Trikdis FLEXi SP3 Assembly instructions

www.trikdis.com UAB Trikdis Draugystės g. 17, LT-51229 Kaunas, Lithuania +370 37 408 040 info@trikdis.lt

Security control panel

“FLEXi” SP3

Installation and programming manual

July, 2020

www.trikdis.com 2 July 2020

Security control panel

„FLEXi“

SP3

Table of contents

DESCRIPTION ................................................................................................................................ 6

1.1 TECHNICAL SPECIFICATIONS ....................................................................................................................................................... 7

1.2 LIST OF COMPATIBLE MODULES................................................................................................................................................... 9

1.3 PURPOSE OF EXTERNAL TERMINALS ........................................................................................................................................... 10

1.4 LED INDICATION OF OPERATION ............................................................................................................................................... 11

POWERING THE SECURITY CONTROL PANEL ................................................................................. 11

2.1 MAIN POWER SUPPLY ............................................................................................................................................................. 11

2.2 BACKUP POWER SUPPLY .......................................................................................................................................................... 11

2.3 CONTROL PANEL KITS.............................................................................................................................................................. 12

2.3.1 Control panel „FLEXi“ SP3 ........................................................................................................................................... 12

2.3.2 Control panel „FLEXi“ SP3 KIT .................................................................................................................................... 12

2.3.3 Control panel „FLEXi“ SP3 KITi ................................................................................................................................... 12

INSTALLATION OF THE SYSTEM .................................................................................................... 12

3.1 RECOMMENDED ORDER OF INSTALLATION .................................................................................................................................. 12

3.1.1 Installing the control panel into the mounting housing .............................................................................................. 13

3.1.2 Order of connecting devices ........................................................................................................................................ 14

3.1.3 Recommendations for setting the control panel’s parameters .................................................................................. 14

3.2 CONNECTING SENSORS ........................................................................................................................................................... 15

3.3 CONNECTING SMOKE DETECTORS .............................................................................................................................................. 16

3.4 SCHEMATIC FOR CONNECTING A SIREN ....................................................................................................................................... 17

3.5 SCHEMATICS FOR CONNECTING KEYPADS AND RFID READERS (WIEGAND 26/34) .............................................................................. 17

3.6 SCHEMATICS FOR CONNECTING TM17, CZ-DALLAS READERS ......................................................................................................... 19

3.7 SCHEMATIC FOR CONNECTING A TEMPERATURE SENSOR ................................................................................................................ 20

3.8 SCHEMATICS FOR CONNECTING A RELAY AND AN LED INDICATOR .................................................................................................... 20

3.9 SCHEMATIC FOR CONNECTING ETHERNET COMMUNICATOR E485 ................................................................................................... 20

3.10 SCHEMATIC FOR CONNECTING RF-SH ........................................................................................................................................ 20

3.11 SCHEMATICS FOR CONNECTING IO SERIES EXPANDER MODULES....................................................................................................... 20

3.12 SCHEMATICS FOR CONNECTING RF TRANSMITTER T16 .................................................................................................................. 21

3.13 TURNING ON THE CONTROL PANEL ............................................................................................................................................ 21

REMOTE CONTROL ....................................................................................................................... 21

4.1 LINKING THE „FLEXI“ SP3 TO A USER’S PROTEGUS ACCOUNT ........................................................................................................ 21

4.2 ARMING/DISARMING THE SYSTEM USING PROTEGUS .................................................................................................................... 22

4.3 CONFIGURATION AND CONTROL VIA SMS MESSAGES .................................................................................................................... 22

4.4 CONTROL VIA PHONE CALL ....................................................................................................................................................... 24

SETTING PARAMETERS USING TRIKDISCONFIG SOFTWARE ........................................................... 24

5.1 DESCRIPTION OF TRIKDISCONFIG STATUS BAR.............................................................................................................................. 25

5.2 “SYSTEM OPTIONS” WINDOW .................................................................................................................................................. 26

5.3 “REPORTING TO CMS” WINDOW ............................................................................................................................................. 30

5.4 “USERS & REPORTING” WINDOW ............................................................................................................................................. 32

5.4.1 Linking RFID key fobs (cards) ...................................................................................................................................... 33

5.4.2 Linking electronic (iButton) keys ................................................................................................................................. 33

5.5 “MODULES” WINDOW ........................................................................................................................................................... 35

5.6 “WIRELESS” WINDOW ............................................................................................................................................................ 36

5.6.1 Linking the wireless equipment transceiver RF-SH to the „FLEXi“ SP3 control panel .................................................. 36

5.6.2 Linking wireless (FW2 series) sensors ......................................................................................................................... 36

5.6.3 Linking a wireless (FW2 series) remote controller ...................................................................................................... 37

www.trikdis.com 3 July 2020

Security control panel

„FLEXi“

SP3

5.6.4 Linking a wireless (FW2 series) siren ........................................................................................................................... 38

5.6.5 Linking wireless (SH series) sensors ............................................................................................................................ 38

5.6.6 Linking a wireless (SH series) keypad .......................................................................................................................... 39

5.7 “ZONES” WINDOW ................................................................................................................................................................ 40

5.8 “PGM” WINDOW ................................................................................................................................................................. 42

5.9 “SENSORS” WINDOW ............................................................................................................................................................. 45

5.10 “SYSTEM EVENTS” WINDOW .................................................................................................................................................... 46

5.11 “EVENTS LOG” WINDOW ......................................................................................................................................................... 47

5.12 RESTORE DEFAULT SETTINGS .................................................................................................................................................... 47

5.13 UPDATING FIRMWARE ............................................................................................................................................................ 47

www.trikdis.com 4 July 2020

Security control panel

„FLEXi“

SP3

Warranty and limitation of liability

The control panel is given a 24-month warranty effective from the date of sale-purchase. For the duration of the warranty

period, free repairs are guaranteed for faults caused by the manufacturer.

The warranty is valid if the control panel was installed by qualified personnel following the instructions in this document

and the applicable regulations for installing electrical equipment and operated following the instructions in this document

and the applicable regulations for safe operation of electrical equipment.

The control panel must be submitted for repairs in the manufacturer‘s packaging along with a defect report stating the

nature of the malfunction.

Once the warranty has expired, the control panel‘s technical maintenance and repairs are performed at the buyer‘s

expense.

The warranty can be terminated prematurely if:

Unauthorized personnel repaired or tried to repair the control panel;

The panel was used for anything other than its intended purpose;

The panel was stored and (or) installed in unsuitable premises that had incompatible climate conditions or an aggressive

chemical environment;

The panel was mechanically broken and (or) intentionally damaged;

The panel was damaged by force majeure circumstances (lightning discharge etc.).

The manufacturer is not responsible for:

the control panel‘s malfunctions if the panel is installed or used not according to its manual.

the control panel‘s malfunctions if the cause is a malfunction or loss of GSM/GPRS/Internet connectivity or malfunctions

in the operator‘s network.

restrictions or termination of GSM/GPRS/Internet connectivity services to the panel‘s buyer or user, and shall not

compensate the panel‘s buyer or user for any property or non-property damages suffered from this.

restrictions or termination of electricity supply service to the panel‘s buyer or user, and shall not compensate the panel‘s

buyer or user for any property or non-property damages suffered from this.

robbery, fire of the premises or any other losses suffered by the panel‘s buyer or user, and shall not compensate the

panel‘s buyer or user for any property or non-property damages suffered from these events.

www.trikdis.com 5 July 2020

Security control panel

„FLEXi“

SP3

Safety precautions

Read this manual carefully before using the control panel.

The „FLEXi“ SP3 control panel is an electrical device, which means it must be installed and serviced only by qualified

personnel following the instructions in this document and applicable regulations for installing electrical equipment.

Power to the panel must be switched off during installation!

The control panel must be installed in a limited access location inside the premises and maintaining a safe distance from

sensitive electronic equipment. The panel is not resistant to vibrations, other mechanical effects, humidity and aggressive

chemical environments. The control panel complies with the demands applicable to Class II environmental specification of the

EN 50131 standard.

The casings, transformers, batteries and programming equipment used must meet the safety requirements of

the EN 60950 standard.

The device is powered from a 230 V voltage 50 Hz frequency power grid through a Class II step-down

transformer that reduces the voltage to 16 – 18 V or from a 16 – 24 V DC power supply. A 12 V battery with at

least 7 Ah capacity is used as a backup power supply. The current consumption depends on the power of the

connected external devices.

A two-pole automatic safety switch must be installed in the power supply circuit for protection. The gap

between switch off contacts must be at least 3mm. The safety switch must be installed in a location known to

the specialists servicing the control panel.

To disconnect the control panel from the power network:

- from the AC network – switch off the automatic safety switch;

- from the battery – disconnect the terminals.

www.trikdis.com 6 July 2020

Security control panel

„FLEXi“

SP3

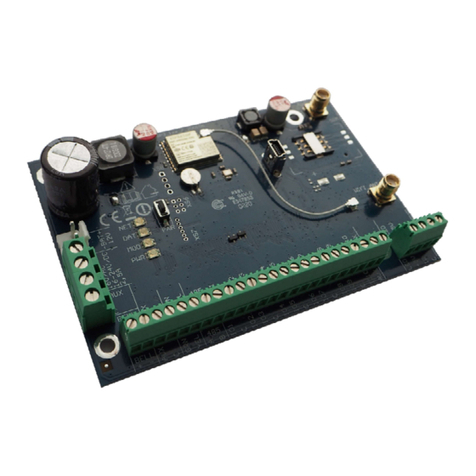

Description

The „FLEXi“ SP3 control panel is a processor part of intrusion and fire alarm system. It comes with a built-in WiFi module and

2G/4G cellular modem. The „FLEXi“ SP3 allows grouping of 32 wired and wireless zones into an 8 partition system. Users can

switch protection modes of different areas of the premises remotely and with ease (with mobile app Protegus, SMS or phone

call) or with devices that support personal identification (wired and wireless keypads, electronic keys, RFID cards, etc.). Any

triggered system event is reported to the central monitoring station (CMS) and to Protegus cloud via WiFi and (or) via cellular

network if a SIM card is inserted.

When it’s recommended to choose the „FLEXi“ SP3 control panel?

- For securing small or medium sized premises which will be monitored by a security company. The „FLEXi“ SP3 supports

both wired and wireless zones. The panel can provide remote control and system information to both end-users and

the security company.

- As a replacement for existing intrusion alarm panel. „FLEXi“ SP3 allows to set a different resistor value to the type used

with the old alarm panel. This saves a lot of time during installation, as then there is no need to change resistors in each

sensor.

- When the alarm system needs to perform more functions than just protection of the premises. For example: opening

the doors and gates, watering the lawn, lighting, heating, ventilation, cooling, controlling as well as many other

automatic start and stop functions.

Features

Reporting to the security company‘s central monitoring

station (CMS):

Event reporting either via the built-in WiFi module or

cellular 2G/4G modem.

Additional modules to send reports via Ethernet or

VHF/UHF radio waves with chosen priority.

Any CMS can receive reports, as long as they have

TRIKDIS software/IP receiver or any other

manufacturer’s IP receiver supporting SIA DC-09 IP

protocol.

Design based on two decades of experience in

transmitting reports to main and backup central

monitoring station receivers, which allows security

companies to provide the highest level of protection to

premises

A setting for necessity to send to CMS, to mandatorily send reports to CMS first, and only then to customers.

Possibility to send event reports to CMS of two different security companies.

Multitude number of message transmission channels and multiple transmission priority settings.

Reporting to user:

Via Protegus mobile app, which gives warnings about alarm system events using push and special sound notifications.

Event reporting via SMS messages to 8 cellular numbers.

Reporting about events using pre-recorded voice notifications (up to 8 cellular numbers).

Remote control of selected premises’ protection mode (Arm/Disarm/Stay/Sleep).

Remote control of connected devices (lighting system, automatic gates, ventilation, heating, watering systems, etc.).

Remote temperature measuring.

Inputs and outputs:

10 I/O terminals, each one can be set as an input (IN) or output (OUT). Input (IN) types: ATZ, EOL, NC, NO. Different

parameters of resistors can be used in EOL and ATZ type circuits. The number of inputs IN can be expanded to 32 by

using keypads, iO-8 and iO-WL expander modules.

The board has 2 dedicated outputs: the bell and the LED. The bell is to control the siren, and the LED is to control

indicator lights. The number of outputs can be expanded to 16 by using iO-8 and iO-WL expander modules.

www.trikdis.com 7 July 2020

Security control panel

„FLEXi“

SP3

Seven output operational settings. Each output can be assigned with an operational logic, a preset operation schedule

or qualities, for example, thermostat mode.

One-wire data bus (“1-Wire”) is designated to connect temperature sensors (up to 8), a temperature and humidity

sensor (1) or a key fob (“iButton”) reader.

The GRN-YEL data bus is designated to connect 8 keypads of the same type.

The RS485 data bus connects iO series expander modules: RF-SH radio wave wireless sensor transceiver, E485 Ethernet

module, T16 VHF or UHF radio wave transmitter.

Control of alarm system

4-digit long control codes (40 in total), which may be used as a coercion code as well. In such scenario, entering the user

code will disarm the alarm, yet a special report will be sent to the CMS indicating that the alarm was disarmed as a result

of coercion.

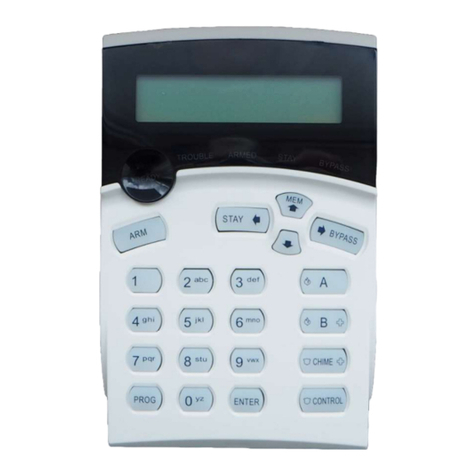

Control using keypads: Protegus SK232LED; Paradox K636, K10H(V) K32+LED, K32LED, K35, TM50, TM70; Crow keypad

CR16, CR-LCD; CZ-Dallas electronic (“iButton”) key reader; TM17 electronic key reader, RFID reader (Wiegand 26/34).

Remote control via Protegus mobile app, phone call or SMS.

Simple installation:

Multiple sizes of „FLEXi“ SP3 mounting kits that include a decorative white metal housing with a built-in step-down

transformer or impulse power supply.

Default „FLEXi“ SP3 operational settings are based on many years of experience. That allows to install the system in 7

out of 10 small and medium-sized premises without the need to change the default settings.

The „FLEXi“ SP3 control panel allows to replace the previous panel without changing the resistors in each wired sensor.

Settings can be saved as a file to be used later.

Device configuration via USB cable or remotely by using TrikdisConfig software.

Remote connection via TrikdisConfig software allows not only altering „FLEXi“ SP3 parameters but monitoring the

operation of the panel as well.

Two access levels for parameter settings: installer and administrator.

Parameter Description

Power supply voltage[AC / DC] 16 V DC or 16-24 V, 2,5 A AC

Current consumption Up to 50 mA (stand-by),

Up to 200 mA (short-term, while sending)

Backup power source [BAT] 12 V lead – acid battery, 4 Ah/7 Ah

Battery charge current Up to 500 mA

Power voltage and current for external devices

[AUX]

12 V DC, up to 1 A

Siren output [BELL] 1 A

Output [LED] 0,1 A

PGM output 0,1 A

WiFi module Yes, built-in

WiFi frequency, protocol, encryption type 2,4 GHz, 802.11 b/g/n, WPA, WPA2, WPA mixed

WiFi network configuration type DHCP or manual

SIM card 1, NANO size

GSM/GPRS modem frequencies 850 / 900 / 1800 / 1900 MHz

4G modem frequencies „FLEXi” SP3_14E

„FLEXi” SP3_24E

B1/B3/B7/B8/B20/B28

www.trikdis.com 8 July 2020

Security control panel

„FLEXi“

SP3

Parameter Description

EMEA/Thailand

4G modem frequencies „FLEXi” SP3_24S

Latin America/Australia/New Zealand

B1/B3/B4/B5/B7/B8/B28

4G modem frequencies „FLEXi” SP3_24A

North America

B2/B4/B12

Report transmission directions - To main and backup receivers of 2 different security companies;

- To Protegus cloud, to iOS/Android Protegus mobile apps;

- To 8 mobile phones via SMS messages.

Calls 8 mobile phones. If a user answers the call, announces what

happened using voice.

Event reporting transmission channels GPRS or 4G, WiFi, LAN (with module E485), SMS, Voice call,

VHF/UHF radio waves (with transmitter T16)

Protocols for connection to CMS TCP / IP or UDP / IP, or SMS

Event encoding Contact ID codes

Report encryption TRK AES 128, SIA IP AES 128

Internal clock Yes

Buffer memory capacity 60 events

Events log memory Up to 1000 events. Oldest entries deleted automatically.

User codes 40

Duress code Two code entry methods can be chosen during programming

Dual purpose terminals [I/O] 10; IN or OUT function selected during programming. When IN is

selected, available types: NC, NO, EOL, EOL_T, ATZ, ATZ_T. When

OUT is selected, the terminal becomes open collector (OC) type

with up to 100 mA current

No. of partitions 8

No. of zones 10 (20 zones if using ATZ), (can be expanded to 32 zones using

expanders)

No. of PGM outputs 2 (can be 12 if IO terminals are set as outputs. Can be expanded to

16 outputs with expanders)

Max. number of connected keypads 8

Supported keypads Protegus SK232 LED B/W

Paradox K636

Paradox K10H(V)

Paradox K32 LED

Paradox K32+ LED

Paradox K35

Paradox TM50

Paradox TM70

Crow CR16

Crow CR-LCD

Max. number of RFID readers (Wiegand 26/34) 2

1-Wire data bus length [1 WIRE] Up to 30 m

Compatible temperature sensors Maxim®/Dallas® DS18S20, DS18B20; AM2301 series

www.trikdis.com 9 July 2020

Security control panel

„FLEXi“

SP3

Parameter Description

Max. number of temperature sensors connected to

1-Wire data bus

8 (Dallas) or 1 (if an AM2301 series sensor is used)

Compatible electronic (iButton) keys [1 WIRE] Maxim®/Dallas® DS1990A

Max. no. of electronic (iButton) keys 40

RS485 data bus length Up to 100 m

Max. no. of devices connected to RS485 data bus 8

Supported modules iO-8 – expander module;

iO – expander module;

iO-MOD – iO-WL radio wave transceiver;

iO-WL – wireless expander module;

RF-SH – radio wave receiver for wireless sensors;

E485 – module for connecting to Ethernet network;

TM17 – iButton key reader;

CZ-Dallas – iButton key reader;

T16 – VHF or UHF radio wave transmitter;

RFID reader.

Operating environment Temperature from -10 °C to +50 °C, relative humidity 80% at

+20C, no condensation.

Dimensions of the control panel 117x79x25 mm

Weight 0,1 kg

Module name Current

Keypad Protegus SK232 LED B/W Min 60 mA, max 150 mA

Keypad Paradox K636 Min 40 mA, max 70 mA

Keypad Paradox K10H(V) Min 44 mA, max 72 mA

Keypad Paradox K32 LED Min 49 mA, max 148 mA

Keypad Paradox K32+ LED Min 49 mA, max 148 mA

Keypad Paradox K35 Min 30 mA, max 70 mA

Keypad Paradox ТМ50 Мin 100 mA, max 230 mA

Keypad Paradox ТМ70 Min 200 mA, max 330 mA

Keypad Crow CR16 Min 40 mA, max 75 mA

Keypad Crow CR-LCD Min 40 mA, max 75 mA

iO-8 expander module Max 20 mA

iO expander module Max 50 mA

iO-MOD – iO-WL radio wave transceiver Min 50 mA, max 150 mA

iO-WL wireless expander module Max 200 mA

RF-SH transceiver for wireless sensors Max 100 mA

E485 Ethernet communicator Min 50 mA, max 150 mA

TM17 iButton key reader Max 50 mA

www.trikdis.com 10 July 2020

Security control panel

„FLEXi“

SP3

Module name Current

CZ-Dallas iButton key reader Max 25 mА

T16 (VHF or UHF) radio wave transmitter Min 100 mA, max 1,2 A

RFID reader (Wiegand 26/34) Max 100 mA

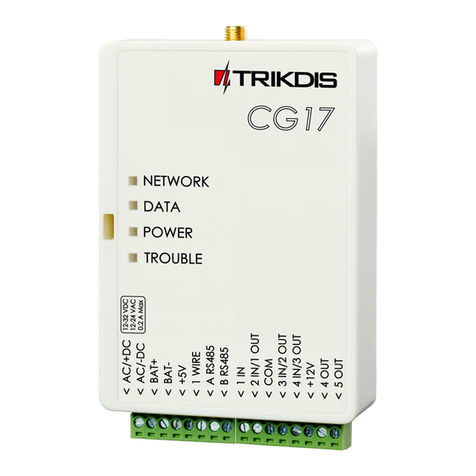

1. Connectivity and operation indicator lights.

2. Backup power supply terminal block.

3. Main power supply terminal block.

4. External terminal block.

5. 1-WIRE data bus terminal block.

6. SMA screw-on type connector for WiFi antenna.

7. Nano-SIM card holder.

8. SMA screw-on type connector for GSM antenna.

9. USB Mini-B connector for configuring the control

panel’s settings.

Terminal Description

Power terminal Power supply terminal (16 V AC or positive 16-24 V DC)

Power terminal Power supply terminal (16 V AC or negative 16-24 V DC)

BAT+ Backup power supply positive terminal 12 V

BAT- Backup power supply negative terminal 12 V

AUX Positive 12 V power terminal for external devices

C Common negative terminal

GRN Keypad data bus

YEL Keypad data bus

A 485 Terminal A of RS485 data bus

B 485 Terminal B of RS485 data bus

IO1 – IO9 Input/output terminals (default setting – input)

IO10 Input/output terminal (default setting – PGM output, Fire Sensor Reset)

www.trikdis.com 11 July 2020

Security control panel

„FLEXi“

SP3

Terminal Description

C Common negative terminal

LED PGM output (default setting – System State)

+5 V Positive 5 V power terminal for 1-Wire devices

1 WIRE 1-Wire data bus terminal

C Common negative terminal

LED indicator Light status Description

NET

Green blinking SIM card is registering on GSM network.

Green solid SIM card registered on GSM network.

Yellow blinking Indicates GSM signal strength from 0 to 5. 3 is sufficient.

DAT

Off No unsent event messages.

Green solid Message is being sent.

Yellow solid There are unsent event messages in buffer memory.

MOD

Green blinking Connecting to WiFi network.

Green solid Connected to WiFi network.

PWR Green blinking No operational problems.

1 red flash No SIM card detected

2 red flashes The PIN card of the SIM card is incorrect

3 red flashes Unable to connect to GSM network

4 red flashes Unable to connect to CMS receiver using channel 1

5 red flashes Unable to connect to CMS receiver using channel 2

6 red flashes Internal clock not set

7 red flashes Insufficient backup power supply voltage

8 red flashes No AC power

9 red flashes Unable to connect to WiFi network

Powering the security control panel

The control panel and the entire alarm system can be powered either from an alternating or a direct current source. In both

cases, a backup power supply – a 12 V battery – must be connected to the system to ensure the supply of power is

uninterrupted. To meet the demands of the EN50131 standard, the backup battery must be able to work for 12 hours for

security Grade II or 60 hours for security Grade III after losing power from the main power supply. Take into account the total

current consumption of the additional connected modules, the current consumption of individual modules is listed in chapter

1.2 “List of compatible modules”.

If there are problems with powering the system from the main power supply, an AC Fault event report will be generated and

the panel will automatically switch to the backup 12 V battery. If the battery’s voltage falls to 11,5 V, a Low Battery event report

will be generated. The battery will be disconnected if the voltage falls bellow 9,5 V. If AC network voltage is restored, an AC

www.trikdis.com 12 July 2020

Security control panel

„FLEXi“

SP3

Restore report will be generated and the battery charging process will begin automatically. When the battery’s voltage rises to

12,6 V, a Battery Restore event report will be generated.

2.3.1 Control panel „FLEXi“ SP3

Name Quantity

„FLEXi“ SP3 control panel board 1 pc.

Wire for connecting battery 1 pc.

Resistor 2,2 kΩ 20 pcs.

Plastic spacer (mounting parts) 4 pcs.

Antenna ME301M with 2,5 m long cable 2 pcs.

2.3.2 Control panel „FLEXi“ SP3 KIT

Name Quantity

„FLEXi“ SP3 control panel board, built into metal housing 1 pc.

Metal housing K01 with 40 VA transformer 1 pc.

Resistor 2,2 kΩ 20 pcs.

Antenna ME301M with 2,5 m long cable 2 pcs.

Wire for connecting battery 1 pc.

Tamper sensor 1 pc.

Terminal block with 0,5 A fuse 1 pc.

2.3.3 Control panel „FLEXi“ SP3 KITi

Name Quantity

„FLEXi“ SP3 control panel board, built into metal housing 1 pc.

Metal housing K02 with Mean Well impulse power supply 1 pc.

Resistor 2,2 kΩ 20 pcs.

Antenna ME301M with 2,5 m long cable 2 pcs.

Wire for connecting battery 1 pc.

Tamper sensor 1 pc.

Terminal block with 3,15 A fuse 1 pc.

Note: USB wire (Mini-B type) for programming the control panel sold separately.

Installation of the system

Planning the system:

Sketch a plan of the premises and mark the areas where the metal housing with the control panel, keypad (-s), signallers,

equipment automatically or remotely controlled by the control panel will be installed.

www.trikdis.com 13 July 2020

Security control panel

„FLEXi“

SP3

After evaluating the premises, the demands raised for their protection and the characteristics of possible sensors,

choose the number of sensors to use, their types, and the locations to install them.

3.1.1 Installing the control panel into the mounting housing

The control panel’s board can be installed into a mounting housing

that already has a step-down transformer with a 500 mA fuse

installed and also has space intended for a backup battery.

Install the control panel into the chosen plastic or metal housing

using plastic spacers. If you chose a metal housing, do not forget to

ground it during installation. The chosen housing must meet

demands described in the EN 60950 and EN 50131 standards.

Plastic spacers.

Dimensions of the „FLEXi“ SP3 board

The picture below shows the dimensions of the board and its mounting holes (in millimeters), and also the locations of the holes.

www.trikdis.com 14 July 2020

Security control panel

„FLEXi“

SP3

3.1.2 Order of connecting devices

1. Connect GSM and WiFi antennas to the antenna connectors.

2. Insert an activated SIM card into the SIM card holder.

3. Using the given connection schematics and the connection schematics for every device to be connected, connect the door

and window magnetic contacts, motion, fire and other sensors, signallers, keypads and controlled devices. Connect the

housing door and wall mounting tamper sensors to the panel’s terminals.

4. Connect the wires of the main power supply to the control panel’s AC/DC terminals. Turn on the main power supply. The

„FLEXi“ SP3 will recognize the keypads, expanders and interfaces that are correctly connected using 1-WIRE and YEL/GRN

data busses.

5. Insert a backup battery into the mounting housing. Connect the battery’s terminals to the BAT+ / BAT– terminals on the

control panel.

Note: The battery must recharge in less than 72 hours for the alarm system to meet security Class II or 24 hours to

meet security Class III.

3.1.3 Recommendations for setting the control panel’s parameters

1. See chapter 5 “Setting parameters using TrikdisConfig” for information on how to connect to the panel to configure it.

2. System settings:

a. Partitions. If you would like to turn on protection for specific zone groups separately, the alarm system can be divided

into partitions. See chapter 5.2 ““System Options” window” on how to divide the system and set the required partition

attributes.

b. Zones. See chapter 5.7 ““Zones” window” to set every zone according to the sensors’ characteristics and desired

operation of the alarm after an event occurs in that zone. If the alarm system is divided into partitions, every zone can

be assigned to a desired area.

c. Users. System users must be created to control the alarm system via keypad, iButton key or phone call (SMS message).

See chapter 5.4 ““Users & Reporting” window” on how to create users and assign them permissions.

3. Message sending:

a. Time setting. The control panel’s time must be set in order to receive messages with exact timestamps. See chapter

5.2 ““System Options” window”.

b. Enable report sending. Default settings enable the event report sending function for all events. If any event occurs, its

report will be sent to the set recipients using the set channels. See chapter 5.10 ““System events” window” on how to

disable reporting of chosen events.

www.trikdis.com 15 July 2020

Security control panel

„FLEXi“

SP3

c. SIM card parameters. If messages need to be sent using mobile networks, you must set parameters for the SIM card

being used (see chapter 5.2 ““System Options” window”).

d. Reports to central monitoring station. Sending reports to the central monitoring station is disabled by default. See

chapter 5.3 ““Reporting to CMS” window” on how to set parameters for sending messages to CMS.

e. Reports to user. Communication with Protegus cloud is enabled by default, and sending reports using SMS messages

and phone calls is disabled. See chapter 5.10 ““System events” window” on how to set parameters for sending reports

to the user’s mobile phone.

4. Remote control of the system:

a. User access. The alarm system can be controlled remotely (via phone call and (or) SMS messages) by users whose phone

numbers are entered into the User list. See chapter 5.4 ““Users & Reporting” window” on how to enter phone numbers.

b. Control via phone call. Phone calls allow not only to arm or disarm all or part of the security system, but also to control

(turn on or off) equipment connected to PGM outputs. See chapter 4.4 “Control via phone call” on what parameters to

change to allow phone calls to modify the state of a selected PGM output that has an equipment control circuit

connected to it.

c. Control via SMS messages. With SMS messages, it is possible to change some of the control panel’s operational

parameters, arm or disarm all or part of the premises, control (turn on or off) equipment connected to the PGM outputs.

See the list of SMS commands on chapter 4.3 “Configuration and control via SMS messages”.

5. Additionally:

a. Changing control codes. We recommend changing the panel’s default alarm control and configuration codes to

something only You know.

The Master user code can be changed in the branch Users & Reporting of the program menu.

The remote SMS control code can be changed in the System Options window of the program menu, in the

SMS Password field of the Access section.

Access codes for connecting with TrikdisConfig can be changed in the Access section of the System Options branch

of the program menu.

There are 10 terminals IO1–IO10 (inputs) on the control panel board for connecting sensor circuits. The number of inputs can

be expanded to 32 using input expanders (iO, iO8, iO-WL, RF-SH). Any terminal can be set as an input and assigned zone

attributes: circuit type (NO, NC, EOL, EOL_T, ATZ, ATZ_T); sensitivity to temporary circuit events; zone function (Delay, Instant,

Instant Stay, Interior, Interior Stay, Fire, Keyswitch, 24_hour, Silent, Silent 24h), see chapter 5.7 ““Zones” window”.

Schematics for connecting sensors.

www.trikdis.com 16 July 2020

Security control panel

„FLEXi“

SP3

To connect a smoke detector circuit to a selected input, the input must be assigned the Fire zone function (see chapter 5.7

““Zones” window”).

To connect a four-wire smoke detector circuit to a selected PGM output, the Fire Sensor Reset function must be assigned to

the output (see chapter 5.8 ““PGM” window””).

Schematic for connecting four-wire smoke detectors.

Schematic for connecting two-wire smoke detectors.

or

www.trikdis.com 17 July 2020

Security control panel

„FLEXi“

SP3

The diagram shows the connection and settings of the MR100 outdoor siren. If the control panel will use a different method

for monitoring the EOL (factory setting is 2.2 kOhm EOL) of the siren tamper (SAB terminals) circuit, it is necessary to close the

JPS1 contacts and connect a resistor of the corresponding rating in series to the tamper circuit. The 24_hours zone type is

factory set for IO9 input.

Up to 8 devices can be connected to the keypad data bus. The type of the connected keypad must be specified using

TrikdisConfig software (see chapter 5.5 ““Modules” window”). The control panel will automatically recognize and link the

connected devices.

www.trikdis.com 18 July 2020

Security control panel

„FLEXi“

SP3

Up to 2 RFID readers can be connected to the control panel. If 2 RFID readers are connected to the control panel, no keypads

can be connected.

www.trikdis.com 19 July 2020

Security control panel

„FLEXi“

SP3

The CZ-Dallas iButton key reader connects to the „FLEXi“ SP3 using the “1 Wire” data bus. The length of the wires connecting

to the data bus can be up to 30 m:

The TM17 reader connects to the „FLEXi“ SP3 using the RS485 data bus. The length of the wires connecting to the RS485 data

bus can be up to 100 m.

www.trikdis.com 20 July 2020

Security control panel

„FLEXi“

SP3

Temperature sensors should be connected according to the

given schematic. Maxim®/Dallas® DS18S20, DS18B20

temperature sensors (up to 8) can be connected to the

„FLEXi“ SP3 security control panel.

If a wire longer than 0,5 meters is used to connect a

temperature sensor, we recommend using twisted pair

cable (UTP4x2x0,5 or STP4x2x0,5).

The +5V terminal on the board is for supplying devices connected to the 1-Wire data bus with 5 V DC voltage. The maximum

output current is 0,2 A. The output is protected from overload. If the maximum allowed current is exceeded, the power will

automatically be switched off. The control panel automatically recognizes and links connected devices.

Using the relay terminals, it is possible

to remotely control (turn on/off)

various electrical devices. The panel’s

universal I/O terminal must be

configured as an output (OUT) and

must have the definition Remote

control assigned.

The E485 module allows the control panel to send and

receive control commands using a wired internet

connection. If an E485 module is connected to the control

panel, reports to the CMS and to Protegus will be sent using

wired internet and mobile internet will not be used. If wired

internet connectivity is lost, mobile internet will be used for

sending reports to the CMS. If wired internet connectivity is

restored, the control panel will automatically stop using

mobile internet and will switch to communicating with CMS

and Protegus mobile app using the E485, i.e. wired internet.

See chapter 5.3 ““Reporting to CMS” window” on how to choose connectivity priority (GPRS, LAN, WiFi). The „FLEXi“ SP3’s

configuarion for the E485 Ethernet module is described in chapter 5.5. ““Modules” window”.

If the E485 is connected, a SIM card is not necessary for the control panel.

With the RF-SH it is possible to connect 64 wireless remote controls, 16

wireless sirens, 32 wireless sensors, 8 wireless keypads to the security

system.

The „FLEXi“ SP3 ’s configuration for expander modules is described in

chapter 5.5 ““Modules” window”.

If the security control panel „FLEXi“ SP3 needs to have more inputs IN or outputs OUT, connect a wired or wireless TRIKDIS

iO series input and output expander. The „FLEXi“ SP3 ’s configuration for expander modules is described in

chapter 5.5 ““Modules” window”.

Other manuals for FLEXi SP3

3

Table of contents

Other Trikdis Control Panel manuals

Popular Control Panel manuals by other brands

Belden

Belden Grass Valley NV9000 user guide

Texecom

Texecom Premier Elite Micro Contact-W installation manual

Alarm Sense

Alarm Sense PLUS AS-5003 Installation, commissioning & operating manual

CAME

CAME ZL90 installation manual

CWSI

CWSI CP-3500D Operating and installation instruction manual

Lofa

Lofa CANplus CP600 Operation guide

Analog way

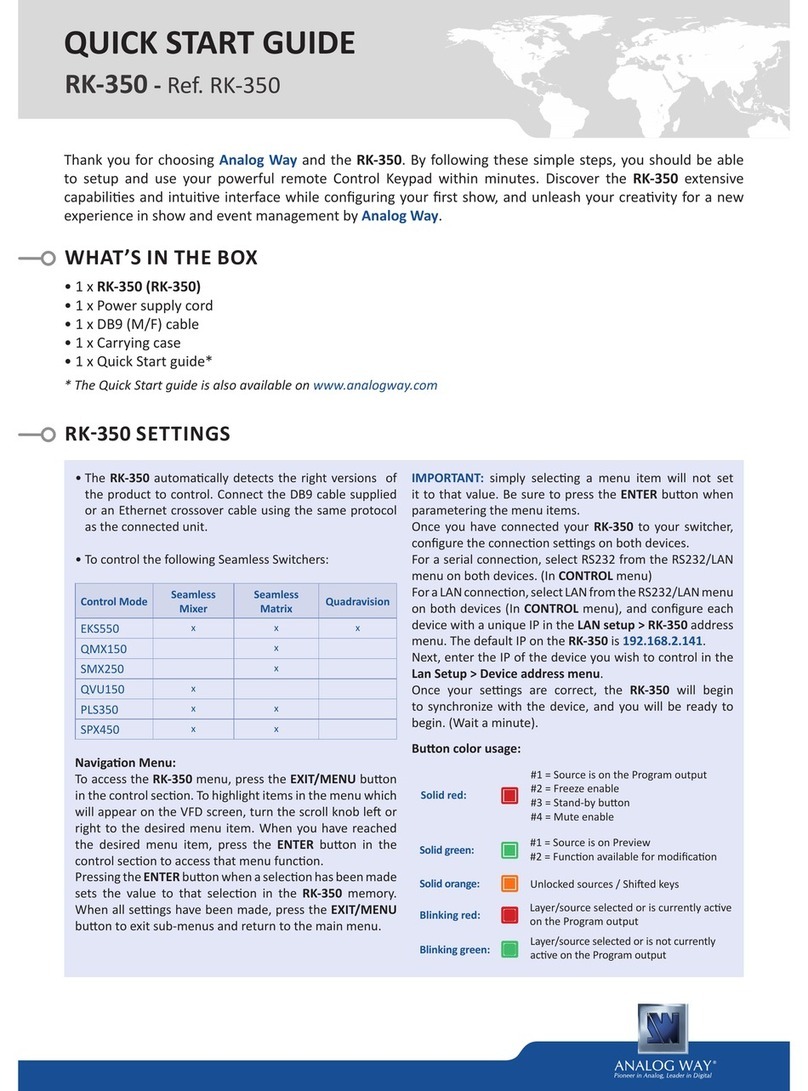

Analog way RK-350 quick start guide

MITOS

MITOS VT6 quick start guide

Cattron

Cattron LOFA EP250 Panel Operation and Troubleshooting Manual

Aerovalley Technologies

Aerovalley Technologies ACP100-300-2 installation manual

Firefly

Firefly Vegatouch Forest River Forester V1 manual

PEAKnx

PEAKnx Controlmini user manual