Twin Busch GmbH

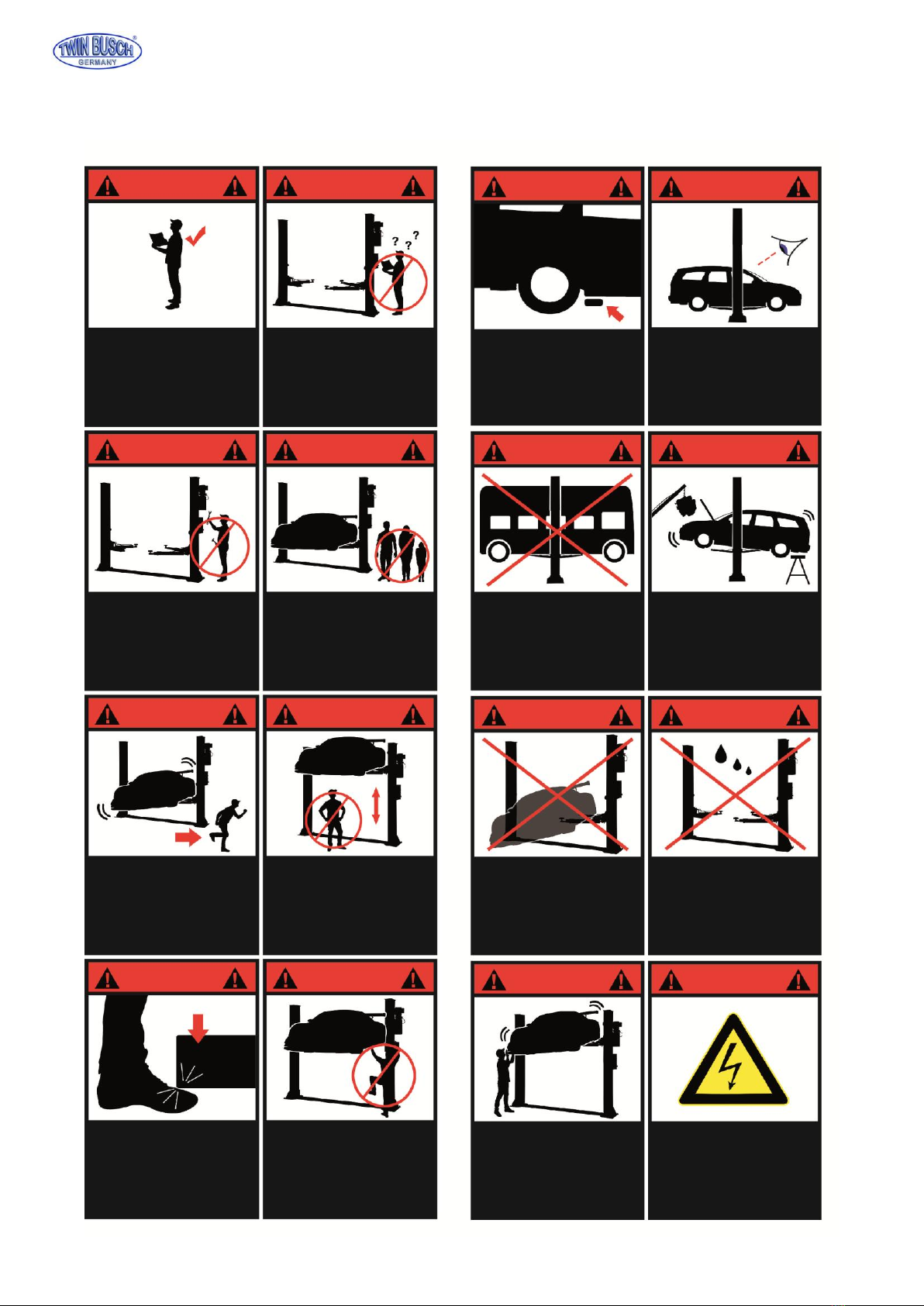

IMPORTANT SAFETY INSTRUCTIONS

1.1 Important notices

Twin Busch offers a one-year's quality warranty for the whole machine, during which any quality problem will be properly solved to

the user's satisfaction. However, we will not take any responsibility for whatever bad consequence resulted from improper

installation and operation, overload running or unqualified ground condition.

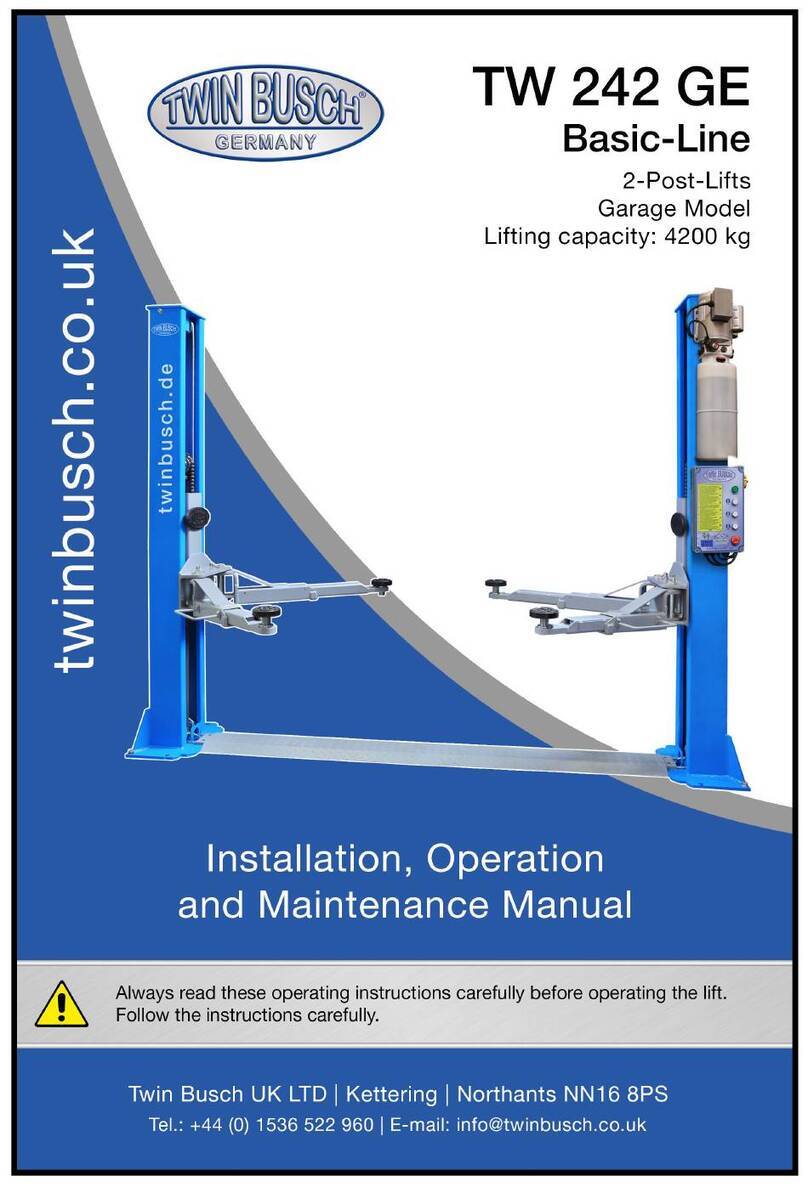

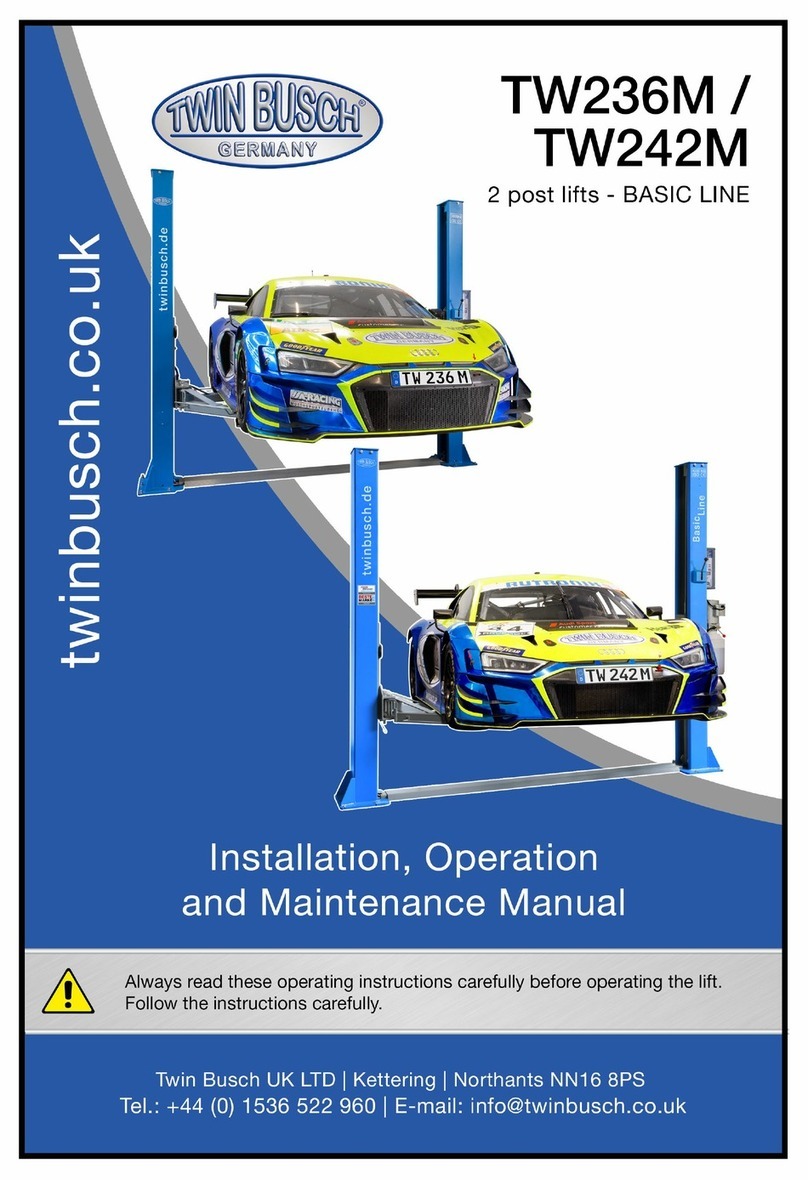

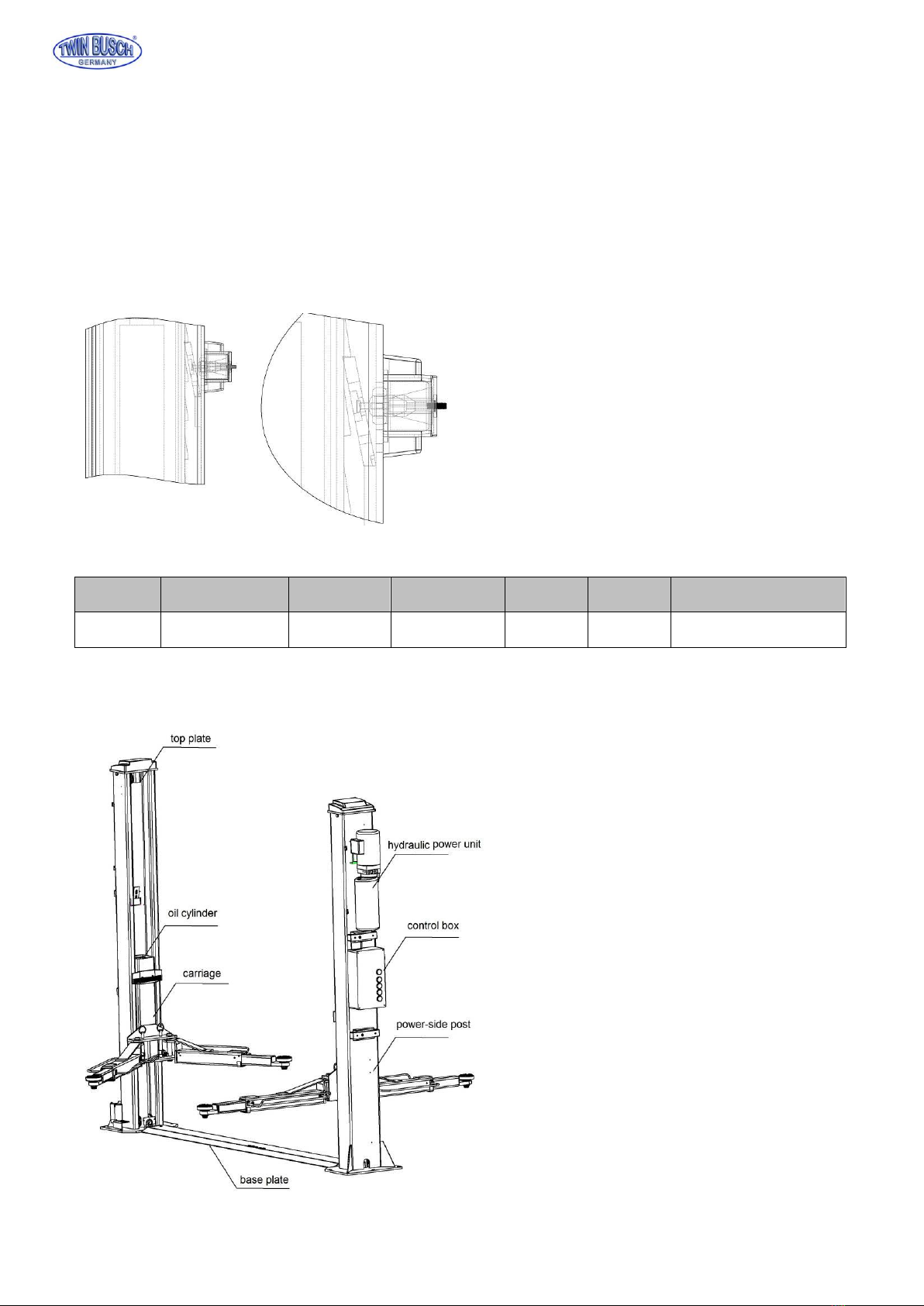

This 2-posts lift is specially designed for lifting motor vehicles that weighs within its outmost lifting capacity. Users are not allowed to

use it for any other purposes. Otherwise, we, as well as our sales agency, will not bear any responsibility for accidents or damages of

the lift. Make sure to pay careful attention to the label of the lifting capacity attached on the lift and never try to lift cars with its

weight beyond.

Read this manual carefully before operating the machine so as to avoid economic loss or personnel casualty incurred by wrong

operation. Without professional advice, users are not permitted to make any modification to the control unit or whatever

mechanical unit.

1.2 Qualified personnel

1.2.1 Only qualified staff, who have been properly trained, can operate the lift.

1.2.2 The electrical connection must be done by a competent electrician.

1.2.3 People who are not concerned are not allowed in the lifting area.

1.3 Danger notices

1.3.1 Do not install the lift on an asphalt surface.

1.3.2 Read and understand all safety warnings before operating the lift.

1.3.3 The lift, is not fit for outdoor use.

1.3.4 Keep hands and feet away from any moving parts. Keep feet clear of the lift when lowering.

1.3.5 Only qualified people that have been properly trained, can operate the lift.

1.3.6 Do not wear unfit clothes such as large clothes with flounces, tires, etc, which could be caught by moving parts of the lift.

1.3.7 To prevent evitable incidents, surrounding areas of the lift must be tidy and with nothing unconcerned.

1.3.8 The lift is simply designed to lift the entire body of vehicles, with its maximum weight within the lifting capacity.

1.3.9 Always insure the safety latches are engaged before any attempt to work near or under the vehicle.

1.3.10 Make sure to place the lifting pads to the positions as suggested by vehicle makers and when gradually lift the vehicle to the

desired height, operators should be certain that the vehicle will not slant, roll-over or slide in lifting process.

1.3.11 Check at any time the parts the lift to ensure the agility of moving parts and the performance of synchronization. Ensure

regular maintenance and if anything abnormal occurs, stop using the lift immediately and contact our dealers for help.

1.3.12 Lower the lift to its lowest position and do remember to cut off the power source when service finishes.

1.3.13 Do not modify any parts of the lift without manufacturer’s advice.

1.3.14 If the lift is going to left used for a long time, users are required to:

a. Disconnect the power source;

b. Empty the oil tank;

c. Lubricate the moving parts with hydraulic oil.

1.4 Training

Only qualified people, who have been properly trained, can operate the lift. We are quite willing to provide professional training for

the users when necessary.