Routing Safety

nDisconnect machine from power source before

carrying out any adjustments.

nCurrent Personal Protection Equipment (PPE) for

eye, ear and respiration protection must be worn.

Keep hands, hair and clothing clear of the cutter.

nBefore each use check that the cutting tool is

sharp and free from damage. Do not use the

cutting tool if it is dull, broken or cracked or if

any other damage is noticeable or

suspected.

nClamping surfaces shall be cleaned to

remove dirt, grease, oil and water.

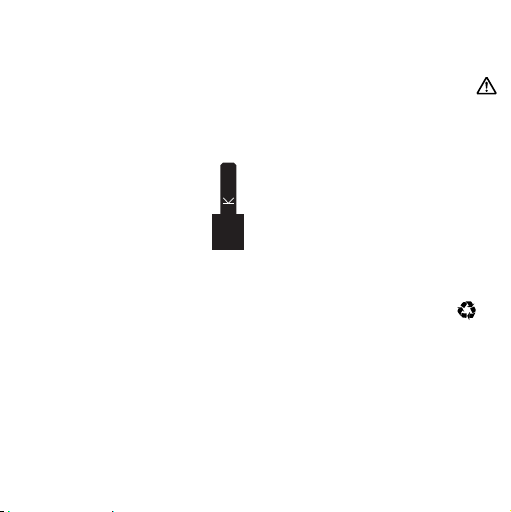

nTool’s shank must be inserted into the

router’s collet until the K mark is at least

covered partially or fully by the collet.

nTools and tool bodies shall be clamped

in such a way that they shall not

become loose during operation.

nCare shall be taken when mounting cutting tools

to ensure that the clamping is by the shank of

the cutting tool and that the cutting edges are not

in contact with each other or with the clamping

elements.

nFastening screws and nuts shall be tightened

using the appropriate spanners etc., and to the

torque value provided by the manufacturer.

nExtension of the spanner or tightening using

hammer blows shall not be permitted.

nClamping screws shall be tightened according to

instructions provided by the manufacturer. Where

instructions are not provided, clamping screws

shall be tightened in sequence from the centre

outwards.

nALWAYS WEAR EYE PROTECTION.

nIn case of excessive vibrations while using the

router stop immediately the operation and have

the eccentricity of the router cutter and clamping

system checked by competent personnel.

Maximum Speed (n.max)

nThe maximum speed marked on the tool, or shown

in the chart or on the packaging, shall not be

exceeded. Where stated, the speed range should

be adhered to.

Router Cutter Repair/Maintenance

nRepair of tools is only allowed in accordance with

the manufacturers instructions.

nThe design of composite (tipped) tools shall not

be changed in the process of repair. Composite

tools shall be repaired by a competent person,

i.e. a person of training and experience, who

has knowledge of the design requirements and

understands the levels of safety to be achieved.

nRepair shall therefore include, e.g. the use of spare

parts which are in accordance with the specification

of the original parts provided by the manufacturer.

nTolerances which ensure correct clamping shall be

maintained.

nCare shall be taken that regrinding of the

cutting edge will not cause weakening

of the body and the connection of the

cutting edge to the body.

ENVIRONMENTAL PROTECTION

Recycle raw materials instead of disposing as

waste.

Packaging should be sorted for environmental-

friendly recycling.

The product and its accessories at the end of its life

should be sorted for environmental-friendly recycling.

GUARANTEE

All Trend products guaranteed against any defects

in either workmanship or material, except products

that have been damaged due to improper use or

maintenance.

Please see Trend website:

A