1

TRAK Machine Tools

Southwestern Industries, Inc.

TRAK 3ntr 3D Printers –SPFU Installation Quick Start Guide

1Introduction

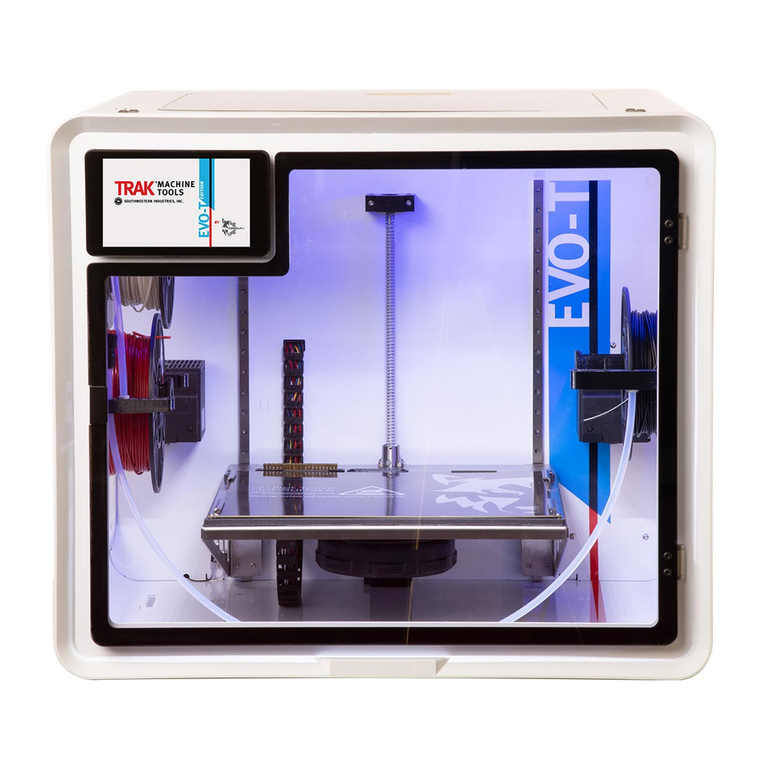

This guide outlines the process to install the Soft Polymer Feeder Unit (SPFU) to Nozzle #1 of your TRAK

3ntr A2 or A4 printer. Before you can install the SPFU, you must complete the Clean Nozzle procedure

(also outlined within this guide).

2Clean Nozzle Procedure

This section details all the steps to clean extruder nozzles. The nozzle cleaning procedure must ALWAYS

be performed BEFORE changing to a new polymer type filament. A nozzle cleaning procedure should

always be performed any time there are unacceptable nozzle flow conditions that cannot be cleared with

several purge cycles.

2.1 Clean Nozzle Procedure Overview:

There are three steps to cleaning nozzles;

1) Remove existing filament(s) using the change filament function

2) Feed cleaning filament (nylon) to the extruder(s)

3) Clean nozzle(s) using the front panel control Clean Nozzle function

CAUTION - Only load factory recommended (nylon or equivalent) filament for cleaning procedures.

NOTE - Before using the Clean Nozzle function from the front panel, you must use the Change/Load

Cleaning Filament procedure to remove build/support filament and feed the nylon cleaning filament to the

extruders to be cleaned.

2.2 Unload Filament Using Change Filament Function

In this section, you will change filament removing existing spools before installing the cleaning filament

(instead of a new build/support material filament spool). It should always be performed before a nozzle

cleaning procedure.

NOTE - If you are using an MMS unit or PolyBox (humidity-controlled container) the process is different.

If feeding material directly from a PolyBox or equivalent container, follow the instructions as applicable

1) Check that there is enough clearance (20-30mm) between nozzle and plate before starting. If

not, move printer plate following instructions for “Move Z axis function”

2) Navigate to the Prepare menu. From the Prepare menu select “Change filament”