20000/top)

(High-order byte)

Communication output register 7 [o00016]

(High-order byte)

22

OL Pre-counter (10000/100 %)

(Low-order byte)

Communication output register 8 [o00017]

(Low-order byte)

23

OL Pre-counter (10000/100 %)

(High-order byte)

Communication output register 8 [o00017]

(High-order byte)

19

24

Motor Temperature (10/1 ℃)

(Low-order byte)

Communication output register 9 [o00018]

(Low-order byte)

25

Motor Temperature (10/1 ℃)

(High-order byte)

Communication output register 9 [o00018]

(High-order byte)

26

Motor Flux (1024/100 %)

(Low-order byte)

Communication output register 10 [o00019]

(Low-order byte)

27

Motor Flux (1024/100 %)

(High-order byte)

Communication output register 10 [o00019]

(High-order byte)

28

(Not specified)

Communication output register 11 [o0001A]

(Low-order byte)

29

(Not specified)

Communication output register 11 [o0001A]

(High-order byte)

30

(Not specified)

Communication output register 12 [o0001B]

(Low-order byte)

31

(Not specified)

Communication output register 12 [o0001B]

(High-order byte)

32

(Not specified)

Communication output register 13 [o0001C]

(Low-order byte)

33

(Not specified)

Communication output register 13 [o0001C]

(High-order byte)

34

(Not specified)

Communication output register 14 [o0001D]

(Low-order byte)

35

(Not specified)

Communication output register 14 [o0001D]

(High-order byte)

140

J-10 = 15

(4 words)

0

Gate driving

Auto measurement

(auto tuning)

in operation

Power failure

DC excitation

Reverse

operation

command

JOG operation

Inverter running

(deceleration

stop included)

Operation/JOG

command input

1

Failure code: ProtectErrorCode (See Table 4.2.3)

DC brake

Initial

excitation

2

Monitor Number 1 Data (low-order byte) (See Table 4.2.4)

3

Monitor Number 1 Data (high-order byte) (See Table 4.2.4)

4

Monitor Number 2 Data (high-order byte) (See Table 4.2.4)

5

Monitor Number 2 Data (low-order byte) (See Table 4.2.4)

6

Monitor Number 3 Data (high-order byte) (See Table 4.2.4)

7

Monitor Number 3 Data (low-order byte) (See Table 4.2.4)

・When the instance 132 (J-10 = 14) is used, the Input Assembly data length is 18 words.

When the internal PLC function is not used, the 15th word and the followings will be unspecified.

・When the instance 140 (J-10 = 15) is used, the Input Assembly data length is four words.

・When the internal PLC function is used, each bit of the fourth word of Input Assembly data becomes

an output relay of the internal PLC function. The fifth word and the followings become output registers

of the internal PLC function.

For the allocation of Input Assembly data to the output relay/register of the internal PLC function,

see Table 4.2.2.

20

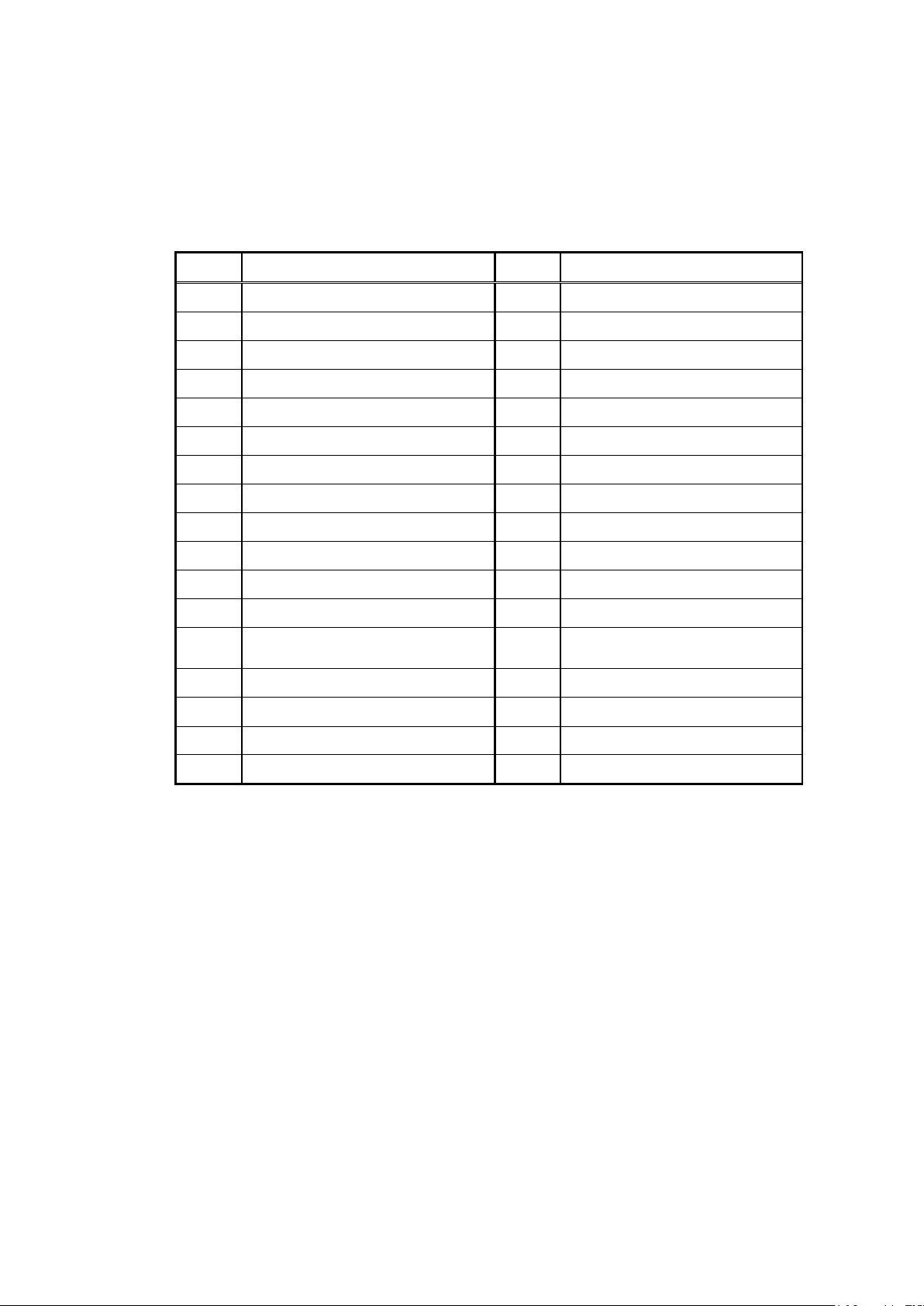

4. 2. 3 Failure Code

The following shows failure codes of the Input Assembly instance 140 (ProtectErrorCode). If multiple

failures/protection operations occur at the same time, a smaller number is used.

Table 4.2.3

Code

Failure/protection item

Code

Failure/protection item

0

No failure/protection

17

Sensorless start error

1

Overcurrent protection

18

Communication timeout error

2

IGBT protection operation

19

Speed control error

3

20

Motor overheat

4

21

Charging resistance overheat

5

GAC abnormality

22

FCL operation

6

DC part overvoltage

23

Setting error

7

Overload protection

24

Open phase

8

DCCT abnormality

25

CPU abnormal process

9

Start delay

26

FAN failure

10

Overspeed protection

27

PG error

11

Overfrequency protection

28

Sensor abnormality

12

Insufficient voltage (power

failure)

29

External failure 1

13

Overtorque protection

30

External failure 2

14

Unit overheat

31

External failure 3

15

Memory abnormality

32

External failure 4

16

Optional error

Other manuals for VF66

1

Table of contents

Other TOYODenki Inverter manuals