ESAB TR-29 User manual

Other ESAB Welding Accessories manuals

ESAB

ESAB PT-31XL User manual

ESAB

ESAB CIGWELD 454342 User manual

ESAB

ESAB TWECO SPRAY MASTER V250 Maintenance and service guide

ESAB

ESAB Eye-Tech 10-12 Select User manual

ESAB

ESAB Origo Feed 304 P4 Guide

ESAB

ESAB PSF 260C User manual

ESAB

ESAB PSF 305 User manual

ESAB

ESAB SAVAGE A40 User manual

ESAB

ESAB Aristo U6 User manual

ESAB

ESAB Versotrac EWT 1000 User manual

ESAB

ESAB Aristo U6 User manual

ESAB

ESAB Aristo U8 User manual

ESAB

ESAB A6 Mastertrac User manual

ESAB

ESAB Eye-Tech 9-13 User manual

ESAB

ESAB SAVAGE A40 User manual

ESAB

ESAB A2 S GMAW Mini Master User manual

ESAB

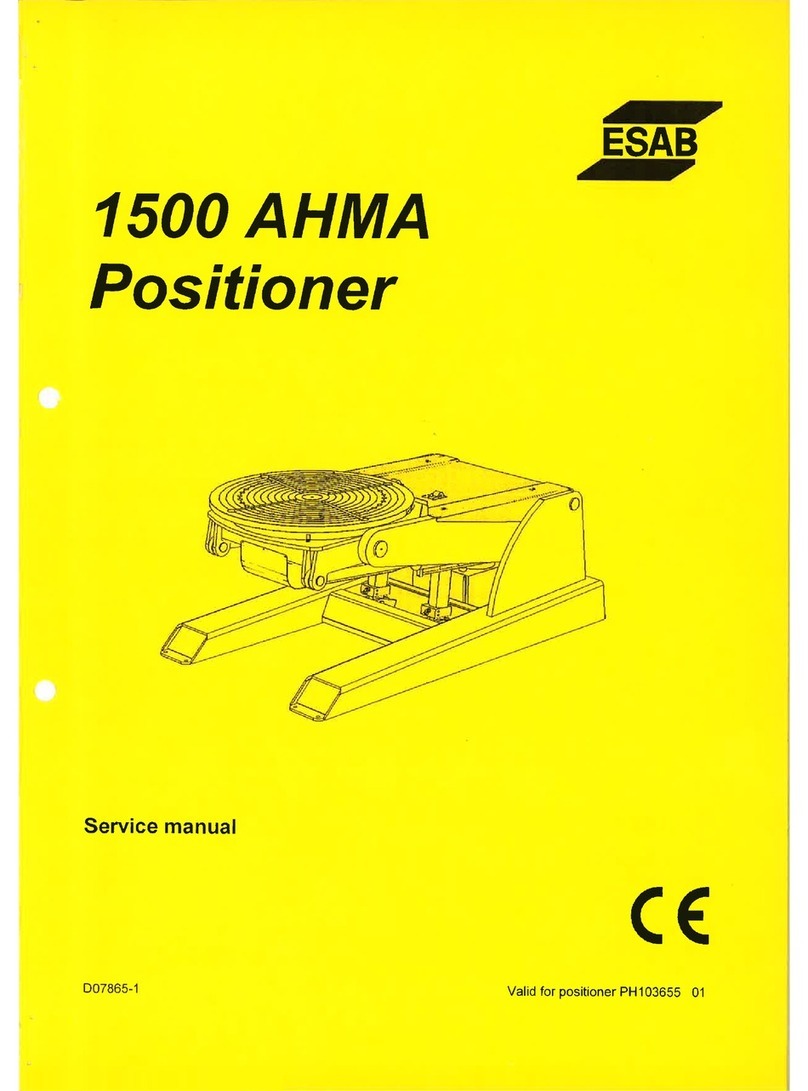

ESAB 1500 ahma User manual

ESAB

ESAB Aristo MA4 User manual

ESAB

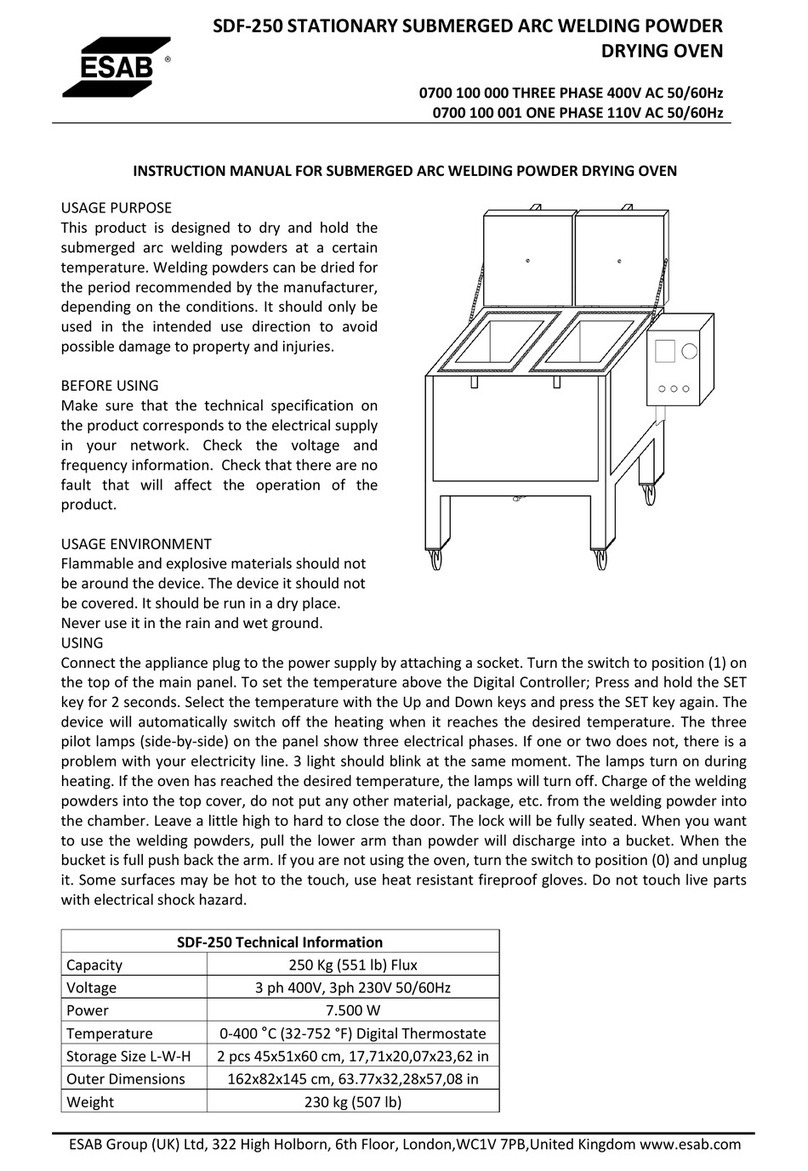

ESAB SDF-250 User manual

ESAB

ESAB SAVAGE A40 User manual

Popular Welding Accessories manuals by other brands

Lincoln Electric

Lincoln Electric LT-7 Tractor Technical specifications

Cornwell Tools

Cornwell Tools MMWC1 Operator's manual

Dohle

Dohle ExOn2A operating instructions

Nederman

Nederman Fume Eliminator FE 840/2500/P150 user manual

3M

3M Speedglas 9100 Series user manual

Miller Electric

Miller Electric OM-842 owner's manual

Miller

Miller A-200 Series owner's manual

Abicor Binzel

Abicor Binzel ABIMIG WT Series operating instructions

Miller

Miller MIGmatic M-25 owner's manual

Tregaskiss

Tregaskiss TOUGH GUN TT3 Reamer owner's manual

Abicor Binzel

Abicor Binzel xFUME PRO Original operating instructions

Sealey

Sealey SR20.V2 instructions