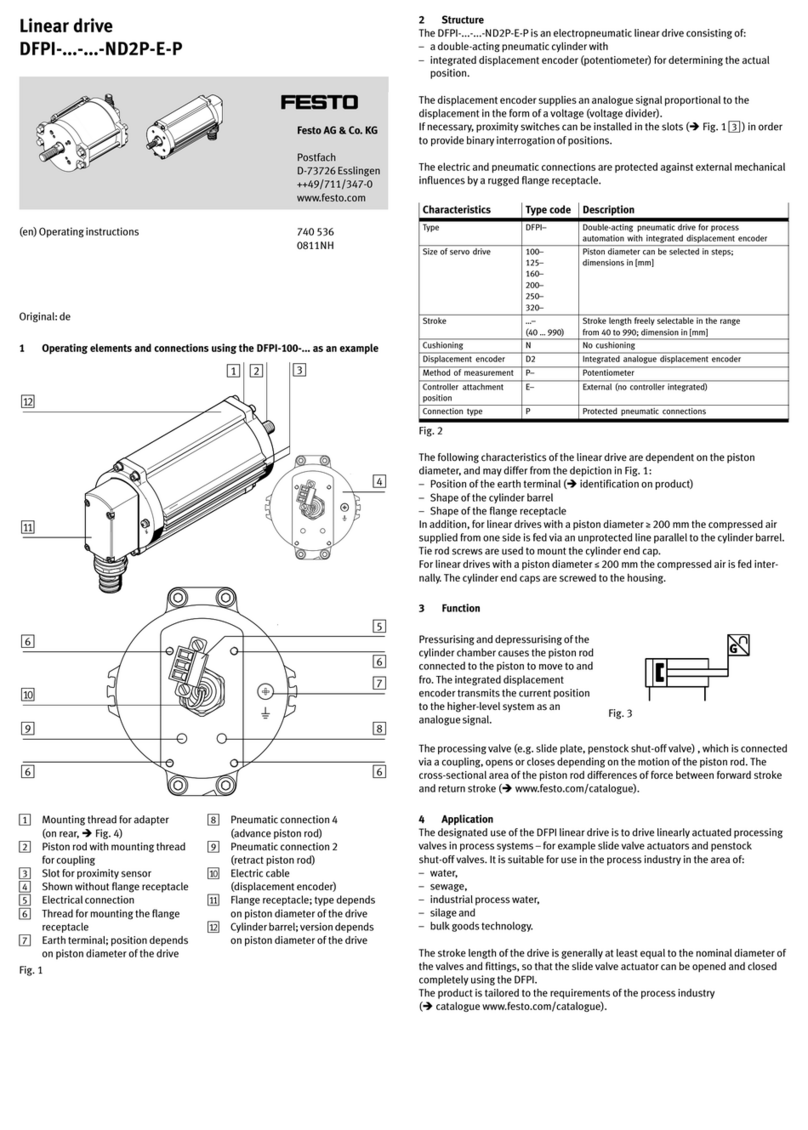

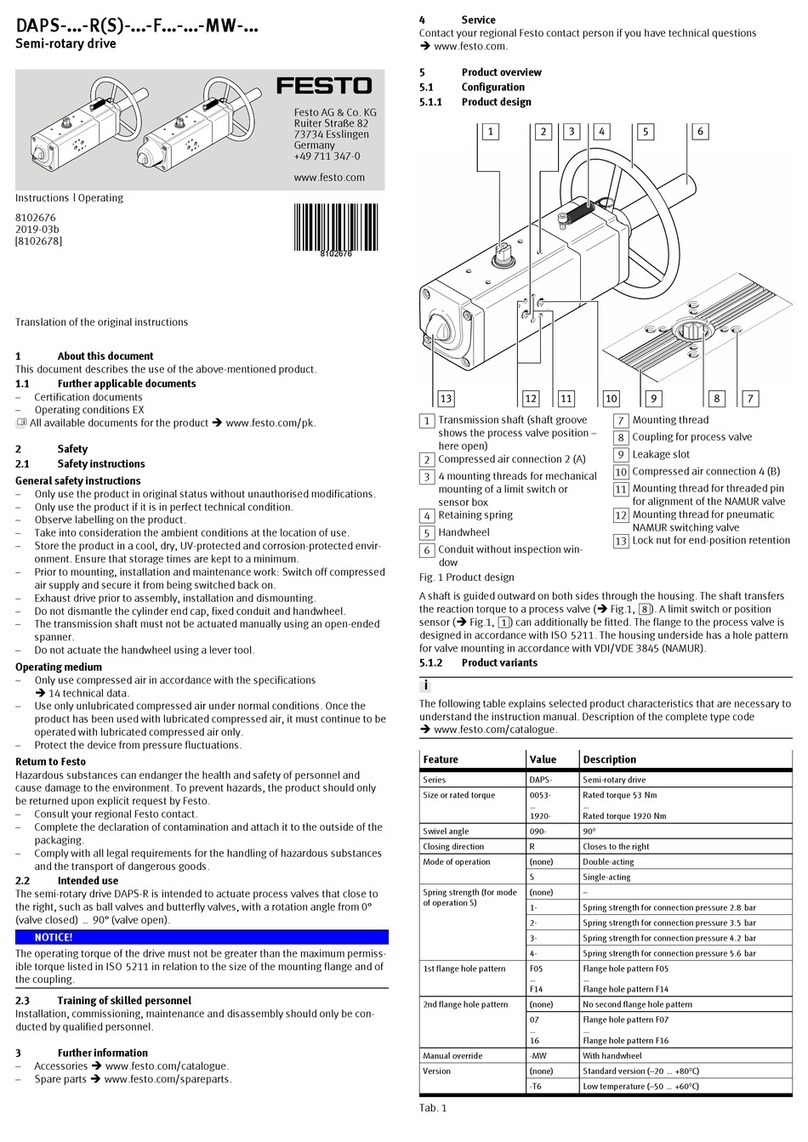

6.2 Product variants and type code

Fig. 2 explains selected product characteristics that are necessary

to understand the instructions.

Description of the complete type code: èwww.festo.com/catalogue.

Characteristic Value Description

Type code DFPD Quarter turn actuator

System of units –

N

Metric

Imperial

Size 700, 900, 1200,

2300

Swivel angle 90, 180 Swivel angle specification in [°]

Closing direction L

R

Closes to the left

Closes to the right

Mode of operation D

S

Double-acting

Single-acting

Spring configuration –, 20, 25, 30, 35,

40, 45, 50, 55, 60

Not for double-acting drive,

for connection pressure with single-acting drive

Flange hole pattern 1 F10, F12, F14 Flange hole pattern according to ISO 5211

Flange hole pattern 2 F12, F16 Flange hole pattern according to ISO 5211

Temperature range T4, T5, T6 èTechnical data

Fig. 2

7 Function

The piston movement of the DPFD is converted through a rack & pinion kinematics

(rack and pinion principle) into a swivel motion of the transmission shaft.

– Single-acting quarter turn actuators: Return is

through spring force.

Fig. 3

– Double-acting quarter turn actuators: Through

pressurising and exhausting of the cylinder cham

bers, the shaft turns back and forth.

Fig. 4

Symbol on the rating plate

Type code Mode of operation Symbol

DFPD-...-RD-...

DFPD-...-LD-...

Double-acting

Closes to the right / left

DFPD-...-RS-... Single-acting (spring return)

Closes to the right

DFPD-...-LS-... Single-acting (spring return)

Closes to the left

Fig. 5

8 Conveying and storage

Warning

Danger of crushing! Danger of shearing!

The product without accessories weighs up to 80 kg, depending on the product

version.

Body parts can be crushed or severed if the product falls.

Use appropriate load handling equipment.

For DFPD-2300: Use additional threaded holes (èFig. 1, 9) for transport lugs.

When dispatching used products: Comply with all legal requirements for hand

ling hazardous substances and conveying dangerous goods.

For return to Festo èChapter 2.

Remove all attachments.

Store the product in a cool, dry, UV-protected and corrosion-protected environ

ment. Ensure that storage times are kept to a minimum.

9 Mounting and installation

Note

Mounting and installation should only be carried out by qualified personnel.

9.1 Mounting without adapter bridge

1. Prepare process valve.

– Adjust the switching shaft of the process valve

so that the desired operating method for open

ing and closing is implemented.

2. Place the quarter turn actuator on the switching

shaft of the process valve. The square of the pro

cess valve must sit in the coupling of the quarter

turn actuator (èFig. 1, aB ) without tilting.

3. Fasten the quarter turn actuator to the connecting

flange of the process valve with 4 corrosion-resist

ant screws and retaining rings (material: CI).

4. Tighten the screws crosswise.

– Tightening torque èFig. 8

Fig. 6

9.2 Mounting with adapter bridge

1. Have suitable adapter bridge and shaft extension

ready.

– Accessories èwww.festo.com/catalogue

2. Mount the adapter bridge (èFig. 7, 1)

to the quarter turn actuator.

– Align studs of the adapter bridge lengthwise

to the actuator.

– Align open side of the adapter bridge

on the process valve.

– Tighten screws, but not yet fully tight.

3. Prepare process valve.

– Adjust the switching shaft of the process valve

so that the desired operating method for open

ing and closing is implemented.

4. Insert shaft extension (èFig. 7, 2). The square

of the shaft extension must sit in the coupling of

the quarter turn actuator (èFig. 1, aB ) without

tilting.

5. Place the quarter turn actuator with adapter

bridge and shaft extension onto the switching

shaft of the process valve. The square of the pro

cess valve must sit in the coupling of the shaft

extension without tilting.

6. Mount the adapter bridge to the connecting flange

of the process valve with 4 corrosion-resistant

screws and retaining rings (material: CI).

7. Tighten the screws at both the actuator and

process valve crosswise.

– Tightening torque èFig. 8

Fig. 7

1

2

Flange type F10 F12 F14 F16

Tightening torque [Nm] 46 … 50 80 … 84 190 … 200 370 … 390

Fig. 8