2

INSTALLER’S GUIDE

Be certain to cap the ends of the cut YL/RD and YL wires that

are not being connected to an accessory or the unit to reduce

the risk of a short.

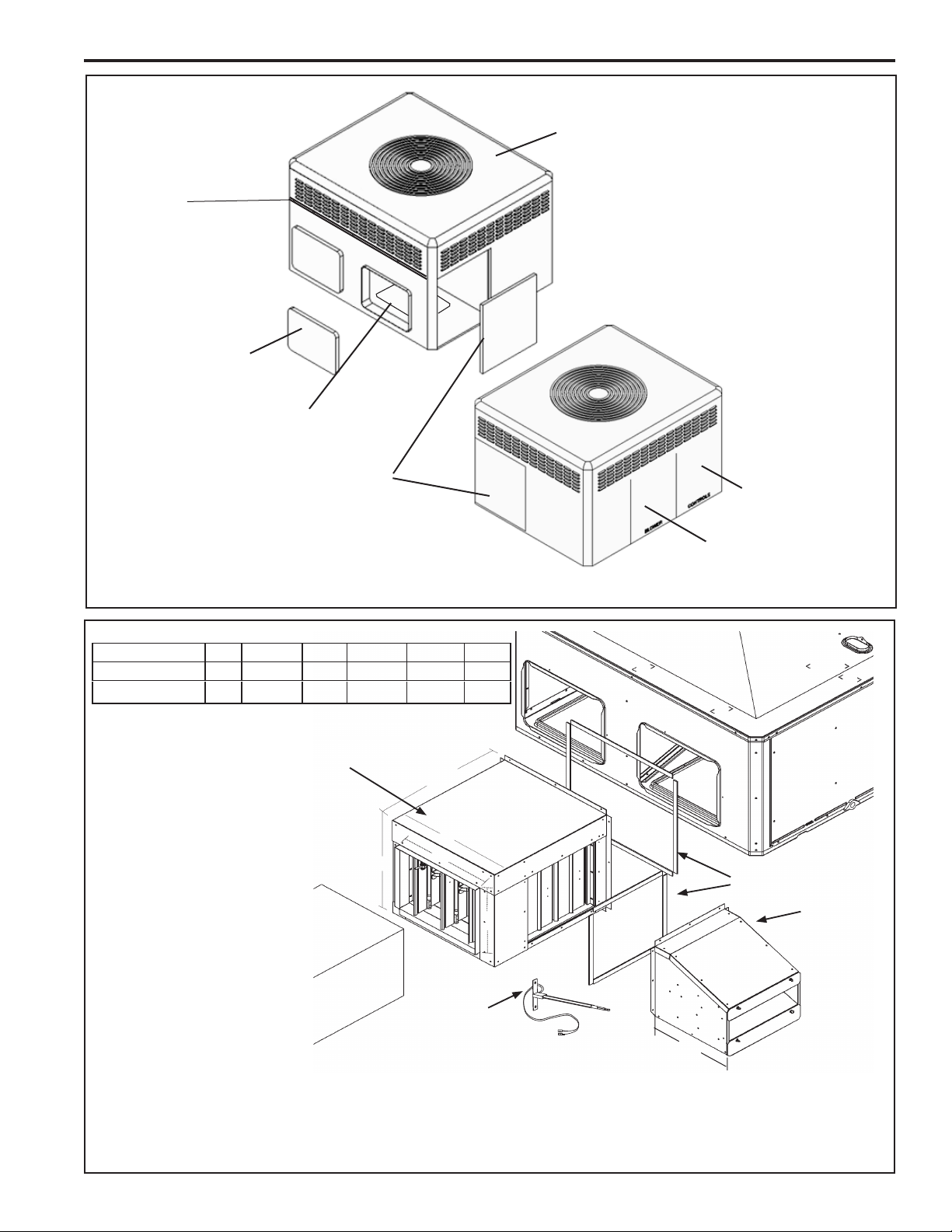

4. Install Economizer Assembly

1. Apply two gaskets to horizontal economizer mounting

anges. See Figure 2 on page 3.

2a. Small Cabinet - BAYECON203AA/AB

(4WCZ6, 4YCZ6024-036, 4DCZ6036)

Set the horizontal economizer over the horizontal return air

opening on the unit. The notches in the bottom ange of the

economizer clear the two existing screws below the return

air opening of the unit.

2b. Medium Cabinet - BAYECON204AA/AB

(4WCZ6, 4YCZ6, 4DCZ6048-060)

Apply a gasket to the economizer and slide the topange of

the economizer under the lip between the top and bottom

sections of the unit. Mate the notches on the top ange of

the economizer with the existing screws between the top and

bottom sections of the unit. The notches on the bottom ange

of the economizer clear the two existing screws below the

return air opening of the unit.

3. Drill three (3) 9/64” holes through the mating holes in the top

ange of economizer and into the unit. Then, drive three (3)

#10 sheet metal screws to secure the top.

4. Drill three (3) 9/64” engagement holes on each side of the

economizer. Then, drive three (3) #10 sheet metal screws

into each side of the economizer to the unit.

5. Mount the Mixed Air sensor to the left Blower partition

using two sheet metal screws. See Figure 4, page 4. The

Yellow and Yellow/Black wires will connect to the Econo-

mizer wiring harness in a later step. Install any economizer

options at this time per instructions provided with the sen-

sor.

6. Apply a gasket to the Rain Hood anges. See Figure 2, page

3.

7. Place the Rain Hood over the horizontal return air opening

of the economizer. See Figure 2, page 3. Use the #10 sheet

metal screws provided to attach the hood to the economizer.

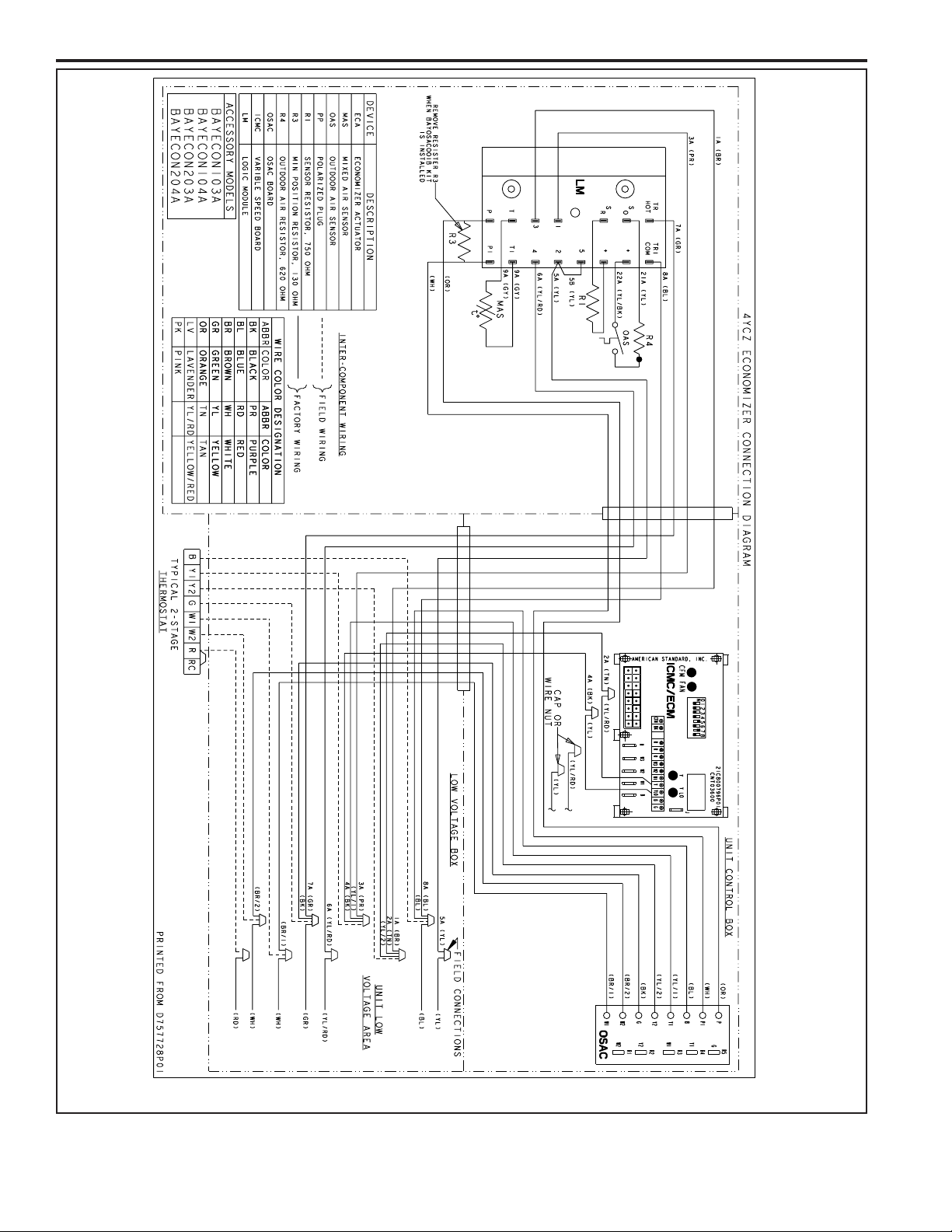

8. Route the main wiring harness. From the Economizer as-

sembly, route the main wiring harness to the Mixed Air sensor

and to the Control Box. See Figure 3, page 4.

9. Connect the two (2) Mixed Air Sensor wires (pulled from har-

ness) to the mating pigtail wires (with female quick connects)

from the Mixed Air Sensor.

10. In the Control Box, locate the ICMC Board in the upper left

hand corner of the Control Box. Find the YL/RD and YL wires

in the 12 pin connector. Leaving enough length of these wires

so that the ends going to the ICMC Board can be stripped,

cut these wires in two. Strip the cut end of the wires going

to the ICMC Board and connect to economizer wires as per

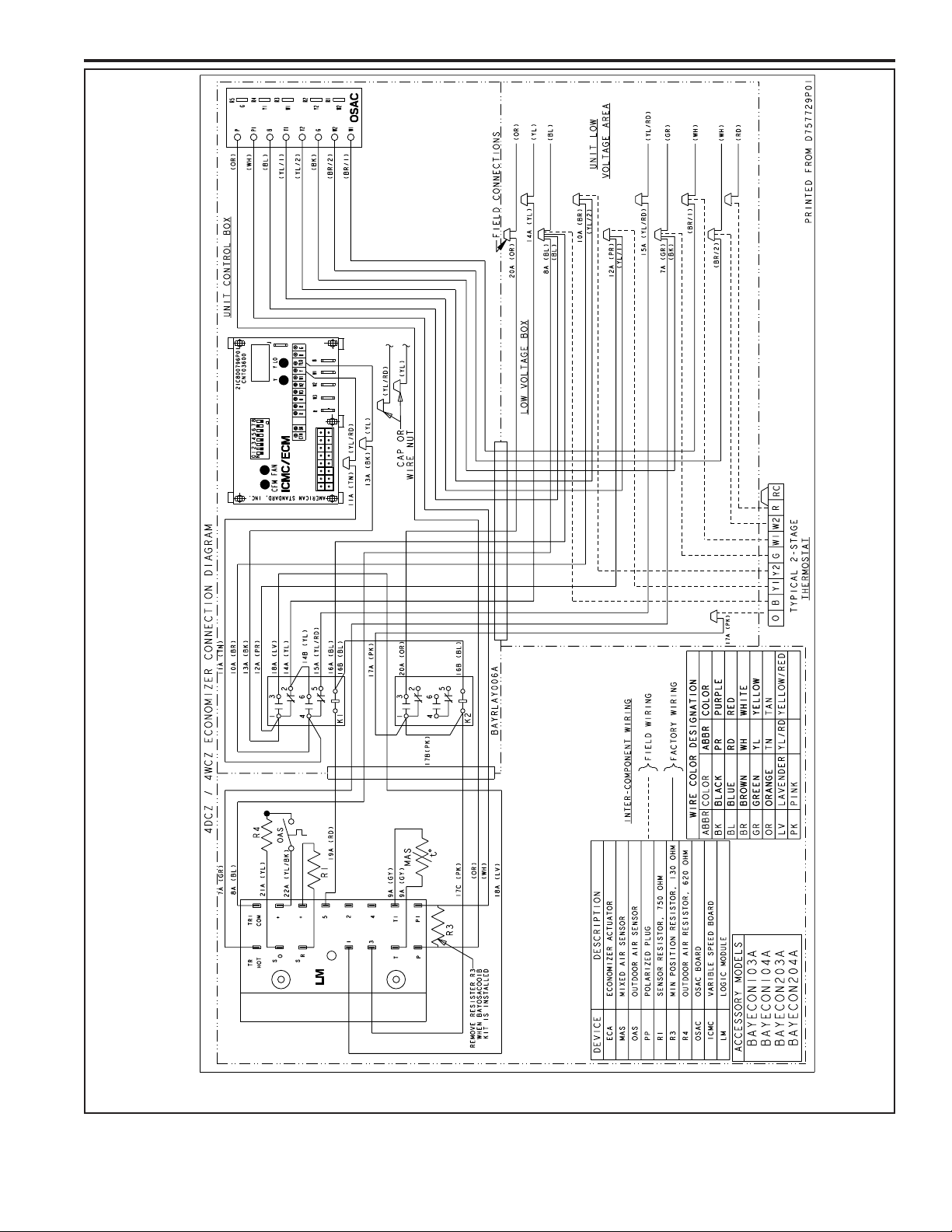

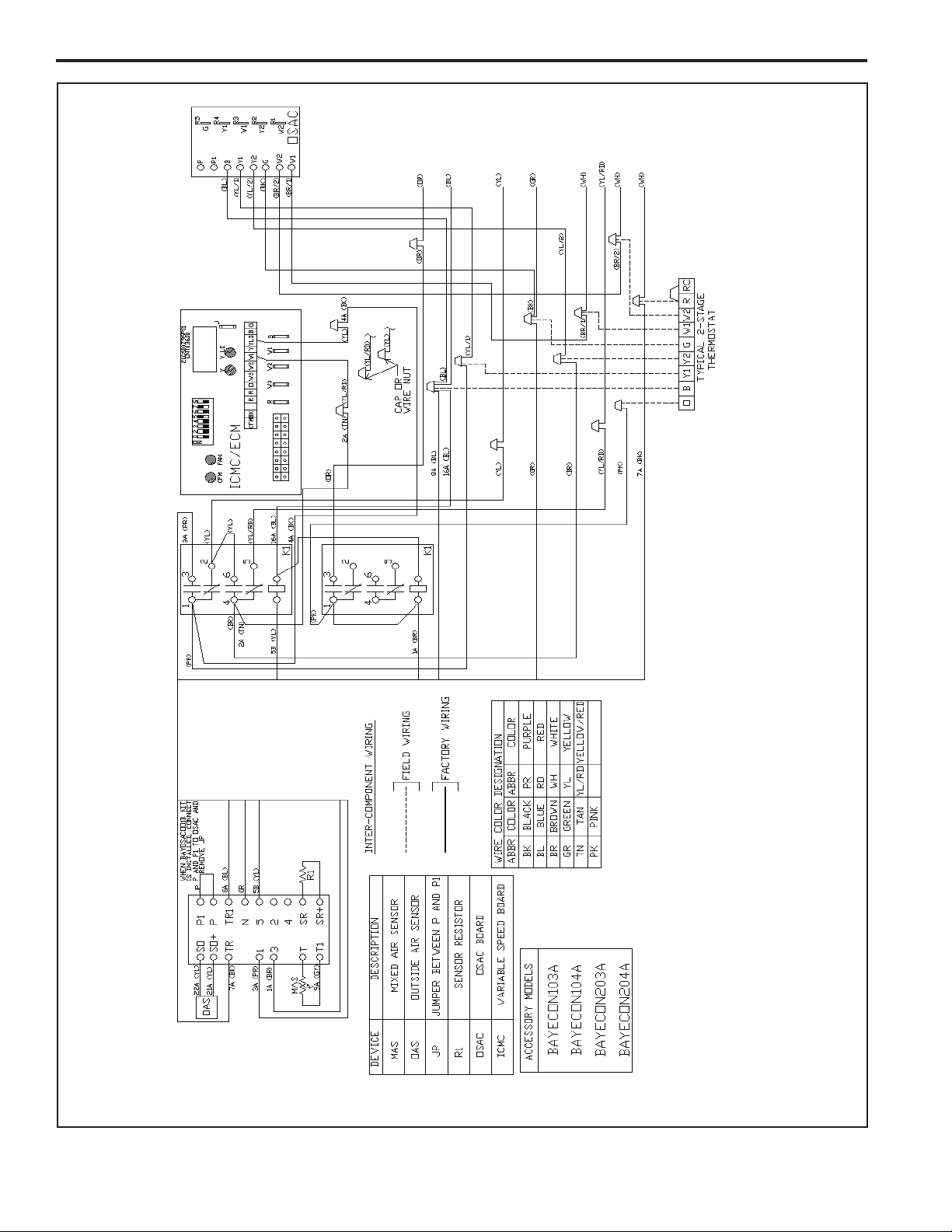

hookup diagrams on pages 6 and 7. Cap the ends of the

Yellow and Yellow/Red wires not being hooked up. Secure

all wires with wire ties so that there is no interference with

any moving parts in the unit.

11. In the Control Box, complete the wiring connections per the

appropriate wiring diagram on pages 6 and 7. Secure all

wires so that there is no interference with any moving parts

in the unit.

12. Attach the return duct to the economizer.

13. Power the economizer and run the checkout procedure on

page 8. Make desired adjustments to the controller: set the

minimum occupied damper position, set the outside air (if

enthalpy used).

14. Replace the unit Coil access panel, the Blower access panel,

and the Control Box access panel.

Sequence Of Operation - Units Equipped With

Honeywell W7459 Logic

NOTE: A (G) signal is required for the economizer to operate.

As shipped, the economizer will not operate when there is a

signal for Heating Modes utilizing gas heat.

Fan Only (G): When the thermostat sends a signal for fan only

(G), the economizer will open to the minimum position setting

regardless of the outdoor air conditions and the indoor blower

will operate at approximately 50% airow.

Heating (W1), (W2), (Y1, Y2 on Heat Pump or Dual Fuel

Models): When the thermostat sends a signal for auxiliary heat

(G) +(W1) or rst stage heat (G) + (Y1,Y2), the economizer

will open to the minimum position setting. When the ambient

temperature may be below 70F, the economizer will not fully

open to the economizing position, when there is a signal for

heat. In order to receive fresh air and open the dampers to the

minimum position setting, you must provide a G signal to the

unit from the thermostat or comfort control being used.

FREE COOLING NOT AVAILABLE: When the outdoor air

conditions are not sucient for “Free Cooling” the Economizer

will open to the minimum position setting only and the unit will

function.

FREE COOLING AVAILABLE:

1st Stage Cooling (Y1) + (O for Heat Pumps and Dual Fuel

models): When outdoor air conditions are sucient for “Free

Cooling” and the thermostat sends a signal for 1st stage cooling

(G) + (Y1) + (O for Heat Pumps and Dual Fuel models), the

economizer will modulate accordingly and the indoor blower will

run at approximately 70% airow.

2nd Stage Cooling (Y1) + (Y2) + (O for Heat Pumps and

Dual Fuel models): When outdoor air conditions are sucient

for “Free Cooling” and the thermostat sends a signal for 2nd

stage cooling (G) + (Y1) + (Y2) + (O for Heat Pumps and Dual

Fuel models), the economizer will modulate accordingly, the

compressor will operate on low speed, and the indoor blower

will operate at 100% airow.

Unit “OFF” Mode

When the economizer is not receiving a 24V signal to the TR

terminal, or if power is disconnected to the unit, the dampers

will be fully closed to the outside air and fully open to the return

air.

NOTE: Free Cooling refers to the process of circulating

unconditioned outside air, without operating the compressor, to

cool the structure.