1. Introduction

Page 4106104 –TW-31-E - V1.9 - 06.04.2021

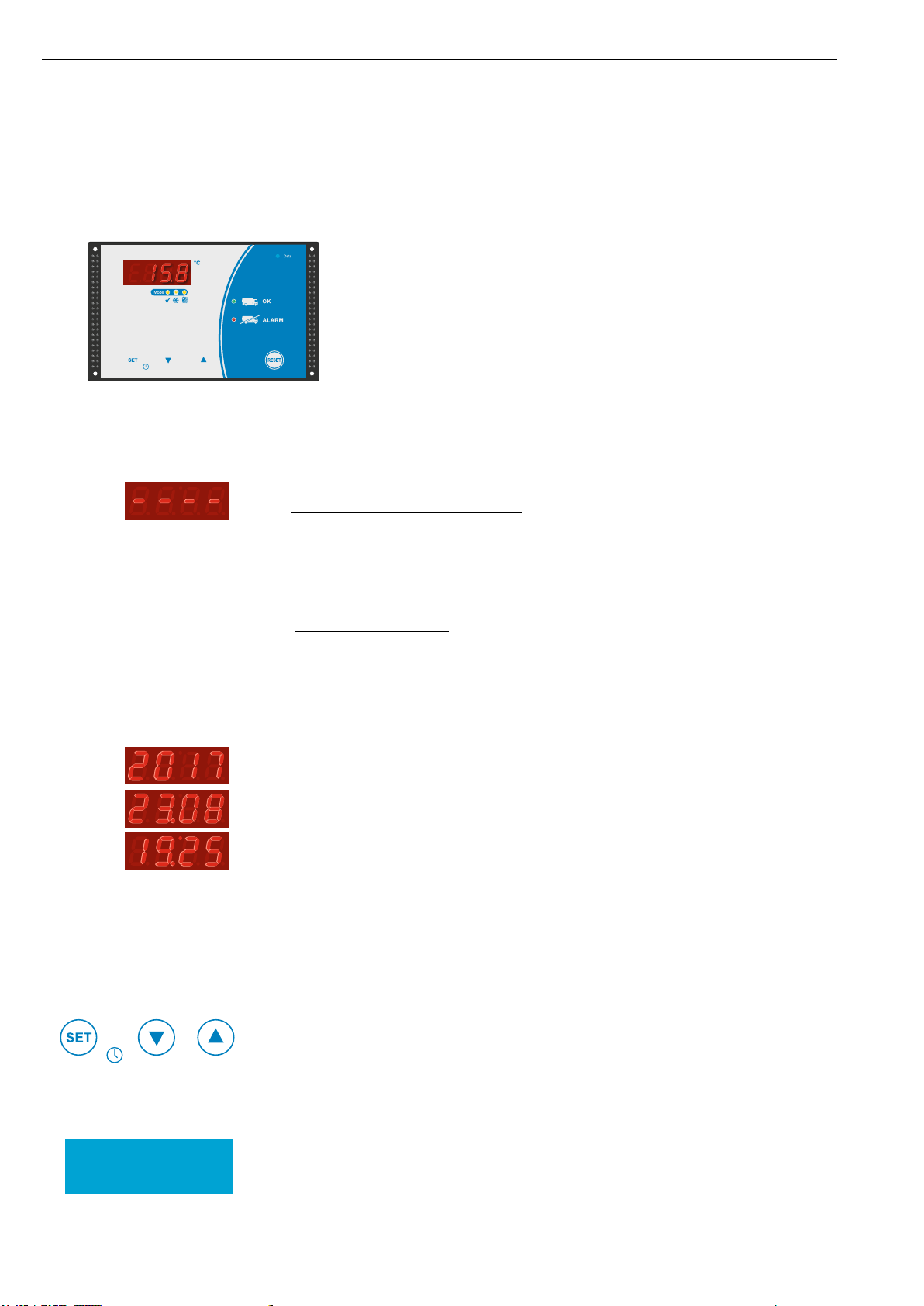

to section 1.2: Device description

Data storage/-evaluation

The determined data of the last 300 days (max.) temperatures, alarms, operating

mode changes, etc.) are stored in the CSV-format and can thus be opened in other

programs.

The data can be read out by simply inserting a standard USB-stick into the USB

socket - without further operation of the tank monitor.

EMAIL or SMS remote maintenance modems

By an optional Email or SMS remote maintenance modem error messages can be

sent via Email or SMS to inform the farmer at an early stage.

1.3 Warning notices in these operating instructions

Important safety information in these assembly instructions are identified by sym-

bols. These instructions on occupational safety must be adhered to and followed. In

these cases, behave particularly carefully in order to avoid accidents, personal injury

and property damage.

In addition to the information in these assembly instructions, the general and local

safety and accident prevention regulations must also be observed and instructed!

Nature and source of danger

This warning signs warns of an imminent danger to health and life of people. Failure

to comply with this warning will result in extremely serious injuries, including death.

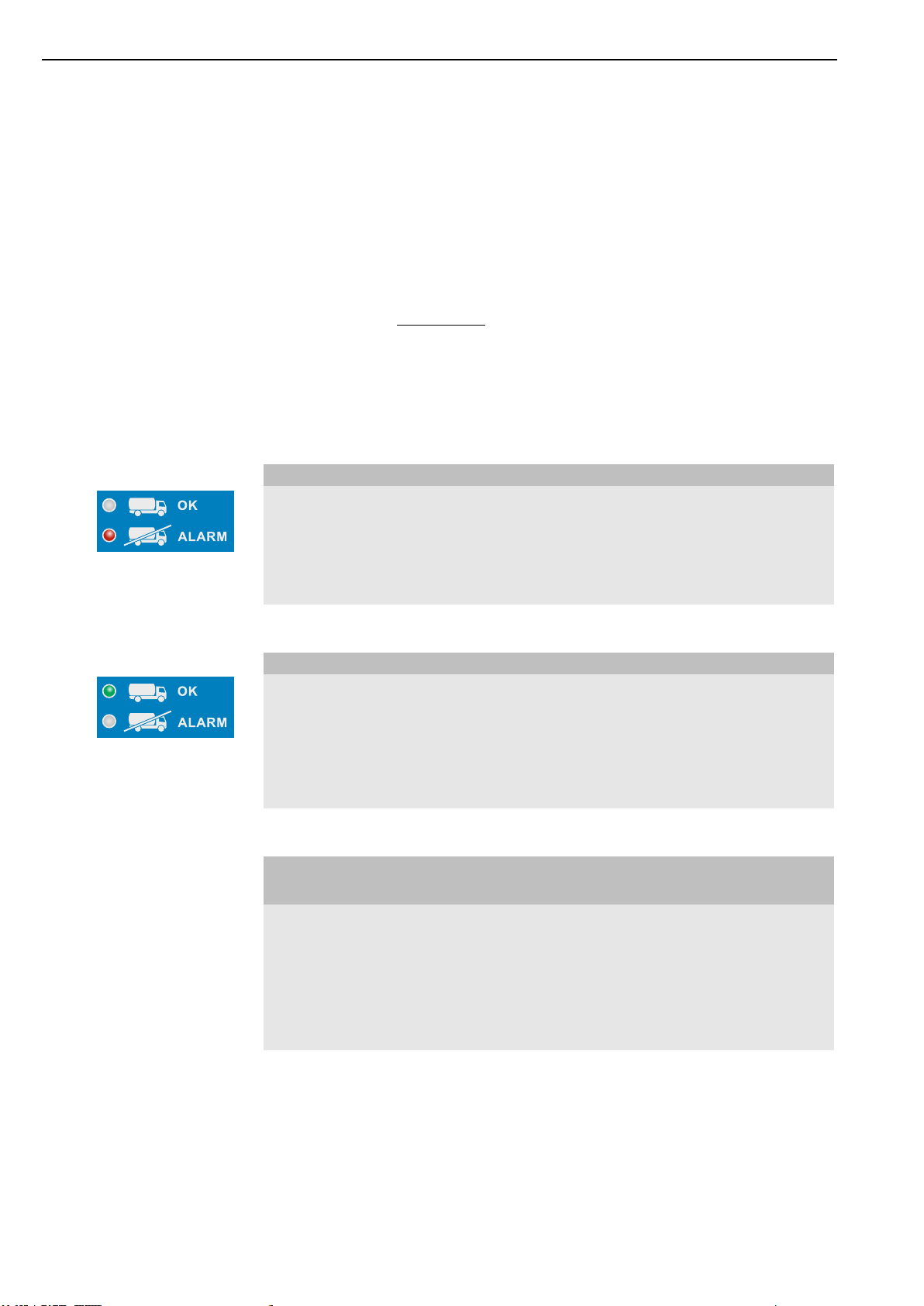

Nature and source of danger

This warning signs warns of possible property damage.

Failure to observe this warning signs can lead to further damage to the system, loss

of data or damage to the milk.

Nature and source of danger

This warning signs warns of possible operating faults. Failure to observe these warn-

ing signs can lead to loss of data or damage to the milk.

Note

General notes contain application tips and particularly useful information, but no

warnings about dangers.

1.4 Limitation of liability

The proper function of the TW-31 depends on many external factors on

which the manufacturer has no influence. The manufacturer accepts no

liability for any damages on the milk cooling tank, the connected

components or the milk. The tank monitor supports only the control of

the milk quality and does neither absolve the farmer (as operator of the

milk tank) nor the driver of the milk collecting truck from the duty of