9

RLC-SVX023B-GB

Installation overview and requirements

Contractor responsibilities

A list of the contractor responsibilites typically associated with the installation process is provided inTable 2.

• Locate and maintain the loose parts. Loose parts are located in the control panel.

• Install the unit on a foundation with flat support surfaces, level within 5 mm and of sufficient strength to support

concentrated loading. Place the manufacturer-supplied isolation pad assemblies under the unit.

• Install the unit per the instructions outlined in the “Mechanical Installation” section.

• Complete all water piping and electrical connections.

Note: Field piping must be arranged and supported to avoid stress on the equipment. It is strongly recommended

that the piping contractor provide at least 1m of clearance between the pre-installation piping and the planned

location of the unit.This will allow for proper fit-up upon arrival of the unit at the installation site. All necessary

piping adjustments can be made at that time

• Where specified, supply and install valves in the water piping upstream and downstream of the evaporator and

condenser, to isolate the heat exchangers for maintenance and to balance/trim the system.

• Supply and install flow switches or equivalent devices in both the chilled water and condenser water piping.

Interlock each switch with the proper pump starter andTracer UC800, to ensure that the unit can only operate when

water flow is established.

• Supply and install taps for thermometers and pressure gauges in the water piping, adjacent to the inlet and outlet

connections of both the evaporator and the condenser.

• Where specified, supply and install strainers ahead of all pumps and automatic modulating valves.

• Supply and install refrigerant pressure relief piping from the pressure relief to the atmosphere.

• Start the unit under supervision of a qualified service technician.

• Where specified, supply and insulate the evaporator and any other portion of the unit, as required, to prevent

sweating under normal operating conditions.

• For unit-mounted starters, cutouts are provided at the top of the panel for line-side wiring.

• Supply and install the wire terminal lugs to the starter.

• Supply and install field wiring to the line-side lugs of the starter.

Table 2 – Installation Responsibility

Requirement Trane supplied

Trane installed

Trane supplied

Field installed

Customer supplied

Customer installed

Foundation Meet foundation requirements

Rigging Safety chains

Clevis connectors

Lifting beams

Isolation Isolation pads Other type of isolators

Electrical - Circuit breakers or fusible

disconnects (Optional)

- Unit mounted starter

- Wye Delta starter or AFD

(Adaptive Frequency Drive)

- Flow switches (may be field

supplied)

- Harmonic filters (on request

according to customer electrical

network and equipment)

- Circuit breakers or fusible disconnect

- Electrical connections to unit mounted

starter (optional)

- Electrical connections to remote

mounted starter (optional)

- Wiring sizes per submittal and local

regulations

- Terminal lugs

- Ground connections

- BAS wiring (optional)

- Control voltage wiring

- Chilled water pump contactor and

wiring including interlock

- Option relays and wiring

Water piping Flow switches (may be field

supplied)

- Taps for thermometers and gauges

- Thermometers

- Strainers (as required)

- Water flow pressure gauges

- Isolation and balancing valves in water

piping

- Vents and drain on waterbox valves

- Pressure relief valves for water side

Insulation Insulation Insulation

Water piping connection

components

- Grooved pipe

- Grooved pipe to flagged

connection (optional)

Caution on exposure to

refrigerant

Respect recommendation of IOM

addendum

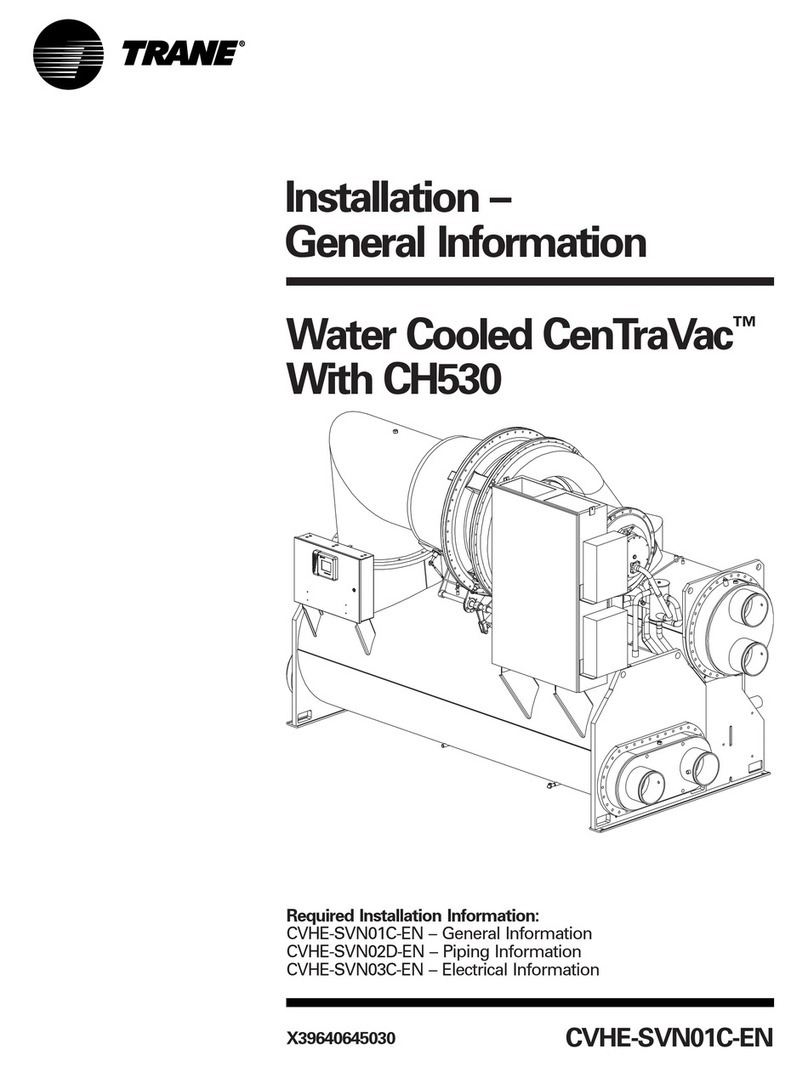

Unit Description