TQC Sheen AB3650 User manual

Automatic Film

Applicator Compact

AB3650, AB3655

Entry level film applicator

Operating Instructions (V1.3 0718)

IMPORTANT! Before taking this instrument

in use we strongly advise you to read this

manual carefully.

3 |

TQC Sheen will grant a warranty for a period of 12 months for the Automatic

Film Applicator Compact and 12 months for all related equipment from

the date of delivery in respect of any evidence of faulty workmanship and

materials.

Should a delivered consignment prove to be contrary to contract upon

inspection, the customer shall grant TQC Sheen the opportunity hereunder

of removing the fault, or else the customer may demand replacement.

Because of size and weight of the instrument TQC Sheen will strive to give

remote support.

Should the supply or delivery of any improvement or replacement not prove

possible, the customer may choose between having the purchase price

reduced or in demanding the contract of sale to be rescinded (conversion).

Damage resulting from natural wear and tear, mechanical or chemical

damage, an act of God or non compliance with the operating instructions

shall be excluded from the warranty as well as mechanical interference by

the customer or by third parties with Automatic Film Applicator Compact

and related equipment without TQC Sheen’s written permission. No liability

will be accepted for defects, damage or injury caused due to use not carried

out in accordance with the manufacturer’s user instructions.

To claim warranty, the rejected product has to be sent to TQC Sheen

together with the original invoice, any exchange before the product has

been returned to TQC Sheen is not possible. TQC Sheen reserve the right to

repair, exchange or supply an equivalent substitute. TQC Sheen is not liable

for handling or transport costs. Warranty on the purchase price is limited, all

liability for consequential damages or changes in technology is expelled.

This product complies to

- Machinery Directive 2006/42 / EC

- Low Voltage Directive 2006/95 / EC

- EMC Directive 2004/108 / EC

This product is RoHS 2 compliant (2011/65/EU)

WARRANTY

5 |

1 General

1.1 Importance of operating manual

1.2 User-responsibility

1.3 Responsibility of personnel

1.4 Dangers

1.5 Designated purpose

1.6 Copyright

1.7 Manufacturer’s/Supplier’s address

2 Safety Instructions

2.1 Meaning of Symbols

2.2 Availability of Safety Information

2.3 Dangers from Electrical Energy

2.4 Modifications to the Equipment

3 Transport and Storage

3.1 Packing

3.2 User: Check on Receipt

3.3 Reporting Transport Damage and

Documentation

3.4 Storage and Protective

Measures when not in use

4 Instrument Data

4.1 Name / Article

4.2 Scope of Supply

4.3 Technical Data

4.4 Dimensions and Weight

4.5 Basic Unit

4.6 Accessories and Spares

5 Instrument Controls and Functions

6 Instrument Preperations

7 Operation

7.1 Navigation

7.2 Starting the machine

7.3 Setting test duration

7.4 Prepare a draw down - Glass bed model (AB3650)

7.5 Prepare a draw down - Vacuum bed model (AB3655)

7.6 Placing an application tool

7.7 Using paper to collect the surplus of paint

7.8 Replacing the drip pan

8 Care and Maintenance

8.1 Disposal of Materials

8.2 Customer Service

9 Disclaimer

6

7

8

9/10

11

12

13/17

18

19

INDEX

| 6

1.1 Importance of operating manual

This manual is written in order to become familiar with all the functions and

possible applications of the instrument. It contains important instructions

about how to use the instrument safely and economically; according to

the purpose designated. Following these instructions is not only essential

to avoid risks. It also reduces repair costs and down-time and increases the

products reliability and service-life.

Anyone who works with the instrument shall follow the instructions in this

manual, particularly the safety related instructions. Additionally local rules

and regulations relating to environmental safety and accident prevention

should be observed. It is mandatory that users have read and understand

this manual prior to first operation of the Automatic Film Applicator

Compact.

1.2 User-responsibility

The user should

a) Only allow persons to work with the instrument who are

familiar with the general instructions on how to work safely and

to prevent accidents. The use of the instrument should have been

instructed duly. The safety chapter and the warnings in this

manual should have been read and understood; acknowledged

as evidenced by their signature.

b) Regularly check the safety-awareness of personnel at work.

1.3 Responsibility of personnel

Before commencing work anyone appointed to work with the instrument

should pay attention to the general regulations relating to working safety

and accident prevention. The safety chapter and the warnings in this manual

should have been read and understood; acknowledged as evidenced by

their signature.

1.4 Dangers

This instrument has been designed and constructed in accordance with

state-of-the-art technology and the acknowledged safety regulations.

Nevertheless, working with the instrument may cause danger to the life and

health of the operator or to others, or damage to the instrument or other

property. Therefore the instrument should only be used for its designated

purpose, and in a perfect technical condition. Any defect that could have a

negative effect on safety should be repaired and recorded.

1.5 Designated purpose

The Automatic Film Applicator Compact is exclusively designed to apply

thin films of liquid or pastes on test specimen. Other applications constitute

improper use. TQC Sheen will not be held liable for damage resulting from

improper use.

Designated purpose also includes properly observing all instructions in the

operation manual, and adherence to inspection and maintenance

schedules. TQC Sheen is entitled to request these form when warranty

claims are made and during inspections to ensure safe operation and

evaluate correct usage.

1.6 Copyright

The copyright of this operating manual remains with TQC Sheen. This

operating manual is intended solely for the user and his personnel. Its

instructions and guidelines may not be duplicated, circulated or otherwise

passed on to others, neither fully, nor partly. Infringement of these

restrictions may lead to legal action may be taken if this restrictions are

infringed upon.

1.7 Manufacturer’s/Supplier’s address

TQC Sheen

Molenbaan 19

2908 LL Capelle aan den IJssel

The Netherlands

T +31(0)10 7900 100

F +31 (0)10 7900 129

1 GENERAL

7 |

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction manual.

2.2 Availability of Safety Information

The instruction manual should be kept in proximity to where the instrument

operates and should be visible and accessible at any time of operation.

In addition to the information contained in the instruction manual, general

and local regulations for accident prevention and environmental protection

shall be kept available and observed. Always ensure all guidelines in respect

of safety and dangers on the instrument are in readable condition.

In case of danger the instrument has to be switched off by means of the on /

off switch at the left back side of the instrument or by unplugging the mains

power, then the danger should be eliminated.

2.3 Dangers from Electrical Energy

• Work on the electrical supply may only be done by a qualified electrician.

• The electrical equipment of the instrument must be checked regularly.

Loose connections and cables damaged by heat must be corrected

immediately.

• Always make sure the instrument’s power is turned off while adjusting any

electrical component.

Make sure that no paint or other liquids are spilled on the

electronics

2.4 Modications to the Equipment

• Any modifications or additions or alterations to the instrument may solely

be made with permission from the manufacturer otherwise the warranty

will be void.

• Instruments which are not in fault-free condition must immediately be

switched off

• Only use replacement parts from the original supplier. Parts used from

other sources aren’t guaranteed to take the loading and meet the safety

requirements.

Possible immediate

danger to the life or

health of personnel.

If this guideline is not noted

it can lead to severe danger

to health, up to fatal injury.

A dangerous situation

could be caused.

Non observance of this

guideline can lead to injury

or to damage to equipment.

Special tips and

particular information.

Guidelines to make optimal

use of the instrument.

2 SAFETY INSTRUCTIONS

| 8

3.1 Packing

• Please take note of pictorial symbols on the packing.

3.2 User: Check on Receipt

• Check packing for damage

• After unpacking check complete supply.

3.3 Reporting Transport Damage and Documentation

• Any damage should be documented as accurately as possible (possibly

photographed) and reported to the relevant insurers or, in the case of sales

“delivered to customers works”, to the supplier.

3.4 Storage and Protective Measures when not in use

• The instrument must be stored in a dry place at a temperature

between 10 - 40˚C.

• If packing is damaged upon receipt immediately inform the forwarder and

make a note on the packing list and have it signed by the forwarder. Ideally

make some pictures of the damage as well.

• Store instrument in the original packing if possible.

3 TRANSPORT AND STORAGE

9 |

4.1 Name / Article

Automatic Film Applicator Compact – Entry level film applicator

4.2 Scope of Supply

4 INSTRUMENT DATA

Automatic Film

Applicator Compact

Drip Pan

Paper Support

Manual

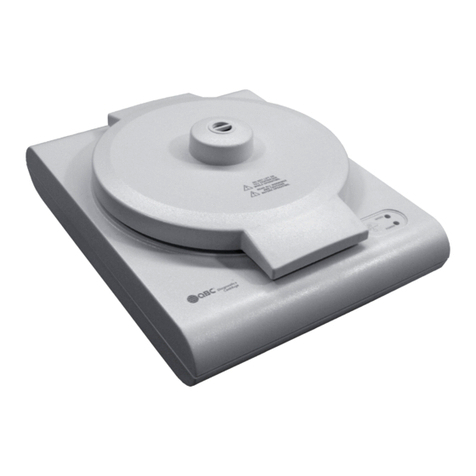

Vacuum Bed

Tube (1m)

24V Adapter

Weight

Glass Bed

Rubber Mat

Standard supplied Only supplied with AB3650 Only supplied with AB3655

4.3 Technical Data

Traverse speed: 1 - 150 mm/s / 0.03 - 5.90 in/s

Traverse speed accuracy: < 1%

Stroke length: 250 mm / 9.84 in

Stroke length accuracy: < 1 mm

Max. test substrate thickness: 8 mm / 0.31 in incl. coating

Max. width alternative film applicators: 200 mm / 7.87 in

Max. test chart dimensions: 216 mm X 355 mm (or with paper sheet support 500 mm) X 8 mm (incl. coating thickness)

Max. height alternative film applicators: 40 mm / 1.57 in

Min. Wire bar length: > 220 mm / > 8.66 in

Wire bar diameter: 6 - 12,7 mm / 0.23 - 0.5 in

Volume drip pan: 30 ml

Drawn down speeds: 1 - 150 mm/s / 0.03 - 5.90 in/s free selectable

Min. vacuum: -100 mbar required for vacuum model

Diameter vacuum holes: 1.3 mm / 0.05 in

Distance between vacuum holes: 22 mm / 0.86 in

Number of vacuum holes: 117

Vacuum connection: 6 mm / 0.23 in quick connect

4.4 Dimensions and Weight

Depth: 335 mm / 13.18 in

Width: 400 mm / 15.74 in

Height: 190 mm / 7.48 in

Net weight: 12,5 kg / 27.55 in

4.5 Basic Unit

Power Supply: 24 VDC

Power consumption: Max. 40 Watt

Display: 128 x 64 pixels graphic, 70 mm x 40 mm / 2.75 x 1.57 in white illuminated

Menu languages: English

Function: Navigation switch

| 10

Accessories

Vacuum Pumps

AB3675 Vacuum Pump, 23 l/min, 1750rpm 115VAC

AB3676 Vacuum Pump, 18 l/min, 1450rpm 230VAC

Optional Weight

AB3680 Optional Weight 250 g

Wire Bar Coaters

AB3720 Wire Bar Coater 4µm, film width 230mm, total width 290mm

AB3721 Wire Bar Coater 6µm, film width 230mm, total width 290mm

AB3722 Wire Bar Coater 8µm, film width 230mm, total width 290mm

AB3723 Wire Bar Coater 10µm, film width 230mm, total width 290mm

AB3724 Wire Bar Coater 12µm, film width 230mm, total width 290mm

AB3725 Wire Bar Coater 14µm, film width 230mm, total width 290mm

AB3726 Wire Bar Coater 16µm, film width 230mm, total width 290mm

AB3727 Wire Bar Coater 20µm, film width 230mm, total width 290mm

AB3728 Wire Bar Coater 24µm, film width 230mm, total width 290mm

AB3729 Wire Bar Coater 30µm, film width 230mm, total width 290mm

AB3730 Wire Bar Coater 34µm, film width 230mm, total width 290mm

AB3731 Wire Bar Coater 38µm, film width 230mm, total width 290mm

AB3732 Wire Bar Coater 40µm, film width 230mm, total width 290mm

AB3733 Wire Bar Coater 50µm, film width 230mm, total width 290mm

AB3734 Wire Bar Coater 56µm, film width 230mm, total width 290mm

AB3735 Wire Bar Coater 60µm, film width 230mm, total width 290mm

AB3736 Wire Bar Coater 76µm, film width 230mm, total width 290mm

AB3737 Wire Bar Coater 100µm, film width 230mm, total width 290mm

AB3738 Wire Bar Coater 120µm, film width 230mm, total width 290mm

AB3739 Wire Bar Coater 150µm, film width 230mm, total width 290mm

AB3740 Wire Bar Coater 200µm, film width 230mm, total width 290mm

AB3741 Wire Bar Coater microns on request, film width 230mm, total width 290mm

AB3742 Wire Bar Coater plain polished, film width 230mm, total width 290mm

Spare parts

AB3670 Spare Glass Bed for Automatic Film Applicator Compact

AB3667 Spare Vacuum Bed for Automatic Film Applicator Compact

AB3657 Spare Drip Pan

AB3662 Spare Paper Support

A large range of applicators are suitable for the Automatic Film Applicator Compact.

For more information about the applicators we refer you to our website.

4.6 Accessories and Spares

11 |

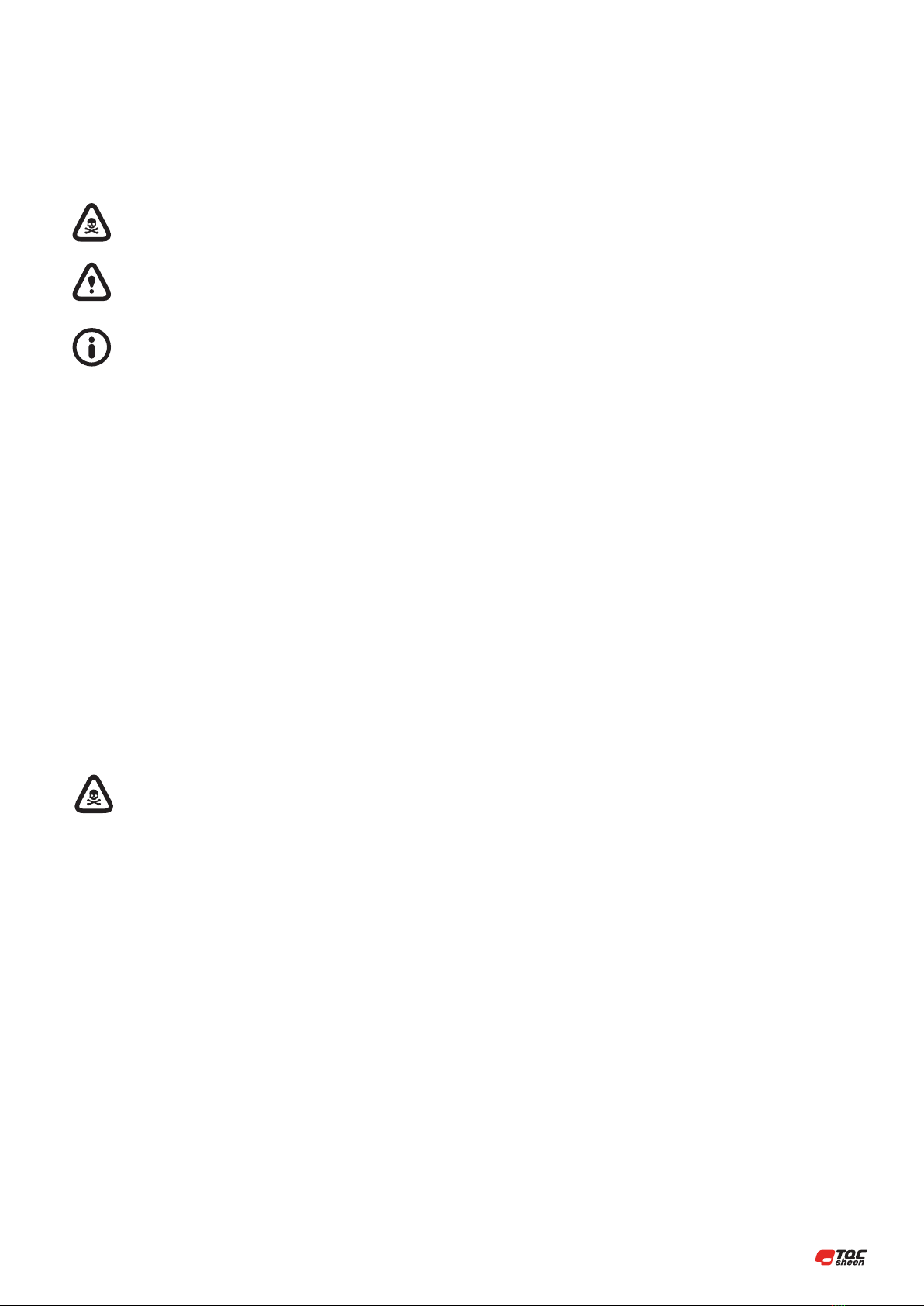

5 INSTRUMENT CONTROLS AND FUNCTIONS

Power Switch

Vacuum Tube Fitting

Test Chart Clamp

Applicator Weight

Optional 250 g Weight

Vacuum Bed at AB3655 or

Glass Bed at AB3650

Display

5

6

7

8

9

10

11

12

13

1

2

3

4

5-key Navigation Switch

Drip Pan or Paper Holder

Machine iD-tag

5x Anti-slip Rubber Bumbers

Red Pushbar

Power Entry

1 2 3

4 5 6

7

11

10 13

8

9

12

| 12

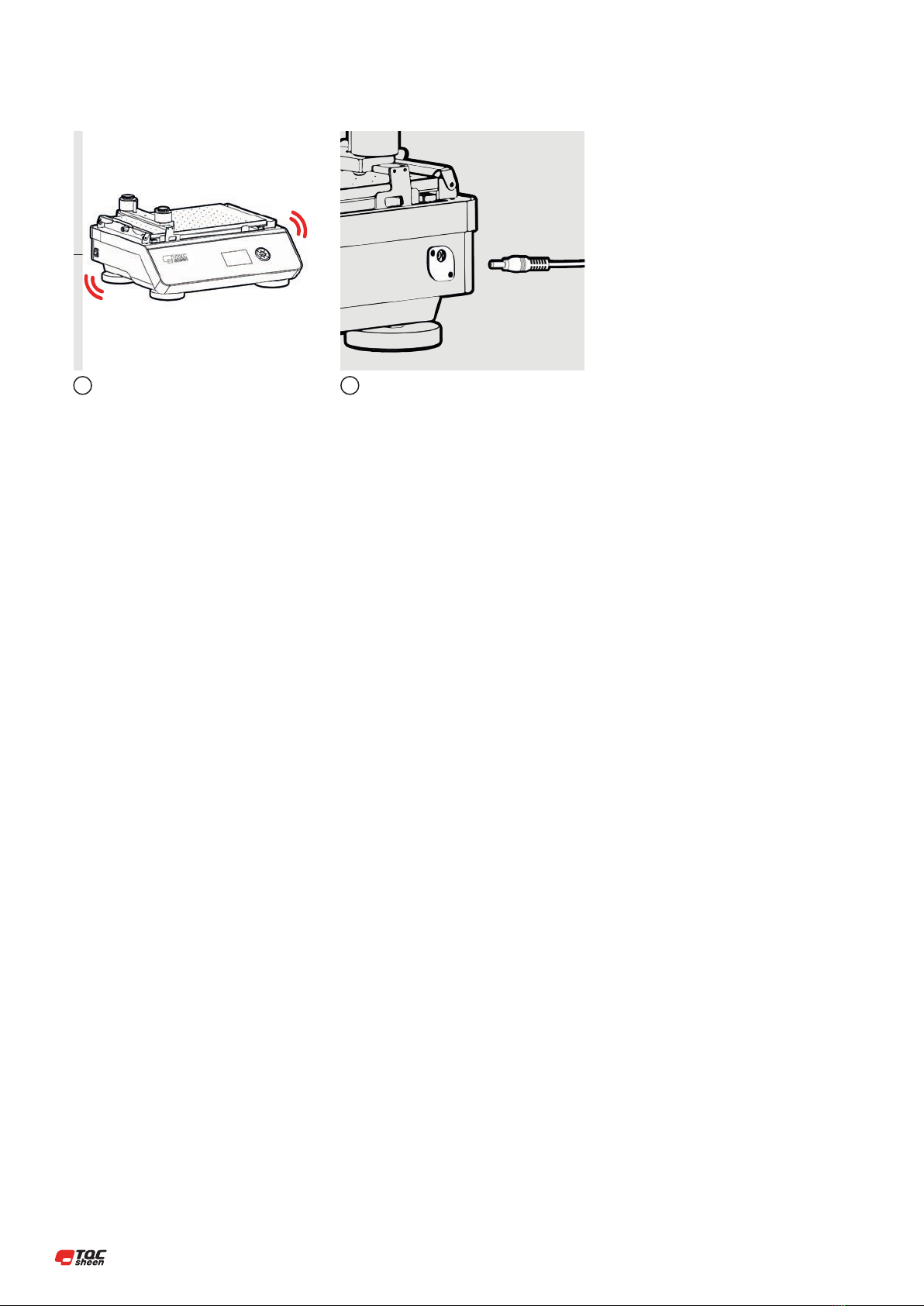

6 INSTRUMENT PREPARATIONS

The instrument has to be installed on a

sturdy table or work area.

Connect the power cable.1 2

13 |

7.1 Navigation

The Automatic Film Applicator Compact is quite simple to operate by means

of the menu in the display and the 5-key navigation switch. Use the 5-key

navigation switch to highlight the function of choice in the menu and

confirm by pressing the“OK” button.

The 5-key navigation switch is equipped with the unique Triple i function

(Intelligent Illumination Interface). Triple i enhances the intuitive operation of

the Automatic Film Applicator Compact by illuminating just those keys that

are active in combination with the position in the operating menu.

7.2 Starting the machine

7.3 Setting test duration

Switch on the machine by using the

switch button on the left side of the

machine.

To alter the notation of the speed or the

actual speed navigate with the arrow key

to “SETUP” and press “OK”.

Press “OK” to start-up the machine.

(Machine will perform an internal

calibration)

If the notation of the speed need to be

changed from mm/s into inch/s or vice

versa navigate the cursor to the desired

choice and press“OK”.

The display shows the current set test

duration.

If the speed needs to be altered navigate

the cursor to the correct digit and change

the digit using the up and down keys.

Move the cursor to the“RUN”option and

activate the “RUN” option. You will return

to the RUN MENU screen with the“START”

option.

1

1

2

2

3

3

7 OPERATION

| 14

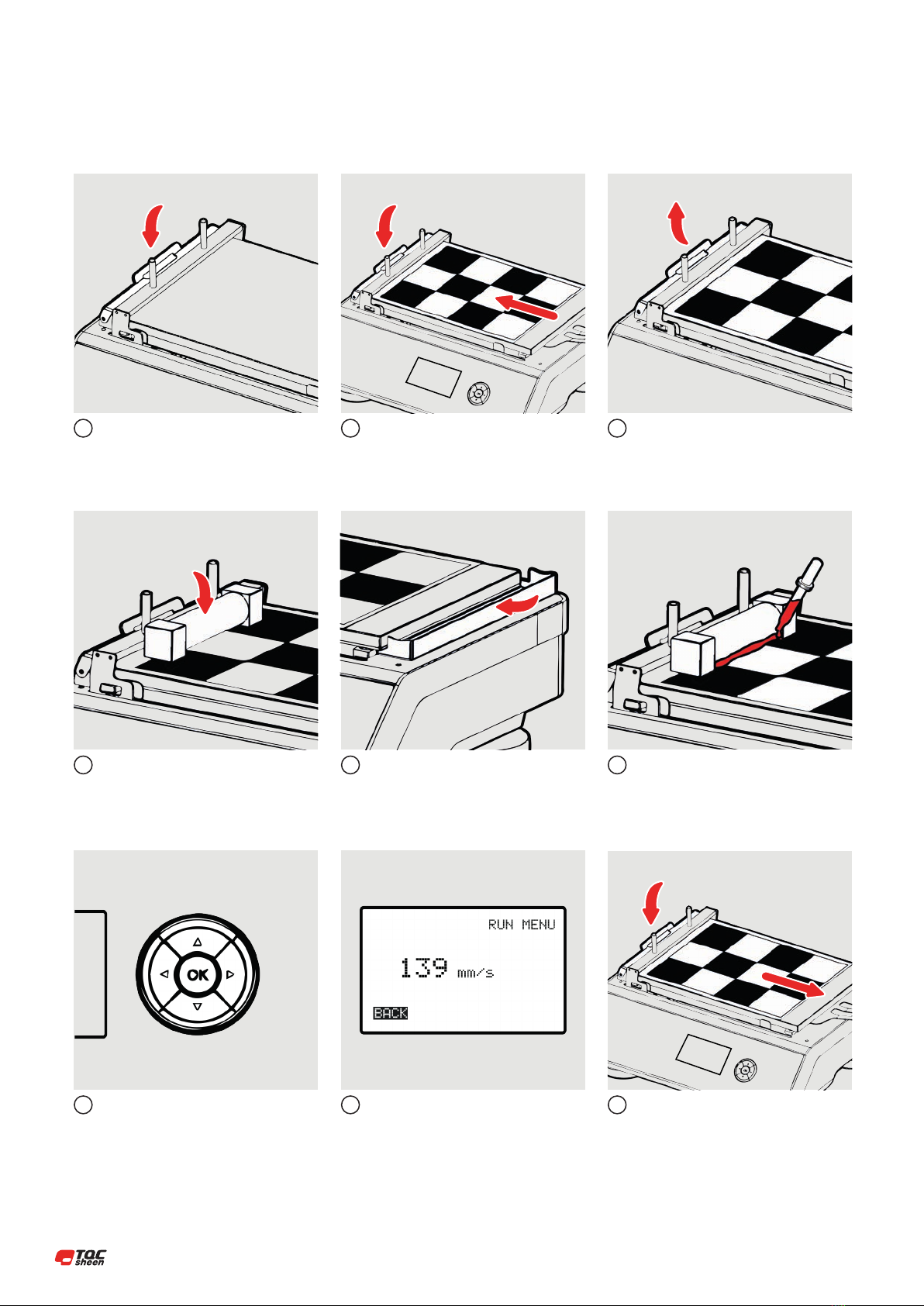

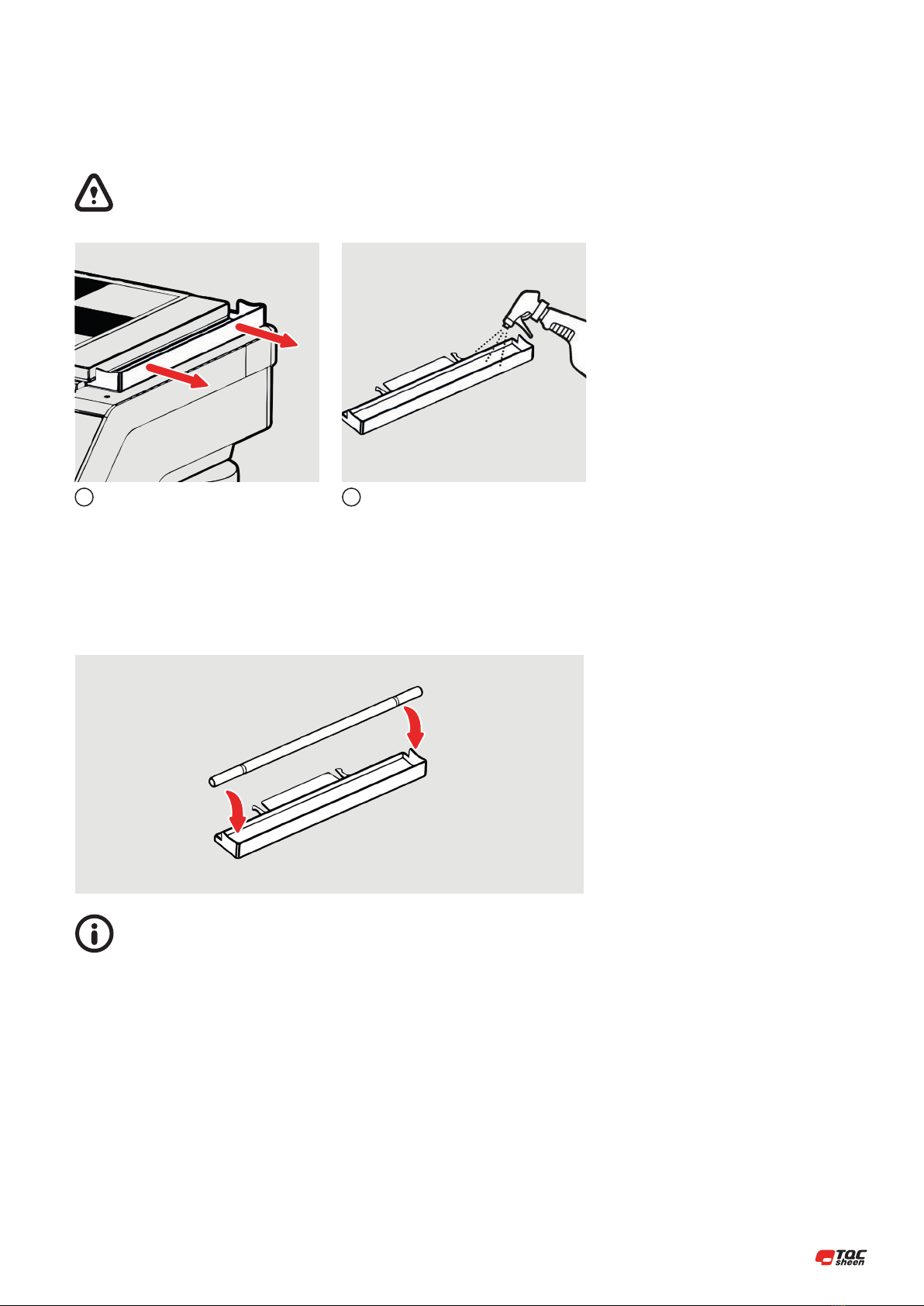

7.4 Prepare a draw down - Glass Bed Model (AB3650)

Press the clamp down to open.

Place the application tool as described in

paragraph 7.6.

Make sure the traverse and application

tool are free to move and press the“OK”

button to start the application.

While pressing the clamp position the

test chart or other specimen on the glass

bed and shift it under the clamp to the

far left side.

Position a sheet of paper to collect the

surplus of paint or make sure the drip

pan is in position and not full. See also

paragraph 7.7 and 7.8.

Once the draw down is made remove the

application tool and return the traverse by

activating the “BACK” option.

Release the clamp mechanism.

Apply the right amount of paint in front

of the application tool.

Remove the test card by releasing the

clamp.

1

4

7

2

5

8

3

6

9

15 |

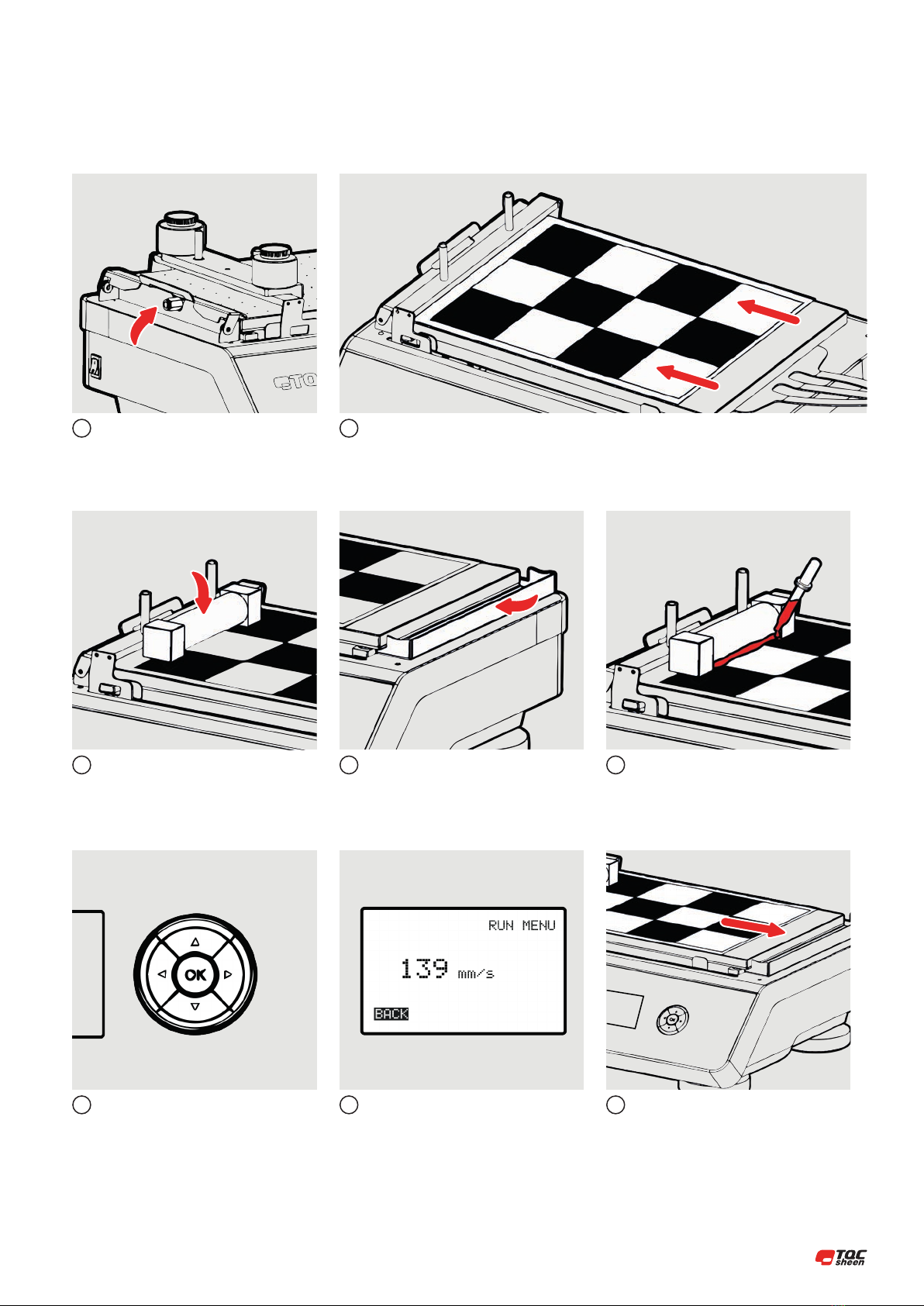

7.5 Prepare a draw down - Vacuum Bed Model (AB3655)

Make sure the vacuum bed is connected

to a proper and active vacuum source.

Place the application tool as described in

paragraph 7.6.

Make sure the traverse and application

tool are free to move and press the“OK”

button to start the application.

Position the test chart on the vacuum bed and make sure it is fully flat and covers all the holes.

* Note that if the chart is too small to cover all the holes the remaining open holes have to be closed

down by means or adhesive tape (use a tape that can be easily removed)

Position a sheet of paper to collect the

surplus of paint or make sure the drip

pan is in position and not full. See also

paragraph 7.7 and 7.8.

Once the draw down is made remove the

application tool and return the traverse by

activating the “BACK” option.

Apply the right amount of paint in front

of the application tool.

Switch off the vacuum and remove the

test chart.

1

3

6

2

4

7

5

8

| 16

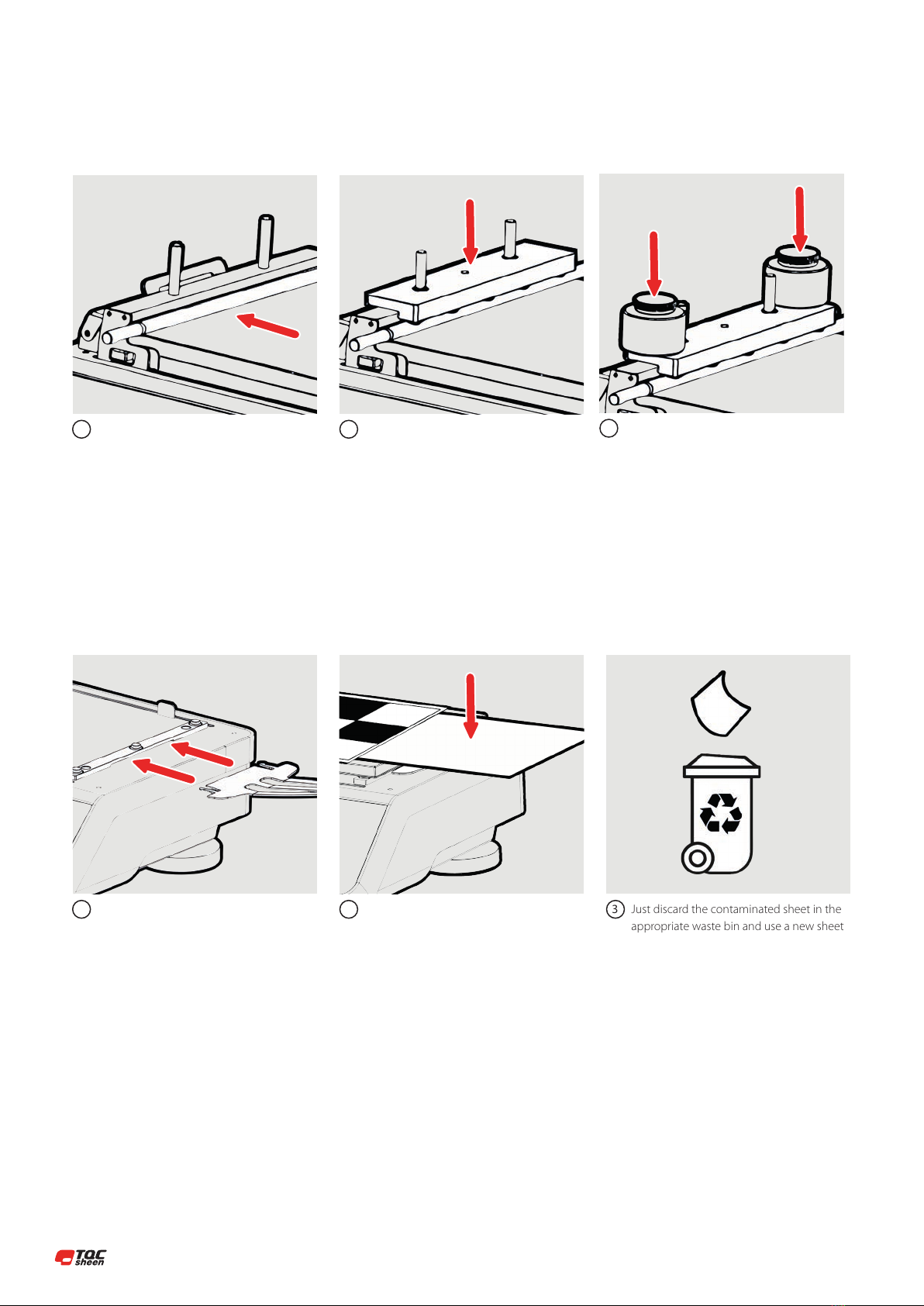

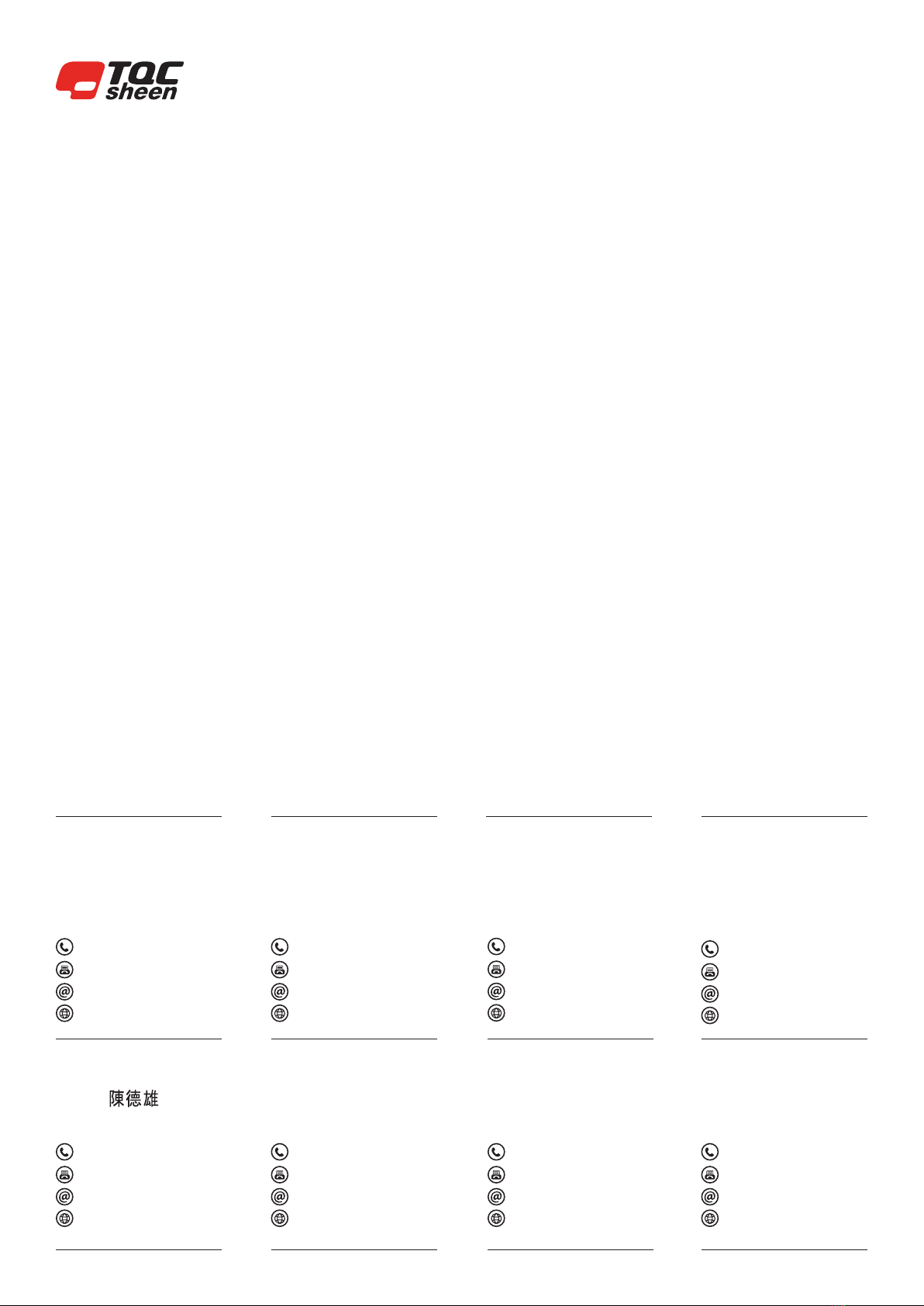

Position the appropriate bird applicator,

wire bar, square applicator, reservoir or

quadruplex or other applicator bar in front

of the red pushbar.

To keep the wire bar from rotating and

when additional weight is needed for

other applicators, set the weight over the

pins of the push bar such that the rubber

feet of the weight bar are resting on the

application tool or wire bar.

1 2

7.6 Placing an application tool

Assemble the paper support on the right

hand side of the machine by sliding it under

the clamp bracket.

When making a drawdown place a thin

sheet of paper just under the trailing edge

of the test-chart so any surplus of paint will

end up on the sheet of paper.

Just discard the contaminated sheet in the

appropriate waste bin and use a new sheet

for the next drawdown.

1 2 3

7.7 Using paper to collect the surplus of paint

TQC Sheen advises to use this method instead of the drip pan. This method does not require any cleaning, just disposal of contaminated sheets.

If required additional option weights can be

mounted on the standard weight.

3

17 |

To remove the pan just pull it horizontally

away from the vacuum bed using two

hands.

The pan is entirely made of stainless steel

so can be cleaned using water or when

required more aggressive media.

Please note that the drip pan can hold a limited volume of 30 ml of paint. It is

important to empty and clean this at a regular basis.

The drip pan is designed in such a way that the wire bar applicator rests above it and

any leftover paint leaks into it.

1 2

7.8 Cleaning the drip pan

| 18

• Though robust in design, this instrument is precision-machined.

Never drop it or knock it over.

• Always clean the instrument after use.

• Clean the instrument using a soft dry cloth. Never clean the instrument

by any mechanical means such as a wire brush or abrasive paper. This may

cause, just like the use of aggressive cleaning agents, permanent damage.

• Be careful when using compressed air to clean the instrument.

• Generally the Automatic Film Applicator Compact does not require any

maintenance.

Make sure that no paint or other liquids are spilled on the

electronics or left in the holes.

10.1 Disposal of Materials

Disposal of materials used in the operation of the instrument or for auxiliary

functions and exchanged items should be dealt with safety and in a manner

that will not harm the environment. Follow the local regulations.

10.2 Customer Service

Customer service is provided on request by

TQC Sheen - Molenbaan 19 , 2908LL Capelle aan den IJssel

The Netherlands, T +31(0)10 7900100, F +31 (0)10 7900129

or by local representatives.

8 CARE AND MAINTENANCE

19 |

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and

any person using the product for any purpose other than that specifically

recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so

at his own risk. Whilst we endeavor to ensure that all advice we give about

the product (whether in this manual or otherwise) is correct we have no con-

trol over either the quality or condition of the product or the many factors

affecting the use and application of the product. Therefore, unless we spe-

cifically agree in writing to do so, we do not accept any liability whatsoever

or howsoever arising for the performance of the product or for any loss or

damage (other than death or personal injury resulting from our negligence)

arising out of the use of the product. The information contained in this man-

ual is liable to modification from time to time in the light of experience and

our policy of continuous product development.

9 DISCLAIMER

TQC Sheen Korea

Bldg Star Plaza, #805

Kimpo-Hangang-8-Ro 410

10071 Kimpo-Si, Gyeonggi-Do

South-Korea

+82 (0) 31 982 7074

+82 (0) 31 997 0827

www.tqcsheen.com

TQC Sheen UK

Po Box 977A

Surbiton, KT1 9XL

England

+44 208 255 0143

-

www.tqcsheen.com

TQC Sheen GmbH

Nikolaus-Otto-Strasse 2

Hilden, D-40721

Germany

+49 (0)2103-25326-0

+49 (0)2103-25326-29

www.tqcsheen.com

TQC Sheen-USA Inc.

3689 Hadley Road

Metamora, MI 48455

USA

+1 810 797 8300

+1 810 797 8303

www.tqc-usa.com

TQC Sheen

Molenbaan 19

2908 LL, Capelle aan den Ijssel

The Netherlands

+31 (0) 10 – 7900 100

+31 (0) 10 – 7900 129

www.tqcsheen.com

TQC Sheen -Singapore

3689 Hadley Road

Tang TH |

Sales & Service Manager APAC

+65 8181 8607

+31 (0)10 7900129

www.tqcsheen.com

TQC Sheen ITALIA s.r.l.

Via Cesare Cantu’ ,26

SEREGNO, (MB) 20831

Italy

+39 0362-1822230

+39 0362-1822234

info@tqcitaly.it

www.tqcsheen.com

TQC Sheen Norge AS

Øvre Langgt. 26

Tønsberg, 3110

Norway

+47 333 10220

-

info@tqc.no

www.tqcsheen.com

This manual suits for next models

1

Table of contents

Other TQC Sheen Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

ibidi

ibidi m–Slide VI 0.4 Series instructions

Biolin Scientific

Biolin Scientific Theta installation manual

Hettich

Hettich HAEMATOKRIT 200 operating manual

Keithley

Keithley 4200-SCS-PK3-903-01 quick start guide

Drucker Diagnostics

Drucker Diagnostics QBC 425740 Service manual

Thermo Scientific

Thermo Scientific 3960 Operating and maintenance manual