3

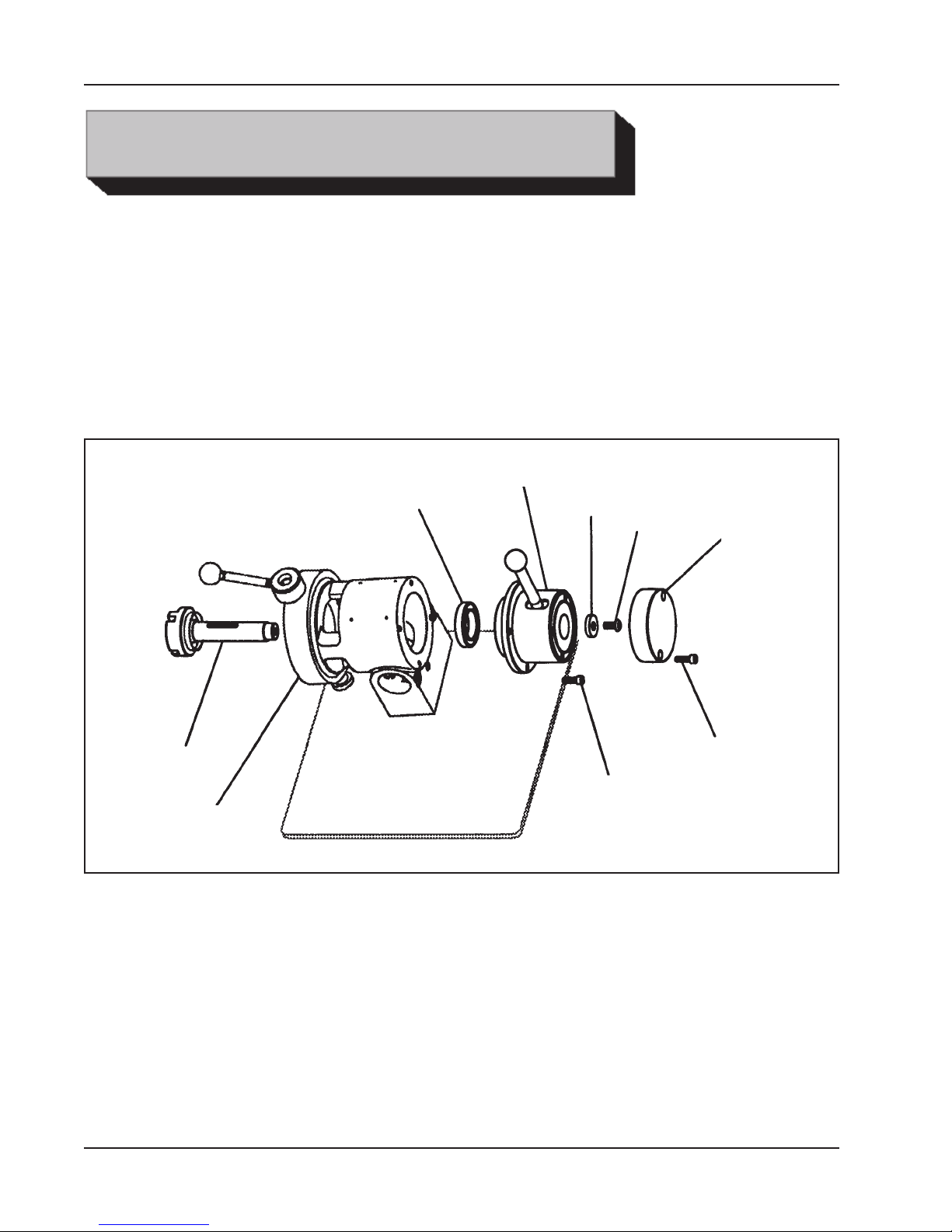

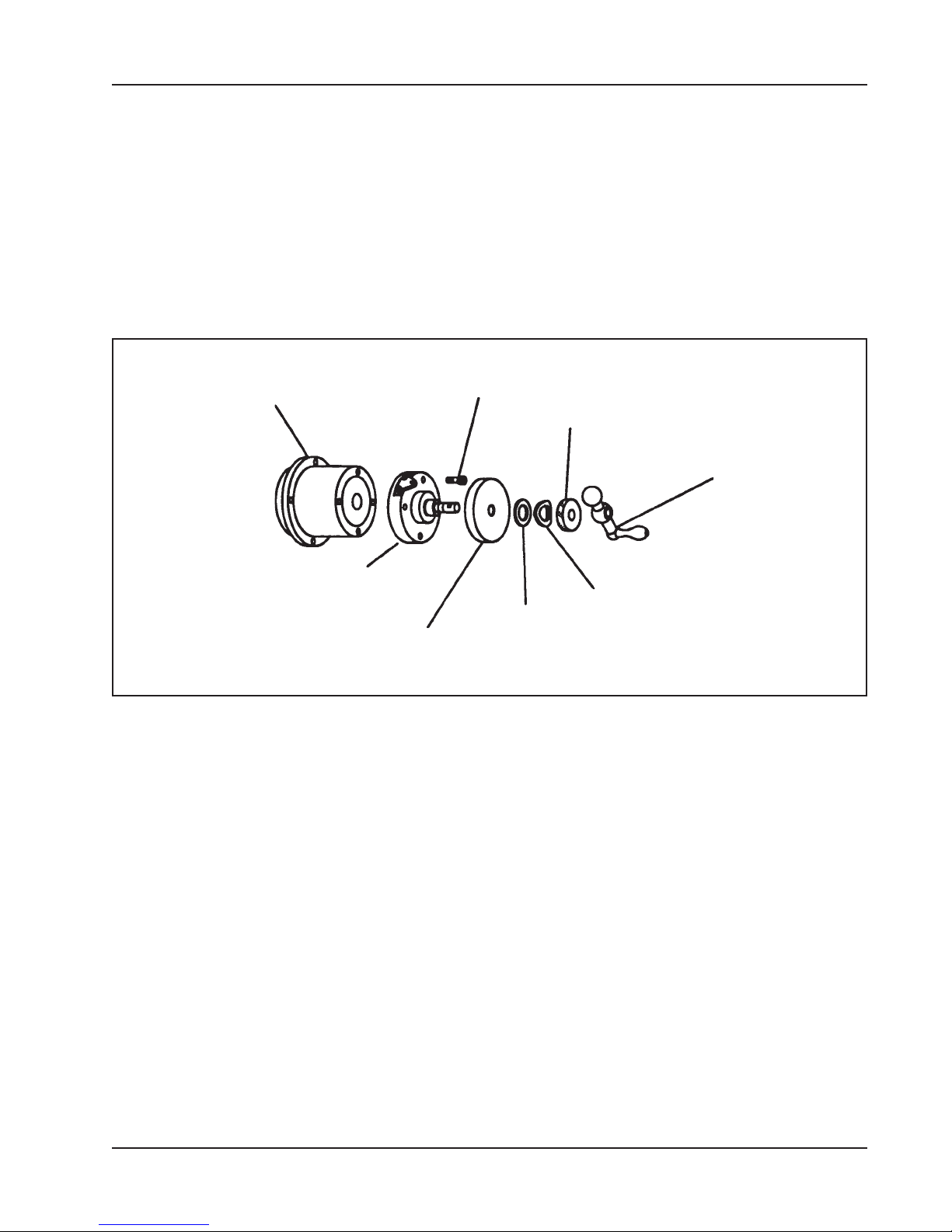

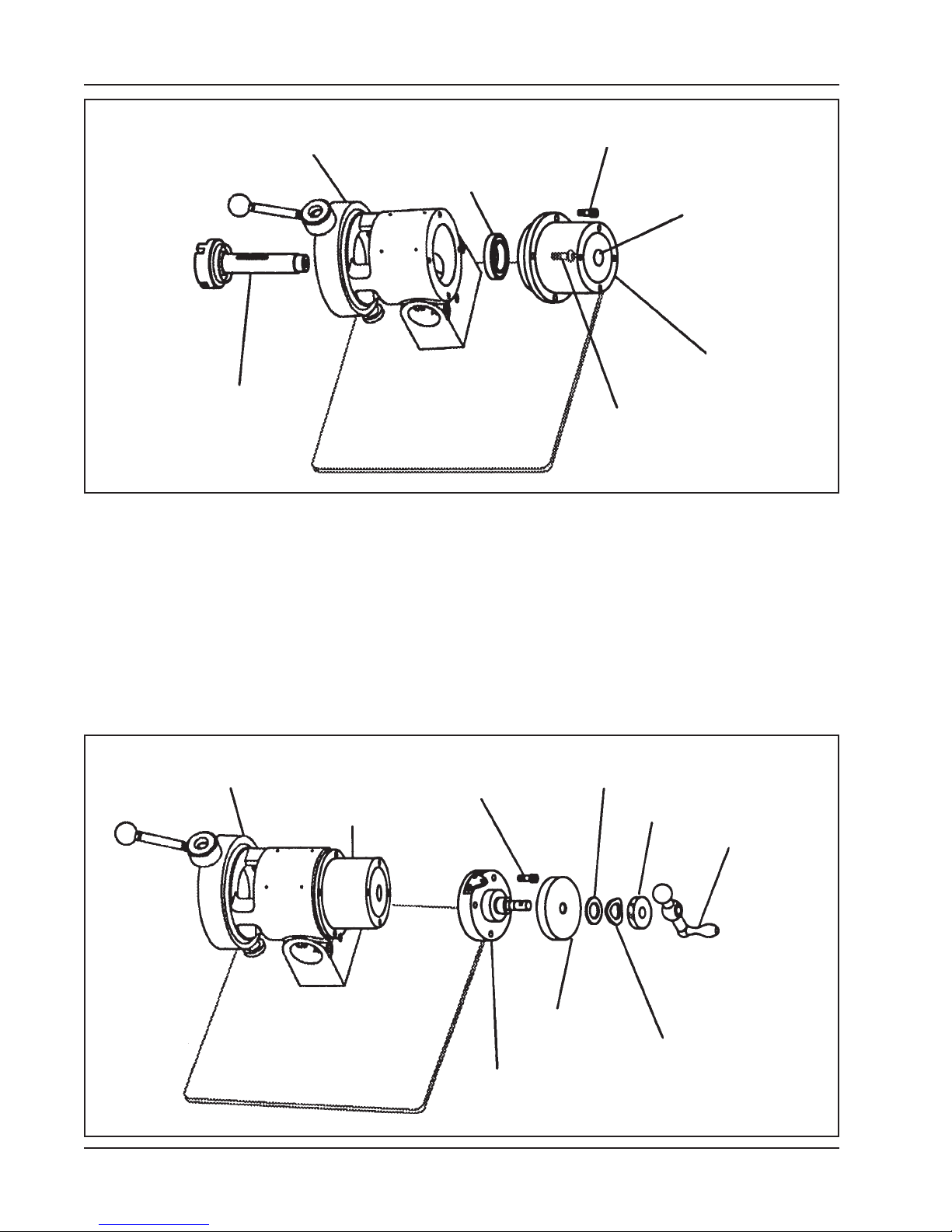

Micro-Feed Assembly for the 302

92-0710 : Rev. 040218

SAFETY PRECAUTIONS

WARNING:

IN GENERAL

When using rotating head cutting equipment, basic safety precautions should always

be followed to reduce the risk of personal injury.

Operate this tool only in accordance with specific operating instructions.

Do not override the deadman switch on the power unit. Locking down, ob-

structing, or in any way defeating the deadman switch on the power drive unit

may result in serious injury.

DRESS CONSIDERATIONS

Use standard safety equipment. Hard hats, safety shoes, safety harnesses, protec-

tive clothes, and other safety devices should always be used when appropriate.

Use safety glasses. Do not operate cutting tools without eye protection.

Dress properly. Do not wear loose clothing or jewelry. They can be caught in rotat-

ing and moving parts. Avoid slippery floors or wear nonskid footwear. If you have

long hair, wear protective hair covering to contain it.

WORK AREA

Keep the work area clean. Cluttered work areas and benches invite injuries.

Consider the work area environment. Keep the area well lit. Keep electrical cords,

cables, rags, rigging straps, and etc. clear of rotating equipment. Do not use power-

cutting tools in the presence of flammable liquids and gasses.

Keep visitors away. Do not let visitors or untrained personnel at or near operating

tools. Enforce eye protection requirements for all observers.

Do not over reach. Keep proper footing at all times.

Stay alert. Watch what you are doing. Use common sense. Do not operate tools

when you are tired.