TQC Sheen SP7310 User manual

BRESLE TEST KIT

SP7310

Operating Instructions (V1.0 0119)

3 |

1 Instrument Data

1.1

1.2

1.3

1.4

Product Description

Name/Article

Standards

Scope of Supply

2 Instrument Layout and Functions

3 Preparations

3.1 Determine Test Area

3.2 Instrument Preparations

3.3 Calibration

4 Use

5 ISO 11127-6

6 Maintenance

7 When Something Goes Wrong

8 Disclaimer

4

5

6/7

8/10

11

11

11

11

INDEX

| 4

1.1 Product Description

The TQC Sheen Bresle Kit complies with the ISO 8502-6 and ISO 8502-9

standards that describe the Bresle Method to assess the level of soluble salts

using a Bresle patch or Bresle sampler, distilled water and a conductivity

gauge. The conductivity is mainly directly proportional to the concentration

of dissolved chloride ions in the solution. The kit includes all the necessary

equipment to execute a Bresle test that will indicate the contamination of

soluble salts on blast-cleaned surfaces prior to coating. Inside the Bresle

Kit is a conductivity gauge used for the assessment of soluble salt ions as

chlorides, sulphates and nitrates.

1.2 Name / Article

SP7310 Bresle Test Kit

1.3 Standards

ISO 8502-6, ISO 8502-9, ISO 11127-6

1.4 Scope of Supply

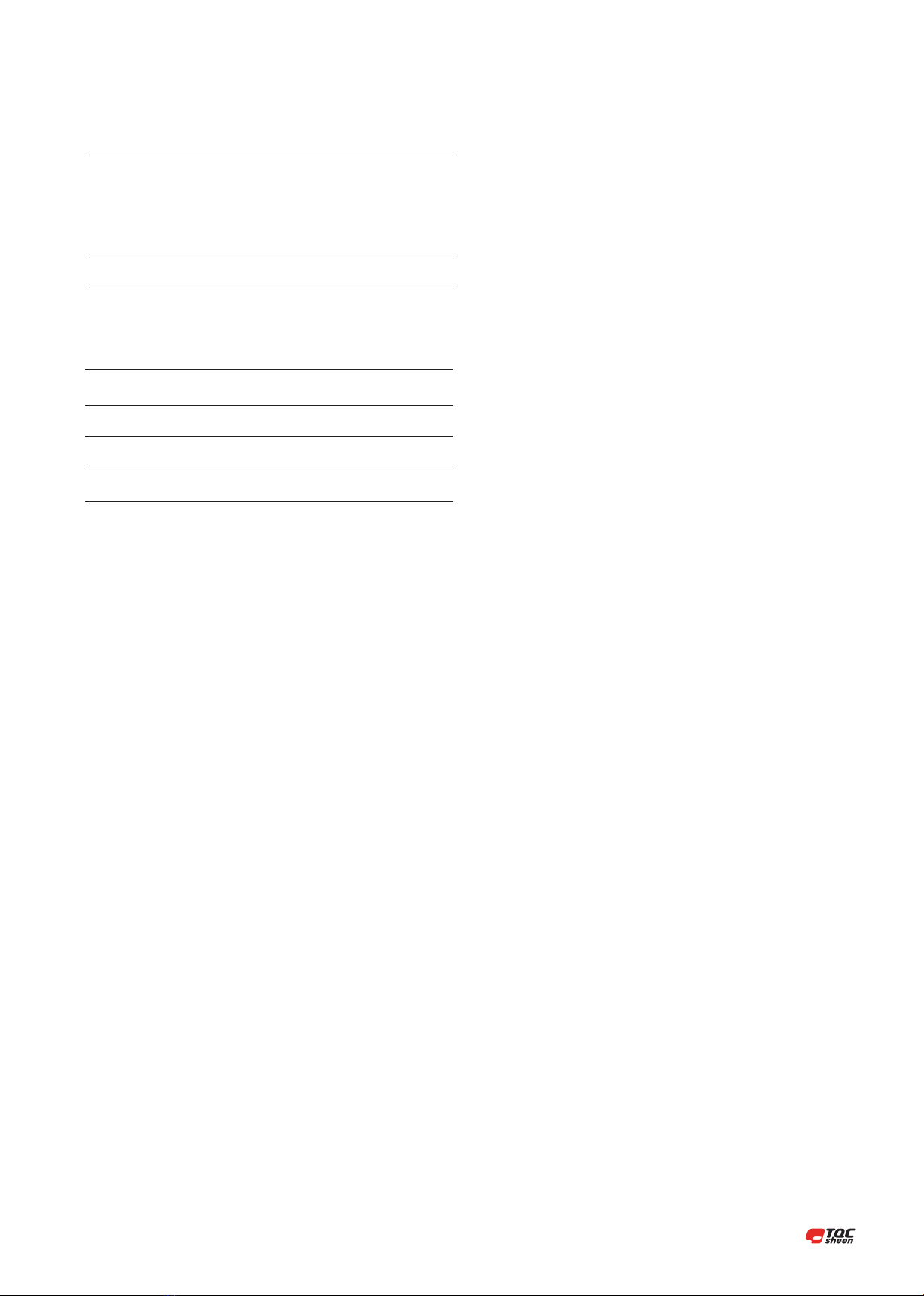

1 INSTRUMENT DATA

Case

Cleansing Solution

Bresle Patches, 25 pieces

Syringe

Calibration SolutionDigital Conductivity Meter

Cup

Deionised Water

Manual

5 |

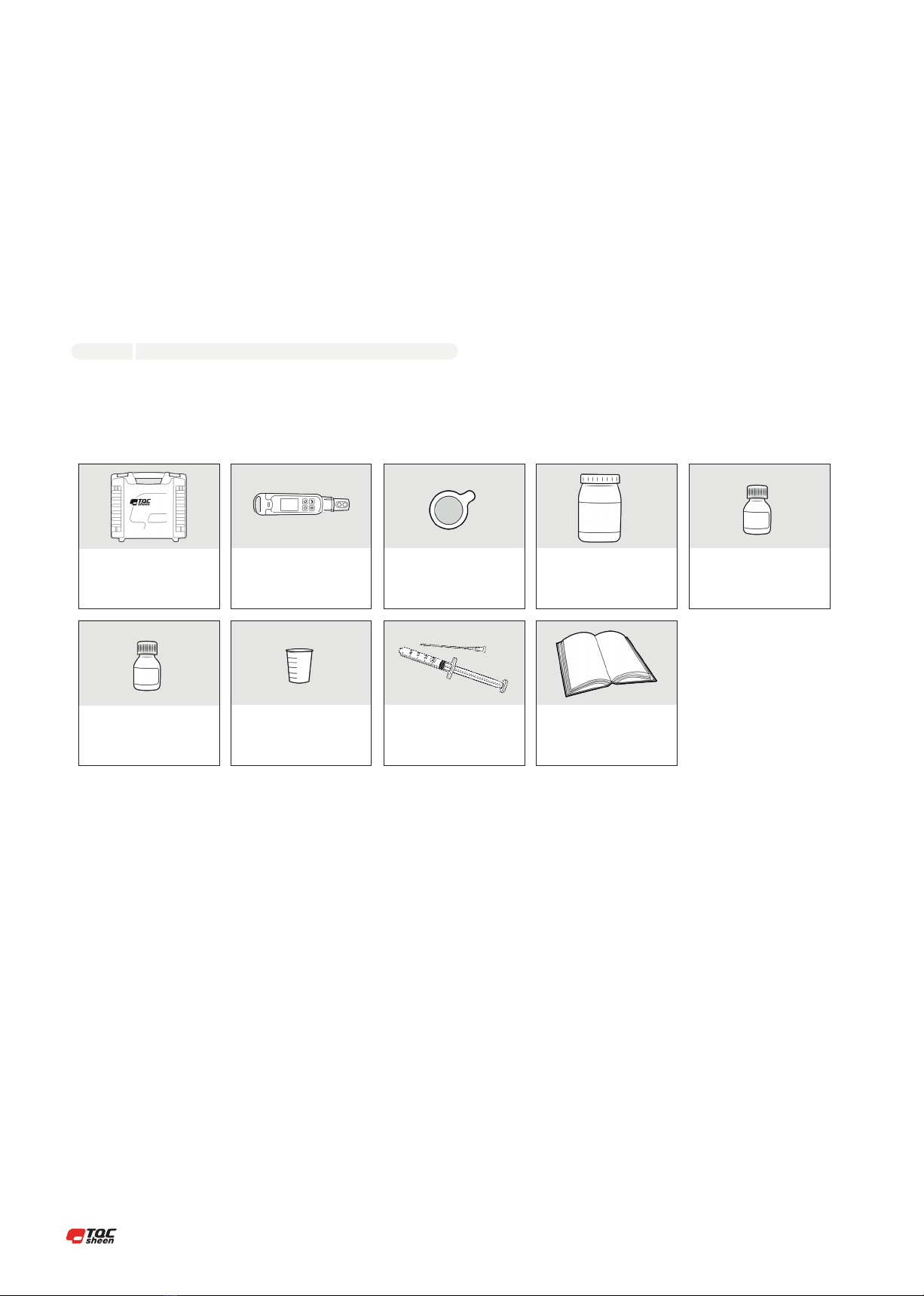

2 INSTRUMENT LAYOUT AND FUNCTIONS

Battery Compartment

Selected Measurement Method (Cond-TDS-Salt) Battery Indicator

Measured Value

Calibration Button (in menu mode‘Exit‘ button)

Enter Button (in menu mode‘Accept‘ button)

EC/Conductivity Electrode

Indication of Unit ( μS/cm of mS/m)

Temperature

On Button

Menu Button (in menu mode ‘Scroll‘ button)

Temperature Electrode

| 6

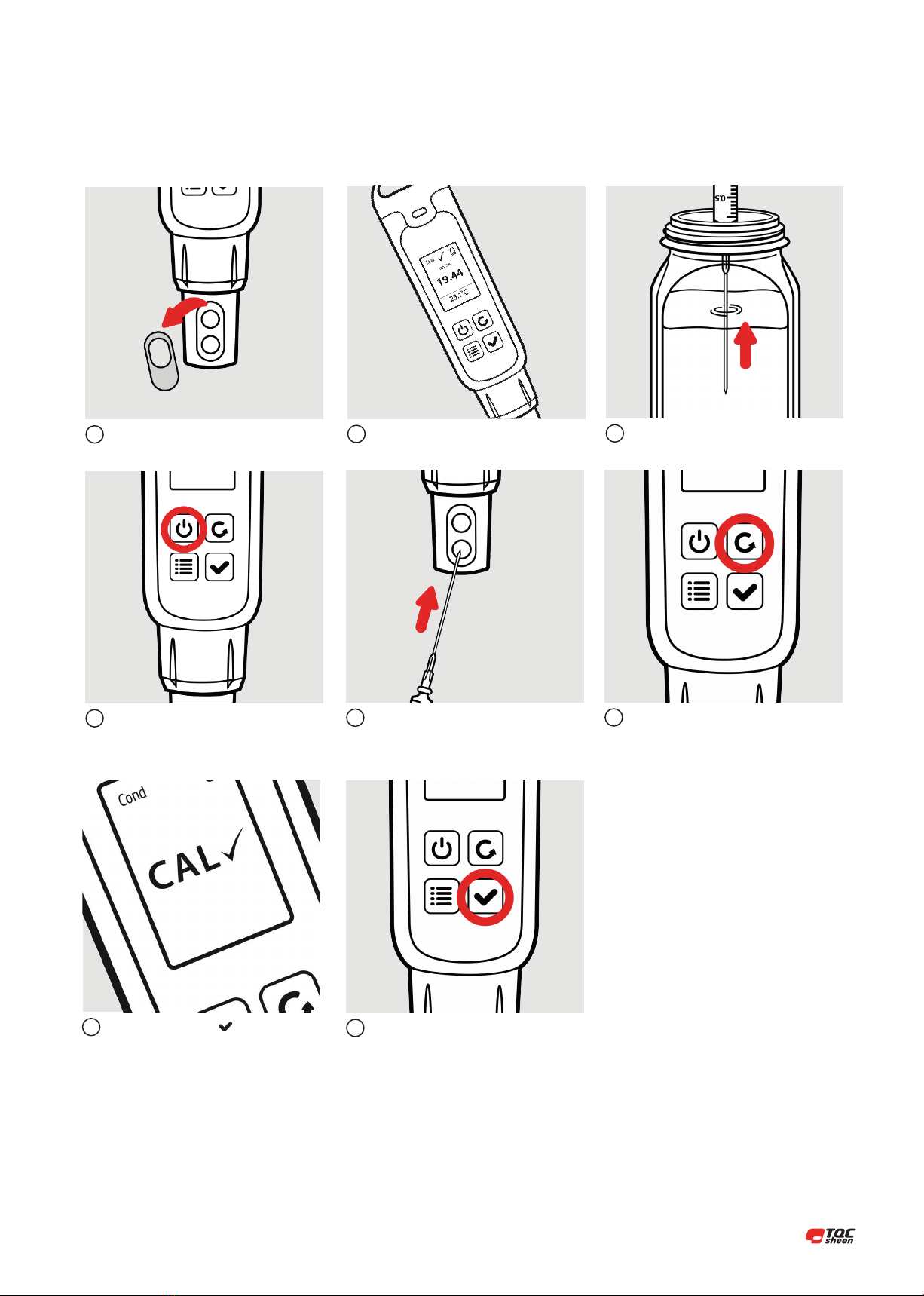

3 PREPARATIONS

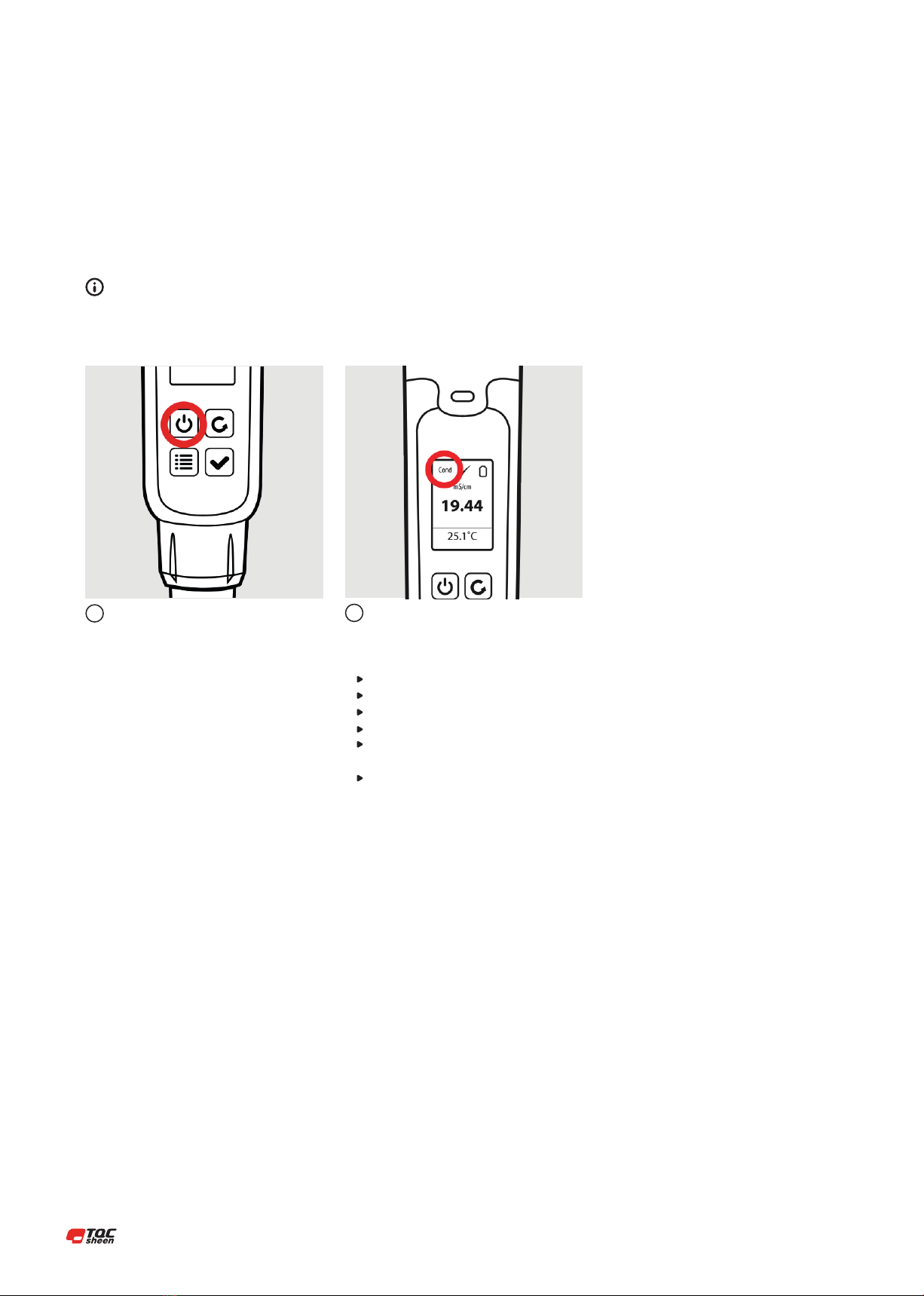

Turn on the Digital Conductivity Meter. Check whether ‘COND’ is shown at the top

left. If so, perform the measurement. If not,

go through the following steps:

12

3.2 Instrument Preperation

Click on menu button.

Scroll with the‘menu / scroll’button until ‘measure’ is selected.

Confirm with the ‘enter / accept’ button.

Scroll with the‘menu / scroll’button until ‘COND’ is selected.

Confirm with the ‘enter / accept’ button.Press‘calibration /

return’ button to return to the measurement screen.

COND is shown at the top left.

3.1 Determine Test Area

Select the section on the steel surface to be used as the test area for

assessment of the total surface density of salts. It should preferably be dry

and with no loosely adherent rust, dirt or moisture (dampness), so that the

patch frame can properly adhere to the surface. The Bresle patch can be

placed in almost every position, vertical, horizontal, slanting or on surfaces

that are not completely flat.

It is recommended to test more than one spot to catch the

variations of the contamination level!

7 |

Place the gauge flat on a flat surface.

The display shows CAL , the calibration

was successful.

Inject the deionised water in the measuring

cell.

Push the enter button to return to the

normal display.

Push the CAL button. Wait until the

measurement is stabilized.

2

7

5

8

6

3.3 Calibration

Calibration prior to each use is desirable for a reliable measurement.

Remove the plastic cap from the measuring

cell.

1Fill up the syringe with deionised water.3

Turn on the Digital Conductivity Meter.4

| 8

4 USE

Remove the protective backing of the Bresle

patch with its inner protective paper and

dispose.

Press firmly in order to create a tight seal.

Inject the deionised water in the measuring

cell until it runs over.

Place the Bresle patch with the adhesive

side to the test surface.

Fill up the syringe with deionised water.

A value is shown on the display.

Take care to trap as less air as possible in the

patch.

Empty the syringe until there is 2,5 ml left

to take care that there are no air bubbles in

the syringe.

1

4

8

2

5

9

3

6

Turn on the Digital Conductivity Meter.7

9 |

Empty the syringe.

Empty the syringe until there is 2,5 ml left

to take care that there are no air bubbles in

the syringe.

Dissolve the salts by tapping the

membrane for 90 seconds.*

* ISO 8502-6 recommended time is 10 minutes.

Most users test at 90 seconds. Always agree on test

time prior to testing.

Empty the meter.

Insert the 2,5 ml of deionised water into

the Bresle patch by injecting it through the

foam at an angle of 30º from the surface.

Extract the water from the patch and

reinject into the patch 4 times.

Fill up the syringe with deionised water.

Inserting through the transparent part

of the Patch or though the bottom side

could cause leakage!

11

14

16

12

15

17

13

Write down the value as blank value.10

| 10

When finished, extract the entire volume

of water into the syringe and remove the

syringe from the Bresle Patch.

A value is shown on the display.

Turn the Digital Conductivity Meter back on.

Write down the measured value. Calculate the difference between the

measured value and the blank value.

(measured value -blank value).

The total surface density of soluble salts/

contaminants (S) in mg/m2soluble salts

measured as Sodium Chloride is 1 x

(measured value –blank value).

(All salts are considered as NaCl or Sodium

Chloride) . “Sample Value” and “Zero

Reference” are in microSiemens (μS) per

centimeter.

If an interpretation of just the chlorides

or cl- is required the multiplier will be 0.6

instead of 1!

Inject 1,5 ml of this water into the

measuring cell of the Conductivity Meter.

18

21

19

22 23

20

11 |

Determination of the water soluble salts in mineral abrasives,

conform ISO 11127-6.

Collect a number of samples , minimum 5, of the abrasive at random at

different places.

Mix them well and take 100 g from this mix into a 100 ml. beaker.

Pour 100 ml. distilled water into a 250 ml. beaker which has been

cleaned before with distilled water.

Take a reading of this water with the conductivity gauge and note the

value. This is the “Zero Reference”

Add 50 g of abrasives to the 100 ml distilled water in the 250 ml. beaker.

Shake the mixture well for about 5 minutes and leave it for one hour.

Shake again for 5 minutes.

Decant some of the water into a clean beaker and measure the

conductivity.

Contact the paint-manufacturer, abrasive supplier or project-manager for the

maximum acceptable conductivity level

6 MAINTENANCE

Maintenance of the conductivity meter is minimal, because it’s quite easy to

perform a measurement. Nevertheless the technology inside the instrument

is very advanced.

Depending on the frequency of use, a thin film may occur on the probe.

Use a damp cloth to remove this.

After each use the instrument should be rinsed with tap water and

demineralized liquid. Make sure the probe stays clean.

A blinking battery indicator indicates the batteries need to be replaced.

Open the battery compartment cover. Note polarity facing up and

remove the old batteries. Replace with fresh ones with the same

polarity. facing up as the old ones.

When the instruments doesn’t perform the way you expected, usually

you can solve it yourself easily. Therefore read this part thoroughly before

claiming warranty.

8 DISCLAIMER

The right of technical modifications is reserved.

The information given in this sheet is not intended to be exhaustive and

any person using the product for any purpose other than that specifically

recommended in this sheet without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does

so at his own risk. Whilst we endeavour to ensure that all advice we give

about the product (whether in this sheet or otherwise) is correct we have

no control over either the quality or condition of the product or the many

factors affecting the use and application of the product. Therefore, unless

we specifically agree in writing to do so, we do not accept any liability

whatsoever or howsoever arising for the performance of the product or

for any loss or damage (other than death or personal injury resulting from

our negligence) arising out of the use of the product. The information

contained in this sheet is liable to modification from time to time in the

light of experience and our policy of continuous product development.

5 ISO 111276 7 WHEN SOMETHING GOES WRONG

Clean the measuring cell with a damp

soft cloth and rinse the measuring cell

thoroughly with demiwater afterwards.

Replace batteries

Always use a‘fresh ‘ calibration

standard. Once opened the calibration

standard will not keep.

The value measured is

unstable

Possible cause: Pollution?

Display fails

Possible cause: Insucient

battery power.

Calibration fails

Possible cause: Dirty

measuring cell or old /

polluted calibration standard.

www.tqcsheen.com

Table of contents

Other TQC Sheen Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Thermo Scientific

Thermo Scientific LevelPRO Series Application guide

NAPCO

NAPCO NAP9600 user manual

Agilent Technologies

Agilent Technologies 1100 Series Reference manual

Altana

Altana BYK byko-drive S Short instructions

Hettich

Hettich UNIVERSAL 320 operating instructions

Excelitas Technologies

Excelitas Technologies OmniCure S1500 PRO user guide

NoiseKen

NoiseKen LSS-6330 Series instruction manual

PRO Scientific

PRO Scientific Bio-Gen PRO200 operating manual

Thermo Scientific

Thermo Scientific CLEARVUE AUTOMATED COVERSLIPPER Daily Operation Guide

Helmer

Helmer QuickThaw DH2 Service manual

MELAG

MELAG Vacuklav 23 B+ Technical manual

Thermo Scientific

Thermo Scientific Ion 520 user guide