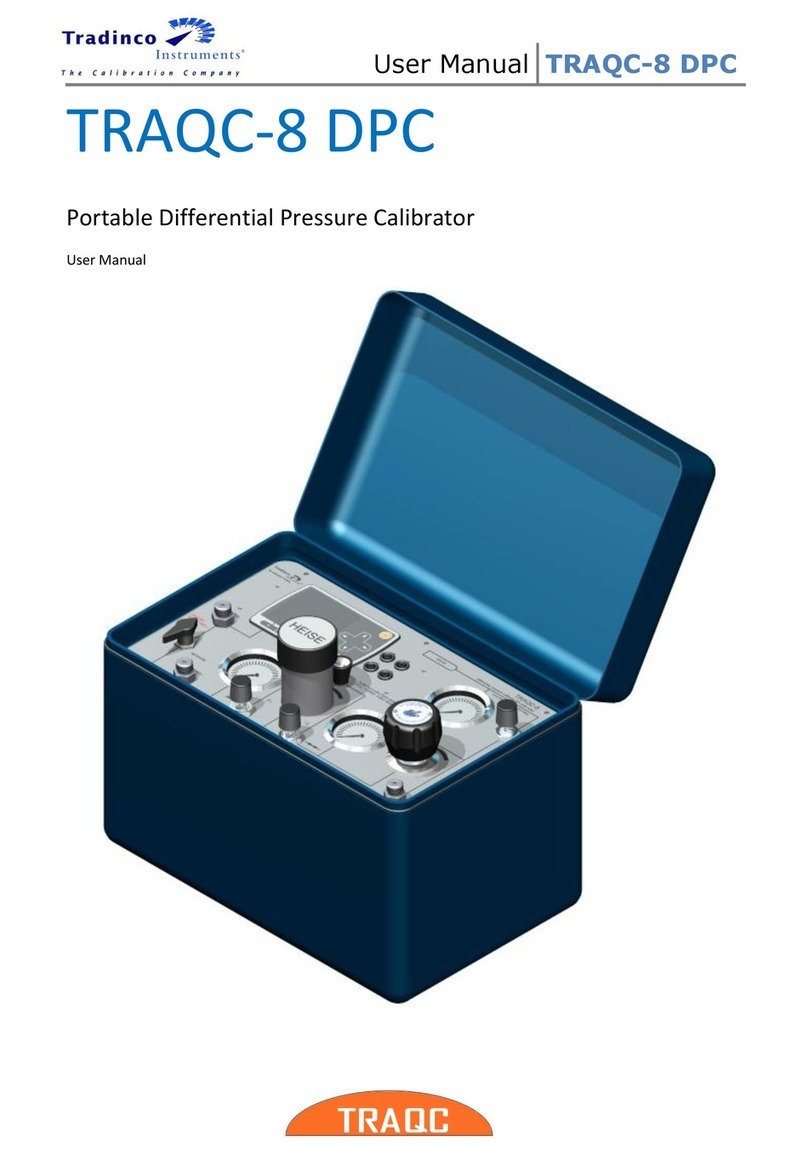

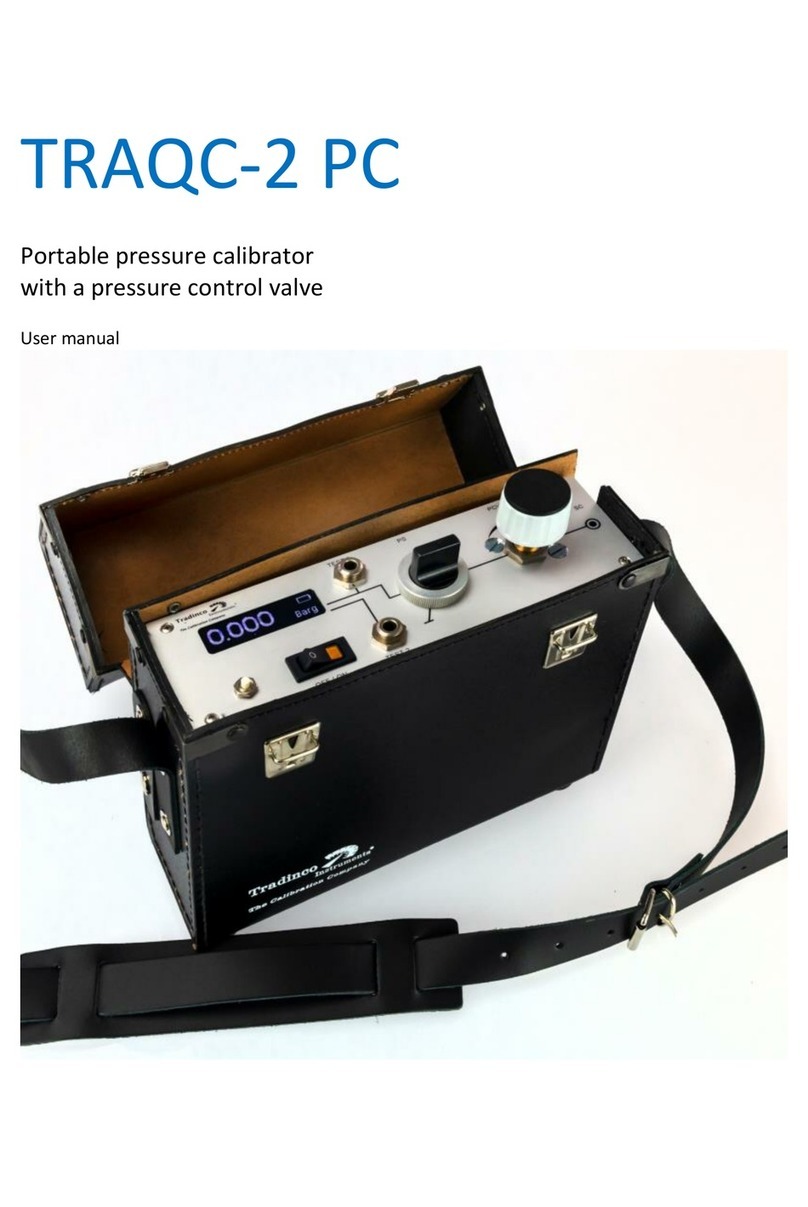

Tradinco TRAQC-2 PCHP User manual

TRAQC-2 PCHP

Portable pressure calibrator

with hand pump

User manual

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 2 van 16

Content

1. General.....................................................................................................................................................................3

1.1 Introduction....................................................................................................................................................3

1.2 Warranty.........................................................................................................................................................3

1.3 Service of Tradinco Instruments.....................................................................................................................4

1.4 Calibration services.........................................................................................................................................4

1.5 Accreditation ..................................................................................................................................................4

1.6 Packaging for shipment ..................................................................................................................................4

2. Safety symbols, notices and warnings .....................................................................................................................5

2.1 Responsible use of the Traqc-2 PCHP.............................................................................................................5

2.2 General safety instructions.............................................................................................................................5

2.3 Warnings and caution notices ........................................................................................................................5

3. About the Traqc-2 PCHP...........................................................................................................................................7

3.1 Functions of the Traqc-2 PCHP .......................................................................................................................7

3.2 Terms of use ...................................................................................................................................................7

3.2.1 Control panel and layout............................................................................................................................7

3.2.2 Display terms..............................................................................................................................................8

3.2.3 Terms of the manual ..................................................................................................................................8

3.3 A closer look at the instrument .....................................................................................................................8

4. Operation of the Traqc-2 PCHP................................................................................................................................9

4.1 On/off switch..................................................................................................................................................9

4.2 Zero/unit switch .............................................................................................................................................9

4.3 Display ..........................................................................................................................................................10

4.4 Two-way switch ............................................................................................................................................10

4.5 Pressure relief valve .....................................................................................................................................10

4.6 Hand pump ...................................................................................................................................................11

4.7 Volume controller.........................................................................................................................................11

5. Using the Traqc-2 PCHP..........................................................................................................................................12

5.1 Applying supply pressure to the UUT ...........................................................................................................12

5.2 Performing a comparative measurement ....................................................................................................12

5.3 Performing a leak test ..................................................................................................................................12

5.4 Measuring external pressure........................................................................................................................12

5.5 Charging the battery.....................................................................................................................................12

6. Maintenance ..........................................................................................................................................................13

6.1 Maintenance.................................................................................................................................................13

6.2 Calibration ....................................................................................................................................................13

7. Specifications .........................................................................................................................................................14

8. Declaration of conformity ......................................................................................................................................15

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 3 van 16

1. General

1.1 Introduction

The Traqc-2 PCHP is a portable calibration instrument to perform calibrations on site:

•by pressurizing an external circuit by means of the built-in hand pump and volume controller (max. 5 bar). After

this, the applied pressure can be read on the display.

•by directly measuring the pressure of a connected external circuit.

Also a leak test can be performed with the Traqc-2 PCHP The built-in pressure cell has been calibrated to confirm

that the measured value is within the accuracy described in the specifications.

1.2 Warranty

During the design and manufacturing of this instrument the at most attention has been given to quality and

durability. This manual contains information needed for the safe and effective use of the capabilities of the

instrument.

Please read the manual carefully before operating the instrument. By doing so, possible damage to the instrument

or damage caused by incorrect use of the instrument can be avoided. Tradinco Instruments warrantees the

instrument in accordance with the Standard Terms and Conditions 2020 of the Instrument Trade as issued by the

Association bearing the name "Federation Het Instrument" (The Instrument Federation, filed with the Chamber of

Commerce of Gooi-, Eem- and Flevoland under number 40507574. You can find and download a copy of the terms

and conditions from our website https://tradinco.com/.

Tradinco Instruments warrantees that this product will be free from defects in materials and workmanship for a

period of 1 year from the date of shipment. If any such product proves defective during this warranty period,

Tradinco Instruments, at its option, will either repair the defective product without charge for parts or labor, or will

provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, the customer must notify Tradinco Instruments of the defect before

the expiration of the warranty period and make suitable arrangements for the performance of the service.

The customer is responsible for packaging and shipping of the defective product to the service center designated by

Tradinco Instruments, with shipping charges prepaid. If no defect can be found Customer may be charged for costs

of the investigation. This warranty does not apply to any defect, failure or damage caused by:

•Improper use of the instrument;

•Battery leakage;

•Normal wear of the product;

•Modification or repair carried out by or on behalf of the owner or by a third party;

•Implementation of modifications to the product that are not supplied or implemented by Tradinco Instruments.

Tradinco Instruments and its vendors will not be liable for any indirect, special, incidental or consequential damages

irrespective of whether Tradinco Instruments or the vendor has advance notice of the possibility of such damages.

The type number of the product, as listed on the instrument tag plate, should always be mentioned in any

correspondence concerning the product.

Tradinco Instrumenten-Apparaten B.V.

Radonstraat 250

2718 TB Zoetermeer

The Netherlands

+31 79 2033133

www.tradinco.com

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 4 van 16

1.3 Service of Tradinco Instruments

Tradinco Instruments has made a concerted effort to provide complete and current information for the proper use

of the equipment. If there are questions regarding this manual, proper use of the equipment, or if you have

problems using your Traqc-2 PCHP and you don’t find the answer in this manual, please contact Tradinco

Instruments if you require personal assistance.

1.4 Calibration services

In addition to servicing our own products, Tradinco Instruments provides complete pressure calibration services for

many pressure instruments. This service includes a Certificate of Compliance and Calibration and a record of

traceability to the pressure standards of the Dutch Accreditation Council RvA.

1.5 Accreditation

Tradinco Instruments is registered to ISO 9001:2015. The calibration program at Tradinco Instruments is accredited

by Dutch Accreditation Council RvA, as complying with EN ISO/IEC 17025:2017.

1.6 Packaging for shipment

If the product must be shipped to a different location or returned for any reason through a common carrier it must

be packaged properly to minimize the risk of damage. The recommended method of packing is to place the

instrument in a container, surrounded on all sides with at least four inches of shock attenuation material such as

styrofoam peanuts.

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 5 van 16

2. Safety symbols, notices and warnings

This warning symbol indicates danger for the system and material if the respective safety precautions are

not taken, or indicates that danger of injury for persons and the environment and/or considerable material

damage (mortal danger, danger of injury) will occur if the respective safety precautions are not taken.

This warning symbol indicates danger by explosion for the system and material and the operator and

bystanders if the respective safety precautions are not taken.

This notice symbol does not indicate safety notices but information for a better understanding of the facts.

2.1 Responsible use of the Traqc-2 PCHP

To ensure safety, the operator must make sure that the following conditions are met:

•The system is used properly, no dangerous media are used and that all technical specifications are observed;

•The system is in perfect operating condition;

•The operation manual is legible and accessible to the user at the system’s location;

•The system is operated, serviced and repaired only by authorized and qualified personnel;

•The user receives instruction on industrial safety and environmental protection, and is knowledgeable of all

operating instructions and safety notices relevant to the current procedure.

2.2 General safety instructions

The system should be operated only by trained personnel who are familiar with this manual and the

operation of the instrument.

The battery of the Traqc-2 PCHP should be charged regularly. Only use the supplied USB cable for this,

which may be connected to a USB charging point that delivers a maximum of 500 mA/hr to prevent

overloading the internal electronics.

A condition for trouble-free and safe operation of this system is proper transport, proper storage,

installation, assembly and proper use as well as careful operation and maintenance.

Any operation not described in the following instructions should be prohibited. The system must be

handled with care required for an electronic precision instrument (protect from humidity, impacts, strong

magnetic fields, static electricity and extreme temperatures). Do not insert any objects into the instrument.

2.3 Warnings and caution notices

WARNING: PRESSURE! Pressure gases are potentially hazardous. Energy stored in these gases can be

released suddenly and with extreme force. Pressure systems should be assembled and operated only by

personnel who have been trained in proper safety practices.

Do not disconnect any pressure connection of the Traqc-2 PCHP when a measurement of any kind is in

progress. Physical injury may exceed when process connections will be disconnected, caused by the

expanding gas.

CAUTION: Pressure testing with compressed gases can lead to additional risks due to release of stored

energy (e.g. burst of system, flying objects). Please take appropriate measures (e.g. shielding, use of

personal protective equipment (PPE)) to prevent hazardous situations which could result in human injuries.

CAUTION: Use proper pressure medium. Use only clean, dry air or nitrogen gas. This instrument is not

designed for oxygen use.

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 6 van 16

WARNING: NOT EXPLOSION PROOF! Using this instrument in an area where devices with intrinsically safe

classification is recommended, is prohibited!

WARNING: Detachable main power supply cord with inadequate ratings should not be used.

WARNING: It is the responsibility of the operator to ensure that pressure in circuits connected to the UUT

will never exceed their safe working pressure. In the event that the maximum safe working pressure of a

circuit / system to be tested is lower than the maximum obtainable output pressure of the UUT, the

operator who will perform the tests must be instructed in advance regarding the maximum safe working

pressure of the external circuit.

Depending on the volume and pressure in the UUT, the risks for humans and material can be very high. For

that reason the end user must ensure that maximum pressure levels for each circuit are established as set

forth by law. (European directive 2014/68/EU or similar guidelines/obligations are specified and applicable

in the country of use.)

Because of the potential risk for human beings in the vicinity of systems/circuits under pressure, the end

user must ensure that risks are kept to the minimum by fencing, warning, forbidding passage or access to

the area for as long as the risk exists.

Do not connect the voltages higher than specified in the specifications to the instrument. If higher voltages

are connected, the interface control may be damaged.

This instrument is equipped with an overpressure protection, which protects the pressure sensor against

overpressure. As soon as the pressure on the pressure sensor increases to 1 bar above the measuring range

specified for the instrument, the supply will be cut off to protect the pressure sensor from damage.

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 7 van 16

3. About the Traqc-2 PCHP

3.1 Functions of the Traqc-2 PCHP

The Traqc-2 PCHP is a portable pressure calibrator to perform a calibration, a simple pressure measurement or a

leak test. The Traqc-2 PCHP is suitable for generating pressure with the built-in hand pump and volume controller.

This pressure will appear on the display. The display can be set to psi, bar or kPa by briefly pressing the push button.

The pressure indication on the display can be zeroed by pressing the push button for a longer period of time.

3.2 Terms of use

3.2.1 Control panel and layout

ID Function Description

HP Hand pump For the purpose of making pressure

VC Volume controller For the purpose of accurate pressure settings

PS Pressure switch May or may not allow reduced pressure to test

connection 1 & leak test function

TEST 1 Test connection 1 Test point to which an UUT can be connected

TEST 2 Test connection 2 Test point to which an UUT can be connected

OFF / ON On / off switch Switching the Traqc-2 PCHP on or off

ZERO / UNIT Push button For the purpose of zeroing the display or changing the

measuring unit

PT Pressure limiting valve Measuring the pressure

PSS Pressure reference sensor Protecting the pressure against overpressure

Underlined components are visible

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 8 van 16

3.2.2 Display terms

Term Description

P test [bar/psi/kPa] Pressure test

3.2.3 Terms of the manual

Term Description

UUT Unit Under Test (the object that is being tested)

3.3 A closer look at the instrument

Battery connector

USB B

Under swivel flap

Pressure control valve

Two-way

pneumatic switch

Test terminals

On/off switch

Zero/unit switch

Display

Hand pump

Volume controller

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 9 van 16

4. Operation of the Traqc-2 PCHP

The supply pressure which must be connected should not exceed 10 bar.

The pressure to the test terminals, test 1 and test 2 , should never exceed the maximum pressure in

accordance with the type label.

4.1 On/off switch

To turn the instrument on and off.

4.2 Zero/unit switch

The instrument is equipped with a push button that can be used to:

•Changing the unit shown on the display. To do this, briefly press the push button.

•Zeroing the reading. To do this, press the push button for at least 3 seconds.

Storage compartment

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 10 van 16

4.3 Display

The display shows the following information:

-The battery status

-The test pressure

4.4 Two-way switch

The instrument is equipped with a two-way pneumatic switch with which two functions can be operated:

•The pressure from the pressure control valve is passed to the pressure sensor and to the test terminal

(test 1 or test 2).

•The test terminals (test 1 and test 2) and the pressure sensor are disconnected from the pressure source.

4.5 Pressure relief valve

The pressure relief valve allows to lower the applied pressure and allow the applied pressure to be reduced

completely up to 0 barg.

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 11 van 16

4.6 Hand pump

With the hand pump a pressure of up to 5 bar can be made.

4.7 Volume controller

The volume controller allows precise control of the pressure applied by the hand pump.

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 12 van 16

5. Using the Traqc-2 PCHP

5.1 Applying supply pressure to the UUT

•Turn on the instrument

•Press short the zero/unit button to set the desired unit (barg, psig or kPag)

•Connect the UUT to the test terminals (test 1 or test 2)

Using a polyflo connector

•Turn the selector switch in the forward direction

•Open and close the pressure relief valve

To release the current pressure

•Zero the pressure reading with the zero/unit button

Press and hold the zero/unit button for 3 seconds

•Generate pressure with the built-in hand pump

•Pressure is generated to the UUT and internal reference sensor

Fine-tune the pressure with the built-in volume controller

5.2 Performing a comparative measurement

•Operate the instrument as described in section 5.1

•Turn the selector switch in the blocking direction

•Wait for the pressure to stabilize

Depending on the environmental conditions, this may take some time

•Read the difference in pressure between the Traqc-2 PCHP and the UUT

5.3 Performing a leak test

•Operate the instrument as described in section 5.1

•Turn the selector switch in the blocking direction

The internal circuit of the Traqc-2 that is part of the leak test is as short as possible

•Wait for the pressure to stabilize

Depending on the environmental conditions, this may take some time

•Zero the pressure reading with the zero/unit button

Press and hold the zero/unit button for at least 3 seconds

•Read off the pressure history from the display

5.4 Measuring external pressure

If no pressure has to be generated, the pressure of an UUT can be measured with the Traqc-2 PCHP. The pressure

can be read off directly from the display. The test circuit and the Traqc-2 PCHP is as short as possible:

•Zero the pressure reading with the zero/unit button

Press and hold the zero/unit button for at least 3 seconds

•Connect the UUT to the test terminal (test 1 or test 2)

•Apply the pressure with the UUT

•Read off the pressure from the display

5.5 Charging the battery

The Traqc-2 PCHP is equipped with a Lithium-Ion battery, which must be charged regularly. When the instrument is

switched on, the status of the battery is visible on the display. The USB cable and the USB charging port are

provided. Always use the supplied cable or a similar cable with a maximum length of 0.8 meters.

The charging specifications are:

•Maximum 500mA

•5 VDC

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 13 van 16

6. Maintenance

6.1 Maintenance

Depending on the number of operating hours, the Traqc-2 PCHP should be maintained on a regular basis. We

recommend to contact our service department for tailor-made advice.

6.2 Calibration

The Traqc-2 PCHP is equipped with a pressure measuring cell, whose measurement accuracy decreases over time.

This is a natural process. To ensure that your Traqc-2 PCHP always displays the correct reading on the display, the

Traqc-2 must be calibrated regularly at Tradinco Instruments. The recommended frequency of the recalibration

(annually, every two years or else) depends, among other things, on the number of operating hours and the required

measurement accuracy. Please contact our service department for tailor-made advice.

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 14 van 16

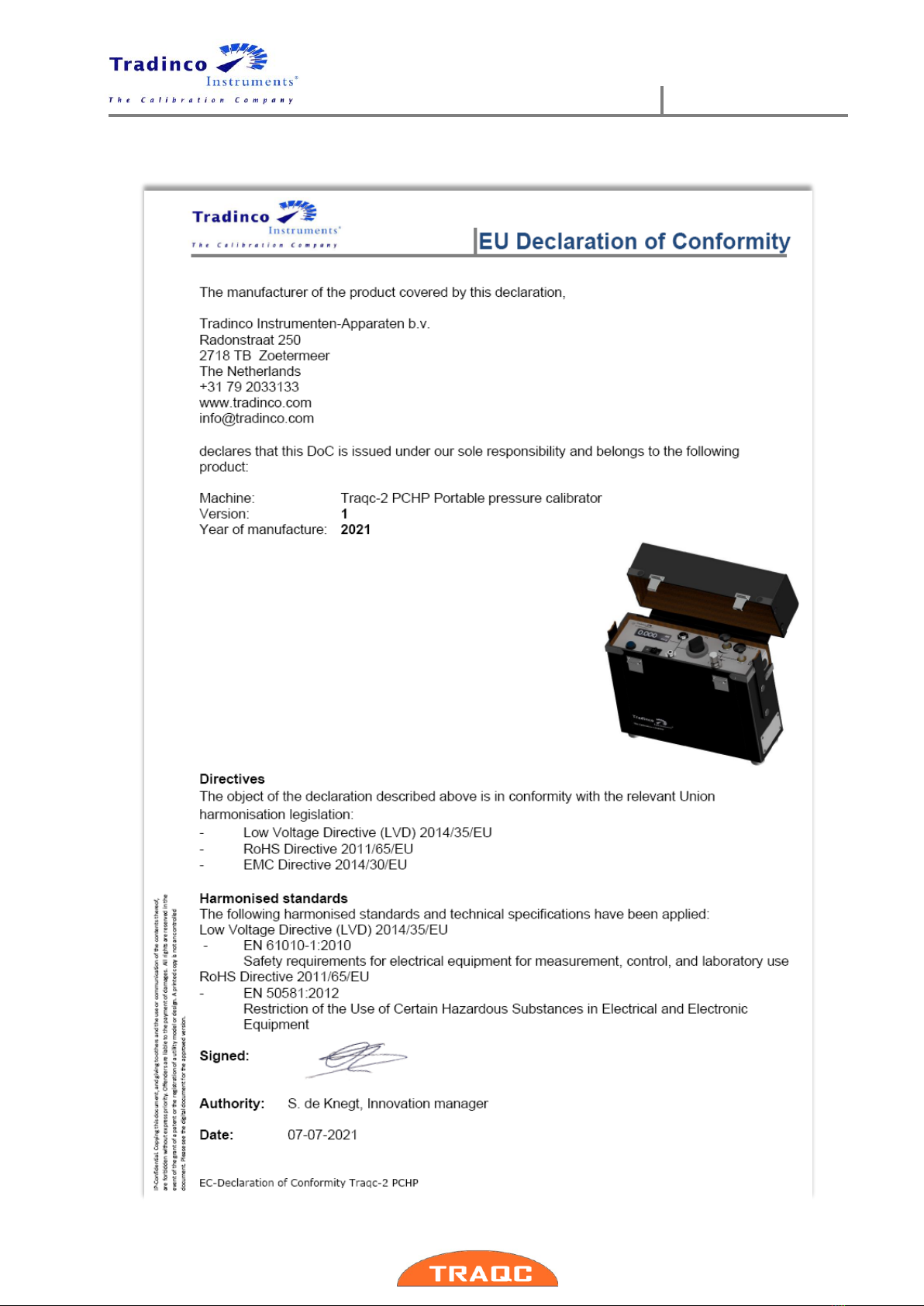

7. Specifications

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 15 van 16

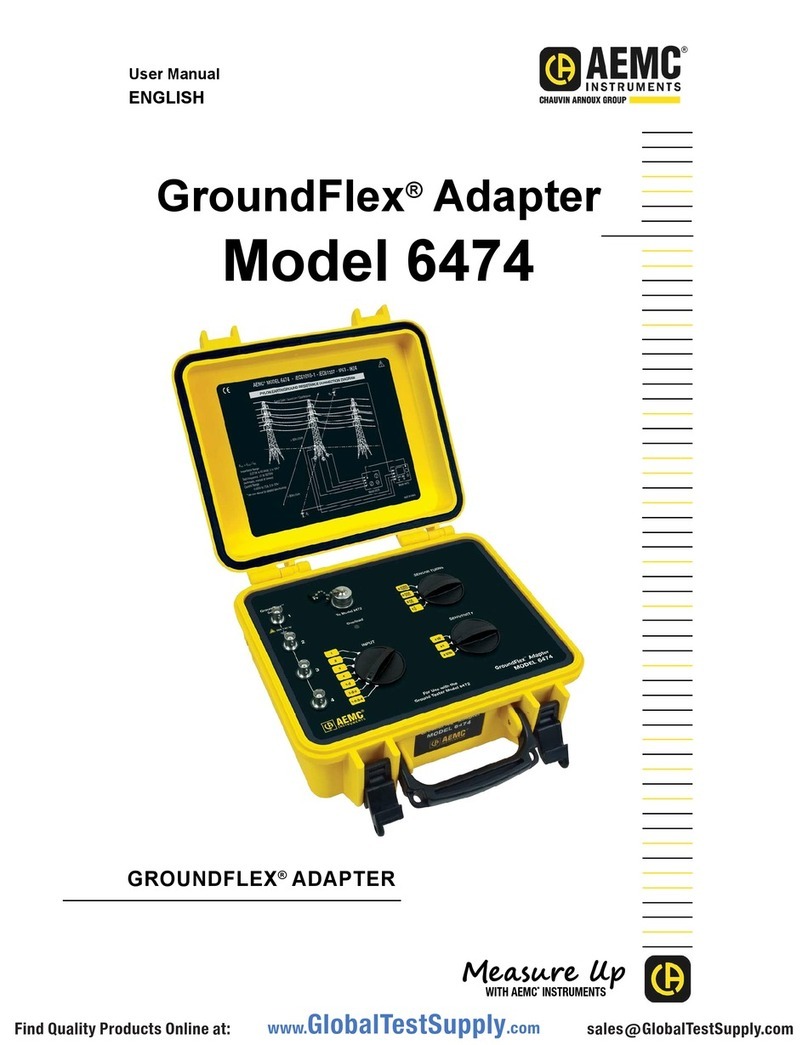

8. Declaration of conformity

User manual Traqc-2 PCHP

User manual Traqc-2 PCHP rev.0

Pagina 16 van 16

Tradinco Instrumenten-Apparaten b.v.

Radonstraat 250

2718 TB Zoetermeer

The Netherlands

+31 79 2033133

www.tradinco.com

Table of contents

Other Tradinco Test Equipment manuals

Popular Test Equipment manuals by other brands

Keysight Technologies

Keysight Technologies U3020AS62 User's and service guide

AEMC instruments

AEMC instruments GROUNDFLEX 6474 user manual

Huazheng

Huazheng HZRG-III user manual

Kurth Electronic

Kurth Electronic xDSL MultiTest KE3700 Guideline

Tektronix

Tektronix P6247 instructions

Hantek

Hantek CC-65 Operator's manual

Apera Instruments

Apera Instruments ORP60-Z instruction manual

Parker

Parker ServiceJunior Test Kit operating manual

Foxwell

Foxwell NT401 manual

National Instruments

National Instruments ECUTS-16000 user manual

Bosch

Bosch Professional GMS 100 M Original instructions

Tektronix

Tektronix 1S1 instruction manual