Energenics UV-MAX User manual

1

www.energenics.com

________________________________________________________________________________________________________________

1470 Don Street ∙ Naples, Florida 34104 Telephone (239) 643-1711

Customer Service (800) 944-1711

Fax (239) 643-6081

Installation & Operations Manual for Energenics UV-MAX

Mobile Disinfection System

Table of Contents Page 1

Energenics UV-MAX Page 2

Advisories (Purpose/Contents) Page 3

UV-MAX Safe Operation Procedure Page 4

Safety Guidelines Page 5

System Description Page 6

System Delivery Page 7

Operation Overview Page 8

Operation Settings (Default) Page 9

Operation Settings (Customizable) Page 10

Cycle Stop Status Screens Page 11

System Care Page 12

Troubleshooting Page 13

FAQ Pages 14-15

CORPORATION

®

2

3

Advisories

Purpose

The Energenics UV-MAX system has been designed to offer direct disinfection exposure to

surface areas. The system design allows for microbial disinfection control.

The Energenics UV-MAX system was developed as a disinfection tool, utilizing Ultraviolet

Light (UV) for direct exposure disinfection. The system can disinfect 360 degrees from the

system center.

Contents

This manual will serve as your reference guide for installation, operation, and service of your

UV-MAX system. Reference to all parts, warranty, and support are included.

This manual covers the system/equipment/products listed below:

oEnergenics UV-MAX

Safety Observation: It is required for the person(s) responsible

for the installation of this equipment, operators of this equipment, and

operation personnel managers to review and understand this manual.

USE OF LISTED SYSTEM / EQUIPMENT MUST COMPLY WITH

INSTRUCTIONS AND SAFETY REQUIREMENTS.

4

UV-MAX Safe Operation Procedure

1.

Always wear personal protective equipment (PPE) when operating UV-MAX to limit

exposure to light

2.

Place UV-MAX in area to be treated

3.

Ensure the PIR Sensors (Passive Infrared) are positioned to the re-entry point. PIR

sensors operations are explained in the FAQ section at the end of this manual.

4.

Connect UV-MAX to 120vac plug receptacle

5.

Press start on UV-MAX control and exit treatment area

6.

Adhere to recommended safety precautions to avoid potential injury

Safety

1.

Do not look directly at a UV lamp in operation without wearing approved safety

glasses.

2.

The space should be vacant and closed prior to UV-MAX operation

3.

Never command the system on when the treatment space is occupied

5

Safety Guidelines

Exposure to UV-C light is dangerous. The adverse health effects that may occur are erythema

(sunburn) and photokeratitis (a feeling of sand in the eyes). These effects are considered

transient. UV-C may also be carcinogenic but since it has very limited penetrating ability, it is

unlikely to cause damage to anything beyond the outer layer of skin or other exposed

surfaces. Unfortunately, there are no immediate warning symptoms to indicate overexposure

to UV radiation and adverse effects typically appear hours after exposure has occurred.

The Energenics UV-MAX is designed for zero user exposure to UV-C; however, we will review

safety factors regarding UV-C for better knowledge and understanding.

Protective Clothing and Eye wear

It is not recommended that any personnel be subject to direct UV-C exposure. Personnel

that may be exposed to harmful amounts and wavelengths of UV must take adequate steps to

shield themselves and in some cases limit the duration of exposure.

If there is any potential for the eyes and face to be exposed to UV radiation, a polycarbonate

face shield stamped with the ANSI Z87.1-1989 UV certification must be worn to protect the

eyes and face. Ordinary prescription eyeglasses may not block UV radiation. UV certified

goggles and safety glasses will protect the eyes, but workers may suffer facial burns in the

areas not covered by the goggles or glasses.

OSHA Guidelines for Ultraviolet Exposure

There is no Occupational Safety and Health Administration (OSHA) standard regarding

exposure to ultraviolet light, but the OSHA general duty clause states the employer must

provide a workplace free of recognized hazards that may cause death or serious physical

harm.

6

System Description

The Energenics UV-MAX is designed for maximum disinfection through the

shortest exposure time. More UV-C wattage allows shorter exposure times

to surfaces. Exposure times vary based on furthest distance from the UV-C

source. The system design provides the optimum in:

oUV dosage output to footprint served

oRugged design build

oEase of use controls

oUser safety protection

INDUSTRIAL STRENGTH

FRAME AND STRUCTURE

CORROSION PROOF

CONSTRUCTION

6” INDUSTRIAL CASTERS

HIGH OUTPUT PRE-HEAT

LAMPS FOR LONG RUN

TIME LENGTH

PIR SENSOR DETECTION

SAFETY SHUTOFF

INDIVIDUAL LAMP

FAILURE INDICATOR

LED’S

EMERGENCY STOP

BUTTON

BUILT TO IP56 WATER

AND DUST STANDARDS

7

System Delivery

When you receive your UV-MAX, you will need to unpack and inspect the

system. Please perform the following procedure:

1.

Unpack your new system and stand upright

2.

Inspect fully for damage

If damage present, contact Energenics prior to use (800) 944-1711

3.

Verify secure lamp installation

4.

Plug in system power cord

5.

Power on the unit

Your Energenics UV-MAX system is now ready for operation

(See Operation Overview)

8

Operation Overview

The UV-MAX is designed to operate in the following manner:

Start Sequence

1.

Locate unit in unoccupied space positioned for operation

2.

Plug system into power supply

3.

Press on-screen logo to display “Start Cycle” state

4.

Initiate system cycle

5.

Evacuate space

Audio and Visual Indicators

1.

Audio Alarm

a.

Once Started: LONG warning beeps increasing in frequency

b.

During Process: SHORT stroke beeps

c.

Process Complete: Three short beeps (no beep thereafter)

2.

Visual Indicator

a.

Blue Light – Warning, process running

b.

Green Indicator Light – Safe/Process complete

3.

Display of System

a.

Operations

b.

Controls

c.

Indication of System Functions

9

Operation Settings

Normal operation for factory default settings are covered on this page.

1.

Review system for condition.

a.

There should be no physical damage to the system

b.

Lamps shall be clean

c.

System frame shall be in good condition

d.

Display of system shall be clean

2.

Plug in system power cord

3.

Ensure all personnel are out of treatment area

4.

Operate system

a.

Press UV MAX logo for Home screen

b.

Select Start Cycle to initiate treatment cycle

c.

The system will enter Countdown mode

d.

Once process is complete, panel will revert to

Home screen

10

Customizable Operation Settings

Customizing settings for normal operation are covered on this page.

1.

From the START CYCLE home screen, press USER SETTINGS button

2.

The COUNTDOWN TIMER / CYCLE TIMER screen is displayed and may be used to

modify system variables as follows:

Countdown Timer– control for time delay from when Start Cycle button is pressed to

when system lamps come on

Cycle Timer – control for duration of cycle operation

3.

After adjusting to preferred settings, press HOME button to return to Start Cycle

4.

Press START CYCLE button to begin customized treatment cycle

11

Cycle Stop Status Screens

Cycle stop displays for normal system operation are covered on this page.

Emergency Stop

Should cycle deactivation occur by engagement of the Emergency Stop button, the following

method will be required to reset the system:

1.

Observe Emergency Stop Active status on control screen

2.

Release Emergency Stop by pulling up on the red knob

3.

Select HOME button to return to main screen

4.

Press START CYCLE to resume normal operation of system

System Faults

Should cycle deactivation occur by means of a system fault, the following method will be

required to reset the system:

1.

Observe the fault status type on the control panel

2.

Ensure all system faults have been properly addressed

3.

Select HOME button to return to main screen

4.

Press START CYCLE to resume normal operation of system

12

System Care

The Energenics UV-MAX system is designed for repeat performance and consistent results.

Based on system designs, minimal maintenance is required. Adherence to the following

regular service of your system should provide years of disinfection.

Each Duty Cycle

1.

Inspect the system interior, exterior, and lamps for clean conditions

2.

Clean as needed

Monthly

1.

Inspect the system interior, exterior, and lamps for clean conditions

2.

Clean as needed

“Service Machine” Message

1. Every 8 running hours it is recommended that lamps be wiped down with isopropyl or

rubbing alcohol. This will remove any debris that may have accumulated on the lamp.

Once cleaned, you can reset this message by pressing USER SETTINGS button

followed by RESET SERVICE LIGHT

Note: The above steps are listed as the basic level of care, should the system be utilized

in a heavy work environment, further care may be required.

Annually

1.

Replace CR 2032 battery (for cycle timer) located in the PLC

13

Troubleshooting

The below statements are listed as troubleshooting guidelines. Further information is available

through Energenics support.

Q: What should I do if the unit will not turn on?

A: Verify there is power to the system

A: Verify the display is reads correctly

A: Verify the Emergency Stop is not engaged

A: Contact Energenics Support for further information

Q: Why does the unit turn off when I enter the room?

A: Safety features turn off lamps based on detection by the PIR sensor.

Q: My system will turn on, but the lamps will not come on.

A: Verify the start cycle button is pressed

A: Inspect the lamps for physical failure

A: Contact Energenics Support for further information

Q: My system is running fine, how do I verify the lamps are operating correctly?

A: Check UV output with dosimeter cards or a radiometer device

A: Faults will indicate if the system is not performing correctly

Q: The touchscreen has presented a flashing “Service Machine” icon.

What does this mean?

A: Every 8 running hours it is recommended that lamps be wiped

down with isopropyl or rubbing alcohol. This will remove any

debris that may have accumulated on the lamp. Once cleaned,

you can reset this message by pressing USER SETTINGS

button followed by RESET SERVICE LIGHT

Q: My system system won't hold the preset countdown or cycle time anymore?

A: The CR 2032 3V battery located in the PLC needs to be

replaced.

14

FAQ (continued)

Q: What is a PIR (Passive Infrared) Sensor?

A: Passive InfraRed sensors (PIRs) are electronic devices which are used in some

security alarm systems to detect motion of an infrared emitting source, usually a human

body.

Q: Is UV-C disinfection strictly line of sight?

A: Yes, it needs to shine on the surface to disinfect. It will not go around objects or

disinfect shadowed areas.

Q: Does UV-C light reflect off surfaces?

A: Yes, UV-C reflects off many surfaces, but loses its intensity dramatically. All material

surfaces offer different reflection property levels.

Q: Is the UV-C light I can see under the door dangerous?

A: Zero exposure to people is imperative so block it or protect your eyes and skin

Q: Does UV-C light go through glass or windows?

A: Standard window glass blocks almost 100% of UV-C light according to the IUVA.

(Normal glass, as used in a window, is transparent to UV radiation to a wavelength of

about 330 nm (UV-A). The transparency is quite high so almost all UV-A light will pass

through glass. Below 330 nm (UV-B and UV-C), almost 100% is blocked by normal

glass.

Q: Can I use a response card with the UV MAX?

A: Yes, it can be used to indicate the correct dosage (intensity x

time x distance) has been applied to a surface

15

FAQ (continued)

Q: Do I need to clean all surfaces first?

A: Best practices for infection prevention remain the multi-step clean and disinfect

process. Visible soil must always be removed from surfaces prior to a UV disinfection

treatment. UV disinfection system operators must comply with guidelines put in place by

their organization.

Q: Why do my ATP readings sometimes come up high?

A: Exposure to ultraviolet germicidal irradiation (UVGI) disrupts the DNA of

microorganisms, inhibiting their ability to replicate and ultimately leading to their demise.

Even after rendering microorganisms "sterile" through UVGI, organic remnants

detectable in ATP tests may persist both within these sterilized microorganisms and in

the residual "skeletons" of deceased microorganisms left on the testing surface. ATP

readings will decline as the UVC inactivated microorganisms perish, and as the remnants

of dead microorganisms are eliminated from the surface through regular activities,

cleaning, or by simply rinsing with water.

Q: How can I test if UV is disinfecting my surfaces?

A: Confirmation of efficacy can be made through adenosine triphosphate (ATP) testing or

by sending test samples to a third-party laboratory. ATP is the energy molecule found in

all living and once-living things, making it a good indicator when trying to determine if a

surface is clean or not. ATP is quantified by measuring the "light" produced through its

reaction with a naturally-occurring enzyme. The amount of light produced, expressed in

relative light units (RLU) is directly proportional to the amount of biological energy present

in the sample. Additional information may be found at https://www.hygiena.com/hygiene-

monitoring/atp-cleaning-verification/surface-atp

LIMITED WARRANTY & DISCLAIMER

STANDARD CONDITIONS OF SALES

Energenics Corporation (herein called Energenics) warrants to the original purchaser, & to the

original purchaser alone, its products to be free from defects in material and workmanship under

normal use & service for a period of twelve (12) months from the date of shipment. Energenics'

obligations under this warranty shall be limited solely to the repair or replacement of such parts,

which Energenics examination shall disclose to Energenics satisfaction to have been thus defective

& to the shipment of the repaired or replacement part or parts to the original purchaser F.O.B. point

of shipment. In no event shall Energenics be liable for any consequential, incidental or special

damages of any kind caused by the defect. The Warranty set forth shall not apply to & Energenics

shall not be responsible for any equipment or part, which has been repaired or altered in any way,

regardless of how or why the part was altered or repaired nor for any equipment or part, which has

been subjected to the negligence or accident, improper use or care, nor for equipment or part with

respect to which Energenics instructions relating to installation, maintenance, or use have not been

followed. This limited warranty is expressly made in lieu of all other warranties, expressed or implied,

and in lieu of all other obligations or liabilities on the part of Energenics.

The purchaser by acceptance of the delivery of any part or product from Energenics agrees to

indemnify Energenics & to hold it harmless against any liability, which may arise if the part or product

received is mis-applied, improperly installed, improperly maintained, misused or abused, altered or

rendered partially or totally inoperative due to any cause.

RETURNS: Merchandise may not be returned unless a RMA is obtained from Energenics. A copy of

the RMA must accompany the returned item as the packing Slip. Energenics will assume no

responsibility for merchandise returned neither without such prior approval nor for any charges or

expenses incurred therewith.

CANCELLATIONS: Any order may be canceled by the purchaser only upon written notice & upon

payment to Energenics of reasonable & proper cancellation charges.

SALES & SIMILAR TAXES: Energenics prices do not include sales, use, gross receipts, excise or

similar taxes, license fees & export or import duties. All taxes or other charges assessed to

Energenics by reason of a transaction with the Purchaser must be paid by the Purchaser.

PRICE POLICY: All sales are made F.O.B. point of shipment and all prices are subject to change

without notice.

DESIGN CHANGES: Energenics reserves the right to make changes in the design & changes or

improvements in its products without notice or without imposing any obligation upon Energenics to

install the same upon products heretofore manufactured.

GENERAL: No alteration, modification or extension of the foregoing conditions shall be binding upon

Energenics unless made in writing & signed by an officer of Energenics.

Other manuals for UV-MAX

2

Table of contents

Other Energenics Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Dynisco

Dynisco LCR7000 Series operating manual

Glas-Col

Glas-Col 099A RD7512 Operating and safety instructions

Cytek Biosciences

Cytek Biosciences Aurora user guide

RR Mechatronics

RR Mechatronics STARRSED TL user manual

Tableau

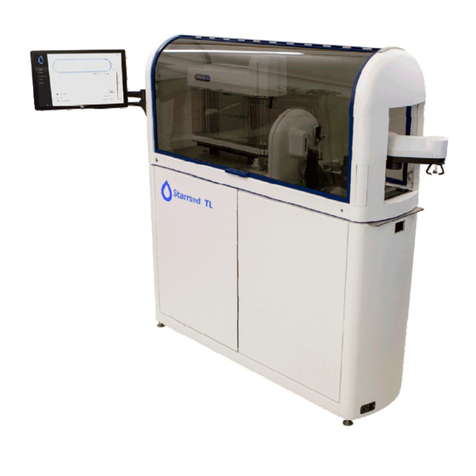

Tableau TX1 Quick reference guide

Thermo Scientific

Thermo Scientific DSQ II Hardware manual

CAS

CAS ScanMaster M1 Quick use manual

Agilent Technologies

Agilent Technologies BIO-DIS Apparatus 3/7 Operator's manual

Pacific Image Electronics

Pacific Image Electronics Slite 600 user manual

VWR

VWR HCO304 operating manual

Boekel

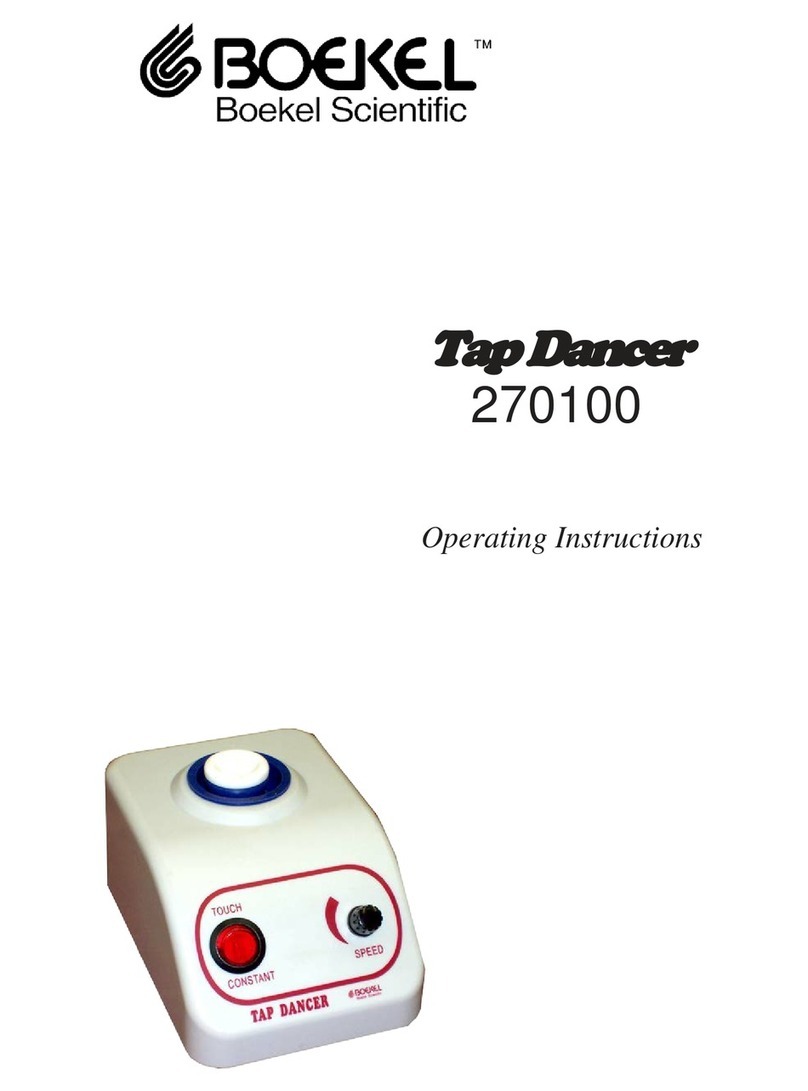

Boekel Tap Dancer operating instructions

EG

EG Xcellerex XDUO 2500 operating instructions