HBK FS22DI User manual

FS22DI

Industrial BraggMETER DI

ENGLISH

Quick Start Guide

Hottinger Brüel & Kjaer GmbH

Im Tiefen See 45

D-64293 Darmstadt

Tel. +49 6151 803-0

Fax +49 6151 803-9100

www.hbkworld.com

HBK FiberSensing, S.A.

Rua Vasconcelos Costa, 277

4470-640 Maia

Portugal

Tel. +351 229 613 010

Fax +351 229 613 020

www.hbm.com/fs

Mat.: 7-2002.4609

DVS: A04609 04 E00 00

02.2022

Interrogator version: v2.0

SW version: v1.8

EHottinger Brüel & Kjaer GmbH

Subject to modifications.

All product descriptions are for general information

only. They are not to be understood as a guarantee of

quality or durability.

3

FS22DI

TABLE OF CONTENTS

TABLE OF CONTENTS

1 Introduction 4......................................................

2 Interrogator Setup 6................................................

2.1 Buttons and Connectors 6............................................

2.1.1 Standard Format 6..................................................

2.1.2 Rack Mountable Format 6............................................

2.2 Turn On 7..........................................................

2.2.1 Power 7...........................................................

2.2.2 Ethernet 8.........................................................

2.2.3 Optical 9...........................................................

2.3 Turn Off 9.........................................................

3 Remote Communications 10..........................................

4 BraggMONITOR DI Software 11........................................

4.1 Installation 11.......................................................

4.2 Graphical User Interface 11............................................

4.2.1 Connect to the Interrogator 11.........................................

4.2.2 Configure Measurements 12...........................................

4.2.3 Set the Configuration 13..............................................

4.2.4 Start Acquisition 14..................................................

FS22DI

INTRODUCTION

4

1 INTRODUCTION

This document is a quick start guide for operating the FS22 - Industrial BraggMETER DI

interrogator from HBK FiberSensing.

For more details please refer to the full user manual provided with the equipment. This

document is also available for download on our website.

This document applies to the following equipment:

FS22 - Industrial BraggMETER DI

Interrogator Characteristics Material Number

Acq.

Rate Enclosure Connectors Configurable Item Standard Item

Dynamic (up to 1000S/s)

Standard

1FC/APC K-FS22-01-500-120 -

SC/APC K-FS22-03-500-120 -

4FC/APC K-FS22-01-500-420 1-FS22DI-ST/4CH

SC/APC K-FS22-03-500-420 -

8FC/APC K-FS22-01-500-820 1-FS22DI-ST/8CH

SC/APC K-FS22-03-500-820 -

Rack-

Mountable

1FC/APC K-FS22-11-500-120 -

SC/APC K-FS22-13-500-120 -

4FC/APC K-FS22-11-500-420 -

SC/APC K-FS22-13-500-420 -

8FC/APC K-FS22-11-500-820 -

SC/APC K-FS22-13-500-820 -

5

FS22DI

INTRODUCTION

The FS22 - Industrial BraggMETER DI set includes:

Standard format Rack-mountable format

- Interrogator

- AC-DC power supply unit 24V

- Ethernet cable (L~2m)

- Mounting blocks with M6 screws

- Connector protection caps

- Mounting hole protection caps

- Quick start guide

- Digital support material

- Calibration certificate

- Interrogator

- Power cord (Type F plug)

- Ethernet cable (L~2m)

- Connector protection caps

- Quick start guide

- Digital support material

- Calibration certificate

FS22DI

INTERROGATOR SETUP

6

2 INTERROGATOR SETUP

2.1 Buttons and Connectors

2.1.1 Standard Format

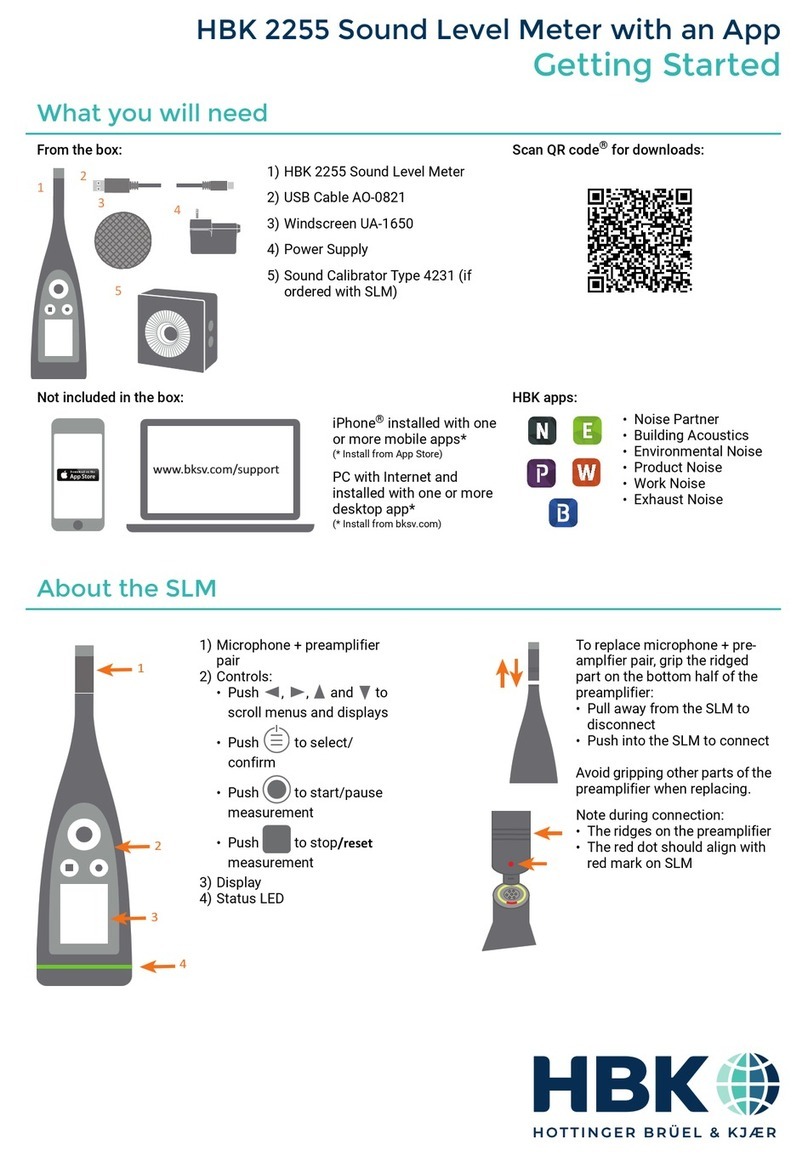

The FS22 - Industrial BraggMETER DI on its Standard format has the following buttons

and connectors:

Front view Back view

Fig. 2.1

The connectors and buttons in Fig. 2.1 are:

1Optical Output Connectors

2ON/OFF Button

3Power Connector

4Ethernet Connector

5POWER and STATUS LEDs

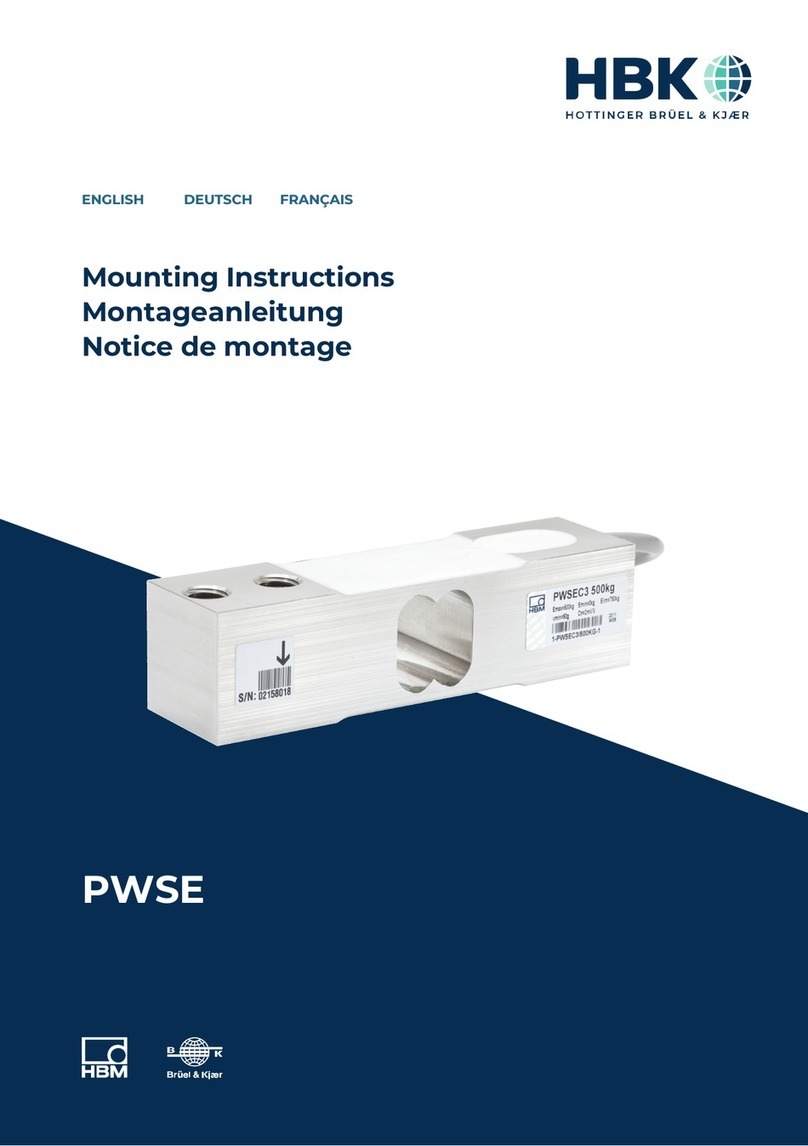

2.1.2 Rack Mountable Format

The FS22 - Industrial BraggMETER DI on its Rack-Mountable format has the following

buttons and connectors:

7

FS22DI

INTERROGATOR SETUP

Front view

Back view

Fig. 2.2

The connectors and buttons in Fig. 2.2 are:

1ON/OFF Button

2POWER and STATUS LEDs

3Optical Output Connectors

4Power Connector

5Electric fuse

6Safety Power Button

7Fans

8Ethernet Connector

2.2 Turn On

2.2.1 Power

For the Standard interrogator connect the provided power adapter to a 100-240 V power

line and the adapter to the interrogator’s power connector. Alternatively, connect the

interrogator directly to an 11-36 VDC power supply.

For the Rack-Mountable format connect the provided power cable to a 100-240 V power

line and to the interrogator’s power connector. Then, switch the safety power button ON.

Notice

Powering above the specified limits will damage the equipment. For the Rack-mountable

version there is a fuse protection that can be replaced. Please refer to the full user manual

for details.

FS22DI

INTERROGATOR SETUP

8

The Power LED will acknowledge the power supply by turning green for 2 seconds

(Fig. 2.3):

Power LED ON

2s

Fig. 2.3

Start the interrogator by pressing the “ON/OFF” button.

The Status LED will start blinking with the following order and meaning:

Status LED

Blinking 2 Hz

Status LED

Blinking 1 Hz

Status LED

On

Status LED

Blinking 2 Hz

Status LED

Blinking 1 Hz

Status LED

Blinking 5 Hz

(initialization issues)

CorrectWrong

ON(0s) ~10s >30s <60s ?s

Status LED

Blinking 5 Hz

(measurement issues)

Fig. 2.4

Please note that the durations stated in Fig. 2.4 are merely indicative and may vary

depending, for example, on the sampling rate of the interrogator.

Important

In case the interrogator does not start correctly, contact HBK FiberSensing for technical

support.

2.2.2 Ethernet

Connect the provided Ethernet cable, or any other cross over cable, from the interrogator

to your PC network.

To communicate with the interrogator using a computer both elements should be config

ured in the same subnet:

9

FS22DI

INTERROGATOR SETUP

SSet the TCP properties of the computer as follows:

-IP address: 10.0.0.xxx (where xxx should not be 150: the default IP of the FS22DI is

10.0.0.150)

-Subnet mask: 255.0.0.0

STest the connection:

-Launch a command line (e.g. Start →Run →type “cmd”, in Windows environment)

-Type and execute the following command: “ping 10.0.0.150”

-On a successful connection the response should be similar to: “Reply from

10.0.0.150: bytes=

32 time<1ms TTL=60”.

Important

The interrogator can be synchronized to other devices using NTP. For further details refer

to the full user manual of the interrogator.

2.2.3 Optical

The FS22 - Industrial BraggMETER DI can be purchased either with FC/APC or SC/APC

connectors. Select the appropriate connector type and adapter, if needed, to connect the

Fiber Bragg Grating (FBG) sensors to the interrogator.

Attention should be paid to the cleaning of the optical connector(s). A dirty connector can

compromise measurements.

2.3 Turn Off

To turn off the interrogator, the “ON/OFF” button should be pressed between 2 s to 6 s.

The power LED will start blinking acknowledging the shutdown.

Power LED blinking at 1 Hz

Fig. 2.5

Important

Pressing the power button for more than 6 s will reset the interrogators’ IP address to its

default value. Please refer to the full user manual for further details.

FS22DI

REMOTE COMMUNICATIONS

10

3 REMOTE COMMUNICATIONS

The FS22 - Industrial BraggMETER DI interrogator can be fully controlled using standard

SCPI syntax commands.

The interrogator has 5 different operational states that answer to the listed commands

below.

Fig. 3.1

For full information on the commands refer to the interrogator user manual.

11

FS22DI

BRAGGMONITOR DI SOFTWARE

4 BRAGGMONITOR DI SOFTWARE

4.1 Installation

The FS22 - Industrial BraggMETER DI interrogator is provided with the BraggMONITOR DI

software.

uTo install the software: Run Setup.exe (as administrator)

uFollow the described steps and press finish

uRestart the PC

uRun BraggMONITOR DI (as administrator)

4.2 Graphical User Interface

The following pages describe the main steps for achieving measurements with the

BraggMONITOR DI Software. For a full description of the software please refer to the full

user manual.

4.2.1 Connect to the Interrogator

To establish a connection to the interrogator press the “connect” button (number 1in

Fig. 4.1) on the general bar available at the bottom of the software window.

Fig. 4.1

FS22DI

BRAGGMONITOR DI SOFTWARE

12

4.2.2 Configure Measurements

The reflected spectrum of the connected sensors can be checked under the Spectral

View tab. Press the corresponding tab, on top of the graphical user interface, to select it

(number 1in Fig. 4.2).

Fig. 4.2

The settings to adjust on the FS22DI Interrogator are the gain (number 2in Fig. 4.2) and

the threshold (number 3in Fig. 4.2). The “get” buttons query the interrogator for the

stored values and the “set” buttons send the new values to the interrogator and store

them. The “set” buttons need to be pressed so that the defined value becomes active.

13

FS22DI

BRAGGMONITOR DI SOFTWARE

Meaning Possible

values

Suited value

Gain Factor for amplifying and

optimizing the received

signals.

0 to 255 Value that sets the power

of the FBGs in the spectrum

below saturation and above

threshold. Saturation

occurs when the peak value

is above 4095.

Thresh

old

Optical power level that

separates noise from rele

vant signal

200 to 3200 Value that leaves all peaks

above and does not cross

side lobes.

Set the values to the most appropriate ones taking into consideration the existing signals.

4.2.3 Set the Configuration

The configuration of the sensors can be adjusted under the Configuration tab (number 1

in Fig. 4.3).

Fig. 4.3

FS22DI

BRAGGMONITOR DI SOFTWARE

14

Press the “autoscan” button (number 2in Fig. 4.3) to automatically populate the sensor

list with the sensors found on the optical network considering the defined settings. The

autoscan searches for peaks and defines those found as sensors. For each sensor the

autoscan:

Sdefines an automatic name (CHxSzzz);

Ssets the reference wavelength (CWL or λ0, in nm);

Sdefines a measurement range of 2.5 nm wide (centered at the peak);

Sexpresses the measurement formula as x (wavelength variation in nm). The measure

ment formula has to be a function of x.

Any of these values can be edited manually by selecting the sensors’ cell in the configura

tion table and pressing the “edit” button (number 3in Fig. 4.3).

4.2.4 Start Acquisition

Still in the Configuration tab configure:

Fig. 4.4

SMeasurement acquisition rate (number 1in Fig. 4.4):

-Possible values: 50 S/s; 100 S/s; 200 S/s; 500 S/s; 1000 S/s

15

FS22DI

BRAGGMONITOR DI SOFTWARE

SData storage settings (number 2in Fig. 4.4):

-When saving, data is stored in separate files named automatically

“BraggMONITOR DI Data [YYYY.MM.DD.hh.mm.ss ; YYYY.MM.DD.hh.mm.ss].txt”

-File interval -> defines the length of the file in terms of acquisition time.

-Data folder -> sets the folder to which data is stored.

To start acquisition, change to the Graphical View tab (number 1in Fig. 4.5) and press the

“start” button (number 2in Fig. 4.5).

Fig. 4.5

Data will be plotted in the graph, which is updated every second. The sensors to plot can

be selected on the channels' checkboxes.

To start saving data to a data file press the “save” button (number 3in Fig. 4.5).

Important

For further information please refer to the user manual provided with the equipment. This

document is also available on our website.

Other manuals for FS22DI

1

Table of contents

Other HBK Measuring Instrument manuals