POF 1200 D3 GB│IE │ 5 ■

4. Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

c) Disconnect the plug from the power source

and/or remove the battery pack, if detach-

able, from the power tool before making any

adjustments, changing accessories, or storing

power tools. Such preventive safety measures

reduce the risk of starting the power tool acci-

dentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check

for misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tool’s operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and accessory

tools etc. in accordance with these instruc-

tions, taking into account the working condi-

tions and the work to be performed. Use of

the power tool for operations different from

those intended could result in a hazardous

situation.

h) Keep handles and grasping surfaces dry,

clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for

safe handling and control of the tool in unex-

pected situations.

5. Service

a) Have your power tool serviced by a qualified

repair person using only identical replace-

ment parts. This will ensure that the safety of

the power tool is maintained.

Safety instructions for routers

a) Always hold the appliance using the insulated

handle surfaces since the milling cutter can

damage its own power cord.

Contact with a live wire may make exposed

metal parts of the power tool live and could

give the operator an electric shock.

b) Fix and secure the workpiece to a stable base

using clamps or other methods. If you only

hold the workpiece in your hands or against

your body it will remain unstable, and this can

result in loss of control.

■ Wear a dust mask.

Supplementary notes

■ The maximum speed of the milling tool used

must be at least as high as the maximum

speed specified for the power tool. Accesso-

ries which rotate faster than the maximum

permissible rate can be destroyed.

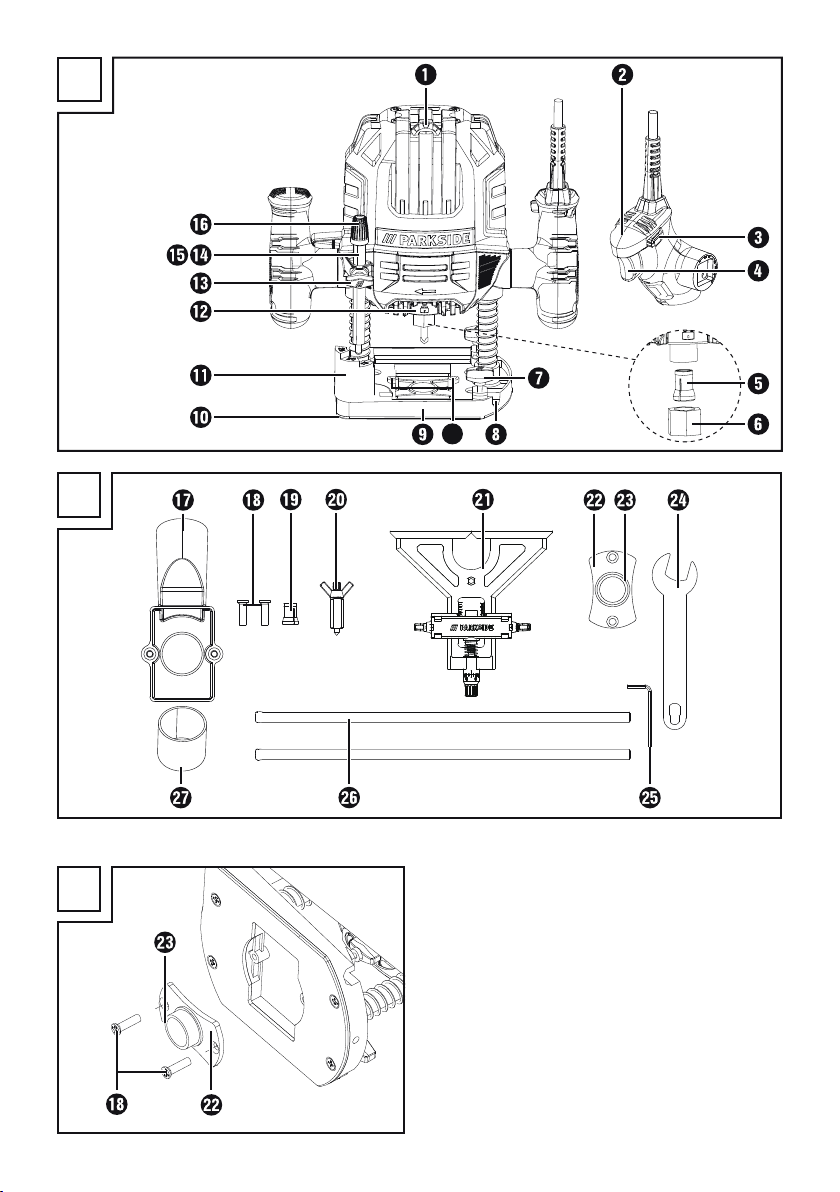

■ Cutters or other accessories must fit exactly

into the collet chuck (shank diameter 6/8 mm)

of your power tool. Milling tools which do not

fit precisely into the collet chuck of the power

tool will rotate unevenly, vibrate severely and

can lead to a loss of control.

■ Always switch on the electrical power tool

before applying it to the workpiece. Other-

wise, there is a risk of a kickback if the acces-

sory tool gets caught in the workpiece.

■ Keep your hands clear of the milling area and

the milling tool. Hold the auxiliary handle or

motor housing with your other hand. If both

hands are being used to hold the milling machine,

neither can be injured by the milling cutter.