Traction Hobby FOUNDER PRO User manual

1

f o u n d e r P R O

Thank you for purchasing the all-new TRACTION HOBBY Founder Pro Scale and Trail Crawler. The design of

the Founder Pro instantly obsoletes the status quo with greatly expanded features and versatility. The

Founder Pro features the powerful 775 motor and a 4s LiPo-capable electronic speed control. The game-

changing portal axles provide greater ground clearance while the rigid steel frame eliminates chassis ex

and allows you to navigate tough terrain. The new VOODOO tires feature tuned foam inserts to deliver

superior bite on rocky surfaces with convincing scale realism. In other words, we built it the TRACTION

HOBBY way rugged powerful, and ready to handle the rigors of remote locations and all-day driving fun!

This manual contains the instructions you will need to operate and maintain your model so that you can

enjoy it for years to come. We want you to feel condent that you own one of the bestperforming models in

the market and that it is backed by a team of professionals who aim to provide the highest level of factory

support possible. TRACTION HOBBY models are about experiencing total performance and satisfaction

not just with your model, but also with the company that stands behind it.

We know you’re excited about getting your new model on the trail, but it’s very important that you take some

time to read through the Owner’s Manual. This manual contains all the necessary setup and operating

procedures that allow you to unlock the performance and potential that TRACTION HOBBY engineers

designed into your model. Even if you are an experienced R/C enthusiast, it’s important to read and follow

the procedures in this manual.

Thank you again for going with TRACTION HOBBY . We work hard every day to assure you the highest

level of customer satisfaction possible.We truly want you to enjoy your new model!

Carefully read and follow all instructions in this and any accompanying materials to prevent serious

damage to your model. Failure to follow these instructions will be considered abuse and/or neglect.

Before running your model, look over this entire manual and examine the model carefully. If for some

reason you decide it is not what you wanted, then do not continue any further. Your hobby dealer

absolutely cannot accept a model for return or exchange after it has been run.

10

7

2

f o u n d e r P R O

All of us at TRACTION HOBBY want you to safely enjoy your new model. Operate your model sensibly and

with care, and it will be exciting, safe, and fun for you and those around you. Failure to operate your model

in a safe and responsible manner may result in property damage and serious injury. The precautions

outlined in this manual should be strictly followed to help ensure safe operation. You alone must see that

the instructions are followed and the precautions are adhered to.

If you have any questions about your model or its operation, call the TRACTION HOBBY Technical Support

Line at:86-0573-84639307/0573-84639306

You may also e-mail customer support with your question at sales.frederick@kingmotor.cn.

TRACTION HOBBY offers a full-service, on-site repair facility to handle any of your TRACTION HOBBY

service needs. Maintenance and replacement parts may be purchased directly from TRACTION HOBBY

by phone. You can save time, along with shipping and handling costs, by purchasing replacement parts

from your local dealer.

Do not hesitate to contact us with any of your product support needs. We want you to be thoroughly satised

with your new model!

1.Your model is not intended for use on public roads or congested areas where its operation can conict with

or disrupt pedestrian or vehicular trafc.

2.Never, under any circumstances, operate the model in crowds of people. Your model could cause injury if

allowed to collide with anyone.

3.Because your model is controlled by radio, it is subject to radio interference from many sources that are

beyond your control. Since radio interference can cause momentary losses of radio control, always allow a

safety margin in all directions around the model in order to prevent collisions.

4.The motor, battery, and speed control can become hot during use. Be careful to avoid getting burned.

5.Don’t operate your model at night, or anytime your line of sight to the model may be obstructed or impaired

in any way.

Your model’s electronic speed control (ESC) is an extremely powerful electronic device capable of delivering

high current.

Please closely follow these precautions to prevent damage to the speed control or other components.

1.Disconnect the Battery: Always disconnect the battery from the speed control when not in use.

2.Insulate the Wires: Always insulate exposed wiring with heat shrink tubing to prevent short circuits.

3.2-4 Li-Po cells (2S): The ESC can accept a maximum input voltage of 14.8 volts (4S LiPo).Always adhere

to the minimum and maximum limitations of the ESC as stated in the specications table.

4.Transmitter on First: Switch on your transmitter rst before switching on the speed control to prevent

runaways and erratic performance.

5.Don’t Get Burned: The ESC and motor can become extremely hot during use, so be careful not to touch

them until they cool. Supply adequate airow for cooling.

6.No Reverse Voltage: The ESC is not protected against reverse polarity voltage.

3

f o u n d e r P R O

Your model is able to use Li-Po batteries. Charging and discharging batteries has the potential for re,

explosion, serious injury, and property damage if not performed per the instructions. Before use, read and

follow all manufacturer’s instructions, warnings, and precautions. In addition, Lithium Polymer (Li-Po)

batteries pose a SEVERE risk of re if not properly handled per the instructions and require special care

and handling procedures for long life and safe operation. Li-Po batteries are intended only for advanced

users that are educated on the risks associated with Li-Po battery use. TRACTION HOBBY does not

recommend that anyone under the age of 14 use or handle Li-Po battery packs without the supervision of

a knowledgeable and responsible adult. Dispose of used batteries according to the instructions.

Important Warnings for users of Lithium Polymer (Li-Po) batteries:

1.LiPo batteries have a minimum safe discharge voltage threshold that should not be exceeded. The

electronic speed control is equipped with built-in Low-Voltage Detection that alerts the driver when Li-Po

batteries have reached their minimum voltage (discharge) threshold. It is the driver’s responsibility to stop

immediately to prevent the battery pack from being discharged below its safe minimum threshold.

2.Low-Voltage Detection is just one part of a comprehensive plan for safe Li-Po battery use. It is critical to

follow all instructions for safe and proper charging, use, and storage of Li-Po batteries. Make sure you

understand how to use your Li-Po batteries. If you have questions about Li-Po battery usage, please

consult with your local hobby dealer or contact the battery manufacturer. As a reminder, all batteries should

be recycled at the end of their useful life.

3.ONLY use a Lithium Polymer (Li-Po) balance charger with a balance adapter port to charge Li-Po batteries.

Never use Ni-MH or Ni-Cad type chargers or charge modes to charge Li-Po batteries. DO NOT charge with

a Ni-MH-only charger. The use of a Ni-MH or Ni-Cad charger or charge mode will damage the batteries and

may cause re and personal injury.

4. NEVER charge Li-Po battery packs in series or parallel. Charging packs in series or parallel may result in

improper charger cell recognition and an improper charging rate that may lead to overcharging, cell

imbalance, cell damage, and re.

5.ALWAYS inspect your Li-Po batteries carefully before charging. Look for any loose leads or connectors,

damaged wire insulation, damaged cell packaging, impact damage, uid leaks, swelling (a sign of internal

damage), cell deformity, missing labels, or any other damage or irregularity. If any of these conditions are

observed, do not charge or use the battery pack. Follow the disposal instructions included with your

battery to properly and safely dispose of the battery.

6.DO NOT store or charge Li-Po batteries with or around other batteries or battery packs of any type,

including other Li-Po batteries.

7.Store and transport your battery pack(s) in a cool dry place. DO NOT store in direct sunlight. DO NOT

allow the storage temperature to exceed 140°F or 60°C, such as in the trunk of a car, or the cells may be

damaged and create a re risk.

8.DO NOT disassemble Li-Po batteries or cells.

9.DO NOT attempt to build your own Li-Po battery pack from loose cells.

Charging and handling precautions for all battery types:

1. BEFORE you charge, ALWAYS conrm that the charger settings exactly match the type (chemistry),

specication, and conguration of the battery to be charged.

2. DO NOT attempt to charge non-rechargeable batteries (explosion hazard), batteries that have an internal

charge circuit or a protection circuit, batteries that have been altered from original manufacturer

conguration, or batteries that have missing or unreadable labels, preventing you from properly identifying

the battery type and specications.

3.DO NOT exceed the maximum manufacturer recommended charge rate.

4

f o u n d e r P R O

Supplied Tools and Equipment

4-way wrench

Required Equipment (not included)

Charger2S-4S Lipo battery

4.DO NOT let any exposed battery contacts or wires touch each other.This will cause the battery to short

circuit and create the risk of re.

5.While charging or discharging, ALWAYS place the battery (all types of batteries) in a re retardant/re

proof container and on a non-ammable surface such as concrete.

6.DO NOT charge batteries inside of an automobile. DO NOT charge batteries while driving in an

automobile.

7.NEVER charge batteries on wood, cloth, carpet, or on any other ammable material.

8.ALWAYS charge batteries in a well-ventilated area.

9.REMOVE ammable items and combustible materials from the charging area.

10.DO NOT leave the charger and battery unattended while charging, discharging, or anytime the charger

is ON with a battery connected. If there are any signs of a malfunction or in the event of an emergency,

unplug the charger from the power source and disconnect the battery from the charger.

11.DO NOT operate the charger in a cluttered space, or place objects on top of the charger or battery.

12.If any battery or battery cell is damaged in any way, DO NOT charge, discharge, or use the battery.

13.Keep a Class D re extinguisher nearby in case of re.

14.DO NOT disassemble, crush, short circuit, or expose the batteries to ame or other source of ignition.

Toxic materials could be released. If eye or skin contact occurs, ush with water.

15.If a battery gets hot to the touch during the charging process (temperature greater than 110°F / 43°C),

immediately disconnect the battery from the charger and discontinue charging.

16.Allow the battery pack to cool off between runs (before charging).

17.ALWAYS unplug the charger and disconnect the battery when not in use.

18.ALWAYS unplug the battery from the electronic speed control when the model is not in use and when it

is being stored or transported.

19.DO NOT disassemble the charger.

20.REMOVE the battery from your model or device before charging.

21.DO NOT expose the charger to water or moisture.

22.ALWAYS store battery packs safely out of the reach of children or pets. Children should always have

adult supervision when charging and handling batteries.

Your model comes with a set of specialty metric tools. You’ll need to purchase other items, available from

your hobby dealer, to operate and maintain your model.

5

f o u n d e r P R O

Steering Servo

775 Brushed Motor Transfer Case

Shifting Servo

Rear Diff Lock Servo

Electronic

Speed Control

Front Diff

Lock Servo

Transmission

Shifting Servo

CH1:Steering Servo

CH2:Electronic Speed Control

CH3:Transmission Shifting Servo

CH4:Transfer Case Shifting Servo

CH5:Front Diff Lock Servo

CH6:Rear Diff Lock Servo

6

f o u n d e r P R O

Radio Maintenance

Bind/VCC

LED

Antenna CH 1-6

Receiver

Battery

Compartment

Button

(Channel 3)

Throttle/Brake

(Channel 2)

Steering

D/R

Power Switch

BACK/Exit

BIND

LED Indicator

LCD

Channel 5

NaviKey

(Rotate to “Select”, press to

“Conrm”)

3 Position Switch

(Channel 4)

Steering Trim

(Channel 1)

Throttle Trim

(Channel 2)

Steering Wheel

(Channel 1)

Channel 6

Antenna

Transmitter

7

f o u n d e r P R O

High Gear Servo state(High speed)

High Gear state

Low Gear state

Low Gear Servo state(Low speed)

Before you go on, here are some important precautions to keep in mind.

1.Allow the model to cool for a few minutes between runs. This is particularly important when using

high-capacity battery packs that allow extended periods of running. Monitoring temperatures will extend the

lives of the batteries and motor.

2. Do not continue to operate the model with low batteries or you could lose control of it. Indications of low

battery power include slow operation and sluggish servos (slow to return to center). Stop immediately at

the rst sign of weak batteries.

3.Do not drive the model at night, on public streets, or in large crowds of people.

4.Drive the Founder Pro primarily in low gear for maximum torque. High gear can be used for high-speed

running on open trails or when clearing steep slopes or gaps in rocks. Driving in high gear for extended

periods of time can result in the motor and/or ESC overheating and premature motor wear.

5.Because the model is controlled by radio, it is subject to radio interference from many sources beyond your

control. Since radio interference can cause momentary losses of control, allow a safety margin of space in

all directions around the model in order to prevent collisions.

6.Use good, common sense whenever you are driving your model. Intentionally driving in an abusive and

rough manner will only result in poor performance and broken parts. Take care of your model so that you

can enjoy it for a long time to come.

7.High-performance vehicles produce small vibrations that may loosen hardware over time. Frequently check

wheel nuts and other screws on your vehicle to ensure that all hardware remains properly tightened.

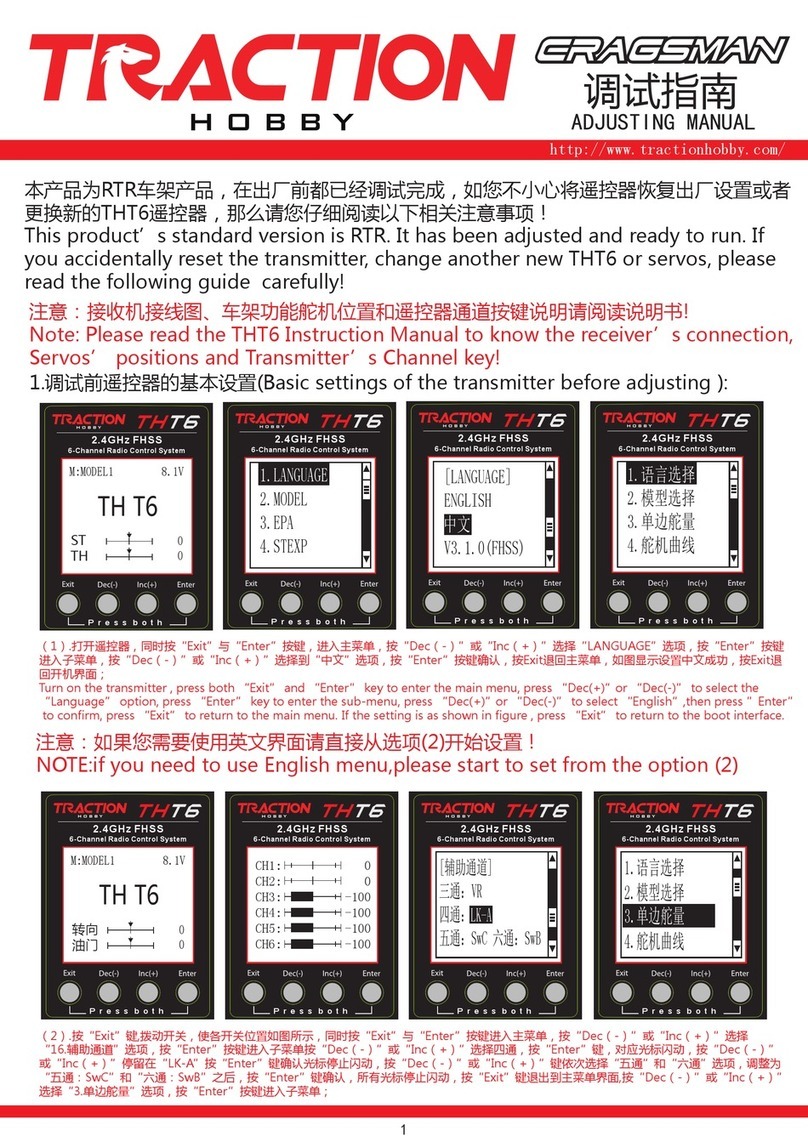

Operating the High-Low Transmission:

1.In the original state, use the third channel button of the remote control to switch the gearbox position.

There are obvious speed changes between the high-speed gear and the low-speed gear. The model

gearbox has a strong torque at low gears, which can extend the service

life of the motor. The corresponding gearbox lever and servo status are shown in the gure.

2.If you replace a new servo or transmitter, please adjust the servo parameters according to the state shown

in the gure. The main purpose is to adjust the EPA parameters of the corresponding channel of the

remote control to ensure the smooth operation of the servo in the working state. The servo will be damaged

due to long-term force.

Operating the Transfer Case:

1.The Founder Pro can switch three driving modes, namely 4WD, FWD and RWD, which are controlled by

the fourth channel of the transmitter, and the driving mode can be selected according to different road

conditions and vehicle states.

8

f o u n d e r P R O

4WD Transfer Case

Shifting Servo State

4WD Transfer Case State

RWD Transfer Case

Shifting Servo State

RWD Transfer Case State

FWD Transfer Case

Shifting Servo State

FWD Transfer Case State

Front Diff Lock servo state

Front Diff Unlock servo state

Rear Diff Lock servo state

Rear Diff Unlock servo state

2.If you replace a new servo or transmitter, the channel switch of the remote control must be in three-way

please adjust the servo parameters according to the state shown in the gure, mainly by adjusting the EPA

parameters of the corresponding channel of the remote control to ensure that the servo is smooth in the

working state. The servo will be damaged due to long-term force.

Operating the Diff Lock:

1.The front and rear differential locks of Founder Pro are controlled by ve channels and six channels

respectively.

2.In most driving environments, the differential can be locked or unlocked at any time. If the speed

difference between the left and right tires is too large, rst release the throttle to reduce the wheel speed

difference and then lock the differential. The Founder Pro performs best when the front and rear differentials

are unlocked in most cases. This gives the Founder Pro the best steering performance and the smallest

turning radius, while also reducing the pressure on the driving components. If the opened differential

causes you to lose grip on loose terrain or prevents you from passing obstacles, you can use the differential

lock switch to lock the corresponding differential.

3.When locking the front differential lock or locking the front and rear differential locks, the high-speed

control and steering accuracy will be limited. The function of locking the differential can be used in any

situation, but when driving at high speeds, unlock the differential can greatly increase the vehicle

maneuverability.

9

f o u n d e r P R O

About Run Time:

Tips for Increasing Run Time:

Precautions:

A large factor affecting run time is the type and condition of your batteries. The milliamp hour (mAh) rating

of the batteries determines how large their “fuel tank” is. A 3000 mAh battery pack will theoretically run

twice as long as a 1500 mAh sport pack. Because of the wide variation in the types of batteries that are

available and the methods with which they can be charged, it’s impossible to give exact run times for the

model. Another major factor that affects run time is how the model is driven. Run times may decrease when

the model is driven repetitively from a stop to top speed and with repetitive hard acceleration.

1.Use batteries with the highest mAh rating you can purchase.

2.Use a high-quality peak-detecting charger.

3.Read and follow all maintenance and care instructions provided by the manufacturer of your batteries

and charger.

4.Keep the ESC cool. Get plenty of airow across the ESC heat sink.

5.Lower your gear ratio. Installing a smaller pinion gear will lower your gear ratio and cause less power

draw from the motor and batteries, and reduce overall operating temperatures.

6.Maintain your model. Do not allow dirt or damaged parts to cause binding in the drive train. Keep the

motor clean.

1.Without proper care, some parts of your model can be seriously damaged due to contact with water.

Know that additional maintenance procedures will be required after running in wet conditions in order to

maintain the performance of your model. Do not run your model in wet conditions if you are not willing to

accept the additional care and maintenance responsibilities.

2.Not all batteries can be used in wet environments. Consult your battery manufacturer to see if their

batteries can be used in wet conditions. Do not use Li-Po batteries in wet conditions.

3.The transmitter is not water resistant. Do not subject it to wet conditions, such as rain.

4.Do not operate your model during a rain storm or other inclement weather where lightning may be present.

5.Do not allow your model to come in contact with saltwater, brackish water, or other contaminated water.

Saltwater is highly conductive and highly corrosive. Use caution if you plan to run your model on or near

a beach.

6.Even casual water contact can reduce the life of your motor. Special care must be taken to modify your

driving style in wet conditions to extend the life of the motor.

Motor Precautions:

1.Founder Pro 775 motor life can be greatly reduced in mud and water. If the motor gets excessively wet or

submerged, use very light throttle (run the motor slowly) until the excess water can run out. Applying full

throttle to a motor full of water can cause rapid motor failure. Your driving habits will determine motor life

with a wet motor. Do not submerge the motor under water.

2.Do not gear the motor by temperature when running in wet conditions. The motor will be cooled by water

contact and will not give an accurate indication of appropriate gearing.

Additional Maintenance:

Increase your frequency of disassembly, inspection, and lubrication of the following items. This is necessary

after extended wet use or if the vehicle will not be used for an extended period of time (such as a week or

longer). This additional maintenance is needed to prevent any trapped moisture from corroding internal

steel components.

10

f o u n d e r P R O

Front Assembly

THJ301

THJ259

THJ259

THJ259

THJ259

THJ259

THJ259

THJ297

THJ407

THJ297

THJ058

THJ058

THJ058

THJ058

THJ058

THJ058

THJ058

THJ058

THJ058

TC2508 THO036

THO036

TF3006

THJ259

THJ056

THJ259

THJ259

THJ259

THJ300

THJ299

TB3014

TB3014

TB3008

THJ277

THJ312

THJ305

TMS3003

TMS3003

THJ315

THJ277

THJ058

THJ058

THJ058

TB3028

TC3016

TC3016

THJ278

TF3008

TBB051104

THJ274

TH01176

TH01176

TC3020

TC3020

TC3022

TC3020

TC3020

TBB051104

TBB051104

THJ259

TC3008

THO026

THJ417

THJ414

THJ413

THJ415

THJ411

THJ418

THJ410

THJ410

THO025

THJ411

THO026

TC3008

TMN30

TMN30

TMN30

TMN30

L/R

TH01048

TF3006

TF3006

TB3012

TH01048

TB3012

TH01048

TF3006

TF3006

TC3010

TC3010

TC2510

TC2510

TB2512

TB2512 TBB050903

TME70

TBB121804

TB2504

TB2504

TB3012

TBB051104

TH01048

TB3012

TB2508

TBB051104

TBB051104

THJ276

TBB101504

TF2012

THJ279

THJ246

THJ318

THJ280

THO006

TBB152104

THJ276

TH01159

11

f o u n d e r P R O

Transmission Assembly

THE002

TB3010

TB3008

TB3008

TW320810

TMN30

TB3010

TB3010

TH01065

TH01065

TH01065

TH01005

TB3010

TF4008

TH01037

TMS4006

TC2510

TC2510

TF2506

TF2506

TH01115

TMN50

TWS051005

TH01002

TH01002

TH01111

TH01111

TH01067

TH01066

TH01066

TH01066

TH01035

TBB051004

TBB050825

TH01018

TH01030

TH01021

TH01106

TH01106

TH01031

TH01031

TH01022

TME25

TH01018

TH01036

TBB071103

TBB071103

TH01055

TBB051004

TH01057

TH01057

TH01006

TH01006

TC2508

THJ367

TC2510

TC2510

TBB051004

TBB051004

TBB050903

TH01029

TH01020

TH01034

TW050805

TW050805

TW050805

TW050805

TW060905

TBB050903

TBB050903

TBB051004

TBB051004

TH01028

TH01034

TH01034

TH01019

TH01034

TBB051004

TBB050903

TH01032

TBB061204

TH01033 TH01017

THP2512

TWS051005 Shaft A

Shaft B

Shaft C

Shaft C

Shaft B

Shaft A

TH01074

TF3010

12

f o u n d e r P R O

Servo Assembly

TF3010

TF3010

TH01074

TH01074

TH01074

THE001

TB3008

TB3008

TMS3005

TH01112

TB2506

TH01074

THJ319

Servo Assembly A

TH01057

THE004 TH01007

TH01007

TH01071

TBB050825

TBB050825

TB3008

TW030705

TF3006

TH01057

THE004

TH01071

TH01071

TH01071

TH01110

TB3016

Servo Assembly B

THE004

TH01071

TH01071

TH01008

TMS3003

TH01051

TBB050825

TB3008

TW030705

TF3006

TB3008

TB3006

TF2506

TMN25

Servo Assembly C

Servo Assembly D

THE004

TH01071

TH01008

TH01008

TH01051

TMS3003

TBB050825

TBB050825

TB3008

TB3006

TW030705

TMN25

TF3006

TF3010

TH01175

TF3010

Receiver box Assembly

Steering servo Assembly

TB3012

TC2508

TB3008

THO030

TH01174

THJ409

TB3012

TB3012

TW320810

TW320810

THE003

13

f o u n d e r P R O

TF3008

TF3008

TB4012

TB4040

TMNF40

THJ091

THJ030

TH01180

TH01180

TH01074

THJ080

TH01180

TF3008

THJ308

THJ308

TF3008

TF3008

TF3008

THJ262

THJ263

TF4025

TF4025

TC2514

TC2514

THJ062

TMNF40

THJ262

THJ068

THJ266

THJ266

THJ267

THJ267

TB3014

TB3014

THJ266

THJ266

THJ267

THJ267

TB3018

TB3012

TB3012

TB3012

TH01173

TH01177

TH01177

TH01177

TH01174

TH01175

TH01177

TH01173

TH01173

TB3012

TB3012

TB3010

TB3018

THJ381

THJ381

TF3008

TF3012

TF3012

TF3014

TF3008

TB3020

TB3020

TB3012

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

TB3012

TB3010

TB3010

TF3012 TB3010

THJ307

THJ307

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

TB3012

TB3012

TF3010

TF3010

TF3010

TF3010

TF3010

TF3010

TF3014

TF3014

TF3010

TF3010

THJ078

TF3014

TB3010

TB3006

TB3006

TB3006

TB3006

TB3006

TB3006

THO027

THO027

THO027

THO027

THO034

THO034

THO034

THO034

THO027

THO027

THO027

THO027

Chassis Assembly

THJ406

THJ406

TF4025

TC2514

TC2514

THJ030

THJ062

THJ263

THJ062

THJ068

THJ068

THJ241

THJ351

Servo A

Servo B

Servo C

Servo D

14

f o u n d e r P R O

THJ277

THJ277

THJ278

TF3008

TC3016

TC3016

TBB051104

TBB051104

TBB051104

TB3006

TB3006

TC3008

TC3008

TB3006

TB3006

TBB051104

TBB051104

TBB051104

TBB051104

TBB051104

TC3008

TC3008

TC3020

TC3020

TC3020

TMN30

TMN30

THJ250

THJ250

THO026

THO026

THO026

TMN30

THJ058

THJ058

THJ058

THJ058

THJ058

THJ058

THJ259

THJ259

TB2510

TB2510

TB2508

THJ333

TB2510

TB2510

THJ412

THJ416

THJ417

THJ413

THJ412

THJ413

THJ412

THJ418

THJ417

THJ412

THJ416

THJ418 TMS3003

THJ306

TMS3003

THJ315

THJ312

TB3008

THJ259

THJ259

THJ259

TC3035

THJ259

THJ259

THJ259

THJ297

THJ297

THJ298

THJ298

THJ058

TC3020

TBB051104

THJ275

Rear Assembly

Shock Assembly

THJ070

THJ049

THJ295

THJ055

THJ243

THJ423

THJ424

THJ425

THJ243

THJ050

THJ051

THJ052

THJ259

THJ296

THJ070

THJ070

THJ054

THJ054

TC2508

TC2508

THO036

THO036

TF3006

TH01159

TH01159

15

f o u n d e r P R O

Body Assembly

THO029

THO032

THO032

THO032

THO032

THJ065

THJ308

THJ308

THJ308

THJ308

THJ267

THJ365

THJ365

THJ063

THJ063

THJ270

THJ365

TB3014

TB3014

THJ063

TC2006

TC2006

TB2510

TB3010

THJ064

THJ065

THJ062

THJ062

THJ064

THJ369

THJ064 THO031

THO031

THO031

THO031

THO031

THO028

THO028

THO028

THO028

THJ064

THJ065

TB2510

TB2510

TB2510

TB2510

TB2506

TB2506

TB2510

TB2510

TB2510

TB2510

TB2510

THJ066

TC2004S

TC2004S

TC2004S

TC2004S

TB3012

TH01179

TC1604S

TC1604S

TC1605

TC1605

TC1605

TC1605

TC1605

TC1605

TC1605

TC1605

TC1605

THJ066

THJ067

THJ067

TB2510

TB2508

TB2508

TC2006

TB3006

TB3006

16

f o u n d e r P R O

Roll-cage Assembly

TB3006

THJ270

TB2504 TB2504

THO031

THJ369

TC2006

TB2510

TB2510

TB2510

TB2010

TB2010

TB3014

TB3014 TB2510

TB2510

TC2006

THJ063

THJ063

THJ063

TB3010

TB3016

TB3016

TH01178

TH01178

TH01178

TH01178

TH01178

TH01178

TH01178

TB3016

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

THJ064

THJ064

THJ064

THJ064

THJ064

THJ064

THJ064

THJ064

THJ064

THJ062

TF3010

TF3018

TF3018

TF3006

TF3006

TF3010

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

TB3010

THJ062

TB3016

TB3016

TB3016

TB3016

TB3008

TB3008

THJ065

THJ065

THJ062

THJ063

THJ062

THJ369

TB3004

17

f o u n d e r P R O

Modular Assembly

TB3022

TB3022

TB3016

TB3016

THJ092

THJ090

THJ089

TC2512S

THJ088 THJ091

TMNF40

THJ219

THO035

THO035

TB3022

THJ244

THJ244

THJ039

THJ039

TMN30

TB3020

TB3012

TC3020

TC3020

TMNF30

TMNF30

194 mm

STEERING LINK

DRAG LINK

PANHARD BAR

UPPER LINK

LOWER LINK

THJ244

THJ244

THJ039

THJ039

120.2 mm

120.2 mm

131.7 mm

138.2 mm

18

f o u n d e r P R O

TH01179 Snokle

TH01066 Transmission housing

TH01071 Servo mount set

TH01177 Floor pans

TH01178 Luggage rack

THJ052 Spring mount set

THJ055 Shock piston

THJ049 Shock upper cap

THJ060 Linkage ball end 7mm

THJ064 Roll-cage top

THJ063 Light bar set

THJ067 Rear car wheel trims

THJ030 Spare wheel bracket

TH01173 Skid plates

TH01065 Transmission housing mount

THE003 TH1036 HV servo

THJ039 Drive shaft

TH01180 Shift linkage

TH01057 Ball 4mm

THJ050 Shock cap nut

TH01051 Cable mount

TH01106 Spring D4.3×16mm

TH01112 Double side tape&EVA kit

TH01111 Slipper pad

TH01115 Transmission strengthen mount

TH01159 Hex hub

TH01174 Steering servo mount

TH01074 Box&Battery tray

TH01175 Rear brace set

TH01176 Linkage mount

TH01048 King pin bushing

TH01067 Spur gear 50T

TH01110 Servo saver spring

THE001 TH-GT5 transmitter

THE002 775 Brushed motor

THE004-HV TH1623 HV servo

THE007 LED light system set

THJ051 Adjusting nut

THJ054 Shock spacer

THJ056 Spacer

THJ057 Ball end 5.8mm

THJ058 Ball 7mm

THJ062 Roll-cage sides

THJ065 Radiator

THJ066 Front car wheel trims

THJ068 Lamp-shade

THJ070 O-ring set

THJ077 Velcro 170mm

THJ080 Velcro strap 20×200mm

THJ089 Inner rim

THJ090 KX Hub carrier

THJ091 KX Hub cap

THJ092 KX Wheel hub

THJ244 M4×2.5×12mm screw shaft

THJ259 Linkage ball set

THJ262 Front bumper set

THJ246 Differential Pads

THJ078 Brushed ESC 80A

THJ088 KX Hub rim

THJ266 Shock hoops set

THJ267 Body mount set

THJ263 Rear bumper set

TH01007 2WD/4WD servo arm

TH01008 Differential lock servo arm

TH01002 Steel disc

TH01005 Transmission motor mount

TH01006 Ball mount set

TH01018 Transmission shaft set

TH01017 Transmission rst shaft

TH01019 Transmission 2-speed shaft

TH01020 Transfer case shaft

TH01028 2-Speed synchronizer

TH01021 2-Speed link

TH01022 Transfer case link

TH01029 Transfer case synchronizer

TH01030 2-Speed shift fork

TH01031 Transfer case fork

TH01032 Drive gear 17T

TH01033 Drive gear 29T

TH01034 Gear 29T

TH01035 Gear 17-29T

TH01036 Gear 23T

TH01037 Pinion gear 14T

TB3008 M3×8 Button head screw

TB3018 M3×18 Button head screw

THO034 Mudguard

TC2510 M2.5×10 Cap head screw

TC2512S M2.5×12 Cap head screw(silver)

THO036 Axle cover

TB3006 M3×6 Button head screw

THO031 Wiper

THO035 All terrain tire

TC1604S M1.6×4 Cap head screw(silver)

TB2506 M2.5×6 Button head screw

TB2510 M2.5×10 Button head screw

THO027 Blade side frame

TB3016 M3×16 Button head screw

TB2508 M2.5×8 Button head screw

TC2508 M2.5×8 Cap head screw

TB3004 M3×4 Button head screw

TB3022 M3×22 Button head screw

TB3014 M3×14 Button head screw

THO028 Armor wheel lintel

THO029 Angry face

TB2504 M2.5×4 Button head screw

TB3020 M3×20 Button head screw

TB3028 M3×28 Button head screw

TB4012 M4×12 Button head screw

TB4040 M4×40 Button head screw

TB3012 M3×12 Button head screw

TC2004S M2×4 Cap head screw(silver)

TC2006 M2×6 Cap head screw

TC1605 M1.6×5 Cap head screw

TB3010 M3×10 Button head screw

THO006 Aluminum differential housing

THO030 Steering arm

THP2512 Pin 2.5×12mm

THO032 Lamp cover

TB2010 M2×10 Button head screw

THJ425 spring D17×60mm

TC2008S M2×8 Cap head screw(silver)

TC2512 M2.5×12 Cap head screw

TC2514 M2.5×14 Cap head screw

THJ276 Bearing seat

THJ299 Front threaded stainless steel link

THJ369-BL Painted body blue

THJ279 36T Bevel gear

THJ300 Steering threaded Stainless steel link

THJ369 Clear body set

THJ319 Antenna pipe set

THJ278 12T Bevel gear set

THJ280 Diff gear set

THJ307 Chassis rail set

THJ296 Ball 5.8mm

THJ305 Front cable set

THJ297 Down threaded stainless steel link(

THJ270 Body decoration set

THJ295 Ball 5.5mm

THJ298 Up threaded stainless steel link

THJ301 Servo threaded Stainless steel link

THJ306 Rear cable set

THJ315 Pin 2.0×21mm

THJ308 Magnet set

THJ274 Solid axle set front

THJ312 Spring D2.6×12.7mm

THJ365 Double side tape kit

THJ367 Gearshift pin

THJ318 Pin 3×23mm

THJ275 Solid axle set rear

THJ369-RD Painted body red

THJ277 Differential lock set

THJ407 Front up threaded stainless steel link

THJ409 Toe Link mount

THJ410 Knuckle carrier

THJ411 Steering knuckles

THJ413 Weight block 108g

THJ414 Weight block 82g

THJ415 Universal axle set

THJ412 Rear portal axle

THJ369-GY Painted body gun gray

THJ416 Straight axle Shaft

THJ417 Portal axle output shaft

THJ418 Gear set 17T-23T

THJ423 Shock absorber body

THJ406 Antenna set

THJ424 Shock shaft

TC3010 M3×10 Cap head screw

TC3008 M3×8 Cap head screw

TC3016 M3×16 Cap head screw

TC3020 M3×20 Cap head screw

TW050805 Washer 5×8×0.5mm

TBB101504 Bearing 10×15×4

TF2506 M2.5×6 Flat head screw

TBB152104 Bearing 15×21×4

TMNF40 M4 Flanged nylon nut

TF3006 M3×6 Flat head screw

TMS4006 M4×6 Set screw

TF2012 M2×12 Flat head screw

TBB050903 Bearing 5×9×3

TF4025 M4×25 Flat head screw

TME25 E-clip 2.5mm

TF4008 M4×8 Flat head screw

TMN50 M5 Nylon nut

TF3018 M3×18 Flat head screw

TF3008 M3×8 Flat head screw

TF3012 M3×12 Flat head screw

TBB050825 Bearing 5×8×2.5

TF3014 M3×14 Flat head screw

TBB071103 Bearing 7×11×3

TF3010 M3×10 Flat head screw

TBB051104 Bearing 5×11×4

TBB121804 Bearing 12×18×4

TME70 E-clip 7mm

TMN25 M2.5 Nylon nut

TC3035 M3×35 Cap head screw

TMN30 M3 Nylon nut

TMNF30 M3 Flanged nylon nut

TMS3003 M3×3 Set screw

TBB061204 Bearing 6×12×4

TBB051004 Bearing 5×10×4

TMS3005 M3×5 Set screw

TC3022 M3×22 Cap head screw

TW030705 Washer 3×7×0.5mm

TW151702 Washer 15×17×0.2mm

TW320810 Washer 3.2×8×1mm

TWS051005 Spring washer 5×10×0.5mm

TW060905 Washer 6×9×0.5mm

Parts List

Table of contents

Other Traction Hobby Motorized Toy Car manuals

Traction Hobby

Traction Hobby Founder II Off-Road Performance User manual

Traction Hobby

Traction Hobby FISO PRO User manual

Traction Hobby

Traction Hobby CRAGSMAN User manual

Traction Hobby

Traction Hobby Cragsman Off-Road Performance User manual

Traction Hobby

Traction Hobby Cragsman C Off-Road Performance User manual