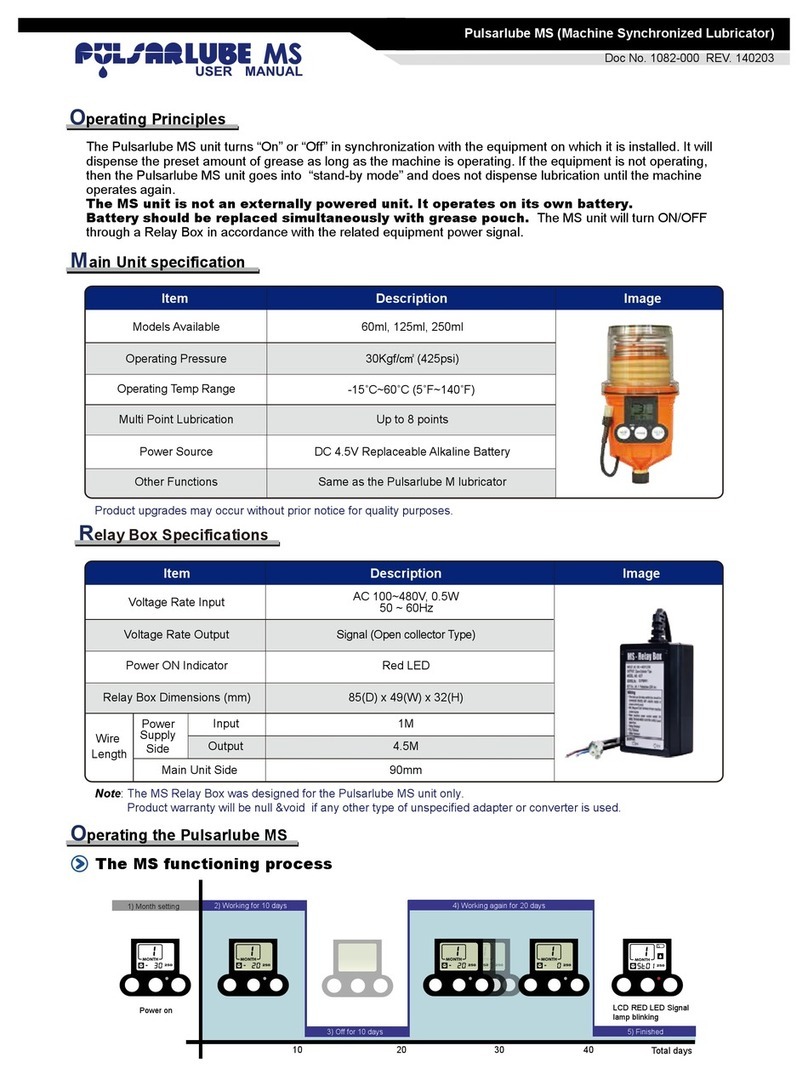

Trico PE-60 Series User manual

1 - 25

Centralized Lubrication Systems

PE-60, 70, 80 Series

Automatic Lubricator

Operation Manual

Thank you for purchasing Trico Corporation centralized lubrication system. For proper operation, please

read the operation manual carefully to avoid incorrect operation and damage.

2 - 25

Contents

Safety Information...............................................................................................................................3

Transportation, Delivery and Storage ..................................................................................................4

Operation............................................................................................................................................6

Instruction.........................................................................................................................................20

Maintenance......................................................................................................................................20

Faults................................................................................................................................................21

Warranty...........................................................................................................................................22

Remarks............................................................................................................................................22

Technical Data ..................................................................................................................................23

3 - 25

1. Safety Information

Please read the operation manual carefully to avoid incorrect operation and damage.

1-1 Application

Trico Corporation centralized lubrication systems are designed for the mechanism lubrication

like, bearing, guide way, drum, gear, chain,….. and so on.

Trico Corporation be applied for lubrication on industrial machinery like, lathe, milling

machine, press machine, grinding machine,….. and so on.

PE-60,70,80 series have to cooperate with piston distributors and depressurization device.

Under the lubrication, the piston distributor lubricates at steady flow rate in every cycle.

1-2 Intended Use

Remark:

Trico Corporation centralized lubrication systems are must only be used for their

intended purpose and in accordance with the specification and installation instructions for the

product in question. Products of

Trico Corporation centralized lubrication systems must not be

used in conjunction with fluids, group I(hazardous fluids), according to the definition of

article 2 paragraph 2 of the Directive 67/548/EC dtd. 27thg June, 1967; and are not approved

for application with such fluids.

None of the products

of

Trico Corporation can be used with gases, liquefied gases, gases

dissolved under pressure, steams or fluids that will reach a stream pressure more than 0.5 bar

above the normal atmospheric pressure in the permissible application temperature range.

Unless otherwise noted, products of

Trico Corporation must not be used in conjunction with

explosive atmospheres according to the ATEX-Directive 94/9/EC.

1-3 Authorized personnel

The installation, operation, repair, and maintenance need to be done by qualified experts.

They have been trained and familiar with the end products into which the lubrication systems

are installed. Qualified experts should be able to carry out the required tasks and to

recognize and to avoid any danger might occur. A definition of what constitutes a qualified

person and who are unqualified persons are stipulated in DIN VDE 0105 and IEC 364.

1-4 Danger relating to electric current

The electrical connection for centralized lubrication systems need to be done by qualified

experts. All local electrical operating conditions such as DIN and VDE must be observed.

Damages to persons and property could be resulted by improperly connected installation.

DANGER! Working on products that have not been disconnected from the power supply

can cause serious injury or death to persons. Installation, maintenance, and repair work may

4 - 25

only be carried out by qualified experts on products that have been disconnected from the

power supply. The supply voltage must be turned off before any product components

are open.

1-5 Danger relating to system pressure

DANGER! Centralized lubrication systems are under pressure during operation. The

system should be depressurized before installation, repair, and maintenance.

5 - 25

2. Transportation, Delivery and Storage

2.1 Transportation

Our products must be transported with care. Products must be protected against impacts.

2.2 Receipt Inspection

The products must be inspected if any damage occurs. Keep the packaging material until

the inspector makes sure there is no discrepancy.

2.3 Storage

Storage conditions are listed as below,

Storage Environment is a dry, dust-free, and well ventilated area

Max. Storage time 12 months

Permitted Air Humidity is below 60%

Warehouse Temperature range is between 10°C to 40°C

Sun light and UV radiation need to be avoided.

General Storage Information

Well package to avoid dust, corrosion, and damage before storage

Well locate on racks or pallets

Permitted Air Humidity is below 60%

Transmission mechanism needs to avoid impacts

6 - 25

3. Operation

3.1 Safety Information

3.1.1 Before Installation

Ensure the wiring of cables and supplied power is correct before installation

Trico Corporation centralized lubrication systems are designed for the mechanism lubrication

ONLY.

3-1.2

Shutdown

□

ONLY qualified personnel is authorized to repair Trico Corporation centralized lubrication

systems by original Trico Corporation spare parts.

7 - 25

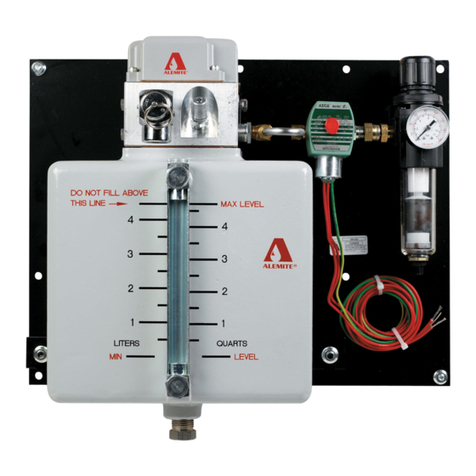

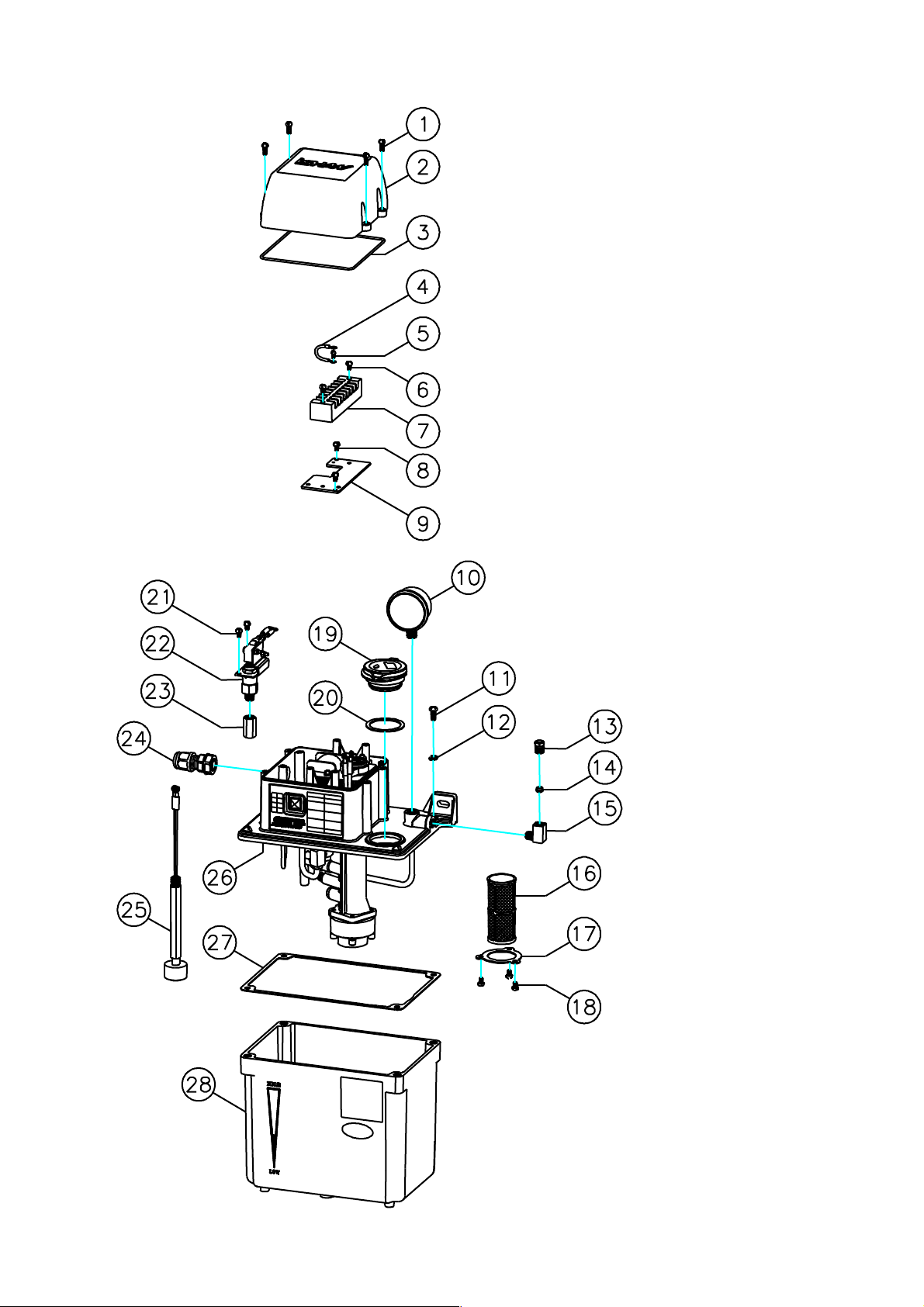

3-2 Parts of lubricator (PE-6003)

8 - 25

No. Description

1Philips screw M4*P0.7*10L

2Top cover of electronic box

3O-ring Ø2*Ø129.5 (S130)

4Wiring(yellow/green)set-CE grounding 130L

5Philips screw M3*P0.5*10L

6Philips screw M4*P0.7*10L

7Terminal plate 8P

8Philips screw M4*P0.7*6L

9Fixing plate for terminal plate

10 Pressure gauge 35kg*PT1/8*1.5" (kg/MPa)

11 Philips screw M5*P0.8*12L

12 Spring washer Ø5

13 Compression bushing Ø4

Compression bushing Ø6

14 Compression sleeve Ø4

Compression sleeve Ø6

15 Straight adaptor Ø4*1/8

Straight adaptor Ø6*1/8

16 Inlet filter (60 mesh)

17 Fixing sheet for inlet filter

18 Philips screw M4*P0.7*6L

19 Set of tank-cap

20 Seal of tank-cap

21 Philips screw M4*P0.7*10L

22 Pressure switch 12-9kg (for PE-60,70,80 series)

23 Connector Ø6XPS1/8

24 Cable gland(black) Ø22

25 Set of float switch

26 Upper module of PE-6003 (110V).

Upper module of PE-6003 (220V).

27 Packing for oil tank 3L

28 PE-6003 oil tank with stickers

9 - 25

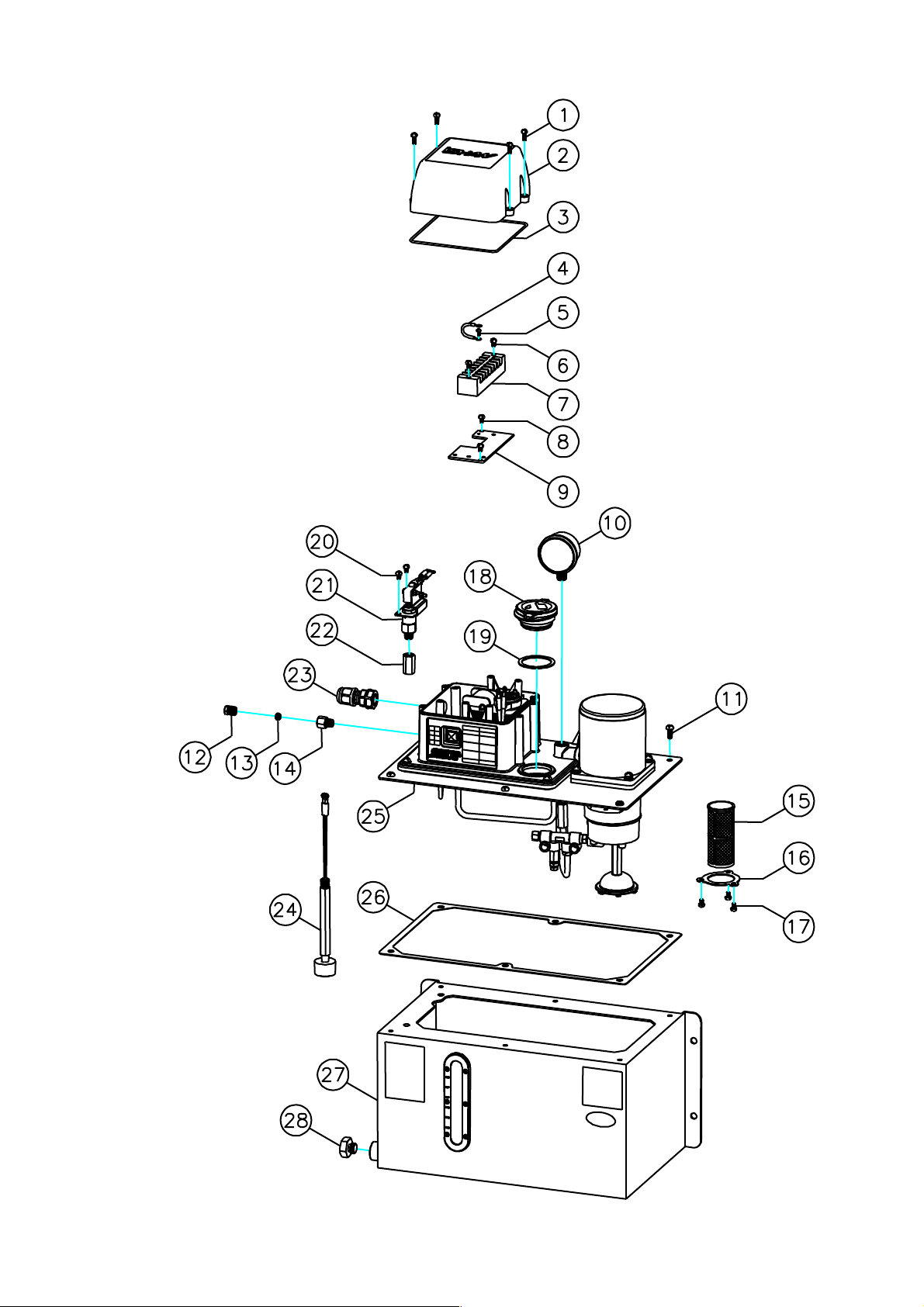

Parts of lubricator (PE-7008)

10 - 25

No. Description

1Philips screw M4*P0.7*10L

2Top cover of electronic box

3O-ring Ø2*Ø129.5 (S130)

4Wiring(yellow/ green)set-CE grounding 130L

5Philips screw M3*P0.5*10L

6Philips screw M4*P0.7*10L

7Terminal plate 8P

8Philips screw M4*P0.7*6L

9Fixing plate for terminal plate

10 Pressure gauge 35kg*PT1/8*1.5" (kg/MPa)

11 Philips screw M5*P0.8*12L

12 Compression Bushing Ø4

Compression Bushing Ø6

13 Compression Sleeve Ø4

Compression Sleeve Ø6

14 Straight adaptor Ø4*1/8

Straight adaptor Ø6*1/8

15 Inlet filter (60 mesh)

16 Fixing sheet for Inlet filter

17 Philips screw M4*P0.7*6L

18 Set of tank-cap

19 Seal of tank-cap

20 Philips screw M4*P0.7*10L

21 Pressure switch 12-9kg (for PE-60,70,80 series)

22 Connector Ø6XPS1/8

23 Cable gland(black) Ø22

24 Set of float switch

25 Upper Module of PE-7008(110V)

Upper Module of PE-7008(220V)

26 Packing for oil tank (for 6L/8L)

27 PE-7008 oil tank with stickers

28 Plug set for oil discharge

11 - 25

Parts of lubricator (PE-8008)

12 - 25

No. Description

1Philips screw M4*P0.7*10L

2Top cover of electronic box

3O ring Ø2*Ø129.5 (S130)

4Wiring(yellow/ green) set-CE grounding 130L

5Philips screw M3*P0.5*10L

6Philips screw M4*P0.7*10L

7Terminal plate 8P

8Philips screw M4*P0.7*6L

9Fixing plate for terminal plate

10 Pressure gauge 35kg*PT1/8*1.5" (kg/MPa)

11 Philips screw M5*P0.8*12L

12 Compression busing Ø4

Compression busing Ø6

13 Compression Sleeve Ø4

Compression Sleeve Ø6

14 Straight adaptor Ø4*1/8

Straight adaptor Ø6*1/8

15 Inlet filter (60 mush)

16 Fixing plate for inlet filter

17 Philips screw M4*P0.7*6L

18 Set of tank-cap

19 Seal of tank-cap

20 Philips screw M4*P0.7*10L

21 Pressure switch 12-9kg (for PE-60,70,80 series)

22 Connector Ø6XPS1/8

23 Cable gland(black) Ø22

24 Set of Float switch

25 Upper module of PE-8008(110V).

Upper module of PE-8008 (220V).

26 Packing for oil tank (for 6L/8L)

27 PE-8008 oil tank with stickers

28 Plug set of oil discharge

13 - 25

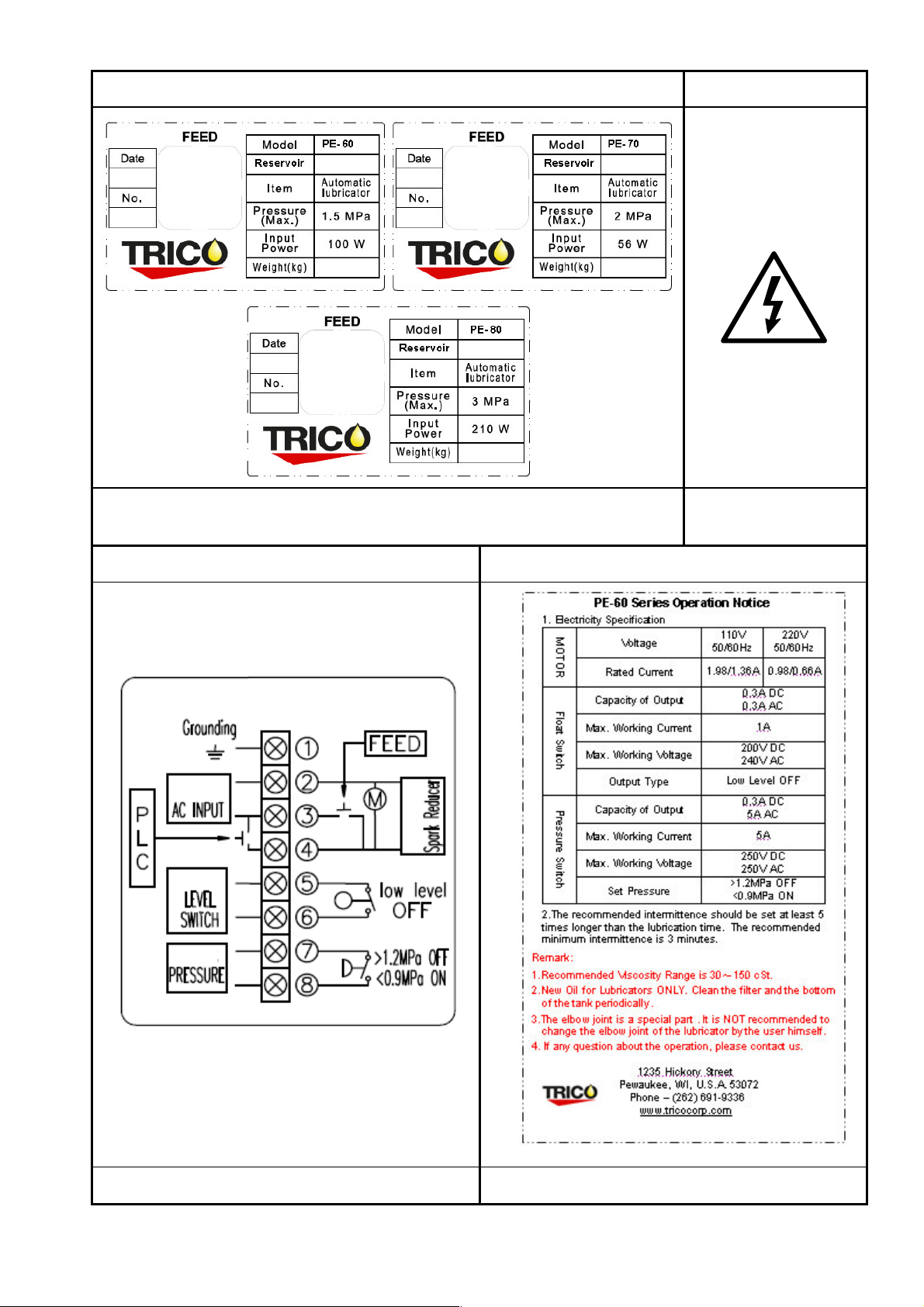

3-3 Label

Label Danger

Right front side of control box

Outside of the electrical

control box top cover

Wiring Diagram Operation Notice (PE-60 Series)

Inside of the e

lectrical control box top cover

Left side of the oil tank

14 - 25

Operation Notice (PE-70 Series)

Operation Notice (PE-80 Series)

Left side of the oil tank

Left side of the oil tank

15 - 25

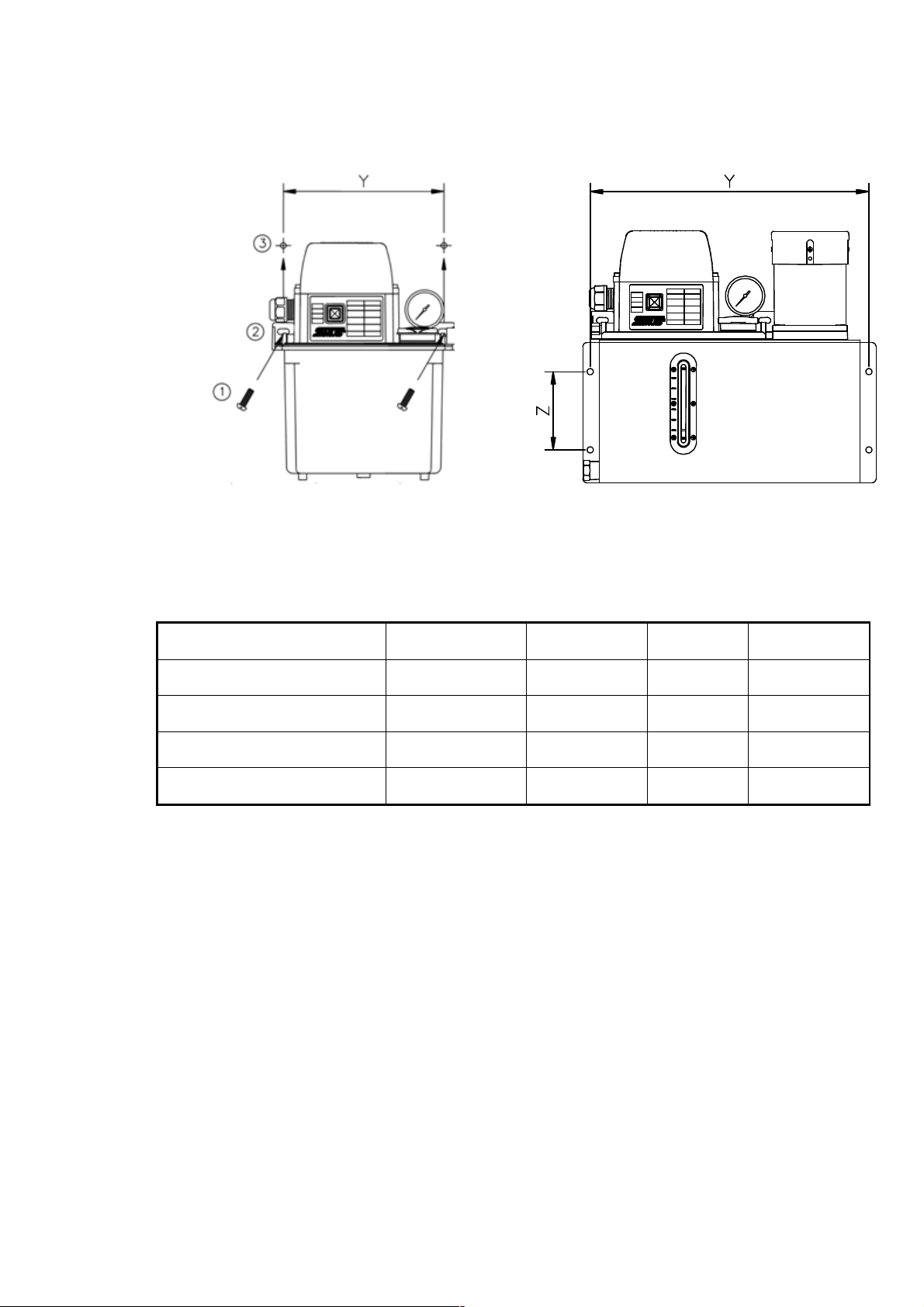

3-4 Installation

3-4.1 Mounting of the system

(Fig. B)

(Fig. C)

1. Mount the system on the machine fixing holes2 by fastening it with two screws (M6)1

at the upper lid holes 3

2. The distance of machine fixing holes is Y and Z as below listed

Model

Tank Capacity

Y Z Remark

PE-60 series 3L 190~205 N/A (Fig. B)

PE-60 series 4L 232~284 N/A (Fig. B)

PE-60, 70 series 6L 339 95 (Fig. C)

PE-70, 80 series 8L 339 95 (Fig. C)

16 - 25

3-4.2 Lubricant filling

Remove the oil tank cap and fill the tank with

clean lubricant at the level of 80% of the tank

height (Fig. D).

NOTE

Approved lubricant viscosity

MODEL

Viscosity Range

PE-60 series 30~150cSt

PE-70 series 30~250cSt

PE-80 series 30~250cSt

(Fig. D)

Viscosity higher (lower) than recommended viscosity range may result the burn down

(insufficient pressure) of the

lubrication systems.

Use new lubricant only.

3-4.3 Oil pipe connection (including related parts list)

PE-60 series parts list

No.

Item Specification

Q’ty

Ø4

1

Compression bushing

Ø6

1

Ø4

2

Compression sleeve Ø6

1

Ø4×1/8

3

Straight adaptor

Ø6×1/8

1

Ø4

4

Aluminum Pipe

(Reference only)

Ø6

1

(Fig. E)

Operation

(Fig. E)

a. Check the parts first

b. Remove the compression bushingand compression sleeveout of the outlet

adaptor.

c. Inset the end of the oil pipe into the compression bushingand compression sleeve

and connect with the outlet adaptor

d. The overhead of the pipeafter inserting the compression sleeveneeds more

than 1mm.

e. Align and tighten the pipewith the compression bushingto avoid the leaking.

If the pipeis loosen, remove the compression bushingand compression

(PE-60 series)

17 - 25

PE-70, PE-80 series parts list

No.

Item Specification

Q’ty

Ø4

1

Compression bushing

Ø6

1

Ø4

2

Compression sleeve Ø6

1

Ø4×1/8

3

Straight adaptor

Ø6×1/8

1

Ø4

4

Aluminum Pipe

(Reference only)

Ø6

1

(Fig. F)

Operation

(Fig. F)

a. Check the parts first.

b. Remove the compression bushingand compression sleeveout of the outlet

adaptor.

c. Inset the end of the oil pipe into the compression bushingand compression

sleeveand connect with the outlet adaptor

d. The overhead of the pipeafter inserting the compression sleeveneeds

more than 1mm.

e. Align and tighten the pipewith the compression bushingto avoid the

leaking.

If the pipeis loosen, remove the compression bushingand compression

sleevethen connect the pipe again.

3-4.4 Installation of power and alarm

Note !! The installation of a fuse between the power supply and Trico Corporation

centralized lubrication systems is strongly recommended !!

Operation

Note !! Make sure the power cable is disconnected before the installation.

a. Remove the e

lectrical control box cover

of the e

lectrical control box

connection box

(Fig. G).

b. Loosen the cable gland (Fig. H).

c. Insert the cable into the e

lectrical control box

through the cable gland hole (Fig. I).

(PE-70 series)

(PE-80 series)

18 - 25

(Fig. G) (Fig. H)

(Fig I) (Fig. J)

(Fig. K)

d.Connect the power cable as the wiring diagram (Fig. J), then connect the ground cable.

e. The function of float switch is to release the warning message to stop the machine

when the lubricant is at the low level.

f. If you need interval lubrication function, the lubricator needs to manage ON/ OFF

through timer function. It is controlled by an external controller.

g. Float switch terminals are available (Standard connection is at NC and COM).

h. Close the cover after connecting all cables.

i. To protect the cable from being pulled out of the box and disconnected from the ports,

fasten the gland again (Fig. K).

j. Connect the lubricator with power supply properly and the lubricator will starts with

operation.

19 - 25

4. Instruction

4-1 Operation

If lubrication is needed during the intermittence, please push the FEED button.

Make sure the power cable is disconnected before the installation or removal of the

system. Turn ON the power after more than twenty seconds of turning OFF.

The adaptor of the system for connecting the pipe is without one-way function for the

system. It is prohibited for changing to non-original set-up to avoid malfunction.

Note !! The set-up of intermittent time needs to be above five times than lubrication

time to prolong the life of the motor(the recommended minimum intermittent

time is 3-minute).

4-2 Lubricant Filling

Always keep the oil level between the level of 30% and 80% of the tank height. Float switch

will output signal when the remainder of the lubricant drops below the height if the float

switch, and it is time to fill the tank. Remove the oil tank cap (Fig. D), you can fill the

tank.

Attention!

Recycled lubricant is PROHIBITED

5. Maintenance

Trico Corporation centralized lubrication systems are of low maintenance. However, related

connection needs to be reviewed if properly fitted to secure the proper function of the system.

Please clean periodically the oil tank of Trico Corporation

centralized lubrications. If the user

wants to clean the tank, please TURN OFF the system first and remove the bolts on the tank

to separate the tank for cleaning. After cleaning the tank, please fasten the bolts to fix the

tank.

Please follow below requirements,

Restart the lubricator after 20 sec. of turning off to stabilize the performance of the lubricator.

It is prohibited for changing to non-original set-up to avoid malfunction.

The One-way adapter cannot be applied.

20 - 25

6 Faults

!Only original

Trico Corporation centralized lubrication systems spare parts are used for Trico

Corporation centralized lubrication systems. It is prohibited for changing to non-original spare

parts.

!

TURN OFF the power before any checking or maintenance Faults / Fault finding

Malfunction Possible cause Rectification

Impermissible lubricant Revised to the lubricant of suitable

viscosity

Float switch fails to work Replace with a new float switch.

1.Check if power cable is

connected in mistake or incorrect

power input.Motor fails to work

2. The repair needs to be done by

authorized personnel.

No lubricant is

discharged from

the system

Insufficient lubricant Refill the tank

Oil suction set is blocked. Clean the setInsufficient

lubricant

discharged Impermissible lubricant Revised to the lubricant of suitable

viscosity

Leaking at the

connection of the

pipe and the

lubricator

Incorrect installation

The pipe must be inserted into the

compression sleeve and at least

1mm over the end of the

compression sleeve further into the

adapter.

After disassembling the outlet, checking if the lubricant is

discharged.

If YES, the piping could be

blocked or leaking. Find out and replace the part of the

pipe in problem.

Motor runs but no

lubricant is

discharged from the

system

If NO, the causes could be,

1. Gear pump is jammed

2. Motor is out of function

The repair needs to be done by

authorized personnel.

1. Piping leaks 1.Find out and replace the part of

the pipe in problem.

2. Motor is out of function 2. The repair needs to be done by

authorized personnel.

Abnormal message

is released

3. Gear pump is jammed 3. The repair needs to be done by

authorized personnel.

Note: If the lubricator is sent to repair, please ensure the lubricant is completely removed to

This manual suits for next models

2

Table of contents

Other Trico Lubrication System manuals

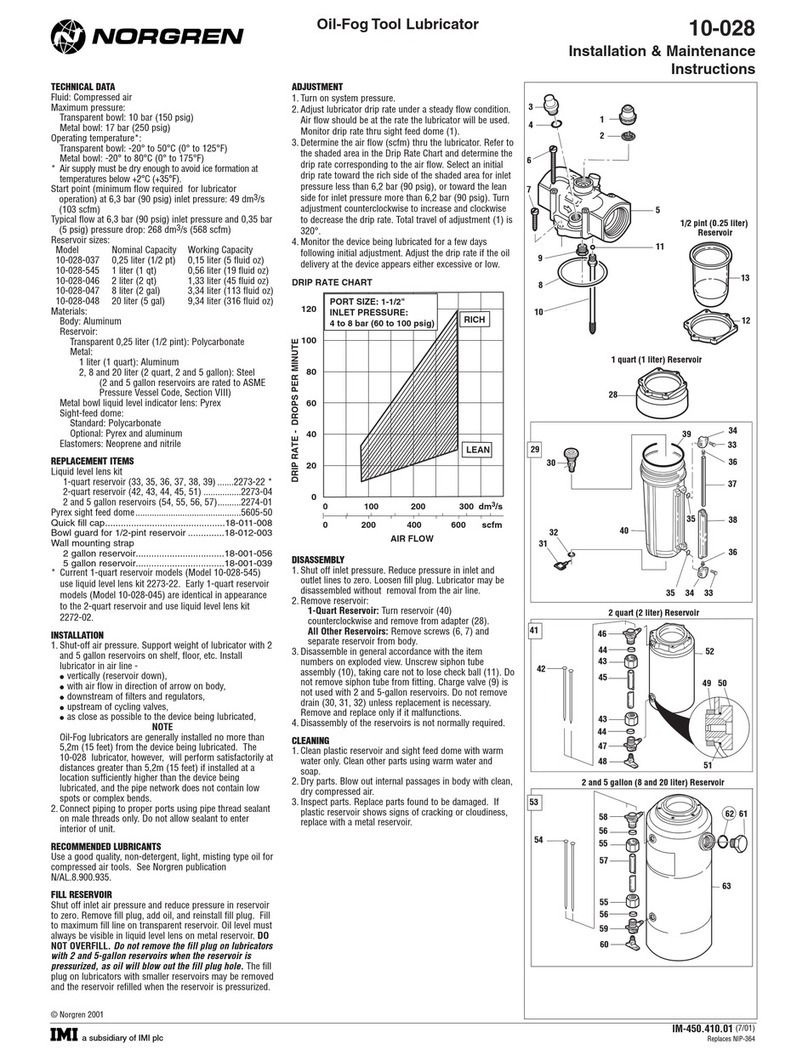

Popular Lubrication System manuals by other brands

Norgren

Norgren 10-028-037 Installation & maintenance instructions

Quantum

Quantum M1500 instructions

Groeneveld

Groeneveld Multiline AC F219157R03 installation manual

LUBMANN

LUBMANN ALP01 product manual

NTN-SNR

NTN-SNR Ready Booster 60 operating instructions

Simatec

Simatec simalube 60 User manual & technical information