Simpro Dumpmaster User manual

© Simpro Handling Equipment Ltd | v25.0 | February 2017

SERVICE MANUAL

S i m p r o D u m p m a s t e r

Copyright © 2017 Simpro Handling Equipment Ltd.

No part of this document may be reproduced or transmitted in any form or by any means,

electronic, mechanical, photocopying, recording, or otherwise, without the written permission of

the publisher.

For reasons of standards compliance and international conformity, this document uses Système

international (SI) units. These may be converted to their Imperial equivalents as follows:

1 kilogram (kg) = 2.2 pounds (lb)

1 metre (m) = 1000 millimeters (mm) = 1.09 yards (yd) = 39.37 inches (in)

The following textual conventions are used throughout this document:

Text in GREEN indicates a point of particular interest or importance.

Text in RED indicates a point of warning, or a safety hazard.

Service Manual | Simpro Dumpmaster | v25.0 | February 2017 | Page 2

Contents

1 Dumpmaster Overview................................................................................................................. 5

2 Layout of Parts.............................................................................................................................. 6

3 Troubleshooting Guide ................................................................................................................. 7

4 Electrical System...........................................................................................................................9

4.1 General Description...................................................................................................................9

4.2 Removal of outer cover.............................................................................................................9

4.3 Batteries ....................................................................................................................................9

4.3.1 Care......................................................................................................................10

4.3.2 Testing .................................................................................................................10

4.3.3 Removal and Refitting .........................................................................................10

4.4 Battery Charger .......................................................................................................................11

4.4.1 Testing .................................................................................................................11

4.4.2 Removal and Refitting .........................................................................................11

4.5 Motor Relay (battery machines only)......................................................................................12

4.5.1 Testing .................................................................................................................12

4.5.2 Removal and Refitting .........................................................................................12

4.6 Lowering Valve Solenoid .........................................................................................................13

4.6.1 Testing .................................................................................................................13

4.6.2 Removal and Refitting .........................................................................................13

4.7 Control buttons and switches .................................................................................................13

4.7.1 Testing .................................................................................................................14

4.7.2 Removal and Refitting .........................................................................................14

4.8 Door Safety Interlock...............................................................................................................15

4.9 Mains Electric Motor ...............................................................................................................16

4.9.1 General Description............................................................................................. 16

4.9.2 1-Phase Configuration .........................................................................................16

4.9.3 3-Phase Configuration .........................................................................................16

4.9.4 3-Phase Direction of Rotation .............................................................................16

4.9.5 Removal and Refitting .........................................................................................16

4.10 Transformer.............................................................................................................................17

4.11 Contactor.................................................................................................................................17

4.12 Variable Speed Drive (VSD) .....................................................................................................17

4.13 Battery Electric Motor .............................................................................................................18

4.13.1 General Description............................................................................................. 18

4.13.2 Motor Brushes..................................................................................................... 18

4.14 Wiring Diagram for Battery Dumpmaster ...............................................................................19

4.15 Circuit Diagram for Battery Dumpmaster ...............................................................................20

4.16 Wiring Diagram for 3-Phase Dumpmaster ..............................................................................21

4.17 Wiring Diagram for 1-Phase Dumpmaster ..............................................................................22

5 Hydraulic Powerpack ..................................................................................................................23

5.1 General Description.................................................................................................................23

5.1.1 Layout of 3-phase powerpack .............................................................................23

5.1.2 Layout of battery powerpack ..............................................................................23

5.1.3 Layout of powerpack valve body.........................................................................24

5.2 Removal and Refitting .............................................................................................................24

5.3 Hydraulic Oil Tank....................................................................................................................24

5.3.1 Removal and Refitting .........................................................................................24

5.4 Lowering Valve ........................................................................................................................25

5.4.1 Removal and Refitting .........................................................................................25

5.5 Pressure-Compensating Lowering Speed Valve......................................................................25

5.5.1 Removal and Refitting .........................................................................................25

5.6 Pressure-Relief Valve...............................................................................................................26

5.6.1 Adjustment ..........................................................................................................26

5.7 Check Valve .............................................................................................................................26

5.7.1 Removal and Refitting .........................................................................................26

6 Hydraulic Ram.............................................................................................................................27

6.1 General Description.................................................................................................................27

6.2 Removal and Refitting .............................................................................................................27

6.3 Dismantling and Servicing .......................................................................................................27

6.4 Ram Alignment ........................................................................................................................28

6.5 Ram Guide Channel.................................................................................................................28

6.6 Hose-burst Valve .....................................................................................................................28

6.7 Ram-end Rollers ......................................................................................................................29

6.7.1 Removal and Refitting .........................................................................................29

6.8 Ram Replacement ...................................................................................................................29

7 Bin Cradle....................................................................................................................................31

Service Manual | Simpro Dumpmaster | v25.0 | February 2017 | Page 4

7.1 General Description.................................................................................................................31

7.2 Removal and Refitting .............................................................................................................31

7.3 Cradle Jamming .......................................................................................................................32

7.3.1 Cradle jams at top of cycle ..................................................................................32

7.3.2 Cradle jams part-way down.................................................................................32

7.4 Cradle Levelling .......................................................................................................................32

8 Guarding and Door .....................................................................................................................33

8.1 Mesh Guarding and Side-hinge Door ......................................................................................33

8.1.1 Mesh guarding assembly.....................................................................................33

8.2 Sheet-metal Guarding and Lift-up Door ..................................................................................33

8.2.1 Sheet-metal guarding assembly: .........................................................................34

8.3 Other Covers............................................................................................................................34

9 General .......................................................................................................................................35

9.1 Lifting Chains ...........................................................................................................................35

9.1.1 Removal and Refitting .........................................................................................35

9.2 Castor Wheels .........................................................................................................................35

9.3 Dumpmaster Lifting Arrangement ..........................................................................................36

10 Common Spare Parts ..................................................................................................................37

1Dumpmaster Overview

Dumpmaster bin tippers use hydraulic force to safely raise and invert bins. The hydraulic oil

pressure is supplied by a ‘powerpack’, which may be powered either by batteries, 1-phase or 3-

phasemains electricity, or compressed air (for hazardous environments).

When the ‘Raise’ button is pressed, a motor drives a pump which forces hydraulic oil under

pressure into the lift ram, causing it to extend. The ram has two chain rollers on one end; as it

extends, two chains are pulled evenly around the rollers. These chains go up to the top of the

machine; one goes around a roller and down inside the ‘near’ mast, and the other goes across the

top and down inside the ‘far’ mast. The chains are attached to plates that run inside the masts;

these plates lift the main axle of the bin cradle.

When the ‘Down’ button is pressed, a valve opens and the oil passes back into the tank at a

controlled rate. The bin and cradle are not powered down –they come down by gravity alone. A

track and roller arrangement at the top of the cradle guides the bin straight up until it reaches the

correct height, then gently rolls it forward. The whole action is smooth and efficient, and can

handle very heavy bins continuously with little or no maintenance.

By default, there is no limit switch fitted to shut the motor off at the top of the cycle. The operator

simply releases the ‘Raise’button once the cradle has stopped moving; because the system is

hydraulic this does not damage the machine. A limit switch may be fitted on request.

Dumpmasters are fully guarded and have a locking door. Various door styles are used, depending

on the application. The most common type on the Dumpmaster is side-hinged with a single door

lock. Some machines have a ‘Lift-up’ door which is supported on 4 arms and balanced by gas struts.

The door lock serves two functions –it keeps the door locked at all times except when the cradle

is fully lowered, and prevents the cradle from being raised unless the door is closed. The locking

and control systems may be monitored to a Category 3/PLd or Category 4/PLe level if required for

additional safety.

Standard Dumpmasters have a hot-dip galvanised main frame, with zinc-plated guarding panels

and powder-coated covers. The bin cradle is normally made from pre-galvanised sheet. Where

required for hygiene or corrosion-resistance, they may be made partially or entirely from stainless-

steel.

Service Manual | Simpro Dumpmaster | v25.0 | February 2017 | Page 6

2Layout of Parts

3Troubleshooting Guide

Faults generally fall into one of three broad categories - Electrical, Hydraulic, or Mechanical. The

first step in troubleshooting should be to determine which category the fault comes under.

Issue

Possible Cause

Category

Action / Reference

Lift motor does

not run when

the Raise

button is

pressed

Battery Discharged (battery

machines only)

E

Refer to Section 4.3 or 4.4

Faulty door lock or wiring

E

Refer to Section 4.8

Door not closed properly or

lock actuator damaged

M

Refer to Section 4.8

Motor relay/contactor faulty

E

Refer to Section 4.5 (battery) or

4.11 (mains)

Key switch or Raise/Lower

switch faulty

E

Refer to Section 4.7

Faulty motor

E

Refer to Section 4.9 (mains) or

4.13 (battery)

Blown control-circuit fuse or

circuit-breaker

E

Refer to Section 4.10

Lift motor runs

but the cradle

does not lift

Motor running wrong

direction

(3-phase machines only)

E

Refer to Section 4.9.4

‘Lower’ button stuck on

E

Refer to Section 4.7

Foreign matter in lowering

valve

H

Refer to Section 5.4

Bin too heavy or pressure-

relief valve set too low

H

Refer to Section 5.6

Oil level too low

H

Identify source of oil leak, and

rectify before topping up oil

reservoir. Refer to Section 5.3

The cradle

won't come

down from the

raised position

Chain not in correct grooves

on roller or wear strip

M

Refer to Section 9.1

Cradle spacer washers tight

between masts

M

Refer to Section 7.3

Lack of lubrication

M

Refer to Section 7.3

Lift Ram binding

M/H

Refer to Section 6.4

Lifting chains rusty or seized

M

Refer to Section 9.1

Faulty lowering valve

H

Refer to Section 5.4

Faulty lowering valve solenoid

E

Refer to Section 4.6

Faulty ‘Lower’ switch or wiring

E

Refer to Section 4.7

‘Hose-burst valve’ activated

H

Refer to Section 6.6

Another problem

E/H/M

Refer to Section 7.3.1

Service Manual | Simpro Dumpmaster | v25.0 | February 2017 | Page 8

The cradle jams

partway down

Cradle not sitting level

M

Refer to Section 7.4

Mast bent or damaged

M

The mast needs to be

straightened/repaired. Contact

your agent for assistance.

Insufficient weight on the

main axles

M

Cradle may need additional

ballast. Contact your agent for

assistance.

Lack of lubrication

M

Lubricate mast, cradle and

guides with silicone spray.

Another problem

E/H/M

Refer to Section 7.3.2

Insufficient

tipping cycles

per charge

Batteries faulty or too old

E

Refer to Section 4.3.2

Faulty charger

E

Refer to Section 4.4.1

Blown fuse or circuit breaker

in mains supply

E

Refer to Section 4.10

Faulty charging lead

E

Refer to Section 4.4.1

Powerpack

noisy, cradle

lifting slowly,

or oil foaming

Worn shaft seal on pump

H

Contact Simpro to request

replacement seal.

Suction pipe leaking

H

Repair or replace suction pipe.

Pump bolts loose, seal leaking

H

Check tightness of all bolts. If

problem persists, seal may

need to be replaced.

Cracked housing

H

Contact Simpro to request

replacement powerpack.

4Electrical System

4.1 General Description

The standard Dumpmaster control circuit is 24v DC (however on certain older 3-phase machines it

may be 24v AC).

On new machines the control buttons switch the negative side of the motor contactor/relay and

lowering coil. The positive side of the circuit is switched off when the door is open.

In all cases, when the ‘Raise’ button is pressed, the motor runs and oil is forced into the lift ram

under pressure, which makes the cradle go up. When the ‘Lower’ button is pressed, a solenoid coil

is energized, which opens a valve and allows oil back into the tank. The cradle comes down by

gravity alone –it does not power down.

Battery-powered Dumpmasters have a 24vdc/800W motor. All mains-powered machines have a

3-phase 0.75kW motor. 1-phase machines have a VSD (Variable Speed Drive) with 1-phase input/3-

phase output, which gives better performance and reliability than using a 1-phase motor.

Some machines with VSD are fitted with a joystick controller instead of ‘Raise’and ‘Lower’buttons.

The Raise/Lower buttons, key switch and Emergency Stop are all rated to IP66. The motor is IP55

but as it is mounted inside the powerpack covers which are sealed to the frame at the top, the

likelihood of water getting into the motor is very low.

4.2 Removal of outer cover

The outer cover must be removed to gain access to the powerpack and most electrical

components. The procedure to remove it is:

1. On battery-powered machines, turn the main isolator switch to the Off position and remove

the key.

2. Undo the two screws at the top of the cover

3. Pull the top of the cover out away from the frame, then lift so the pins at the bottom come

out of the holes in the base frame.

4. The wires on the cover may be left connected, and the cover leant against the frame;

alternatively the loom may be separated at the plug and socket, and the cover moved right

out of the way. The control voltage is 24vdc as standard.

5. Refitting is a reversal of the steps above.

4.3 Batteries

Battery-powered machines normally have two sealed gel batteries in series, to give a 24-volt

operating system. They are installed below the powerpack.

The useful life per charge is dependent on a number of factors including the age of the batteries,

the condition of the charger, and the ambient temperature.

Service Manual | Simpro Dumpmaster | v25.0 | February 2017 | Page 10

Overall battery life is also dependent on a number of factors, including the total number of

discharge/charging cycles and the average depth of discharge.

4.3.1 Care

Keep the batteries clean and dry by wiping with a soft cloth. Ensure that both terminal clamps are

securely tightened.

4.3.2 Testing

1. Remove the outer powerpack cover as described in Section 4.2, but leave the loom

connected, and sit the cover to one side.

2. Measure the battery voltage with a multimeter, with the charger disconnected.

3. Plug the charger in, and measure the voltage again.

4. Disconnect the charger, and measure the voltage again.

5. Finally, measure the voltage while pressing the ‘Raise’ button.

If the voltage increases when the charger is connected, but drops back to below 24 volts when it

is disconnected, the batteries probably need replacing.

If voltage does not increase when the charger is connected, check the charger as per Section 4.4.

If the voltage drops by more than 1.5 volts when the ‘Raise’button is pressed with no load on the

cradle, the batteries probably need replacing.

If you are unsure, or if the batteries are no more than a year old, return them to your battery

supplier for testing.

4.3.3 Removal and Refitting

1. Remove the outer powerpack cover as described in Section 4.2.

2. Disconnect the cables and joining link from the battery terminals and slide the batteries out

of the retaining brackets.

3. To avoid shorting across the positive and negative terminals (which are adjacent to each

other), we recommend firstly removing the link plate connecting the two batteries on the

right-hand side.

4. Undo the red cable from the outer battery and slide it out.

5. Undo the black cable and slide the ‘inner’ battery out.

6. Install in reverse order, ensuring all four terminal bolts are tight.

4.4 Battery Charger

4.4.1 Testing

If the battery does not hold its charge, or will not accept a charge, the fault could be either the

battery or the charger. Follow the steps below to determine the problem.

1. Check the charging lead and that the power point is live, by connecting another appliance or

power tool.

2. If the supply voltage is OK, remove the outer cover. Using a good quality digital multimeter

in DC range, measure the voltage across both batteries, with the charger disconnected.

3. Plug the charger in and measure the voltage again. If the voltage does not increase when the

charger is plugged in, it is likely that the charger is faulty. If the voltage does increase, one or

both batteries may be faulty.

4. Unplug the charger again, then measure the voltage of each battery separately while holding

the Raise button. If the voltage drops by 2 or more volts, the battery should be replaced.

Normally both batteries should be replaced together.

4.4.2 Removal and Refitting

1. Remove the outer powerpack cover as described in Section 4.2.

2. Disconnect the charger plug, loosen the bolt that holds the charger in the bracket, and slide

the charger out.

3. To replace, slide the charger into the bracket, tighten the bolt and reconnect the plug. Do

not over-tighten the bolt.

4. Reconnect the main loom plug and socket, and replace the outer cover.

Battery Charger

•Fitted into steel bracket

in battery compartment

•Works with any mains

supply between 110-240v

•Digital battery

management to prevent

overcharging

Service Manual | Simpro Dumpmaster | v25.0 | February 2017 | Page 12

4.5 Motor Relay (battery machines only)

4.5.1 Testing

1. Remove the outer powerpack cover as described in Section 4.2.

2. The relay is mounted on the side of the motor. It should ‘click’ when the ‘Raise’ switch is

pressed. If there is no click, check that a signal is getting to the switching wires on the relay

by connecting a multimeter to the small wires and pressing the ‘Raise’ switch. If a signal is

present but the relay does not ‘click’, it may be faulty. If no signal is present, check the wiring

and switch.

3. If the relay ‘clicks’ but the motor does not run, hold a screwdriver across the two large

terminals on the relay. If the motor runs now, the relay is faulty and should be replaced. If it

still does not run, the fault is probably either the battery or the motor itself.

4.5.2 Removal and Refitting

1. Disconnect the wires from the relay, noting their position for correct replacement.

2. Remove the screws or band clamp holding the relay on to the motor.

3. Replace the relay, reconnect the wires and test.

Motor Relay

•Electromechanical

solenoid switch

•Activates the

motor when the

'Raise' button is

pressed

4.6 Lowering Valve Solenoid

4.6.1 Testing

1. Remove the outer powerpack cover as described in Section 4.2.

2. The solenoid should make a faint ‘click’ when the ‘Lower’ switch is pressed, and an LED in

the plug should glow.

3. If no signal is present, check the Raise/Lower switch and wiring.

4. If a signal is present, the coil itself may be faulty, or the valve may be sticking. To check the

coil, use a multimeter in 200 ohms range, and hold a probe on the two opposite terminals;

it should give a reading of between 6 and 8 ohms. If this is OK, remove and check the valve

as described in Section 5.4. If not, replace the solenoid as described below.

4.6.2 Removal and Refitting

1. Undo the nut on the valve stem.

2. Remove the solenoid coil, noting the orientation.

3. Replace the correct way around, refit the O-ring and nut. The nut must be tightened finger-

tight only.

4.7 Control buttons and switches

Lowering Valve

Solenoid

•When open, this

electromagnetic valve

allows oil to flow back

into the reservoir,

lowering the cradle

Raise/Lower

Switch

•Switch unit

•2 x N.O. Contact

blocks

•Rubber boot

Service Manual | Simpro Dumpmaster | v25.0 | February 2017 | Page 14

4.7.1 Testing

1. Check that the button unit is assembled correctly, is not sticking, and that the contact block

is activated correctly.

2. Test the contact block with a multimeter.

3. If faulty, either the contact block or the complete button unit may need to be replaced.

4.7.2 Removal and Refitting

1. Remove the powerpack cover as described in Section 4.2.

2. The coupler and contact block(s) can be unclipped from the actuator by turning the release

clip.

3. The individual contact blocks can be unclipped from the coupler.

4. The actuator portion of the switch can be removed by unscrewing the nut under the control

panel. When refitting, note that the small location lug on the Raise/Lower switch goes in the

cut-out in the cover.

5. A rubber boot is normally fitted over the top portion of the Raise/Lower switch before it is

screwed onto the cover.

6. To refit, first replace the top section in the cover, and then clip the lower section on. Note

that these can only be fitted in the correct orientation.

Key Switch

•1x Switch unit

•1x N.O.

Contact block

•2x Keys

Emergency

Stop Button

•1x Button

•1 x N.C. Contact

block

4.8 Door Safety Interlock

All Dumpmasters are now fitted with a door interlock unit, which has contacts that are ‘made’

when the door is shut and/ locked. The door lock gets a signal to unlock only when the cradle is on

the ground, and only allows the machine to be operated when the door is closed.

The door lock operates on a ‘power to release’ principle, which means the door cannot be opened

if the power supply is disconnected or faulty. However, the door does need to be opened during

the initial assembly process, before the power is connected. For this reason, Dumpmasters are

shipped with the door lock disabled using a manual override key. The lock should be re-enabled

using this key before use.

The door lock can be retrofitted to some older Dumpmaster models.

If required by a Hazard and Risk Assessment or the end-user’s site policies, Dumpmasters may be

fitted with a system which continuously monitors all electrical equipment including the door lock.

Dumpmasters may be monitored up to a Category 4/PLe level if required.

Door Safety

Interlock

•Note yellow lock

override key

•Always turn to'Lock'

position before use

Service Manual | Simpro Dumpmaster | v25.0 | February 2017 | Page 16

4.9 Mains Electric Motor

4.9.1 General Description

The motor fitted to 3-phase Dumpmasters is a two-pole type and generates 0.75kW. The motor

only runs when the ‘Raise’ button is pressed; the cradle is lowered by gravity alone.

It is connected in ‘star configuration’ on machines with a 1-phase supply and VSD, and ‘delta

configuration’ on 3-phase machines.

4.9.2 1-Phase Configuration

4.9.3 3-Phase Configuration

4.9.4 3-Phase Direction of Rotation

The motor must rotate anticlockwise when viewed from above, for the machine to operate. If

rotation is incorrect, the motor will run but the cradle will not lift. To change the direction, swap

any two phase wires over in the plug.

4.9.5 Removal and Refitting

1. Remove entire powerpack as described in Section 5.2.

2. Undo the four screws holding the adaptor flange to the powerpack and lift the motor away.

3. If replacing with another motor, swap the adaptor flange and coupling over to the new

motor.

4. When reassembling the powerpack, ensure the motor coupling lines up with the pump shaft.

1-Phase

Dumpmaster

with VSD

•Star

configuration

3-Phase

Dumpmaster

•Delta

configuration

4.10 Transformer

A 240-24v or 400-24v transformer is used on standard (non-monitored) mains-powered machines

to provide the control voltage. The transformer is rated at 26VA, and has input and output fuses

(both 1.25 amp) and/or a 1.5A circuit-breaker.

If there is no voltage in the control circuit, firstly check the fuses in the electrical enclosure. If the

fuses are OK but there is still no current, the transformer may need to be replaced.

4.11 Contactor

The maximum current draw of the contactor coils is 1 amp.

If replacement is necessary, ensure that the specifications match the original (preferably sourced

from Simpro or your Simpro agent).

4.12 Variable Speed Drive (VSD)

The Variable-Speed Drive used on 1-phase Dumpmasters has 1-phase/230vac/50Hz input, with

220v/3-phase/<60Hz output and is suited for a 0.75kW motor.

There are dozens of parameters that can be set to suit specific applications. A list of settings is

available from Simpro if needed. They can be connected to and calibrated by a PC that has the

appropriate program and cable drivers loaded.

On some models the program can be simply downloaded from a small plug-in module.

Residual voltages may be retained in the inverter after it has been disconnected from the power

supply. Use extreme caution when the main supply or motor cables.

Service Manual | Simpro Dumpmaster | v25.0 | February 2017 | Page 18

4.13 Battery Electric Motor

4.13.1 General Description

Battery-powered Dumpmasters are fitted with a series-wound 24V DC electric motor, which

generates 0.8kW. The motor only runs when the ‘Raise’ button is pressed; the cradle is lowered

by gravity alone.

Positive supply to the motor comes through the relay mounted on the side of the motor (see

Section 4.5); negative is permanently connected to the motor terminal.

4.13.2 Motor Brushes

The motors have four brushes which wear down over time. As the brushes are difficult and time-

consuming to replace, it is usually better to fit a complete new motor.

4.14 Wiring Diagram for Battery Dumpmaster

This is a generic diagram only. Individual machines may differ depending on date of manufacture.

Always refer to the ‘as-built’ circuit diagram affixed to the inside of the powerpack cover.

Other manuals for Dumpmaster

1

Table of contents

Other Simpro Lifting System manuals

Simpro

Simpro Multi-Tip 1600 User manual

Simpro

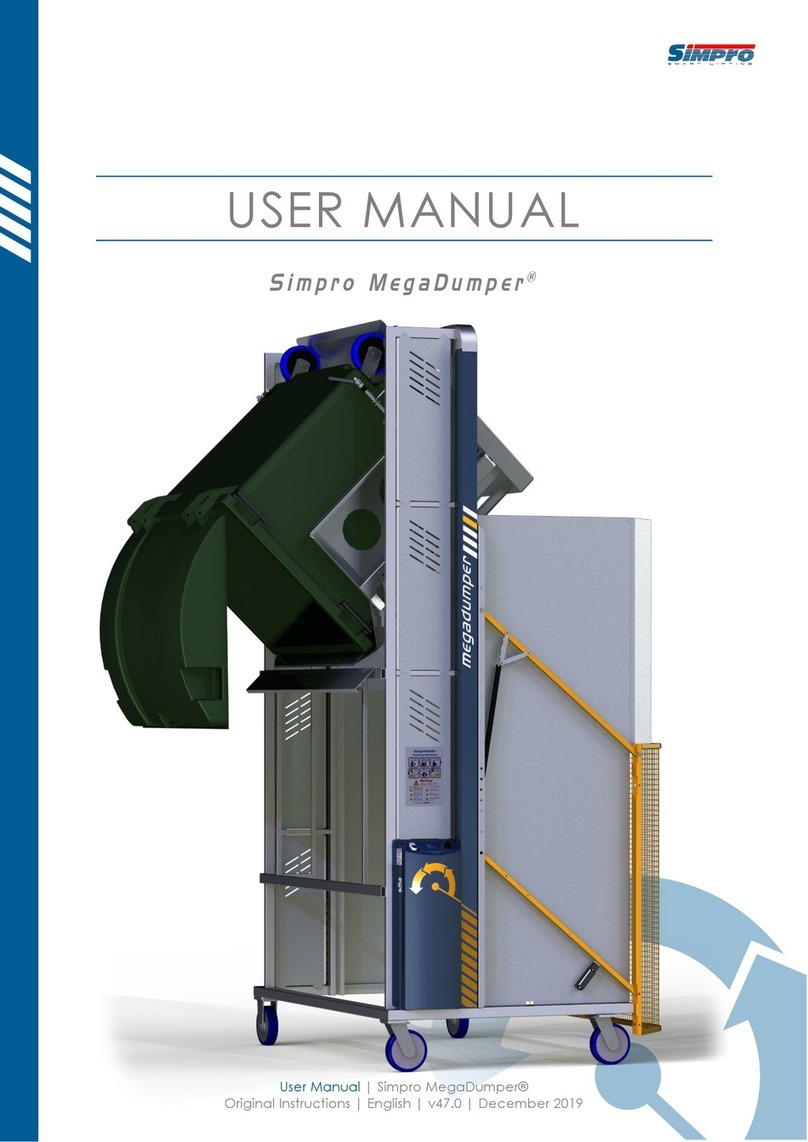

Simpro MegaDumper Series User manual

Simpro

Simpro Multi-Tip User manual

Simpro

Simpro Multi-Tip MT1200 User manual

Simpro

Simpro Multi-Tip User manual

Simpro

Simpro MegaDumper User manual

Simpro

Simpro Microstacker User manual

Simpro

Simpro QUIKSTAK QS10MM User manual

Simpro

Simpro EUROVER User manual

Popular Lifting System manuals by other brands

Stenhoj

Stenhoj MASCOT 1.25 Operation and maintenance instructions

morse

morse 400A-96SS-125 Operator's manual

JLG

JLG LIFTLUX 210-25 Operation and safety manual

Titan Lifts

Titan Lifts HD2P-10000AC-D Installation, operation & maintenance manual

morse

morse 195A-A Operator's manual

Lifton

Lifton DUO user manual