Trafimet Sacit Pantera Operating instructions

PANTERA AIR SYSTEM

sacit.com

DA Brugs- og vedligeholdelsesmanual

DE Bedienungs- und Wartungsanleitung

EN User and maintenance manual

ES Manual de uso y manutención

FI Käyttö- ja huolto-ohje

FR Manuel d’utilisation et d’entretien

IT Manuale d’uso e manutenzione

NL Gebruikers- en onderhoudshandleiding

NO Bruker- og vedlikeholdsveiledning

PL Instrukcja obsługi i konserwacji

PT Manual de usuário e manutenção

SV Användar- och underhållshandbok

TR Kullanım ve bakım kılavuzu

ZH 用户和维护手册

2

1.

3.

2. 1.

2.

3.

4.

5.

6.

7.

8.

1.

3.

8.

12.

4.

9.

13.

5.

10.

14.

6.

11.

15.

7.

11.

2.

USER AND MAINTENANCE MANUAL

3

4.

5.

6. 7.

1.

1.

1. 1.

2. 2.

3.

3.

2.

2.

5.

4.

4

8.

9.

1.

1.

1. 1.

2. 2.

2. 3. 4.

3.

5.

7.

2.

4.

6.

8.

10. 11.

USER AND MAINTENANCE MANUAL

5

DECLARATION OF CONFORMITY

http://shop.tramet.com/it/Dcue-TrametGroup-Adf3.html

Tramet Group Spa, a duly registered Italian Manufacturing Company, located in Via del

Lavoro, 8 36020 Castegnero (VI), hereby declares that products identied and described

on these pages are in conformity with the Regulation: EU 2016/425 and the standards

EN 175:1997, EN 379:2009, CSA Z94.3, ANSIZ87.1, EN 12941: 1998 +A1:2003+A2:2008

TH3 R SL

WARNINGS

Please read carefully the user and

maintenance manual before operating.

Taking into use and all maintenance

work must be implemented and carried

out by qualied personnel only. The

expression ‹qualied personnel› refers

to operators working in compliance

with the above-mentioned provisions

and standards; said operators must

recognize and properly evaluate

possible risks/dangers related to the

use of welding torches.

Dispose of this product responsibly

after use. All used parts and equipment

must be properly recycled according

to the local requirements/ regulations.

BEFORE WELDING

Make sure to remove any additional

protection foil from both sides of the

protection lens.

MAINTENANCE

Regularly replace the cracked/

scratched protection cover lens.

USE

Never place the helmet or the lter on

hot surface.

Use only within the temperature range

of -10°C (14°F) – +60°C (140°F)

SAFETY PRECAUTIONS

Fumes are hazardous for health.

Operate under a hood or in ventilated

areas only.

Do not immerse the auto-darkening

lter in water. Do not expose the lter

to liquids and protect it from dirt.

Do not modify or implement structural

changes to the helmet.

Keep the torch turned away from

yourself and others.

If the welding lter doesn’t darken

when the arc is ignited, stop welding

immediately and contact your

supervisor or your dealer.

Pack contents

PANTERA Autodarkening mask (see g. 1)

CODE DESCRIPTION

LVE000238 Outside protection plate 114x133x1 mm 5

LVE000237 Inside protection plate 106x66x1 mm 5

VCE000010 Ergonomic headgear 1

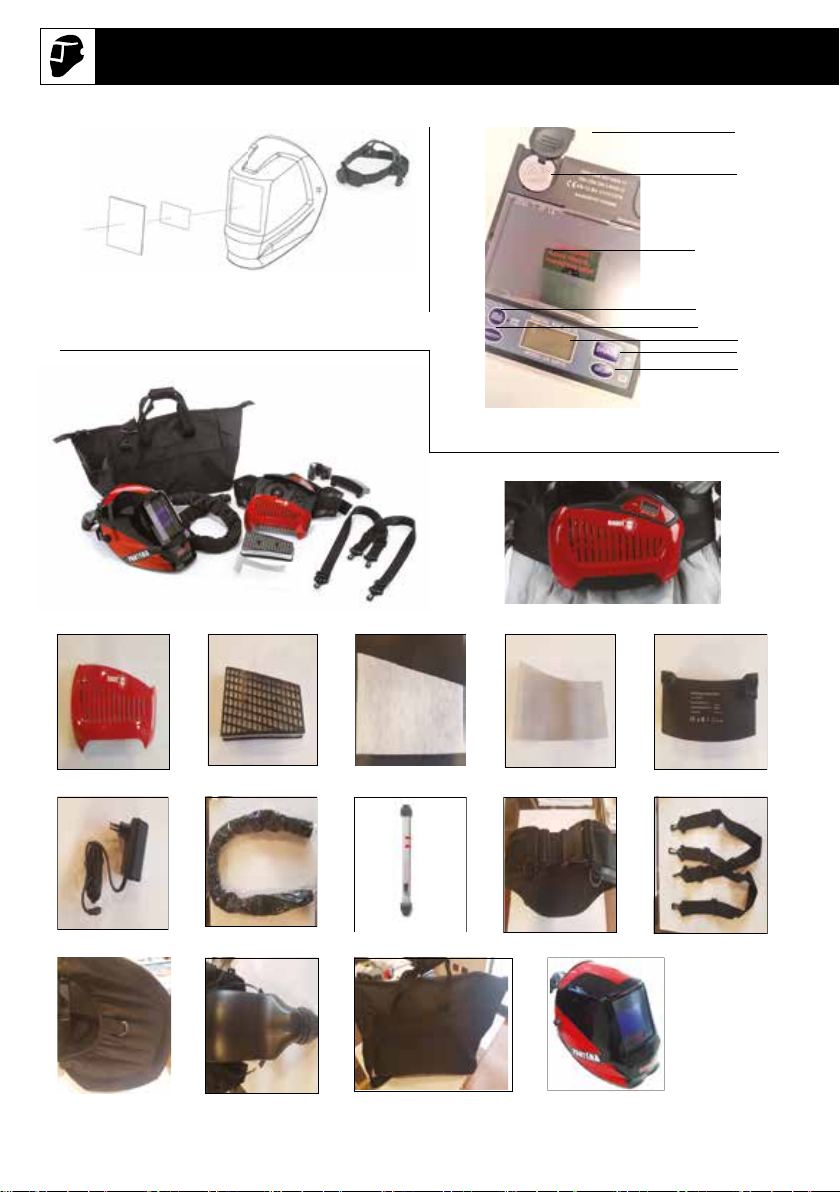

LCD Filter included (see g. 2)

1. Battery cover (2 pcs)

2. Battery (2 pcs)

3. Display

4. WELD/GRING button

5. SENSITIVITY button

6. LCD display

7. SHADE button

8. DELAY button

6

EN USER AND MAINTENANCE MANUAL

Introduction

This manual is made of 2 parts:

1 - “PANTERA” AUTODARKENING MASK

2 - COMPLETE “PANTERA AIR SYSTEM”

1. PART 1 - “PANTERA” AUTODARKENING MASK

1.1 Summary

The PANTERA autodarkening welding mask is a new generation welding helmet integrating some

of the most innovative technologies such as digital LCD, optoelectronics detection with 4 sensors

and very wide viewing area, solar power and litium batteries, microelectronics, and True Color ADF

technology.

The PANTERA automatic welding mask is equipped with an ADF lter with digital regulations, for an

easy and fast adjustment of all functions.

The main functions are: MIG/MAG, TIG, PLASMA CUTTING, GOUGING and GRINDING.

The mask ergonomy has been studied to guarantee an excellent protection of head/neck/ears.

WARNING

Read and understand all instructions before using.

• Be sure that the DIN of the welding mask lter is the correct shade number for your application.

• The PANTERA autodarkening welding mask and lter are not suitable for overhead welding

applications, laser welding, or laser cutting applications.

• The PANTERA autodarkening welding mask is designed to protect the eyes and face from

sparks, spatter, and harmful radiation under nor-mal welding conditions.

• The PANTERA autodarkening welding mask will not protect against explosive devices or

corrosive liquids. Machine guards or eye splash protection must be used when these hazards are

present.

• Impact resistant, primary eye protection, spectacles or goggles that meet current ANSI

specications, must be worn at all times when using this welding helmet.

• Avoid work positions that could expose unprotected areas of the body to spark, spatter, direct

and/or reected radiation. Use adequate protection if exposure cannot be avoided.

• Before each use, check that the protection plates are clean and that no dirt is covering the

sensors on the front of the lter.

• Inspect all operating parts before each use for signs of wear or damage.

• Any scratched, cracked, or pitted parts should be replaced immediately.

• Do not make any modications to either the welding lters or helmet, other than those specied in

this manual.

► Do not use any replacement parts other than those specied in this manual,

Unauthorized modications and replacement parts will void the warranty and expose the

user to the risk of personal injury.

►If this lens does not darken when the arc is ignited, stop welding immediately and contact

the manufacturer’s representative.

►Do not immerse this lter in water: this model is not water proof.

►Do not use any solvents on any lter or helmet components.

► The recommended operating temperature range for welding lter is -5°C (23°F) – +55°C

(131°F). Do not use this device beyond these temperature limits.

• Failure to follow these warnings and/or failure to follow all of the operating instructions could

cause severe personal injury.

7

1.2 Characteristics

PANTERA automatic welding helmet is equipped with an auto-darkening lter with 4 sensors, digital

display and a wide view area.

Before activation the lter shade is DIN 4, so that the operators may clearly observe the work surface

clearly.

Once the arc is ignited, the lter darkens automatically. When the arc goes out, the lter will becomes

transparent again. The mask is equipped with DIN 9-13 darkness adjusting. The switching time from

light to dark is about 0.08 ms. The switching time from dark to light (DELAY) may be set up within 0.1-

0.9 second. The operator can also adjust the SENSITIVITY and select the operation method WELD or

GRIND.

PANTERA automatic welding mask gives the operators complete protection against UV/IR even in the

lter’s light state. The UV/IR protection level is up to DIN15 at all times. The power is provided by solar

cells and replaceable battery.

The mask is equipped with 4 sets of photo sensors to sense arc light. In addition, the mask is also

provided with an outer protection plate made of high polymer materials.

The plate is wear-resistant, thermostable, and has no dregs-sticking, thus a very long service life.

1.3 Main specications

Filter dimension 114 x 133 x 9.5 mm

View area 100 x 60 mm

Light shade number DIN 4

Dark shade number DIN 9-13

UV/IR protection up to up DIN15

Time from light to dark 0.08 ms

Time from dark to light 0.1-0.9 s

Sensitivity adjustable stepless

Power supply solar cells & replaceable battery

Operating temperature -5°C (23 °F) – +55°C (131°F)

Warranty 2 years as per sales conditions

Grinding function Yes

Optical classication 1/1/1/1

1.4 Method of operation

1. Assemble the mask as shown in the construction and assembly gure.

2. The power supply of the PANTERA auto-darkening mask is provided by solar cells with

two lithium batteries.

3. Darkness selection Adjust to the optimum darkness as needed. Press the SHADE button

to choose the Shade number range 9-13 according to the current welding process.

4. Delay time selection Press the DELAY button to choose the Delay option from 1 to 5,

0.1~0.9 second.

5. Sensitivity selection Press the SENSITIVITY button to choose the Sensitivity option to

alter the sensitivity to ambient light.

Turn to 1: The photosensitivity changes to be lower. Suitable for high amperage welding

and welding in bright light conditions (lamp light or sun light).

Turn to 5: The photosensitivity changes to be higher. Suitable for steady arc process such

as TIG welding.

8

EN USER AND MAINTENANCE MANUAL

6. Because the shapes of users’ heads vary from person to person. The work position and

the observing angle is dierent, operator may adjust the headband adjusting button 15 and

the segmental positioning plate 16 to select an appropriate observing angle.

By pushing and turning the adjustment screw 11, the perimeter of the head band can be

adjusted.

7. Grind function Press the WELD/GRIND button to choose the Grind option. The grind

ash light will ash at the same time. To avoid any harm to eyes, do not conduct welding

while on grinding mode.

8. Battery indicator in the up right corner there is a battery indicator. We suggest replacing

the battery when the indicator ashes.

1.5 Points for attention

1. Make sure that the helmet is used in correct condition and check it according to WARNING

content.

2. There is a liquid crystal-valve in the lter. Although it has inner and outer protection plate, it

is important to avoid heavy knocks to keep it intact.

3. The outer protection plate of helmet should be periodically inspected and cleaned to keep

it clear. In case break, crack, pitting or more serious inuencing vision eect occurs, the

plate must be replaced.

4. In order to operate more eciently and safely, please select correct dark shade number.

5. If the lter is not a water-proof model, please pay attention to protect it from water.

6. Make sure that the arc light can be completely received by the sensor, if not, the lter will

be in light state or unstable in darkness and may cause injury to the user.

7. Please use the automatic lter at temperature between -10°C (14°F) – +55°C (131°F).

8. Please don’t disassemble the lter, any problems arising, please contact our company or

agent.

1.6 Marking

4Clear DIN level

9-13 Shade DIN level

SA Manufacturer

1Optical class

1Diusion of light class

1Variations in luminor transmittance class

1Angular dependance class

EN379 CE Directive reference and conformity mark

9

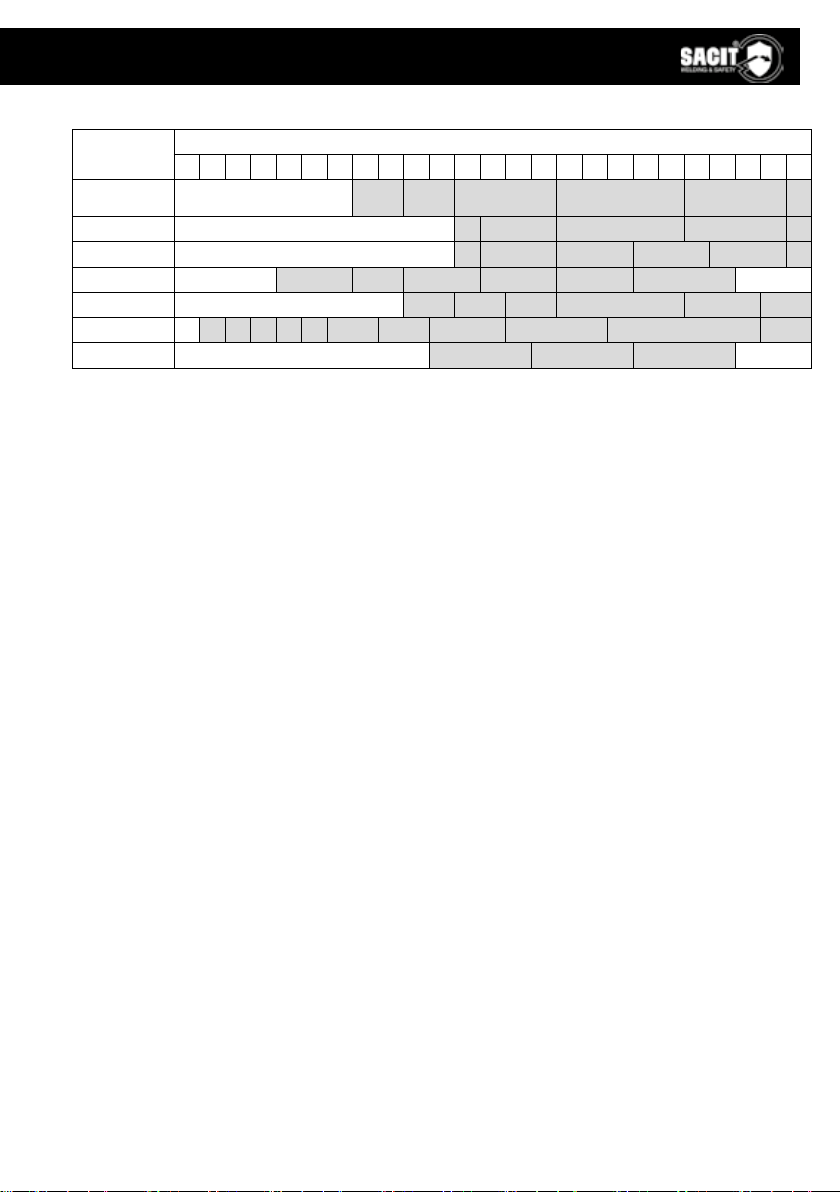

1.7 Recommended shade number according to EN 379

Welding

process

Amperes

0.5 1 2.5 5 10 15 20 30 40 60 80 100 125 150 175 200 225 250 275 300 350 400 450 500 550

Covered elec-

trodes 9 10 11 12 13 14

MIG (steel) 10 11 12 13 14

MIG (light alloys) 10 11 12 13 14 15

TIG 9 10 11 12 13 14

MAG 10 11 12 13 14 15

Plasma welding 56789 10 11 12 13 14 15

Plasma cutting 11 12 13

2. PART 2 - COMPLETE PANTERA AIR SYSTEM

2.1 Introduction

Pantera Air System is a combined face and respiratory protection device for increased safety and

comfort during welding. Please read these instructions carefully before unpacking.

The respiratory protection system must not be used:

• In a dangerous environment for the user’s health and safety, an environment with an oxygen level

below 17% or containing unknown substances.

• In conned or non-ventilated environments such as curves, etc.

• Near ames or projections.

• In an explosion risk zone.

• In a very windy zone.

• If the lter is not installed.

2.2 Approvals

The system complies with the requirements of PPE Regulation 2016/425 and European Standard EN

12941: 1998 +A1:2003+A2:2008 TH3 R SL. The Respiratory System is designed to provide a supply

of ltered air via a breathing tube to a welding headpiece. The equipment can be used in environment

that requires a class TH3 P breathing protection device. It protects against particulate contamination.

All components used in Respiratory System must be manufacturer approved parts, and must be used

in accordance with the instructions in this manual.

1. The approval is not valid if the product is incorrectly used together with non-approved parts

or components.

2. Only the particle lter and pre-lter can be used together with this system. Filters from

other manufacturers should under no circumstances be used.

2.3 Warning and limitations to use

Before each use, inspect the Respiratory System for damage and verify that it operates properly.

Before using the Respiratory System, test air ow to verify it is providing an adequate volume of air.

Always wear the Respiratory System and do not remove the head top or turn o the air lter unit until

outside the contaminated area. Otherwise, there is a risk of high concentration of CO2 and oxygen

level in the head top will fall, thus little or no protection is given.

If you are not sure about the concentration of pollution, or about equipment performance, ask the

industrial safety engineer.

10

EN USER AND MAINTENANCE MANUAL

The manufacturer is not responsible for injury due to the following incorrect use or incorrect choice of

equipment.

Warning:

• The respiratory devices should be use with well-trained personal and qualied person only.

• Before using the devices ensure you have understood that at very high work rates the pressure in

the device may become negative at peak inhalation ow.

• Before and during using the devices, attention shall be drawn to possible incorrect use and, where

appropriate, the possibility of looped hoses and/or cables becoming caught up.

• Before or during using the devices if the devices in the power-o state little or no respiratory

protection is to be expected, and that this is considered to be an abnormal situation.

• Please leave the work place and remove the headgear, when the devices in the power-o state a

rapid build-up of carbon dioxide and depletion of oxygen within the hood may occur.

• The lters shall only be tted to the turbo unit and not directly to the helmet/hood.

• The user should not confuse the markings on a lter relating to any standard other than EN 12941

with the classication of this device when used with this lter.

• DO NOT use with the blower unit switched o.

• DO NOT use in an atmosphere that is immediately hazardous to user hygiene or health and/or

has oxygen content of less than 19,5% or contains unknown substances.

• DO NOT use in an explosive atmosphere.

• DO NOT use in conned spaces or areas of poor ventilation

• DO NOT use in high winds.

• DO NOT alter or modify in any way.

• DO NOT touch any of the moving parts.

• DO NOT allow water or other liquids to enter the impeller chamber, the lter or battery

compartment.

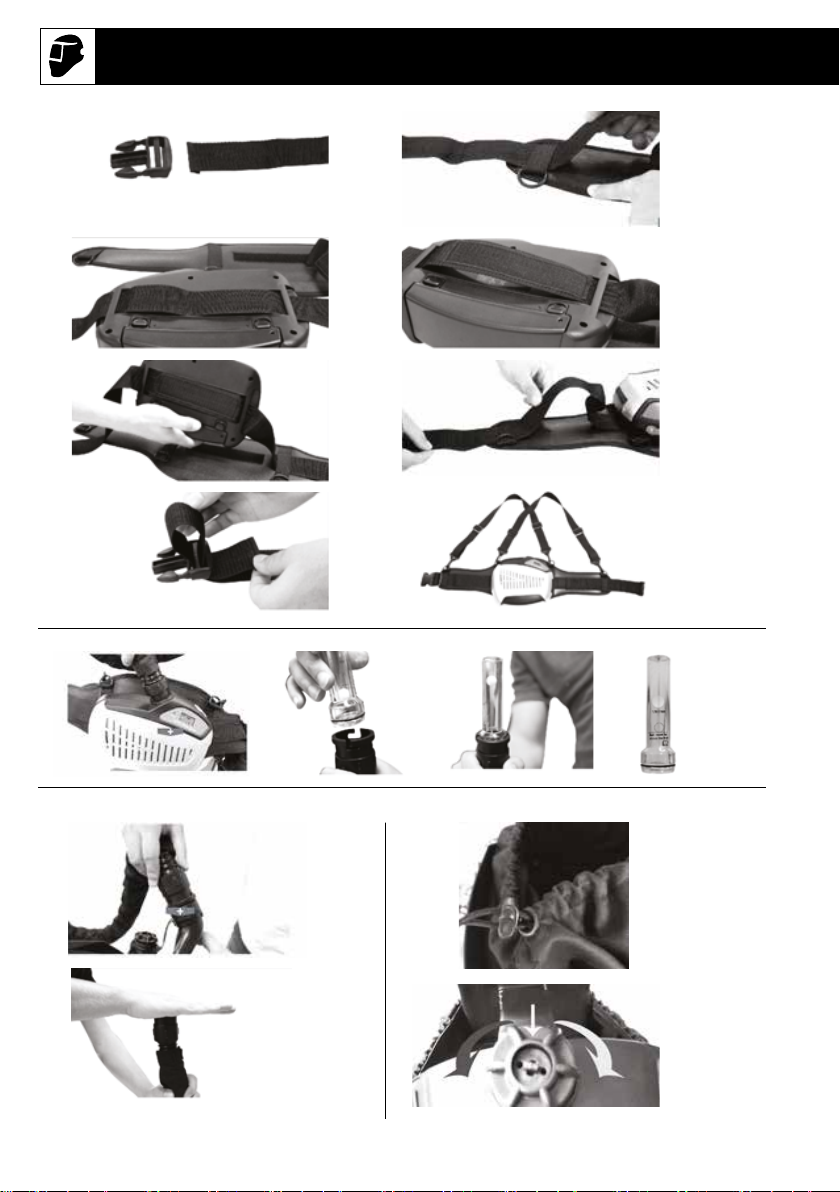

2.4 Part list (see g. 3)

Code Description Picture

MSC000441 PANTERA AIR SYSTEM 1

MU0361 BLOW UNIT SACIT AIR SYSTEM 2

BW0755 FILTER COVER 3

SPL000386 PARTICULATE FILTER 4

SPL000381 PRE-FILTER 5

SPL000382 SPARK ARRESTOR 6

SPL000383 RECHARGEABLE BATTERY LI-ION 7

SPL000394 240V BATTERY CHARGER 8

SPL000392 BREATHING TUBE (0.6 m) WITH CLOTH 9

SPL000387 ASSEMPLED FLOW METER 10

SPL000385 BELT + SHOULDER HARNESS 11

SPL000393 THROAT PROTECTION 12

VCE000698 HEADGEAR WITH AIRDUCT + HOLE 13

SPL000389 CARRIER BAG FOR SACIT AIR SYSTEM 14

PANTERA AUTODARKENING MASK 15

LVE000238 OUTSIDE PLATE 114X133X1 mm 16

LVE000237 INNER PLATE 106X66X1 mm 17

11

2.5 Unpacking/Assembly

Check that correct number of components has been supplied, as in gure 3-1. Check that the

apparatus is complete, undamaged and correctly assembled. Any damaged or defective parts must be

replaced before use.

If any of the above components are not included in your kit, please contact the supplier immediately.

2.6 Filter replacement (see g. 4)

1. Remove the lter cover by pressing in the latch of the lter cover.

2. The lter cover is released.

3. Remove the used lter by lifting it out from the lter cover. Remove the used lter by lifting

it out from the lter cover.

4. Remove the pre-lter.

5. If the ltration grill is dirty, clean it (blower).

The pre-lter and lter expected lifetime is 12 months. When under intensive use, check the lter

cleanliness periodically and if needed, change them more often than every 12 months.

2.7 Installing the battery/Charging (see g. 5)

1. Slide the battery towards the back of the ltration unit.

2. Make sure that the battery is locked in position.

3. The battery can be charged on the ltration unit or separately.

The battery is partially charged when delivered. It must be charged at a 100% before the

rst use. It is recommended to charge the batteries at a 100% before each use.

The charger must not be used for anything else than it was designed for. Do not charge

the battery in a potentially explosive area. The charger must only be used indoors.

The charger regulates the charge automatically, once the battery is fully charged, it will

maintain it at a 100% (oating charge). The charge time is 3 to 4 hours.

The battery will discharge itself after long storage periods. Always charge the battery if the

device was stored for more than 15 days. Once the battery is new or has been stored for

more than 3 months, charge it and discharge it at least twice in a row to reach the nominal/

rated charge capacity.

Battery charge:

1. Connect the charger to the mains.

2. Connect the battery to the charger. The connector is above the battery.

3. The state of charge is displayed via a red LED on the mains charger.

4. Once the charge is nished, the oating charge becomes active: the red LED switches o

and a green LED switches on.

5. Disconnect the charger from the mains (do not keep the charger plugged to the mains if

it’s not in use).

2.8 Installing the respiratory system on the belt (see g. 8)

1. Remove the belt’s release buckle.

2. Remove the fastening belt from the waist connector’s 2 belt loops

3. Make the fastening belt pass through the respiratory system’s 2 belt loops.

4. Position the Velcro® between the 2 loops.

5. Flip the ltration system and attach the Velcro® on the belt.

6. Put the fastening belt back through the 2 belt loops.

12

EN USER AND MAINTENANCE MANUAL

7. Put the buckle back.

8. Attach the harness to the belt’s 4 plastic rings.

Make sure the belt is securely fastened.

2.9 Connecting the tube (see g. 6)

1. Connect the air tube to the respiratory system and twist it clockwise to lock its position.

2. Connect the other end of the tube to the headgear in the same way.

1. Check that the respiratory tube is strongly connected. If the tube is broken, replace it.

All components must be installed/ used in accordance with this manual if the equipment is to oer the

specied protection. If any component is missing, or if anything is not clear, contact the supplier.

2.10 Adjust airow rate (see g. 7)

The airow rate in the middle and both side of the airduct outlet can be adjusted by a switch

assembled on airduct according to personal preference.

1. Counter-clockwise adjust the switch, airow rate from middle outlet will be 20% and both

side outlet will be 80%

2. Clockwise adjust the switch, airow rate from middle outlet will be 80% and both side

outlet will be 20%

All components must be installed/used in accordance with this manual if the equipment is to oer the

specied protection. If any component is missing, or if anything is not clear, contact the supplier.

3. Before use/Fitting (see g. 9)

3.1 Air ow test

1. Connect the breathing tube to the ltration unit and twist it clockwise to lock it.

2. Insert the owmeter at the tip of the tube.

3. Press the ON button and maintain the tube in a vertical position at eyes’ height.

4. The air ow is sucient if the marble reaches the minimum ow level O.

The airow must be tested before using.

If the marble can’t reach the minimum ow level, don’t use the system. change the lter or the battery

and retest the air ow.

3.2 Air ow alarm test (see g. 10)

1. Remove the tube from the helmet and press the ON button.

2. Cover the air output with your hand and wait approximately 15 seconds.

If the alarm does not work, please repair or change Respiratory System.

3.3 Fitting (see g. 11)

1. Pull down the face seal ring and put on the head top.

2. Adjust the headgear to suitable tightness (push and turn left to loosen, turn right to tighten)

Make sure the face seal is positioned properly, otherwise, you can’t get sucient sealing needed to

oer the correct protection factor.

13

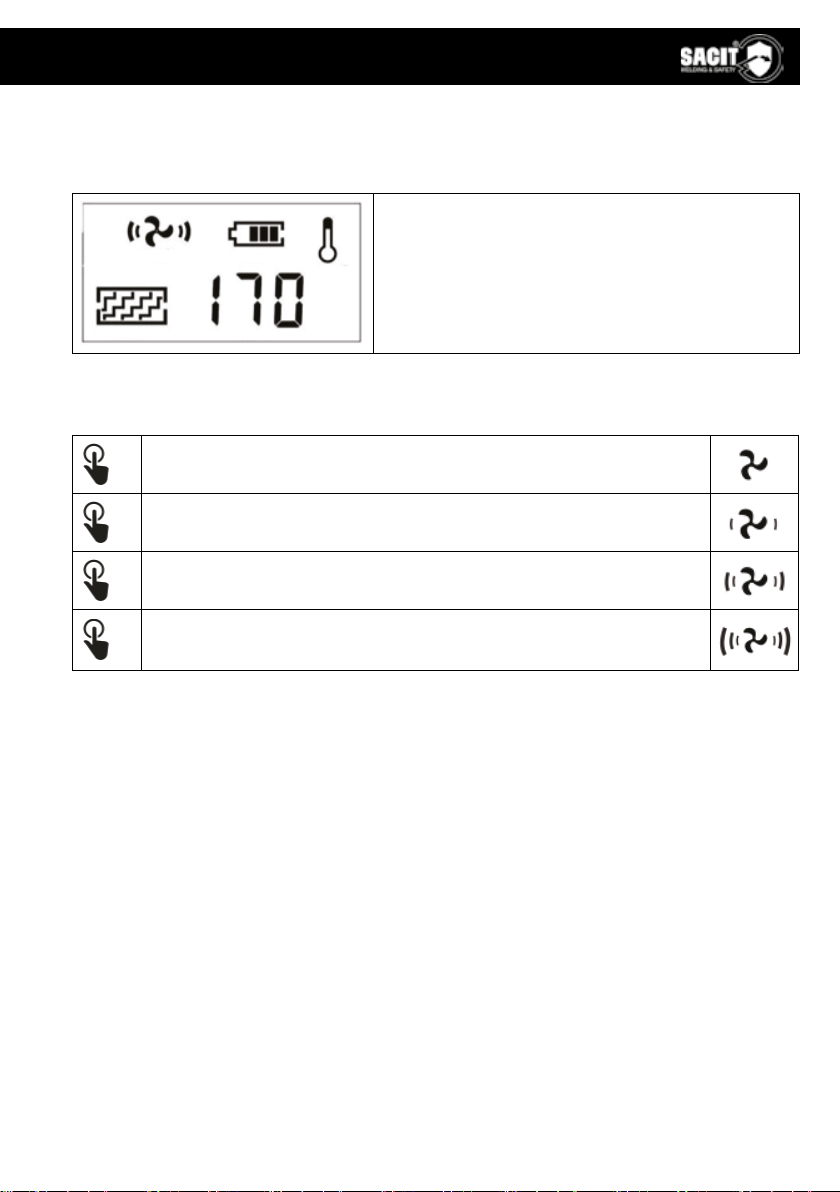

4. LCD and Operation

4.1 LCD display screen

There is a LCD display screen on Pantera Air System to show the working system condition.

1.

2. 4. 5.

3.

Part 1 shows the data of current air ow.

Part 2 shows the level of the airow.

Part 3 shows the lter condition.

Part 4 shows the battery.

Part 5 shows the temperature of the battery.

Any of them will ash if there are any disfunctions on Pantera Air System.

4.2 Operation

x1

Switch the device on by pressing the ON button once.

x2

Press the ON button once again, the air ow is at level 1 (~170L/min).

x3

Press the ON button once again, the air ow is at level 2 (~200L/min).

x4

Press the ON button once again, the air ow is at level 3 (~230L/min).

Press the ON button once again, the air ow reverts to level 1 (~170L/min).

1. The system will turn o the turbo unit if long press the OFF button more than 3 seconds.

2. The system will shut down the entire circuit and switch to sleep mode if not used for more

than 30 minutes. Pressing the ON button can activate the system.

3. The system must be operated in the temperature range of -5°C to +55°C and relative

humidity less than 90%RH.

14

EN USER AND MAINTENANCE MANUAL

5. MAINTENANCE & STORAGE

5.1 Maintenance

The Pantera Air System must be checked regularly and must be changed if it is damaged and cause

leakage.

The lter must be changed if it is broken, or it is blocked and does not give enough airow.

The breathing tube must be changed if it is broken or has crevasse.

The battery must be charged when the low battery alarm rings.

Use a soft cloth to wipe the external surfaces. Don’t use water!

The lter should be replaced together with the pre-lter.

5.2 Storage

The Pantera Air System must be stored in a dry, clean area, in the temperature range of -10°C to

+55°C and relative humidity less than 90%RH. If the equipment is stored at temperature below 0°C,

the battery must be allowed to warm up to achieve full battery capacity. The equipment must be

protected from dust, particles and other contamination.

If the equipment is not used for a long time, the battery should be fully charged, removed from

Respiratory system unit and stored separately.

Transport the equipment with original packaging box and away from direct sunlight.

6. SPECIFICATION

Code MSC000441

Norm EN 12941: 1998 +A1:2003+A2:2008 TH3 R SL

Filter type TH3 P R SL

Filter eciency level 99,99% = 0,3 µm

Airow level

1. speed: 170 l/min

2. speed: 200 l/min

3. speed: 230 l/min

Noise level Max 75 dB

Belt size 900 ÷ 1300 mm

Blower unit size 240 x 165 x 70 mm

Blower unit weight 1,1 Kg

Battery model Rechargeable LI-ON 4400 mAh

Battery life

1.speed > 8h

2.speed > 6h

3.speed > 4h

Battery charge time 3,5 h

Number of battery recharges 500

Information on the digital display

Air ow rate and data

Battery level

Filter status

Usage temperature -5°C – +55°C

Storage temperature -10°C – +55°C

15

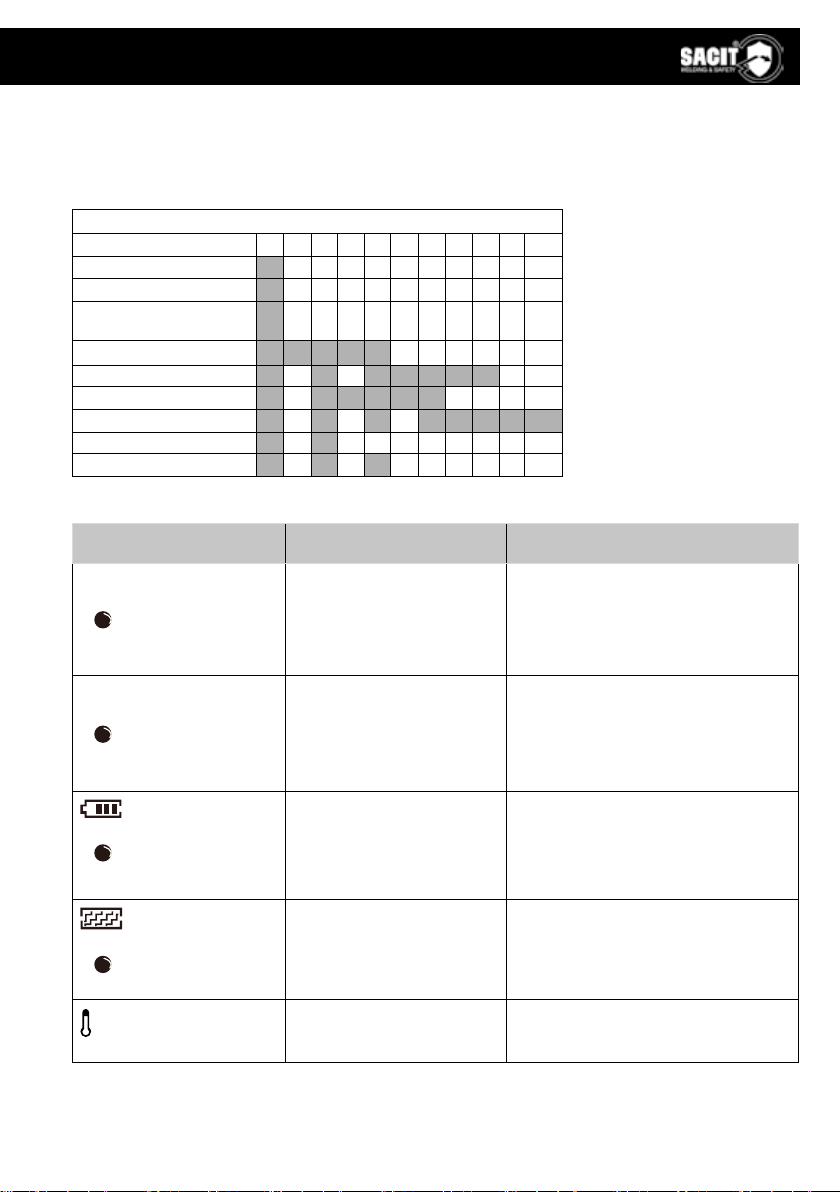

Warning sound indication

Each grid stands for a period of 100ms. Gray is the beep sound and blank grid is a quiet period. If

several continued grids are in gray then there’s a continuous beep sound.

For example, when the current is overloaded, the system sounds like beep~beep~beep~~~~~.

100ms per grid

0 1 2 3 4 5 6 7 8 9 10

Install the battery

Turn on the system

Change the air ow

speed

Turn o the system

Current overload

Air outlet jam

Over heat

Low battery

Filter jam

7. TROUBLE SHOOTING

Problem Probable cause Action

Fault code «E01»

+ warning blinks

1. Motor is stuck

2. Motor is damaged

3. Blower structure failure

caused by outer force

4. Circuit failure

Check and remove physical failure

and restart the system. Return to

dealer if LCD still shows E01

Fault code «E02»

+ warning blinks

1. Motor is damaged

2. Motor impeller rubs blow-

er shell

3. Circuit has excessive

current.

Check and remove physical failure

and restart the system. Return to

dealer if LCD still shows E02

blinks

+ warning blinks

+ alarm sounds

Low battery Charge the battery

blinks

+ warning blinks

+ alarm sounds

Filter blocked

Tube blocked Remove obstruction, change the lter

Clean tube

blinks

+ alarm sounds

Battery high temperature Stop working and rest

16

2797

EN USER AND MAINTENANCE MANUAL

No air ow, no alarm

1. No power

2. Battery contact damaged Charge the battery

Check battery contact

Battery run time is too short

1. Battery is not fully charged

2. Filter is blocked

3. Battery is damaged

Charge the battery

Remove obstruction, change lter

Change battery

Air supply to hood smells

unusual

1. Filter broken

2. Tube broken

3. ADF helmet broken

Leave current area immediately.

1. Change lter

2. Change tube

3. Change ADF helmet

Supply insucient air to

hood

1. Breathing tube broken o

2. Breathing tube broken

3. Filter is blocked

1. Check tube connection to hood and

Respiratory system unit

2. Change breathing tube

3. Remove obstruction, change lter

PANTERA AIR SYSTEM Marking

EN 12941: 1998 +A1:2003+A2:2008

TH3 P R SL

CE1024

Marking explanation:

EN12941:1998 +A1:2003 +A2:2008 = Directive reference

TH3 = Filter model (Protection level)

P = Particle lter / R = Reusable type of particle lters

SL = Tested against particles of liquid and solid.

CE = Conformity mark / 1024 = Certication authority

Notied Body: Vyzkumny ustav bezpecnosti prace, v. v. i., Jeruzalémská 1283/9,

110 00 Praha 1, Czech Republic (Notied body number 1024)

CE mark followed by number of notied body who

carried out module D surveillance.

5

OVERENSSTEMMELSESERKLÆRING

http://shop.tramet.com/it/Dcue-TrametGroup-Adf3.html

Tramet Group Spa, en behørigt registreret italiensk produktionsvirksomhed, beliggende

i Via del Lavoro, 8 36020 Castegnero (VI), erklærer hermed, at produkter identiceret og

beskrevet på disse sider er i overensstemmelse med følgende forordning: EU 2016/425,

samt standarderne EN 175:1997, EN 379:2009, CSA Z94.3, ANSIZ87.1, EN 12941: 1998

+A1:2003+A2:2008 TH3 R SL

ADVARSLER

Læs bruger- og

vedligeholdelsesvejledningen

omhyggeligt før brug.

Ibrugtagning og vedligeholdelse

må kun iværksættes og udføres af

kvaliceret personale. "Kvaliceret

personale" henviser til brugere,

der arbejder i overensstemmelse

med førnævnte bestemmelser og

standarder, og som skal kunne

identicere og vurdere potentielle risici/

farer, der kan opstå under brug af

svejsebrændere.

Produktet skal bortskaes på ansvarlig

vis efter endt levetid. Alle dele og

udstyr skal genbruges korrekt i

overensstemmelse med lokale lovkrav

og forskrifter.

FØR SVEJSNING

Sørg for at fjerne eventuelt

beskyttelsesfolie fra begge sider af

beskyttelsesglasset.

VEDLIGEHOLDELSE

Udskift revnede eller ridsede beskyt-

telsesglas med jævne mellemrum.

ANVENDELSE

Placer aldrig hjelmen eller lteret på et

varmt underlag.

Må kun anvendes i temperaturområdet

-10 °C til +60 °C

SIKKERHEDSFORANSTALTNINGER

Dampe er sundhedsskadelige. Anvend

altid hætte eller udfør arbejde i

ventilerede områder.

Nedsænk ikke det automatiske

nedblændingslter i vand. Udsæt ikke

lteret for væsker og beskyt det mod

snavs.

Foretag ikke modikationer eller

strukturelle ændringer på hjelmen.

Vend brænderen væk fra dig selv og

andre.

Hvis svejselteret ikke bliver mørkt,

når lysbuen antændes, skal du straks

stoppe svejsningen og kontakte din

supervisor eller forhandleren.

Pakkens indhold

PANTERA-maske med automatisk nedblænding

(se g. 1)

KODE BESKRIVELSE

LVE000238 Udvendig beskyt-

telsesplade

114 x 133 x

1 mm

5

LVE000237 Indvendig beskyt-

telsesplade

106 x 66 x 1 mm 5

VCE000010 Ergonomisk hjelm 1

LCD-lter medfølger (se g. 2)

1. Batteridæksel (2 stk.)

2. Batteri (2 stk.)

3. Display

4. WELD/GRIND-knap

5. SENSITIVITY-knap

6. LCD-skærm

7. SHADE-knap

8. DELAY-knap

6

DA BRUGS- OG VEDLIGEHOLDELSESMANUAL

Indledning

Denne manual består af 2 dele:

1. PANTERA-MASKE MED AUTOMATISK NEDBLÆNDING

2. KOMPLET "PANTERA-LUFTSYSTEM"

1. DEL 1 - "PANTERA"-MASKE MED AUTOMATISK NEDBLÆNDING

1.1 Oversigt

PANTERA svejsehjelm med automatisk nedblænding er en ny generation af svejsehjelm, der

integrerer nogle af de mest innovative teknologier såsom digital LCD, optoelektronikdetektion med 4

sensorer og meget bredt visningsområde, solenergi- og litiumbatterier, mikroelektronik og True Color

ADF-teknologi.

PANTERA svejsehjelm med automatisk nedblænding er udstyret med et ADF-lter med digitale

reguleringer, for en nem og hurtig justering af alle funktioner.

Hovedfunktionerne er: MIG/MAG, TIG, PLASMA CUTTING, GOUGING og GRINDING.

Maskens ergonomi er blevet undersøgt for at garantere en fremragende beskyttelse af hoved/nakke/

ører.

ADVARSEL

Læs og forstå alle instruktioner før brug.

• Kontroller, at DIN'en for svejsehjelmlteret har det korrekte nummer til din anvendelse.

• PANTERA-svejsehjelm med automatisk nedblænding og lter er ikke egnet til svejsning i højden,

lasersvejsning eller laserskæring.

• PANTERA-svejsehjelm med automatisk nedblænding er designet til at beskytte øjne og ansigt

mod gnister, svejsesprøjt og skadelig stråling ved anvendelse under normale svejseforhold.

• PANTERA-svejsehjelm med automatisk nedblænding beskytter ikke mod eksplosive anordninger eller

ætsende væsker. Maskinskærme eller øjenbeskyttelse skal anvendes, når disse farer er til stede.

• Slagfast øjenbeskyttelse eller sikkerheds-/beskyttelsesbriller, der opfylder gældende ANSI-

specikationer, skal til enhver tid anvendes ved brug af denne svejsehjelm.

• Undgå arbejdsstillinger, der udsætter ubeskyttede kropsdele for gnister og svejsesprøjt samt

direkte og/eller indirekte stråling. Brug tilstrækkelig beskyttelse, hvis eksponering ikke kan

undgås.

• Før hver brug skal du kontrollere, at beskyttelsespladerne er rene, og at der ikke sidder snavs,

der blokerer for sensorerne foran lteret.

• Inspicer altid betjeningselementerne for tegn på slid eller beskadigelse før brug.

• Eventuelle dele med ridser, revner eller huller skal straks udskiftes.

• Foretag ikke ændringer på hverken svejselteret eller hjelmen ud over dem, der er speciceret i

denne vejledning.

► Brug ikke andre reservedele end dem, der er speciceret i denne manual. Uautoriserede

ændringer og reservedele ugyldiggør garantien og øger risikoen for personskade.

►Hvis beskyttelsesglasset ikke blænder ned, når lysbuen antændes, skal du straks stoppe

svejsningen og kontakte forhandleren.

►Nedsænk ikke dette lter i vand: Denne model er ikke vandtæt.

►Brug ikke opløsningsmidler på lter- eller hjelmkomponenter.

► Det anbefalede driftstemperaturområde for svejselteret er -5 °C til +55 °C. Anvend ikke

denne enhed ud over disse temperaturgrænser.

• Manglende overholdelse af disse advarsler og/eller brugervejledningen kan resultere i alvorlig

personskade.

7

1.2 Egenskaber

PANTERA automatisk svejsehjelm har et automatisk nedblændingslter med 4 sensorer, en digital

skærm og et bredt udsynsområde.

Før aktivering er lterskærmen DIN 4, så brugeren tydeligt kan se arbejdsaden.

Når lysbuen antændes, vil lteret automatisk blænde ned. Når lysbuen aftager, bliver lteret

gennemsigtigt igen. Hjelmen er udstyret med DIN 9-13 nedblændingsregulering. Nedblændingstiden

fra lys til mørk er ca. 0,08 ms og kan indstilles til mellem 0,1–0,9 sekund med DELAY-knappen.

Brugeren kan også justere SENSITIVITY (lysfølsomhed) og vælge driftsmetode (WELD eller GRIND).

PANTERA automatisk svejsehjelm giver brugeren fuld beskyttelse mod UV/IR, selv når lteret er sat

til den svageste indstilling. UV/IR-beskyttelsesniveauet overholder til enhver tid DIN 15. Strømmen

forsynes af solceller og et udskifteligt batteri.

Hjelmen er udstyret med 4 sæt fotosensorer til registrering af lysbue. Desuden er hjelmen forsynet

med en ydre beskyttelsesplade fremstillet af højpolymermaterialer.

Pladen er slidstærk, termostabil, fri for klæbestof og har en meget lang levetid.

1.3 Hovedspecikationer

Filterstørrelse 114 x 133 x 9.5 mm

Udsynsområde 100 x 60 mm

Let skygge DIN-nummer 4

Mørk skygge DIN-nummer 9-13

UV/IR-beskyttelse op til op til DIN 15

Tid fra lys til mørke 0,08 ms

Tid fra mørke til lys 0.1 ... 0,9 s

Følsomhed justerbar trinløs

Strømforsyning solcelle og udskifteligt batteri

Driftstemperatur -5°C (23°F) °F – +55°C (131°F)

Garanti 2 år i henhold til salgsbetingelser

Slibefunktion Ja

Optisk klassikation 1/1/1/1

1.4 Driftsmetode

1. Saml hjelmen som vist på opbygnings- og samlingsillustrationen.

2. Strømforsyningen til PANTERA-hjelmen med automatisk nedblænding forsynes af

solceller med to lithiumbatterier.

3. Valg af nedblændingsgrad Juster til den optimale nedblændingsgrad. Tryk på knappen

SHADE for at vælge mellem nedblændingsgrad 9 og 13. Indstil i henhold til den aktuelle

svejseproces.

4. Valg af tidsforsinkelse Tryk på knappen DELAY for at vælge en forsinkelse på mellem 1

til 5, 0,1–0,9 sekunder.

5. Valg af lysfølsomhed Tryk på knappen SENSITIVITY for at indstille lysfølsomheden over

for det omgivende lys. Vælg mellem fem lysfølsomhedsniveauer.

Indstil til 1: Lysfølsomheden ændres til et lavere niveau. Velegnet til svejsning med høj

strømstyrke og svejsning under skarpe lysforhold (lampelys eller sollys).

Indstil til 5: Lysfølsomheden ændres til et højere niveau. Velegnet til en konstant

lysbueproces såsom TIG-svejsning.

8

DA BRUGS- OG VEDLIGEHOLDELSESMANUAL

6. Fordi hovedform varierer fra person til person. Arbejdspositionen og udsynsvinklen

er forskellige. Brugeren kan justere hovedremmens justeringsknap (15) og

segmentpositioneringspladen (16) for at tilpasse udsynsvinklen.

Juster hovedremmen ved at skubbe og dreje justeringsskruen (11).

7. Slibefunktion Tryk på knappen WELD/GRIND for at vælge slibefunktionen. Slibeblinklyset

vil samtidigt blinke. For at undgå skade på øjnene, må du ikke udføre svejsning i

slibetilstand.

8. Batteriindikator batteriindikatoren er placeret i øverste højre hjørne. Vi foreslår at udskifte

batteriet, når indikatoren blinker.

1.5 Vigtige punkter

1. Sørg for, at hjelmen er i god stand. Kontrollér dens tilstand i henhold til ADVARSEL-

meddelelser.

2. Der sidder en ventil med ydende krystaller i lteret. Selv om den har en indre og ydre

beskyttelsesplade, er det vigtigt at undgå kraftige stød, så den forbliver intakt.

3. Hjelmens ydre beskyttelsesplade skal efterses og rengøres med jævne mellemrum.

Sørg for, at der er frit udsyn. Hvis der opstår brud, revner, huller eller mere alvorlig

synspåvirkning, skal pladen udskiftes.

4. For bedre eektivitet og sikkerhed skal du vælge en korrekt mørk nuance.

5. Hvis lteret ikke er en vandtæt model, skal du beskytte det mod våde miljøer.

6. Sørg for, at lys fra lysbuen opfanges af sensoren. Hvis ikke, vil lteret være for lyst eller

ustabilt i mørke, hvilket kan forårsage personskade.

7. Det automatiske lter kan anvendes i en temperatur fra -10 °C til +55 °C.

8. Adskil ikke lteret. Hvis der opstår problemer, bedes du kontakte os eller agent.

1.6 Mærkning

4 Tydeligt DIN sikkerhedsniveau

9-13 Skygge DIN-sikkerhedsniveau

SA Producent

1 Optisk klasse

1 Lysdiuserende klasse

1 Variationer i lysgennemtrængelighedsklasse

1 Vinkelafhængighedsklasse

EN379 CE Direktivhenvisning og overensstemmelsesmærke

Table of contents

Languages:

Other Trafimet Welding Accessories manuals

Popular Welding Accessories manuals by other brands

Smith

Smith Little Torch owner's manual

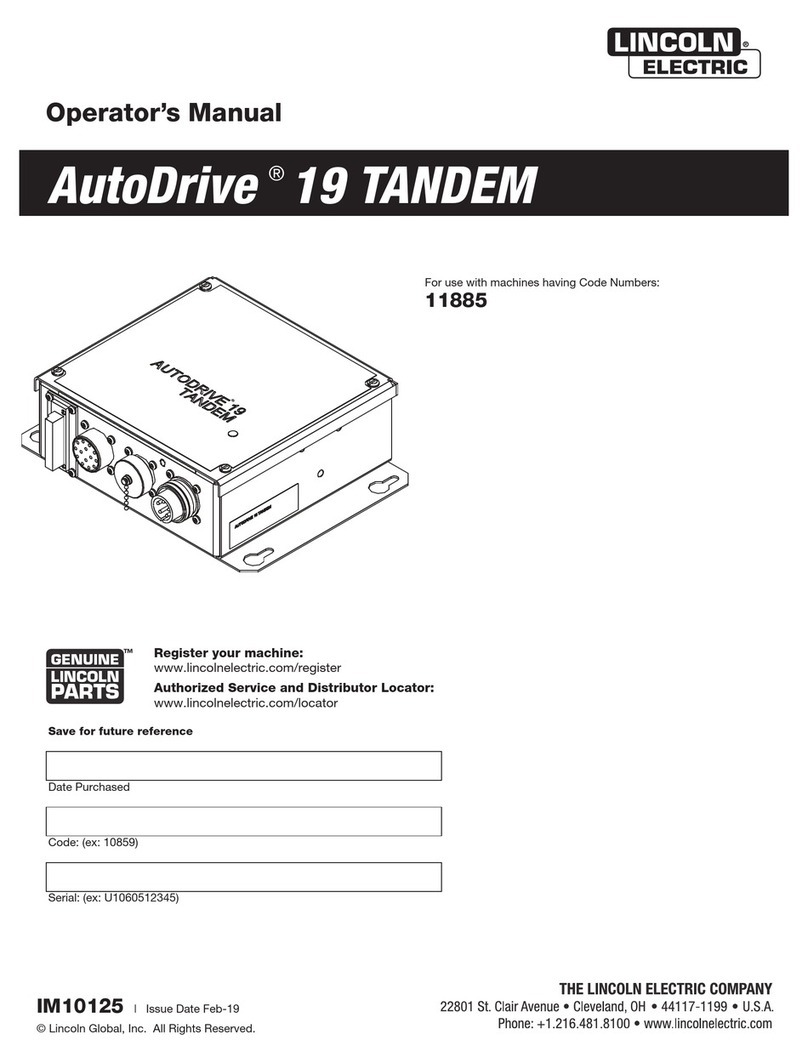

Lincoln Electric

Lincoln Electric AutoDrive 19 TANDEM Operator's manual

Miller Electric

Miller Electric S-75D owner's manual

ESAB

ESAB Aristo U6 instruction manual

Abicor Binzel

Abicor Binzel FES-200 operating instructions

3M

3M Speedglas 9100 FX Series Care & maintenance