AEMC instruments GROUNDFLEX 6474 User manual

GroundFlex®Adapter

Model 6474

User Manual

ENGLISH

GROUNDFLEX®ADAPTER

WITH AEMC

®

INSTRUMENTS

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Copyright©Chauvin Arnoux®, Inc. d.b.a. AEMC®Instruments. All rights reserved.

No part of this documentation may be reproduced in any form or by any means (including electronic

storage and retrieval or translation into any other language) without prior agreement and written consent

from Chauvin Arnoux®, Inc., as governed by United States and International copyright laws.

This documentation is provided “as is,” without warranty of any kind, express, implied, or otherwise.

Chauvin Arnoux®, Inc. has made every reasonable eort to ensure that this documentation is accurate;

but does not warrant the accuracy or completeness of the text, graphics, or other information contained

in this documentation. Chauvin Arnoux®, Inc. shall not be liable for any damages, special, indirect,

incidental, or inconsequential; including (but not limited to) physical, emotional or monetary damages

due to lost revenues or lost prots that may result from the use of this documentation, whether or not the

user of the documentation has been advised of the possibility of such damages.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Statement of Compliance

Chauvin Arnoux®, Inc. d.b.a. AEMC® Instruments

certies that this instrument has been calibrated

using standards and instruments traceable to

international standards.

We guarantee that at the time of shipping your

instrument has met its published specications.

NIST traceable calibration is only possible when

the Model 6474 is connected to the Ground

Tester Model 6472. To obtain NIST calibration

(for a nominal charge), the instrument would

need to be returned to our facility along with

your Ground Tester Model 6472.

The recommended calibration interval for this

instrument is 12 months and begins on the date of

receipt by the customer. For recalibration, please

use our calibration services. Refer to our repair and

Serial #:

Catalog #: 2136.03

Model #: 6474

Please ll in the appropriate date as indicated:

Date Received:

Date Calibration Due:

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

TABLE OF CONTENTS

1. INTRODUCTION..................................................................5

1.1. PRECAUTIONS FOR USE ............................................................. 6

1.2. RECEIVING YOUR SHIPMENT .................................................... 6

1.3. ORDERING INFORMATION.......................................................... 7

1.3.1. Accessories............................................................................. 7

1.3.2. Replacement Parts ................................................................. 7

2. GROUNDFLEX®ADAPTER ...............................................8

2.1. CONTROL FEATURES .................................................................. 8

2.2. GROUNDFLEX®SENSOR ............................................................ 9

2.2.1. Calibration of GroundFlex®Sensors ..................................... 10

2.3. MEASUREMENTS IN AUTO MODE........................................... 12

2.3.1. Preparation of the GroundFlex®Adapter .............................. 12

2.3.2. Making a Measurement (Resistance of Legs)...................... 14

2.3.3. Other Measurements............................................................ 16

2.4. MANUAL MODE AND SWEEP MODE ....................................... 16

2.5. TOWER TESTING MEASUREMENT ......................................... 18

2.5.1. Choosing the positions for the H, S electrodes: ................... 18

3. SPECIFICATIONS .............................................................26

3.1. ELECTRICAL................................................................................. 26

3.2. MECHANICAL .............................................................................. 28

3.3. ENVIRONMENTAL ....................................................................... 28

3.4. SAFETY......................................................................................... 28

4. MAINTENANCE ................................................................29

4.1. CLEANING .................................................................................... 29

4.2. REPAIR AND CALIBRATION ...................................................... 29

4.3. TECHNICAL AND SALES ASSISTANCE .................................. 30

4.4. LIMITED WARRANTY ................................................................. 30

4.4.1. Warranty Repairs .................................................................. 31

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

1. INTRODUCTION

Thank you for purchasing an AEMC®Instruments GroundFlex®Adapter

Model 6474.

For the best results from your instrument and for your safety, you must

read the enclosed operating instructions carefully and comply with the

precautions for use. Only qualied and trained operators should use this

product.

Symbols & Denitions

Signies that the instrument is protected by double or reinforced insulation.

CAUTION - Risk of Danger! Indicates a WARNING. Whenever this symbol is

present, the operator must refer to the user manual before operation.

Indicates a risk of electric shock. The voltage at the parts marked with this

symbol may be dangerous.

Ground/Earth

Indicates Important information to acknowledge.

In the European Union, this product is subject to a separate collection system

for recycling electrical and electronic components in accordance with directive

WEEE 2002/96/EC.

Denition of Measurement Categories

CAT IV corresponds to measurements performed at the primary electrical supply

(< 1000 V).

Example: primary overcurrent protection devices, ripple control units, and

meters.

CAT III corresponds to measurements performed in the building installation at the

distribution level.

Example: hardwired equipment in xed installation and circuit breakers.

CAT II corresponds to measurements performed on circuits directly connected to

the electrical distribution system.

Example: measurements on household appliances and portable tools.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

6 GroundFlex®Adapter Model 6474

1.1. PRECAUTIONS FOR USE

These safety warnings are provided to ensure the safety of personnel. Please

read and comply with these precautions:

This instrument is protected from accidental voltages of not more than

50V with respect to earth in measurement CAT IV. The guaranteed level of

protection of this equipment may be compromised if used in a manner not

specied by the manufacturer.

Safety is the responsibility of the operator.

All metal objects or wires connected to the electrical system should be

assumed to be lethal until tested. Grounding systems are no exception.

Never exceed the maximum rated voltage and current, and the

measurement category.

Never exceed the protection limits, and always comply with the conditions

and place of use, indicated in the specications.

Do not use the instrument or its accessories if they appear damaged.

Use accessories that have overvoltage category and service voltages

greater than or equal to those of the instrument (CAT IV 50V). Use only

accessories that comply with safety standards (IEC 61010-2-031 & 32).

Wear the appropriate protective gear (insulating boots and gloves).

Check that no terminal is connected and the switch is set to OFF before

opening the device.

Use only the charging unit supplied with the instrument to recharge the

battery.

Troubleshooting and metrological verication procedures must only be

performed by qualied, approved personnel, or the factory.

NOTE: The potentials on the various rods used for an earth measurement

may be dierent if a nearby electrical installation is defective or certain

weather conditions prevail (thunderstorms). It is up to the operator to decide

whether to continue or postpone measurements in these situations.

1.2. RECEIVING YOUR SHIPMENT

Upon receiving your shipment, make sure that the contents are consistent with the

packing list. Notify your distributor of any missing items. If the equipment appears

to be damaged, le a claim immediately with the carrier and notify your distributor

at once, giving a detailed description of any damage. Save the damaged packing

container to substantiate your claim.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

GroundFlex®Adapter Model 6474 7

1.3. ORDERING INFORMATION

NOTE: The GroundFlex®Adapter Model 6474 only operates in

combination with the Ground Tester Model 6472 Kit - 500 ft.

GroundFlex®Field Kit (Model 6472 and 6474) .............................Cat. #2136.03

Includes: (Ground Tester Model 6472 Kit-500 ft (Cat #2135.54)); Model 6472,

(1) carrying bag, (2) 500 ft. color-coded leads on spools (red/blue), (2) 100 ft.

color-coded leads (hand tied, green/black), (1) 30 ft. lead (green), (2) 5 ft. color-

coded leads (red/blue), 100/240 V power adapter with US power cord, optical

USB cable, (4) T-shaped auxiliary ground electrodes, set of (5) spaded

lugs, (1) 100 ft. tape measure, rechargeable NiMH battery pack, USB stick with

DataView®software, ground tester workbook and user manual. GroundFlex®

Adapter Model 6474, (4) GroundFlex®sensors (5 m), (12) color-coded rings,

connection lead, (2) extension leads on H reel (black/green) with color-coded

alligator clips, (1) extra green and black alligator clips, (2) BNC extension leads,

calibration loop, (3) C-clamps, set of (2) reel caddy’s, (1) inverter 12 VDC to 120 VAC

watt (vehicle use), carrying case with wheels and handle for meters and user

manual.

1.3.1. Accessories

Bag #6 - Carrying Bag for Ground Kits............................................ Cat. #2119.82

Tape Measure - AEMC®Instruments (100 ft)................................... Cat. #2130.60

Set of two, 14.5 in T-shaped Auxiliary Ground Electrodes .............. Cat. #2135.39

Optical USB Cable ........................................................................... Cat. #2135.41

1.3.2. Replacement Parts

Connection Lead for Model 6472/6474............................................ Cat. #2135.75

One BNC (15 m/50 ft) Extension Lead............................................ Cat. #2135.76

Set of 12, GroundFlex®Rings

(red, yellow, brown, orange) ............................................................. Cat. #2135.77

Green Extension Lead ..................................................................... Cat. #2135.78

Black Extension Lead ...................................................................... Cat. #2135.79

Set of 3, C-clamps ...........................................................................Cat. #2135.80

Calibration Loop ............................................................................... Cat. #2135.82

Carrying Case ..................................................................................Cat. #2135.83

One GroundFlex®(5 m/16 ft) Sensor............................................... Cat. #2135.92

Safety Alligator Clip (black)..............................................................Cat. #5000.99

Safety Alligator Clip (green) ............................................................. Cat. #5100.06

GroundFlex®Sensor 10 m ............................................................... Cat. #2135.87

Order Accessories and Replacement Parts Directly Online

Check our Storefront at www.aemc.com/store for availability

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

8 GroundFlex®Adapter Model 6474

2. GROUNDFLEX®ADAPTER

2.1. CONTROL FEATURES

50V CAT IV

1-2-3-4

1-2-3

1-2

1

2

3

4

For Use with the

Ground Tester Model 6472

GroundFlex

®

Sensor

SENSOR TURNS

SENSITIVITY

To Model 6472

Overload

INPUT

1

2

3

4

GroundFlex®Adapter

MODEL 6474

2

4

1

6

5

3

1. Inputs 1 through 4 for GroundFlex®sensors

2. Connector for connection lead to the Ground Tester Model 6472

3. OVERLOAD indicator

4. SENSOR TURNS selector: 1, 2, 3 or 4

5. SENSITIVITY selector: x10, x1 or x1/10

6. INPUT SELECTION: 1, 2, 3, 4, 1-2, 1-3 or 1-4

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

GroundFlex®Adapter Model 6474 9

2.2. GROUNDFLEX®SENSOR

The GroundFlex®sensors are placed around a conductor (tower leg or pole) and

closed using a screw connector, which is part of the sensor. This closed loop is

then used to make a contact-free measurement of the current owing in the con-

ductor (leg) it is wrapped around.

These sensors are current measurement clamps but are able to enclose objects

that are much larger.

GroundFlex®sensors are available in lengths of up to approx 24 ft (8 m) and can

be placed around objects (such as tower legs) up to in approx 8ft diameter (2.7 m).

50V CAT IV

1-2-3-4

1-2-3

1-2

GroundFlex

®

Sensor

To Model 6472

Overload

INPUT

1

2

3

4

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

10 GroundFlex®Adapter Model 6474

2.2.1. Calibration of GroundFlex®Sensors

Calibration is necessary for a new sensor, one that is no longer identied when a

sensor has been replaced, or more than 2 lengths of extension cable is used. The

calibration coecients are then stored in the Model 6474.

WARNING: Do not move or touch the GroundFlex®sensor or the

calibration loop during the calibration. This could cause errors.

Start by identifying each sensor using the identication rings that are supplied with

the Model 6474: (1) Brown (2) Red (3) Orange (4) Yellow

• Connect the calibration loop between terminals H and E of the Model 6472.

• Connect the Model 6472 and 6474 together using the connection cable.

• Connect the GroundFlex®sensor with the Brown ring to Input 1 of the Model

6474, the one with the Red ring to Input 2, the one with the Orange ring to

Input 3, and the one with the Yellow ring to Input 4.

• Coil the GroundFlex®sensor four times around in the calibration loop and

close it using its screw connector. Place the connector as far as possible from

the calibration device.

6472 6474

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

GroundFlex®Adapter Model 6474 11

1. Set the switch of the 6472 to SET-UP.

2. Set the SENSOR TURNS switch to 4.

3. Set the SENSITIVITY switch to x1.

4. Set the INPUT SELECTION switch to 1.

1-2-3-4

1-2-3

1-2

1

2

3

4

SENSOR TURNS

SENSITIVITY INPUT

5. Press the Hz/OPTIONS button 5 times.

The device starts by comparing the current IInt injected by the device into the

calibration loop to the current IAmeasured by the GroundFlex®sensor. If they

are dierent, the "CAL" symbol blinks to recommend a calibration.

x 5

4

H

E

S

x

11

AUTO

mA

m A

NOTE: To avoid measurement errors, do not touch the GroundFlex®

sensor or the calibration loop during the calibration.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

12 GroundFlex®Adapter Model 6474

6. To start the calibration, press 2nd + START.

7. The device calculates and stores a calibration coecient for the GroundFlex®

sensor connected to channel 1.

4

H

E

S

x

11

AUTO

mA

m A

This operation must be repeated for channels 2, 3 and 4; the INPUT SELECTION

switch must be set to the corresponding position each time.

The calibration values are now stored into memory.

After calibration, the GroundFlex®sensors must always be connected to their

respective channels.

NOTE: Always connect the same sensor to the same input..

2.3. MEASUREMENTS IN AUTO MODE

2.3.1. Preparation of the GroundFlex®Adapter

The GroundFlex®Adapter Model 6474 is designed to be used only with the Model

6472 device. The two instruments must be connected using the special connection

cable supplied. The Model 6474 has no ON/OFF button, and is powered only by

the Model 6472, via this connection cable.

The Model 6474 is intended primarily to measure the current that ows through

a high-voltage tower to the ground. You can wrap up to 4 legs of the towers each

with a GroundFlex®sensor and measure the current owing to earth through each

of the legs or through several legs.

1. Set the rotary function switch to GroundFlex®on the Model 6472.

When you connect the GroundFlex®Adapter Model 6474 to the 6472, a self-

test will begin. During this test, the OVERLOAD check light on the 6474 is lit.

2. Connect the required number of sensors to channels 1, 2, 3, and/or 4.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

GroundFlex®Adapter Model 6474 13

NOTE:

• The sensors have arrows to indicate a direction.

• All sensors should face the same direction

(clockwise or counter-clockwise around the tower legs)

• All sensors should have the same number of wraps.

• Sensors should encircle both leg AND ground system.

6474

To the Model 6472

3. On the Model 6474, set the INPUT selection switch accordingly. You can mea-

sure the current owing through one GroundFlex®sensor (1, 2, 3, or 4), or

through several sensors (1, 2 or 1, 2, 3), or through all of the sensors (1, 2, 3,

4).

4. Select how many times the sensor is wrapped around the conductor to be

measured (from 1 to 4 turns) using the SENSOR TURNS selection switch.

NOTE: To increase measurement sensitivity, we recommend when

possible, wrapping a maximum number of turns (up to 4) around the

structure.

5. Set the SENSITIVITY switch to the desired sensitivity: x1/10, x1, or x10. The

choice of sensitivity depends on the expected current value. As a precaution,

always start with the lowest sensitivity, x1/10, and increase it as needed.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

14 GroundFlex®Adapter Model 6474

2.3.2. Making a Measurement (Resistance of Legs)

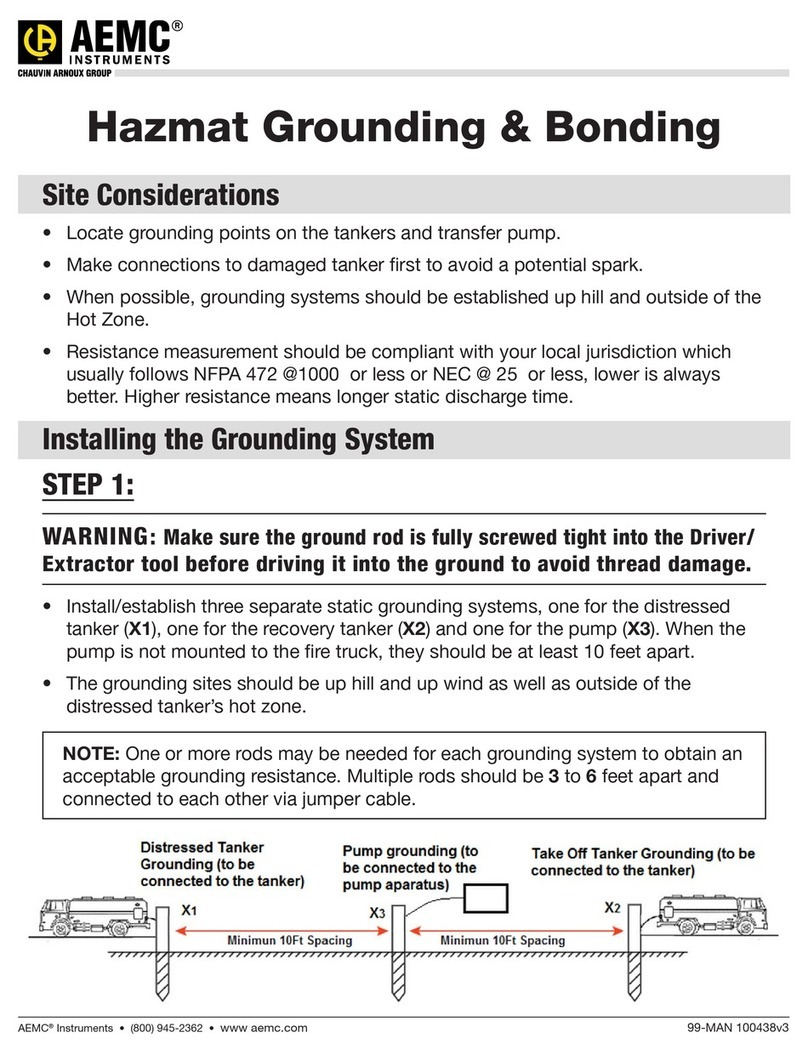

1. Place auxiliary electrodes H (Z) and S (Y) on opposite sides of the tower, as

far away as possible (100-150 ft) and, if possible, perpendicular to the high-

voltage line (depth is not important). This will eliminate interference with the

measurement by stray voltages or currents induced under the high-voltage

line.

NOTE: The H (Z) and S (Y) electrodes can be placed in the same direction

if necessary. In this case, the S (Y) electrode should be placed at 62% the

distance of H (Z).

2. In order to avoid electromagnetic interference, it is best to unwind the full

length of each cable from the reel, to keep the cables as far apart as possible

on the ground, taking care not to form loops, and to avoid placing the cables

near or parallel to metallic conductors (cables, rails, fences, etc.). Eects of

interference are measured in milli-ohms.

3. Connect these auxiliary electrodes to the terminals H (Z) and S (Y) on the

Model 6472's front panel.

4. Important: The terminals ES (Xv) and E (X) must be connected to a conduct-

ing metallic part of the tower located above the GroundFlex®sensors. This

ensures measurement of the current owing downward and towards the earth

(otherwise, you would measure the current owing upward, from the earth to

the top of the tower).

This will tell the condition of the overhead ground conductor.

5. Connect the required number of GroundFlex®sensors to channels 1, 2, 3,

and/or 4 (the channels for which they are calibrated) and place the Ground-

Flex®sensors around the legs of the tower.

NOTE: The direction of coiling of the sensors around tower legs have no

eect on the measurement, but all of the GroundFlex®sensors must be

coiled in the same direction and have the same orientation (check arrow

direction on the sensor) and they must all have the same number of

turns. Sensors should encircle both leg AND ground system.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

GroundFlex®Adapter Model 6474 15

E

S

H

RS

RH

ES

1

2

3

4

6474

6472

Overhead earth wire

High-voltage

lines

4 GroundFlex®sensors

connected with the

same orientation

WARNING: If the GroundFlex®Adapter Model 6474 is connected to the

earth tester, the earth potential connected to the terminals E (X) and ES

(Xv) will also be present at the BNC connectors of the GroundFlex®sensors

and at the connecting cable between the adapter and tester. Whenever any

doubt exists about this earth potential, the user should proceed to a voltage

measurement using the S (Y) and ES (Xv) terminals of the tester.

1. Set the 3 switches (Inputs, Turns and Sensitivity) of the GroundFlex®Adapter

according to the connection made.

2. Start the measurement by pressing the START/STOP button.

1

AUTO

k

Ω

mA

V

H

S

ES

E

S

x

12

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

16 GroundFlex®Adapter Model 6474

To display the measurement parameters, press DISPLAY several times.

The device displays the following parameters:

RSEL, US-ES and its frequency, ISEL, R-Act (RPASS), U-Act (US-ES and its frequency,

UH-E and its frequency), I-Act (ISEL and its frequency).

To measure the resistances of electrodes H (Z) and S (Y), or if the resistance of

the electrodes is too high, start the measurement by a long press (approx 2 sec) of

the START/STOP button (you will hear a 2nd beep).

RH, RS, UH-E, IH-E will be displayed.

2.3.3. Other Measurements

As explained in Step 4 on the previous page, terminals ES (Xv) and E (X) must be

connected to a metallic part of the tower above the GroundFlex®sensor in order to

measure the current owing ISEL downward through the sensor towards the earth

to measure ground resistance of the leg.

If connections ES (Xv) and E (X) are placed below the GroundFlex®sensor, the

latter measures the current owing towards the top of the tower via the overhead

ground conductor at its top, and you can in this way evaluate the quality of this

overhead ground conductor.

You can even make this measurement without moving the contacts of ES (Xv)

and E (X) on the tower by simply passing the 2 connecting cables through the

GroundFlex®sensor. The current in connecting cable E(X) and the current through

the leg of the tower then cancel each other out.

You can also measure any leakage currents (I-Act) owing through each leg of

the tower in normal operation of the high-voltage line. If you nd dierent leakage

currents in each leg, but they cancel out when added together, you can conclude

that these currents, induced by the rotating eld of the high-voltage lines, indicate

an earthing fault of the tower via the overhead ground wire at the tip of the

mast.

2.4. MANUAL MODE AND SWEEP MODE

Use the Hz/OPTIONS button and ►button to change to MANUAL mode. The fol-

lowing parameters can be modied:

• 128Hz blinks Change the test frequency

• Test voltage blinks Switch between 10, 16, 32 and 60V

You can also perform a frequency sweep and a smoothing.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

GroundFlex®Adapter Model 6474 17

In the sweep mode, the measurements can be made at frequencies up to 5kHz.

On a single tower, frequencies in the order of 5kHz do not always entail inductive

eects, but the "current loops" formed by the adjacent towers and the return chan-

nel through the ground may result in inductances that can be detected only at high

frequencies.

An equivalent diagram of the components forming this circuit is as follows:

Point of injection

of the current

Overhead

earth wire

LLL

Rpylon

Next pylon

to the left

Pylon

measured

Next pylon

to the right

A measurement in sweep mode (SWEEP) of an installation like this having 10

towers gives the following results assuming an earth resistance Rpylon of 10Ωfor

each tower and an inductance L of 550µH for the link via the overhead ground

conductor at the tip of the towers:

Impedance of the towers

0

2

4

6

8

10

12

14

16

0 1000 2000 3000 4000 5000

F (Hz)

Z (ohm)

Measurement of a tower earth impedance with GroundFlex®

sensors

Conventional 4 pole measurement

Measurement into the top of a tower (iterative network impedance)

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

18 GroundFlex®Adapter Model 6474

2.5. TOWER TESTING MEASUREMENT

1. Connect the green Current (E) and black Voltage (ES) test leads to the ground-

ing system to be tested using separate cables. Connection points should be

side by side and above the GroundFlex®(Rogowski) coil when testing tower

leg resistance and/or impedance.

Figure 1

2. Wrap the GroundFlex®coils around the tower's leg(s). By increasing the num-

ber of turns around the tower's leg(s), the resulting measurements will be more

robust. All coils must have the same number of turns around each tower leg.

3. Install all coils in the same rotational direction, either clockwise or counterclock-

wise. The coax cables on the GroundFlex®sensors have arrows to indicate the

rotational direction that must be consistent between tower legs. On towers with

3 or 4 legs, the sensors must be in sequence from one leg to the next.

Figure 2

2.5.1. Choosing the positions for the H, S electrodes:

1. If possible, position the H and S electrodes 90° to the High Voltage (HV) line,

and place one to the left and the other to the right with respect to the HV

transmission line. If this is not possible, stay at least 30° oparallel to the HV

line. The minimum distance should be 150 – 300 ft (50-100m). Never place an

electrode within the minimum distance from the HV line and/or parallel to the

HV line.

2. Connect the H electrode using the red (H) lead and the S electrode using the

blue (S) lead (see Figure 2).

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

GroundFlex®Adapter Model 6474 19

NOTE: The resistance for the Hand Selectrodes to earth should each

be below 1 kΩto ensure good test results.

Figure 3

3. For the most accurate measurements, roll the cable completely out to elimi-

nate any inductance problems in locations with high overhead energy from the

HV line. Normally errors are in the milliohm region when the cables are not

fully removed from the spool.

4. Conrm that the umbilical cable connection between the 6472 and 6474 is

secure. Check the position of the rotary switches (Input, Sensor Turns and

Sensitivity) on the 6474 to be sure they match the test requirements (see

Figure 4).

5. Make sure the number of turns between tower legs are the same. The number

of turns must correspond to the number of turns used on the installed Ground-

Flex®coils on each tower leg.

Figure 4

6. Use input switch position "1-2-3-4" for measurement of the total pylon earth

current on four leg towers. Use the corresponding switch position for 2 (1-2)

and 3 (1-2-3) leg towers.

7. Start the test with x10 amplication.

8. Turn the rotary switch on the model 6472 to the GroundFlex®position. The

6474 amplier will turn on after the 6472 is powered on and the calibration of

the connected GroundFlex®sensors will be veried. The Overload LED will

come on for a few seconds during power up. If this LED is ashing continu-

ously and the 6472 is beeping continually, then the current in the GroundFlex®

sensor(s) are too high for the selected amplication. Reduce to X1 and then

to X1/10 if necessary. If it is still present in the 1/10 position, then reduce the

number of turns of the GroundFlex®sensors.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

20 GroundFlex®Adapter Model 6474

First check (see Figures 5, 6, 7, and 8):

1. Press the DISPLAY button until U-Act. and US-ES or UH-E is shown. U-Act.

refers to live actual voltage. U S-ES equals measured voltage between S and

ES. Disturbance voltage measurements on the S Probe and the H Auxiliary

electrode will run continuously as long as a test has not been initiated with the

START button.

2. Press the DISPLAY key again until U-Act. and UH-E is shown. UH-E equals

the measured voltage between H and E. The frequency of US-ES or UH-E

appears when the corresponding voltage is higher than 0.1V. The measured

voltage is caused by the current owing through the tower into the Earth.

3. Check if the values for UH-E and US-ES are equal. When UH-E equals US-

ES, the electrodes are placed far enough from the potential inuence of the

tower legs.

4. If one of the values is smaller than the other value, you should reposition the

electrode that shows the smaller voltage further away from the HV-line and

check US-ES and UH-E again.

5. Press the START-button when both measurements are equal to each other

for a reliable active measurement. When both US-ES and UH-E are close to

zero, then the HV-line is not in service or the overhead ground conductor is

completely corroded or disconnected. In this case, the total pylon current will

be also nearly zero.

6. Press the DISPLAY button until ISEL appears. This is the total pylon earth

current and is measured by the 4 GroundFlex®sensors (channels 1-2-3-4

selected for a 4 leg tower).

Figure 7 (model 6472)

Figure 6

Figure 5

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com

Other manuals for GROUNDFLEX 6474

2

This manual suits for next models

1

Table of contents

Other AEMC instruments Test Equipment manuals

AEMC instruments

AEMC instruments 3640 User manual

AEMC instruments

AEMC instruments 6422 User manual

AEMC instruments

AEMC instruments 6418 User manual

AEMC instruments

AEMC instruments 8510 User manual

AEMC instruments

AEMC instruments PMR-1 User manual

AEMC instruments

AEMC instruments CA7027 User manual

AEMC instruments

AEMC instruments 6416 User manual

AEMC instruments

AEMC instruments 2121.04 User manual

AEMC instruments

AEMC instruments 6470 User manual

AEMC instruments

AEMC instruments CA7028 User manual