T5

-3-

6. Respiratory protection. Wear a face or

dust mask, or powered respirator.

Dust masks/filters should be changed

regularly.

7. Do not switch router on with the cutter

touching the workpiece. At the end of

the cut, release the router plunge and

allow spindle to stop rotating. Never

use the spindle lock as a brake

8. The direction of routing must always

be opposite to the cutter's direction of

rotation. Do not back-cut or climb-cut.

9. Check before cutting that there are no

obstructions in the path of the router.

Ensure there are no obstacles

beneath workpiece when cutting full

thickness, and that a sacrificial work

surface is used.

Router Cutter Safety

1. Cutting tools are sharp. Care should

be taken when handling them. Do not

drop cutters or knock them against

hard objects. Handle very small

diameter cutters with extra care.

Always return cutter to its packaging

after use.

2. Always use cutters with a shank

diameter corresponding to the size of

the collet installed in your tool.

3. The maximum speed (n.max) marked

on the tool, or in instructions or on

packaging shall not be exceeded.

Where stated the speed range shall

be adhered to. Recommended speeds

are shown in the Trend Routing

Catalogue and/or website.

4. Always use router cutters in a router.

Drill and boring bits must not be used

in a router. Router cutters must only

be used for the material cutting

application for which they are

designed. Do not use on metal or

masonry.

5. Never use cutters with a diameter

exceeding the maximum diameter

indicated in the technical data of the

powertool or attachment used.

6. Before each use check that the cutting

tool is sharp and free from damage.

Do not use the cutting tool if it is dull,

broken or cracked or if in any other

damage is noticeable or suspected.

7. Cutters should be kept clean. Resin

build up should be removed at regular

intervals with Resin Cleaner®. The

use of a PTFE dry lubricant will

reduce resin build up. Do not use

PTFE spray on plastic parts.

8. When using stacked tooling (multi-

blade, block and groover etc.) on a

spindle arbor, ensure that the cutting

edges are staggered to each other to

reduce the cutting impact.

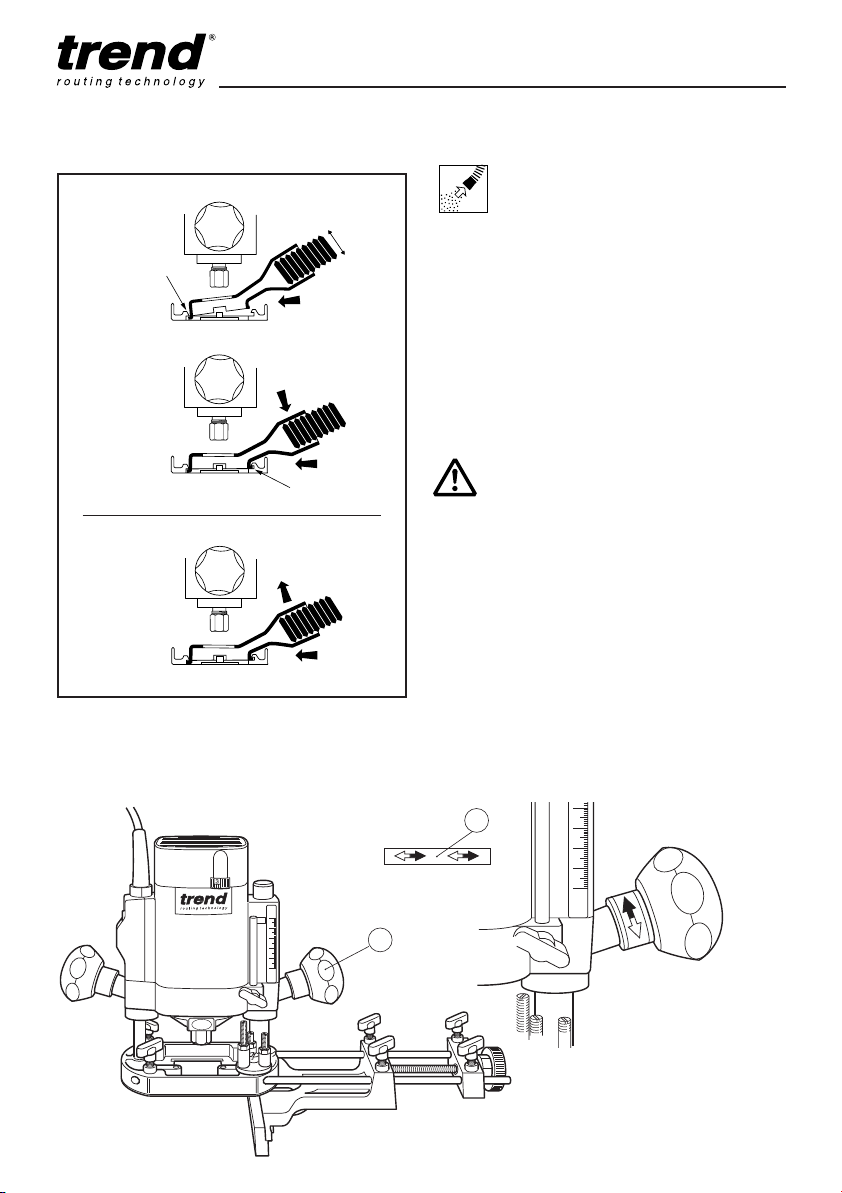

9. Cutter shanks should be inserted into

the collet all the way to the line

indicated on the shank. This ensures

that at least

3

⁄

4

of the shank length is

held in the collet. Ensure clamping

surfaces are cleaned to remove dirt,

grease, oil and water.

10. Observe the correct assembly and

fitting instructions in the router

instruction manual for fitting the collet,

nut and cutter.

11.Tool and tool bodies shall be clamped

in such a way that they will not

become loose during operation. Care

shall be taken when mounting cutting

tools to ensure that the clamping is by

the shank of the cutting tool and that

the cutting edges are not in contact

with each other or with the clamping

elements.

12. It is advisable to periodically check

the collet and collet nut. A damaged,

worn or distorted collet and nut can

cause vibration and shank damage.

Do not over-tighten the collet nut

13. Do not take deep cuts in one pass;

take several shallow or light passes to

reduce the side load applied to the

cutter and router. Too deep a cut in

one pass can stall the router.

15. In case of excessive vibrations whilst

using the router stop immediately and

have the eccentricity of the router,

router cutter and clamping system

checked by competent personnel

15. All fastening screws and nuts should

be tightened using the appropriate

spanner or key and to the torque

value provided by the manufacturer.

16. Extension of the spanner or

tightening using hammer blows shall

not be permitted.

17.Clamping screws shall be tightened

according to instructions provided by

the manufacture. Where instructions

are not provided, clamping screws

shall be tightened in sequence from

the centre outwards.

Using Routers In A Fixed Position

1. Attention should be made to the

HSE’s Safe Use of Vertical Spindle

Moulding Machines Information Sheet

No.18 and any revisions.

2. After work, release the router plunge

to protect the cutter.

3. Always use a push-stick or push-block

when making any cut less than

300mm in length or when feeding the

last 300mm of the cut.

4. The opening around the cutter should

be reduced to a minimum using

suitably sized insert rings in the table

and closing the back fence cheeks or

fitting a false fence on the back fence.

5. Whenever possible use a work

holding device or jig to secure

component being machined. Ensure

any attachment is securely fitted to the

workbench, with table surface at

approximately hip height.

6. Use a No-Volt Release Switch. Ensure

it is fixed securely, easily accessible

and used correctly.

7. In router table (inverted) mode, stand

to the front right of the table. The

cutter will rotate anti-clockwise when

viewed from top so the feed direction

is from the right (against the rotation of

the cutter). In overhead mode, stand

to the front left of the machine table

and the feed direction is from the left.

8. Do not reach underneath table or put

your hands or fingers at any time in

the cutting path while tool is connected

to a power supply.

9. Never thickness timber between the

back of the cutter and the backfence.

Useful Advice When Routing

1. Judge your feed rate by the sound of

the motor. Feed the router at a

constant feed rate. Too slow a feed

rate will result in burning.

2. Trial cuts should be made on waste

material before starting any project.

3. When using some attachments e.g. a

router table or dovetail jig, a fine

height adjuster is recommended.

4. When using a template guide bush,

ensure there is sufficient clearance

between cutter tip and inside edge of

bush and that it cannot come into

contact with collet and nut. Ensure

cutter and guide bush are concentric.

Router Cutter Repair/Maintenance

1. Repair of tools is only allowed in

accordance with the manufacturers

instructions.

3. The design of composite (tipped) tools

shall not be changed in process of

repair. Composite tools shall be

repaired by a competent person i.e. a

person of training and experience, who

has knowledge of the design

requirements and understands the

levels of safety to be achieved.

4. Repair shall therefore include, e.g. the

use of spare parts which are in

accordance with the specification of

the original parts provided by the

manufacturer.

5. Tolerances which ensure correct

clamping shall be maintained.

6. Care shall be taken that regrinding of

the cutting edge will not cause

weakening of the body and the

connection of the cutting edge to the

body.

Version 7.1 06/2006

MANU/T5 v9.0 19/2/09 13:10 Page 3