4 UNT-PRC002-GB

Technical Data

FWD 08 12 20 30 45

Power supply (V/Ph/Hz) 230/1/50

Capacities

Cooling capacity on water (1) (kW) 5,2 8,3 15 18,8 30,1

Heating capacity on water (2) (kW) 6,3 11,9 18,9 20,9 38,2

Fan motor (type) 2 x direct drive centrifugal

Fan power input (3) (kW) 0,23 0,46 0,65 1,04 1,51

Current amps (3) (A) 1,1 2,2 3,1 4,7 5,5

Start-up amps (A) 3,2 5,5 9,3 14,1 16,5

Air flow

minimum (m3/h) 490 980 1400 1800 2700

nominal (m3/h) 820 1650 2300 3000 4500

maximum (m3/h) 980 1970 2600 3600 5400

Main coil

Water entering/leaving connections (type) ISO R7 rotating female

(Dia) 3/4" 3/4" 1 1/2" 1 1/2" 1 1/2"

Electric heater (accessory for blower only)

Electric power supply (V/Ph/Hz) 230/1/50 230/1/50 or 400/3/50 400/3/50 400/3/50 400/3/50

Heating capacity (kW) 2/4 8 10 12 12

Hot water coil (accessory for blower only)

Heating capacity (4) (kW) 6,3 12 17,4 22,4 34,5

G2 filter (filter box accessory)

Quantity 2 2 2 2 2

Dimensions ( LxWxth) (mm) 386x221x8 486x271x8 586x321x8 586*421*8 586*621*8

G4 filter (filter box accessory)

Quantity - 2 2 2 2

Dimensions ( LxWxth) (mm) - 486x264x48 586x314x48 586*414*48 586*614*48

Condensate pump (accessory) (type) Centrifugal

Water flow - lift height (l/h - mm) 24 - 500

Not available for FWD30 and FWD45

Sound level (L/M/H speed)

Sound pressure level (5) (dB(A)) 36/40/43 38/41/44 46/50/53 47/52/57 47/52/58

Sound power level (5) (dB(A)) 46/50/53 48/51/54 56/60/63 57/62/67 57/62/68

Unit dimensions

Width x Depth (mm) 890 x 600 1090 x 710 1290 x 820 1290 x 970 1290 x 1090

Height (mm) 250 300 350 450 650

Shipped unit dimensions

Width x Depth (mm) 933 x 644 1133 x 754 1333 x 864 1333 x 1008 1333*1133

Height (mm) 260 310 360 460 660

Weight (kg) 32 46 61 76 118

Colour galvanised steel

Recommended fuse size

Unit alone (aM/gI) (A) 8/16 8/16 8/16 8/25 8/25

Unit with electric heater (gI) (A) 16 (2kW),25 (4kW) 40 (230V),3*16 (400V) 3*20 3*25 3*25

(1) Conditions: Water entering/leaving temperature: 7/12 °C, Air inlet temperature 27/19°C DB/WB - Nominal air flow

(2) Conditions: Water entering/leaving temperature: 50/45 °C, Air inlet temperature 20°C DB - Nominal air flow

(3) At high speed with nominal air flow.

(4) Water entering/leaving temperature 90/70 °C, air inlet temperature 20 °C DB, Nominal air flow.

(5) A rectangular glass wool duct 1m50 long is placed on the blower.The measurement is taken in the room containing the blower unit.

Heat exchanger operating limits:

FWD:

*water temperature: max 100° C

*absolute service pressure: min 1 bar/max 11 bars

Accessories - Hot water coil:

*water temperature: min. +2° C/max. 100° C

*absolute service pressure: min 1 bar/max 11 bars

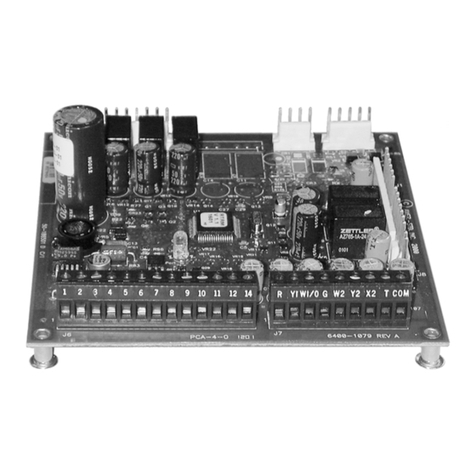

Low Voltage Wiring / Ice Making (Optional)

Low Voltage Wiring

The remote devices described below require low voltage

wiring. All wiring to and from these remote input devices

to the Control Panel must be made with shielded,

twisted pair conductors. Be sure to ground the shielding

only at the panel.

Important:

To prevent control malfunctions, do not run low voltage

wiring (<30 V) in conduit with conductors carrying more

than 30 volts.

Emergency Stop

UC800 provides auxiliary control for a customer

specified/installed latching trip out. When customer

furnished remote contact 6S2, the chiller will run

normally when the contact is closed. When the contact

opens, the unit will stop and a manually resettable

diagnostic is generated. This condition requires manual

reset at the chiller switch on the front of the control

panel.

This customer-furnished contact must be compatible

with 24 VDC, 12 mA resistive load.

External Auto/Stop

If the unit requires external Auto/Stop function, the

installer must provide remote contact 6S1.

The chiller will run normally when the contact is closed.

When contact opens, the compressor(s), if operating, will

go to the RUN: UNLOAD operating mode and cycle off.

Unit operation will be inhibited. Closure of the contact

will permit the unit to return to normal operation.

Field-supplied contacts for all low voltage connections

must be compatible with dry circuit 24 VDC for a 12mA

resistive load. Refer to the field diagrams that are

shipped with the unit.

Ice Making (Optional)

When the Ice Making Command is removed (i.e. all

the installed Ice Making inputs are set to “auto”), the

compressors shall be stopped after the run unload

period (if not already stopped due to Ice Making

Complete). The chiller shall return to normal Auto mode

of operation, and allowed to restart only after enforcing

a 2 minute delay called the “Ice to Normal Transition

time”. During this inhibit, the Evaporator water flow

request shall be commanded on. After the delay, the

chiller can restart again per the differential to start and

the normal Chilled Water Setpoint (or Hot Water Setpoint

– if in Heating Mode). The Ice To Normal Transition

inhibit shall be annunciated as a Chiller Submode and a

countdown timer showing the remaining time left shall

be displayed.

Ice Making Configuration:

Ice Making is configured through TU, and there shall be

two installation options:

1. Not Installed

2. Installed with Hardware

Ice Making: Not Installed

If the Ice Building Configuration item is set to ‘Not

Installed’, the application will not build the Ice Making

objects, and will require none of the Ice Making specific

LLIDS.

Ice Making: Installed with Hardware

If the Ice Making Configuration item is set to ‘Installed’,

the application will require the following LLIDs:

• External Ice Making Input (Dual Low Voltage Binary

Input)

Ice Making Setpoints:

After Ice Making is configured, there shall be three Ice

Making Settings or Setpoints:

1. Ice Making Command

2. Ice Making Enable/Disable

3. Ice Making Termination Setpoint

The ice making setpoints can all be manipulated through

TU. Some of the Setpoints can be manipulated with User

Interface on the Display, the External Hardware Interface

BAS (if a BAS is installed).

The setpoints associated with ice making are explained

in more detail below.

Ice Making Command

This is the command to enter ice making. This setting is

defined as an Auto/On settings. Setting this to On will

command the application into ice building if ice building

is enabled and the Chiller is in the “Auto” command

mode. Setting the Ice Making command to Auto will

command the application to follow the next priority

functional mode.

Regardless of the setting of the Setpoint Source (see

setpoint arbitration.doc) any of the following 4 signals

can combine to comprise the Ice Building Command

(assuming they are each installed).

Contact closure input for External Ice Making Command

Front Panel Ice Making Command (also writable from

TU Lontalk Communicated Ice Making Command (LCI-C,

BACnet, Modbus)

Time of Day scheduler

All ice making signals have to be turned to “auto” to be

able to turn back Ice Making Command to “Auto” mode.

The overall Ice Making Command, must be toggled from

“Ice Making”, to “Auto” to “Ice Making” again, before

Ice Making can be entered a second time.

Ice Making Enable/Disable setting

This setting does not start or stop ice building. This is

the command to enable or disable the entire ice building

feature. It can only be set through the Display or TU.

The Ice Making Command starts and stops ice building.

Ice Making Termination setpoint

This setpoint controls when Ice Making is complete. If

the Entering Water Temperature decreases below this

setpoint with no deadband Ice Making will be deemed

complete. This setpoint has a range of –6.7°C (20°F) to

0°C (32°F) with a default of -2.8°C (27°F).