TRIMALCO ATHENA 70 User manual

Introduction

Thank you for purchasing this Table Top Cutter. It has been manufactured in the UK to the highest

standard and if used in accordance with these instructions and properly maintained, it will give you

years of trouble-free performance.

e want your experience using this machine to be exceptional, so for maximum safety and

productivity, please read and understand this manual thoroughly before operating.

Product warranty

The manufacturer warrants the machine purchased to be free from defects in parts and

workmanship for five (5) years from the date of purchase. The manufacturer warrants that it will

repair or replace any such defective machine or replace parts, providing the machine has been

under normal use and service and the defective part or machine is returned to the manufacturer at

the purchaser’s expense. The manufacturer must authorise the return in writing. Proof of

purchase must be submitted to validate warranty coverage. The warranty is in lieu of all other

agreements and warranties expressed or implied.

THE MANUFACTURER DOES HEREBY EXPRESSLY DISCLAIM ANY ARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. The manufacturer does not authorise any company

employee or representative to assume for it any other liability than that set forth in this Product

arranty. The manufacturer shall not be liable for any damages or losses, whether incidental or

consequential, direct or indirect, arising out of the use or abuse of this machine. This arranty is

valid only when the machine is used with the manufacturer’s consumables and replacement parts.

In any event, THE PURCHASER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS OR ANY OTHER

ARRANTY IS LIMITED TO RETURN OF THE PURCHASE PRICE PAID FOR THIS MACHINE.

Safety first !

Please read through this manual before operating this Table Top Cutter. If after reviewing these

pages you still have questions about the safe use of this machine, contact your supplier.

1Contents

2 Packing list

2.1 Unpacking your machine

3 Before set up

3.1 Checking the work table for installation

3.2 Checking and adjusting the worktop for flatness

3.3 The base locating brackets

3.4 Positioning the base locating brackets

3.5 Fitting the cutter assembly

4 Set up

4.1 Adjusting the cutting groove alignment

4.2 The rotating mechanism

4.3 The integral levelling adjustment

4.4 Checking and adjusting for flatness and grip

4.5 Building up the table top surface

5 Operation

5.1 Inserting the material to be cut

5.2 Blades and blade holders

5.3 Using the utility blade holder

5.4 Using the scoring blade holder

5.5 Using the rotary blade holder

Maintenance

6.1 Cleaning and lubrication

6.2 Adjusting the cutting head bearings

7 Fitting to the Atlas for Athena Table

7.1 Fitting to the Atlas for Athena Table

1 CONTENTS 1

NOTE: HEN LIFTING THE MACHINE FROM THE

BOX, ENSURE THAT T O PEOPLE ARE USED FOR

LIFTING. THE MACHINE COMES FULLY

ASSEMBLED AND THE LONGER MODELS ARE VERY

HEAVY.

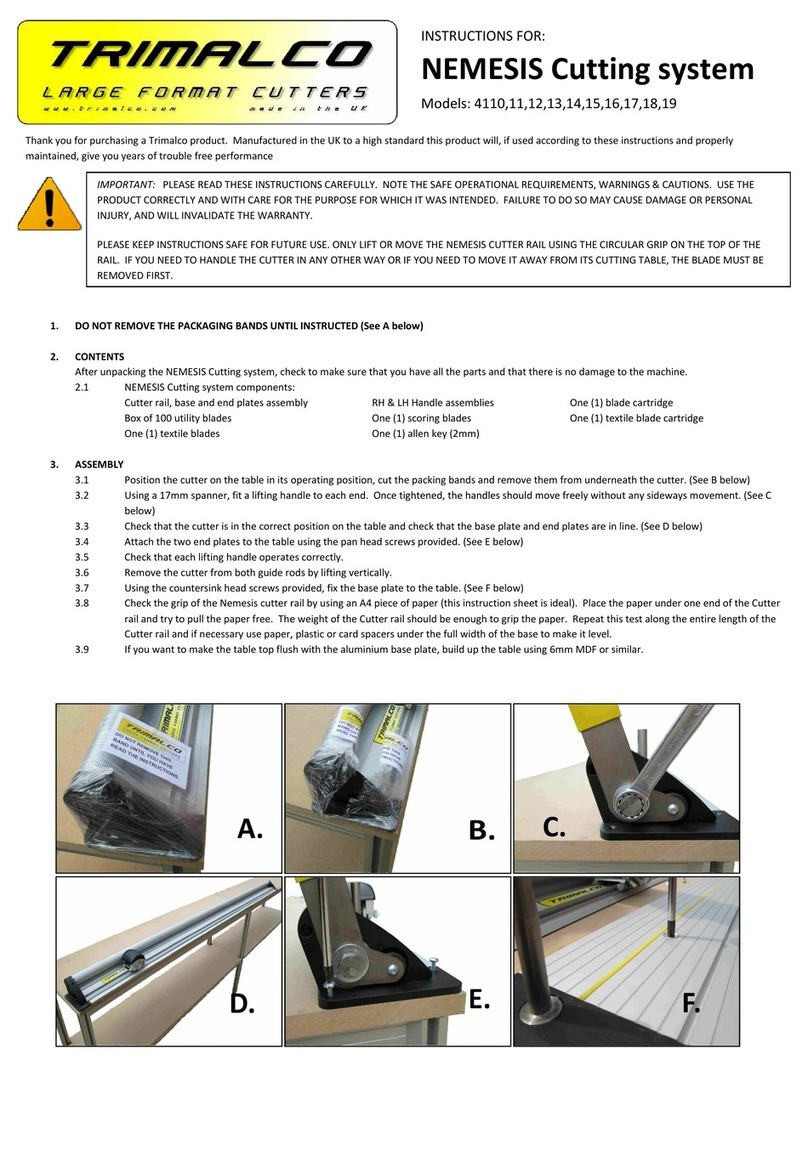

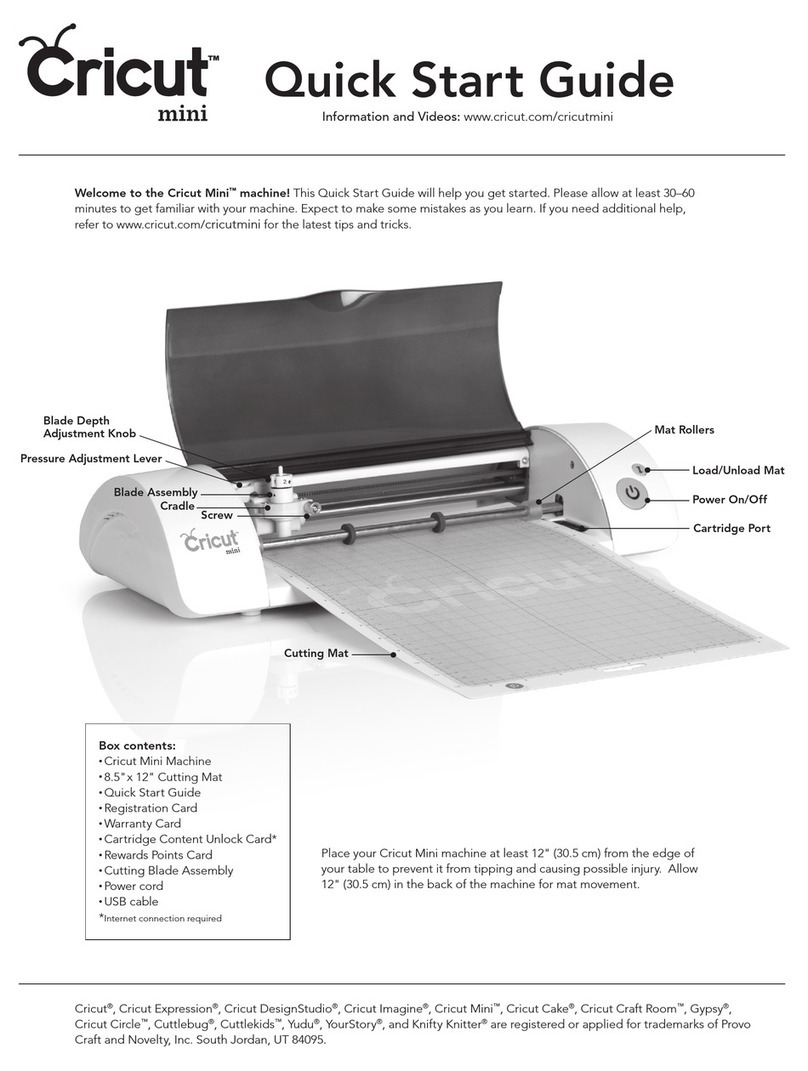

After unpacking your machine, check with the lists

below and the photographs opposite to make

sure that you have all the parts and that there is

no damage.

Your machine comprises of the following items:

ATHENA A3 CUTTER

A3 FIXINGS BAG

CUTTER RAIL ACCESSORY BAG

Fastenings can come loose in transit. Do not

throw any packaging away until installation is

complete.

2.1 UNPACKING YOUR MACHINE 2.1

CHECKING THE WORK TABLE FOR INSTALLATION

The cutter can be fixed to one of our purpose built

tables or it can be fitted to an existing table. The

table needs to be rigid with a flat worktop made

from MDF or similar and capable of accepting the

fixing screws. The table top needs to be flat to

within 3mm (1/8”)

To enable the flip-over storage function to

operate, the cutter must be fitted along the front

edge of the worktop.

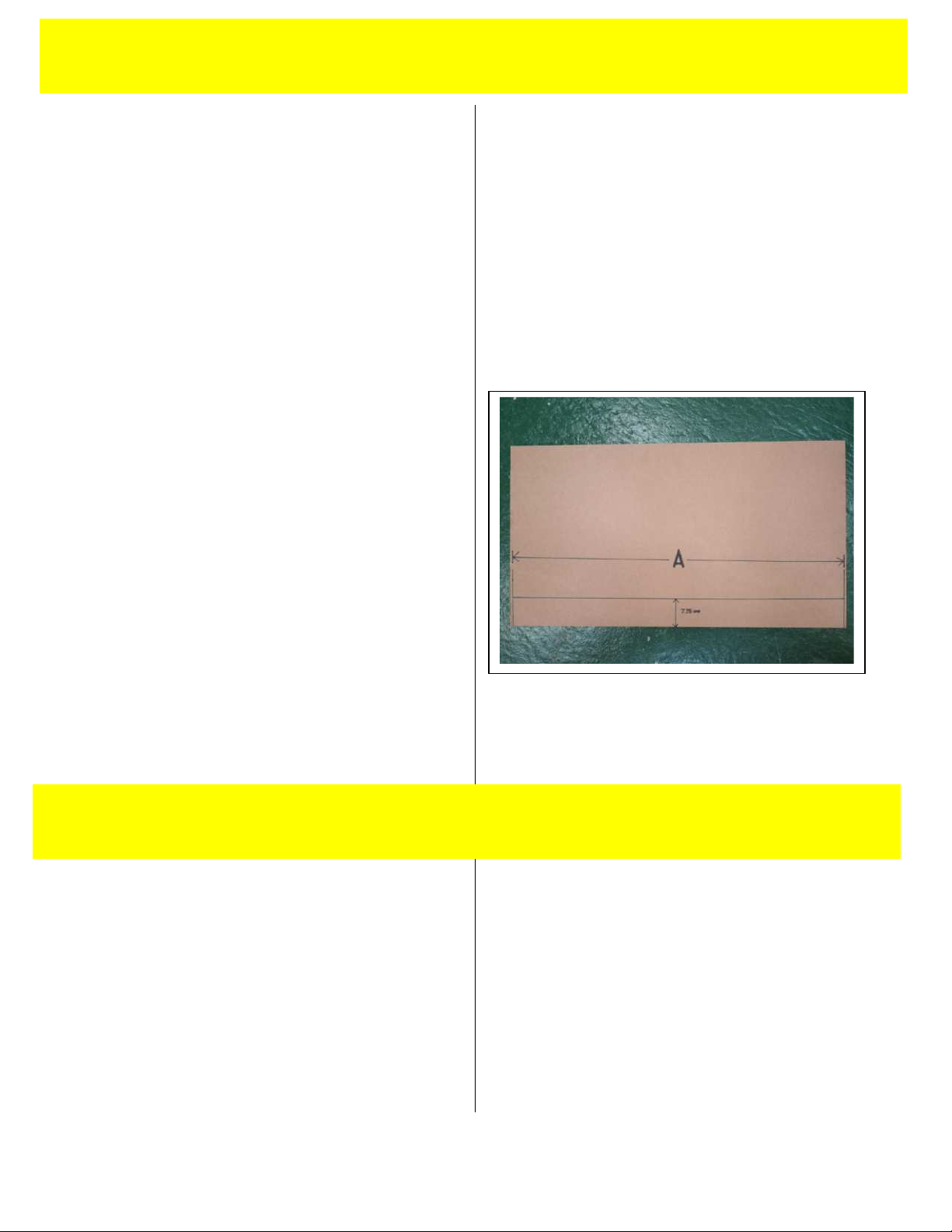

If the cutter is to be mounted along the front

edge, draw a line 7.75 cms (3.1”) in from, and

parallel, to the front edge. The line “A”, should be

the overall length of the cutter.

70cms (28”) A = 90cms (36”)

110cms (44”) A = 130cms (52”)

160cms (64”) A = 180cms (72”)

210cms (84”) A = 230cms (92”)

260cms (104”) A = 280cms (112”)

310cms (124”) A = 330cms (132”)

360cms (144”) A = 380cms (152”)

Should you wish to use the cutter say 15cms (6”)

from the front edge then draw the line 15 + 7.75 =

22.75cms (9.1”) from, and parallel to, the front

edge.

CHECKING AND ADJUSTING THE WORKTOP FOR

FLATNESS

You can check the flatness of the worktop by

stretching a thin piece of strong thread between

two blocks of the same height. Measure the

highest and lowest part of the worktop under the

thread, the difference should not exceed 3mm

(1/8“). If the difference is greater it will be

necessary to adjust the flatness with a new top or

by using spacers under each locating bracket.

3.1 BEFORE SET UP 3.1

3.2 BEFORE SET UP 3.2

CHECKING AND ADJUSTING THE WORKTOP FOR

FLATNESS (continued).

Adjust the surface flatness by adding packing

pieces, made from 1.5mm-3mm (1/16” – 1/8”)

thick rigid material such as PVC Foamboard, under

the mounting plates during installation (see 3.3).

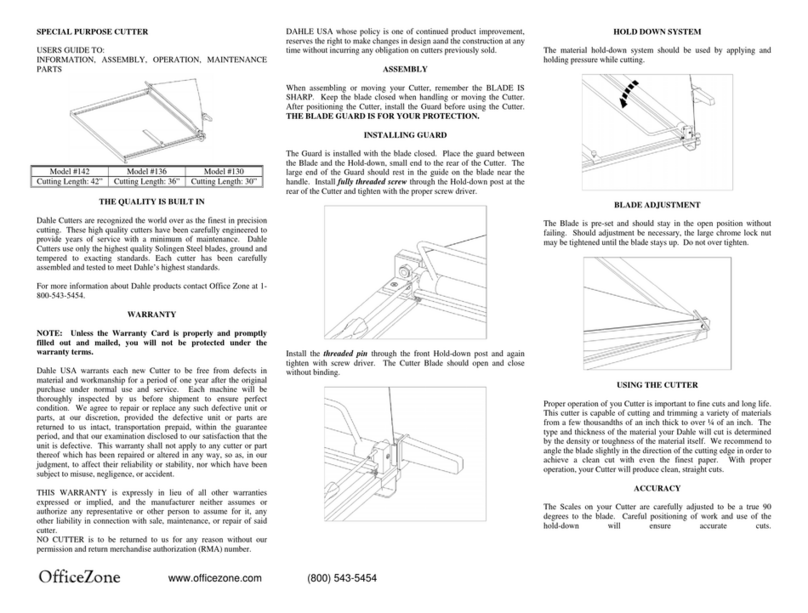

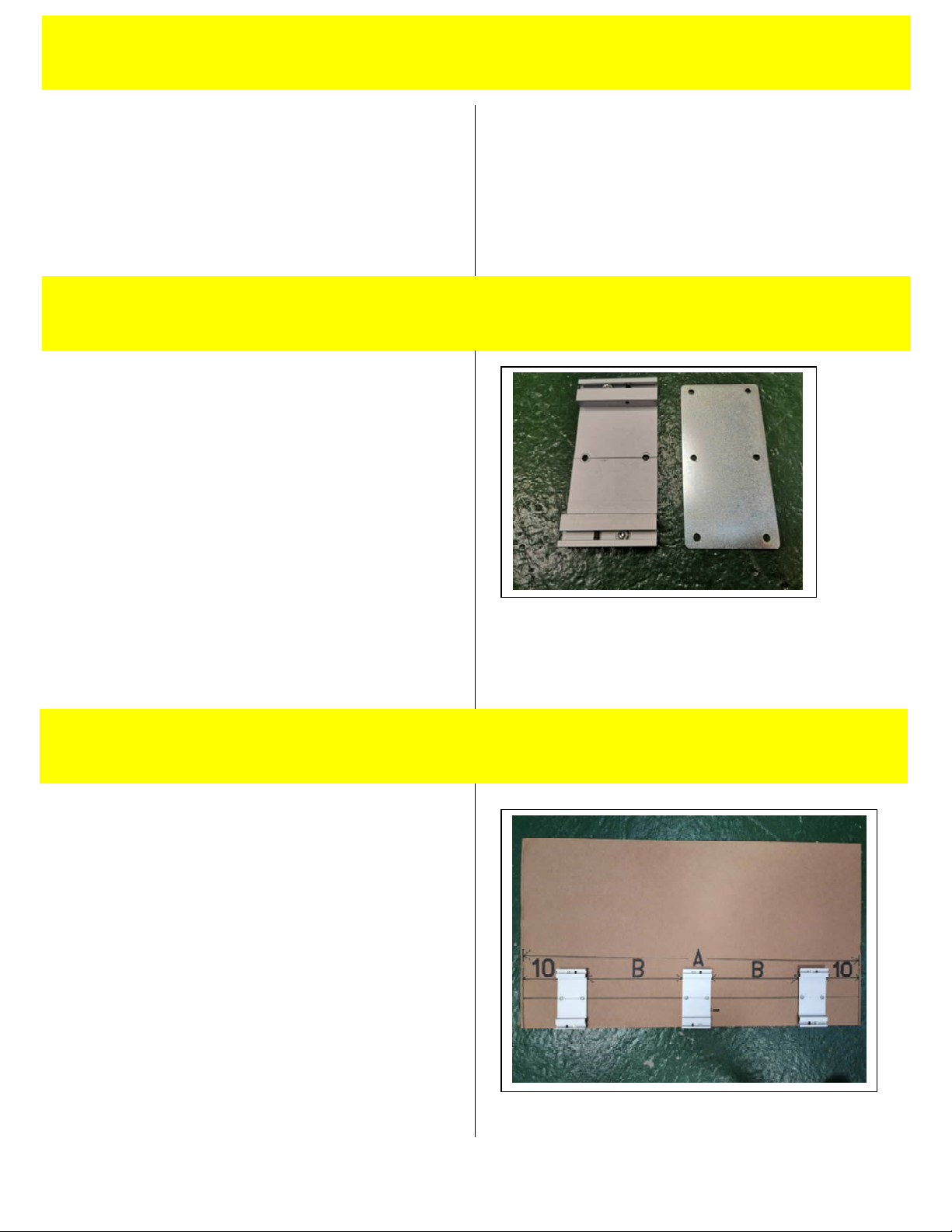

THE BASE LOCATING BRACKETS & MOUNTING

PLATES

The base locating brackets and mounting plates

are designed to hold the base of the cutter firmly

in place and provide a means to adjust the base

for both flatness and alignment of the cutting

groove. Before fitting the brackets, check that the

tips of the grub screws are aligned with the inside

of the bracket. These are factory set but may

have moved in transit. Check that the jacking

screws are present and are finger tight.

IF YOU ARE FITTING THE ATHENA 3 TO THE ATLAS

FOR ATHENA TABLE PLEASE PROCEED TO 7.1

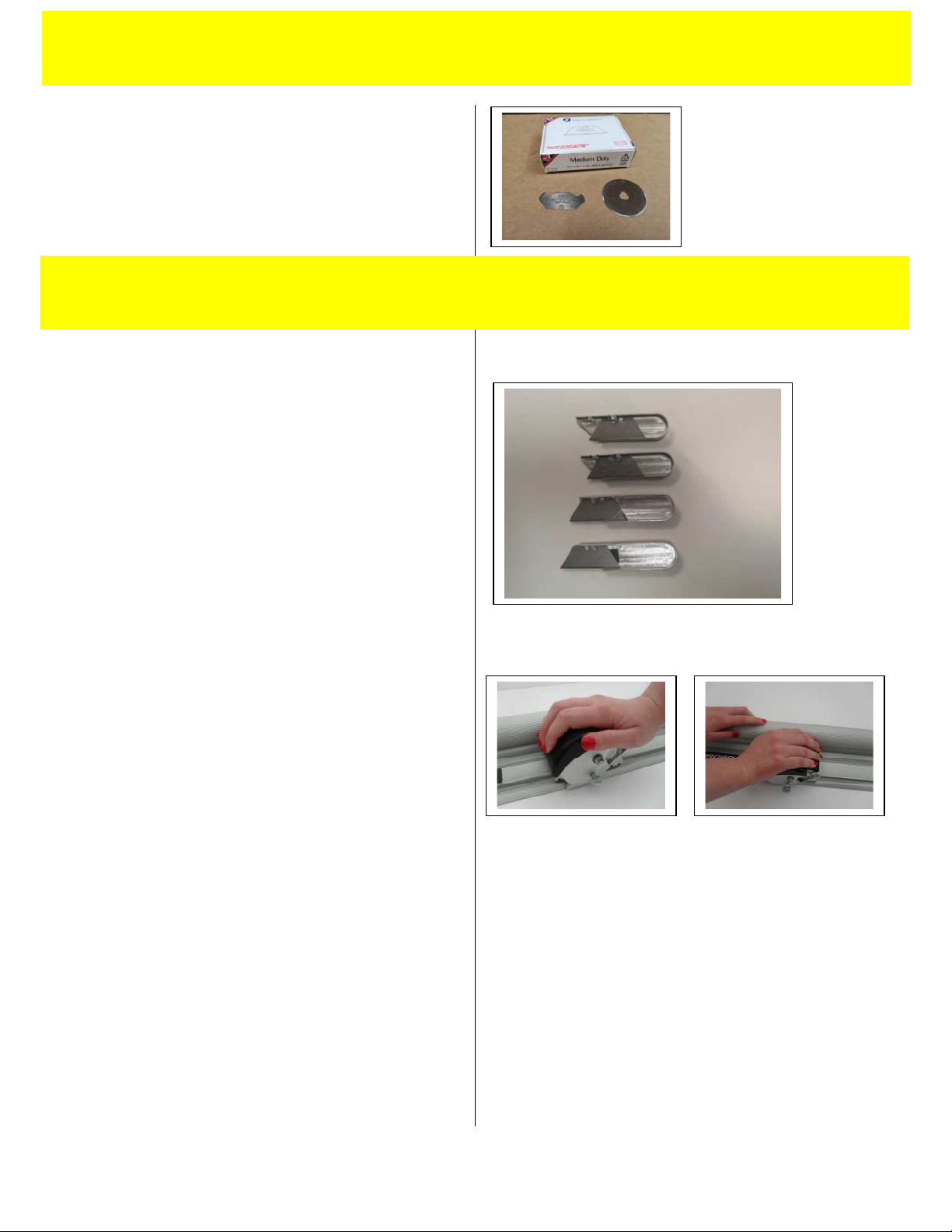

POSITIONING THE BASE LOCATING BRACKETS &

MOUNTING PLATES

Position a bracket & plate 10 cms (4”) inboard

from either end of the line drawn as described in

3.1, ensuring that the centre of the bracket is

aligned with the pencil line and fix to the worktop

using the screws provided. Position the remaining

brackets accurately along the line with equal

spacing (B) between each bracket. Check that all

brackets are aligned correctly and if not, remove

any incorrectly positioned brackets slightly to one

side of the original position to create new screw

holes.

3.3 BEFORE SET UP 3.3

3.4 BEFORE SET UP 3.4

3.2 BEFORE SET UP 3.2

FITTING THE CUTTER ASSEMBLY

Lift the cutter assembly and place it centrally on

the locating brackets. The larger cutters are

heavy and this will require two people.

Remove the clear stretch wrap and gently

manoeuvre the assembly until it is located

properly on each of the brackets.

Tighten the grub screws at the back of each

bracket (see 4.1 picture 1) by 8 full turns and then

tighten the front grub screws (see 4.1 picture 2)

up fully (approx 7-8 turns).

ADJUSTING THE CUTTING GROOVE ALIGNMENT

The cutter bar is guaranteed to be straight to

within 0.4mm (.016”) along its full length. If you

need to adjust the cutting groove in the base to

match this, the base brackets provide the means

to do so.

Adjust the straightness of the base by adjusting

the front and rear grub screws in the base locating

brackets.

To move the cutting groove towards the back of

the table, loosen the rear grub screw in the

nearest bracket and tighten the front grub screw

until the groove is aligned. Tighten the rear grub

screw. To move the cutting groove towards the

front of the table, loosen the front grub screw and

reverse the sequence above.

3.5 BEFORE SET UP 3.5

4.1 SET UP 4.1

ADJUSTING THE CUTTING GROOVE ALIGNMENT

(cont).

If you find that there is insufficient base alignment

using the adjusting screws it is probable that one

or more of the brackets need to be removed and

realigned on the table top.

THE ROTATING MECHANISM

Insert two of the four wood screws provided in

the front holes of the fixed arm and screw them

into the worktable but do not tighten.

Loosen by one full turn anti clock-wise, the four

hexagon screws (two at each end) joining the

fixed arms to the cutter base. Now fully insert the

two wood screws.

hen not in use, the cutter bar can be rotated to

a safe position under the cutting table leaving the

work surface free for performing other

procedures.

NOTE: ASSISTANCE MAY BE REQUIRED, THE

LONGER VERSIONS OF THESE CUTTERS CAN BE

HEAVY

Carefully rotate the bar and place the remaining

two wood screws into the two holes towards the

rear of the fixed arms. Now tighten all four

hexagon screws.

4.2 SET UP 4.2

4.1 SET UP 4.1

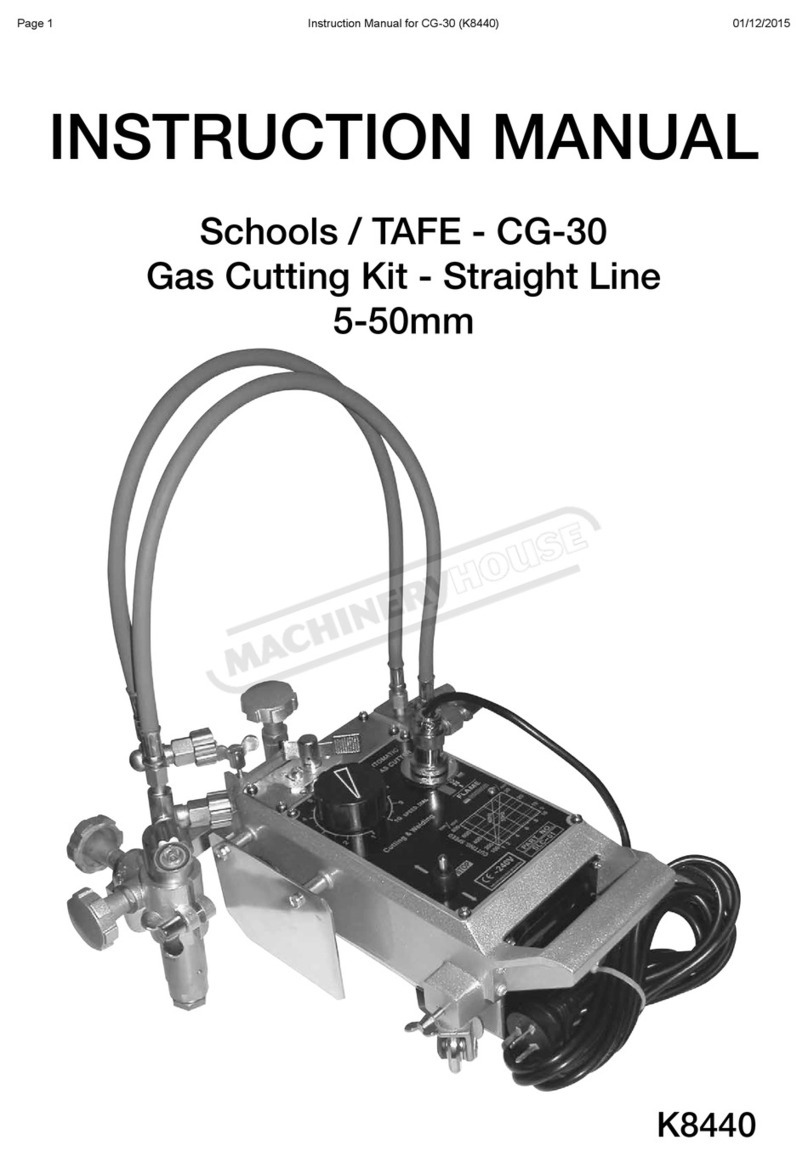

THE INTEGRAL LEVELLING ADJUSTMENT

It is essential that the material being cut is held

securely in the cutter during the cutting process.

There are two silicon cords on the underside of

the cutter bar and one in the base to assist with

this.

There is an integral levelling adjustment that

allows the cutter bar to sit flat on any thickness of

material. Place the material to be cut under the

cutter bar and release the both knobs (RH shown

opposite). The cutter bar will settle and sit on the

surface of the material. Raise the cutter bar using

the yellow lift handle and lower again to ensure

correct alignment. Now tighten both knobs.

CHECKING AND ADJUSTING FOR FLATNESS AND

GRIP

Check the grip of the cutter bar using a sheet of

copy paper. Starting at one end, raise the cutter

bar and place the paper under it. hen lowered,

the weight of the cutter bar should grip the paper.

Try to pull the paper free, you should feel

resistance. If there is not sufficient resistance,

note its position and work your way along the

cutter repeating the paper test and noting where

it is not clamping.

Adjust the clamping using the jacking screws in

the locating brackets next to the areas where the

clamping is insufficient. Turning the screws

clockwise as you look down on them will lift the

base. Adjust the front and back screws by the

same amount until the resistance is sufficient.

You may find that two or three adjacent brackets

need to be adjusted if a wide area does not

provide sufficient clamping.

4.3 SET UP 4.3

4.4 SET UP 4.4

BUILDING UP THE TABLE TOP SURFACE

Once the cutter has been installed, all that

remains is to raise the level of the surrounding

surface by 19mm (3/4”). The best way of doing

this is to add a new work top made from MDF or

similar.

The worktop should not extend beyond the edges

of the base extrusion.

4.5 SET UP 4.5

INSERTING THE MATERIAL TO BE CUT

Use either lift handle to raise the cutter bar. Place

the material to be cut on the base and then lower

the cutter. To align the edge of the cutter bar

with your crop marks, slightly raise the cutter bar

and adjust the position of the material at both

ends. The blade will cut close to the edge. This

small gap is intentional and allows easier

alignment when cutting to the edge of an image.

Check that the width of the cutting bar (front

edge to back) is lying flat on the surface of the

material to be cut. If not, loosen both tilt

adjustment knobs, raise and then lower the cutter

to settle it into position and tighten both knobs.

The cutter is now ready to cut all materials of that

thickness.

The flip stop is provided to prevent tough

materials such as PVC Foamboard from moving

during cutting.

If you are cutting a small piece of board, place it

against the flip stop and place scraps of the same

thickness material along the length of the cutter

bar to support it.

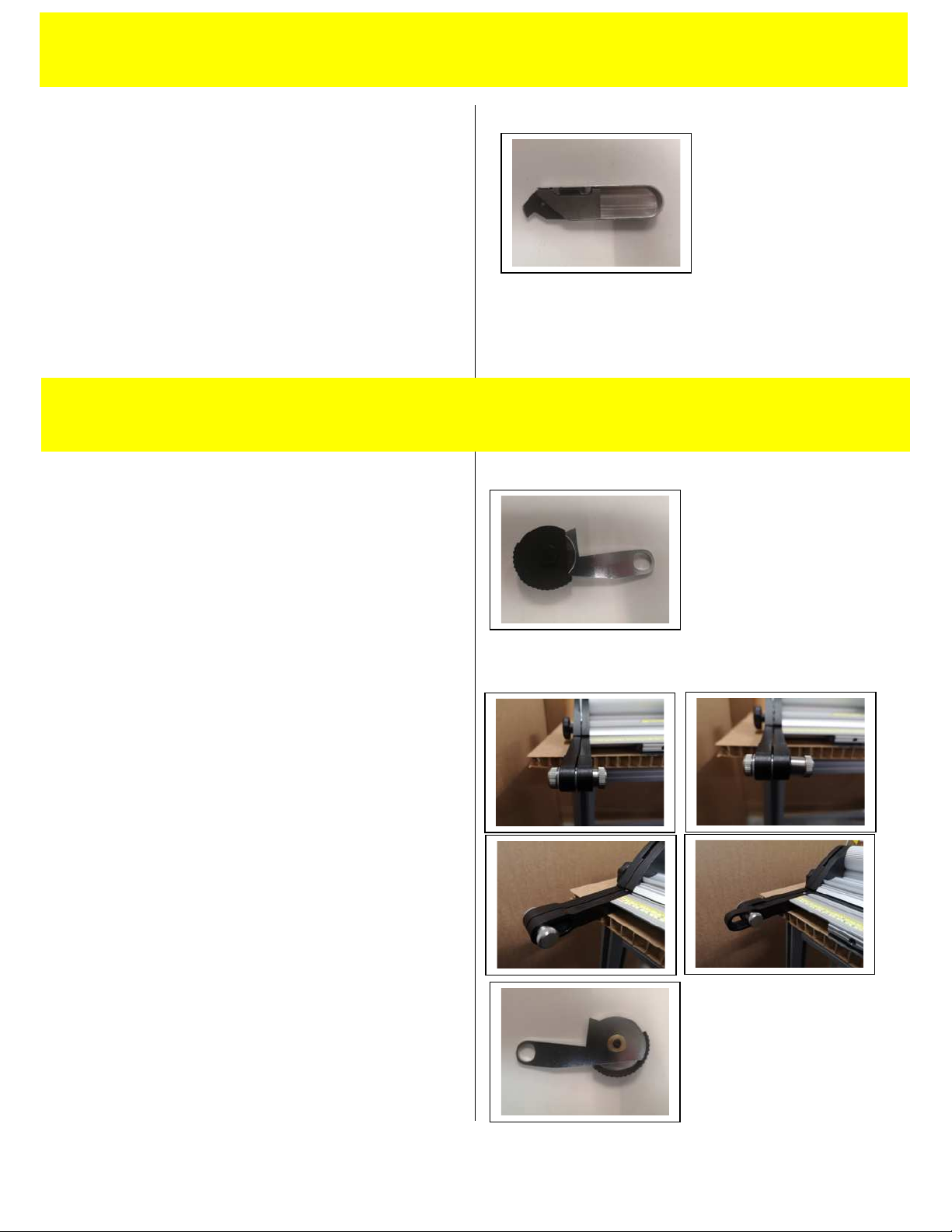

BLADES AND BLADEHOLDERS

All cutters come with two different blade holders

as standard. One blade holder accepts Medium

Duty Blades as well as a Scoring Blade for acrylic

and other rigid plastics. A separate blade holder

takes a rotary blade which is ideal for textiles and

thinner materials.

To fit a blade holder, loosen the BLADE CLAMP

THUMB SCRE and insert a cartridge. The utility

blade and scoring blade cartridge is inserted from

the rear of the holder and the textile blade

cartridge is inserted from the front.

5.1 OPERATION 5.1

5.2 OPERATION 5.2

herever possible it is our policy to use standard

blades. Each cutter comes with 100 x Medium

Duty Utility Blades, 1 x Scoring Blade and 1 x

Textile heel. All of these blades are available

from your distributor.

USING THE UTILITY BLADE HOLDER

Blade depth is important and should be set so

that the blade will cut through the thickness of

material being cut plus 1mm. Avoid setting the

depth too deep so that the blade tip hits the

bottom of the cutting groove.

The utility blade can be located in any one of four

positions allowing materials up to 19mm (3/4”)

thick to be cut. Fine adjustment of the blade

depth can be carried out by undoing the BLADE

CLAMP THUMB SCRE and moving the cartridge

itself.

To cut lightweight materials, place your right hand

on the cutter head, depress the cutter and pull

the cutting head towards you. To cut

heavyweight materials, place your left hand on

cutter bar and apply downward pressure, place

your right hand on the cutter head, depress the

cutter with the palm of your hand and push away

from you to cut. Multiple passes may be needed

for thicker materials.

The cutting head requires no dexterity and can be

easily used with the right and left hands.

5.3 OPERATION 5.3

5.2 OPERATION 5.2

USING THE SCORING BLADE HOLDER - The

scoring blade should be located in the cartridge as

shown opposite. To score fracture sensitive

plastics such as acrylic use the same technique as

used for cutting heavyweight materials (see

above). To break, move the material so that the

score line runs along the front edge of the table

and using the cutter as a clamp, apply downward

pressure to the overhanging plastic to break.

(SAFETY GLASSES AND GLOVES SHOULD BE

ORN)

USING THE ROTARY BLADE HOLDER

The rotary cutter blade holder supplied with this

machine is used to cut textiles, thin paper and

other flimsy material. It uses a circular blade to

press down onto the substrate to be cut. The

substrate being cut is supported by a plastic

cutting strip embedded in the base of the

machine. The blade guard makes it safe to handle

but be careful as the blade is very sharp.

To change the cutting channel, first raise the

cutter bar using the Lift and Hold lever. Then

loosen both of the hinge location screws until the

underside of the screw clears its location recess.

Push the cutter bar back until the underside of the

location screw lines up with the rear recess and

tighten the hinge location screw. Repeat at the

other end. The cutter bar is now positioned over

the plastic cutter strip.

The cutting strip can also be removed, turned

around or flipped over allowing four tracks to be

used before the strip requires replacement.

Replacement strip are available from your dealer.

CHANGING THE ROTARY BLADE

Blades can be replaced by undoing the knurled

brass knob on the rear of the unit.

5.4 OPERATION 5.4

5.5 OPERATION 5.5

CLEANING AND LUBRICATION.

Regularly clean your Cutter rail using a dry cloth,

stubborn stains can be removed with a cloth

dampened with a little water/detergent.

Silicon spray can be used to lubricate the cutting

head slideway.

NEVER USE OIL OR SPIRITS TO LUBRICATE OR

CLEAN THE CUTTER RAIL, SOME OF THE PLASTIC

COMPONENTS AND BEARINGS MAY BE DAMAGED

CUTTING HEAD BEARINGS

The bearings used to control the sliding motion of

the CUTTING HEAD are made from a high-quality

polymer and under normal use will last for an

extremely long time. As they settle into position

you may find a slight amount of side play, this can

be removed by tightening the two adjustment

screws.

Place the long end of the 2mm Allen key provided

into any of the two grub screws and very gradually

tighten with one hand while moving the cutting

head along the cutter bar with the other. Once

you feel the sliding motion begin to tighten, undo

the screw the smallest amount, allowing the

cutting head to slide easily.

Repeat this for the other screw.

6.1 MAINTENANCE 6.1

6.2 MAINTENANCE 6.2

POSITIONING THE BASE LOCATING BRACKETS &

MOUNTING PLATES

Position a bracket & plate assembly 10 cms (4”)

inboard from either end of the Athena Support

Beam. Position the remaining assemblies along

the length of the Athena Support Beam with equal

spacing between each. If one of the bracket

assemblies coincides with a centre frame beam

simply move that bracket to either side of the it.

FITTING THE CUTTER ASSEMBLY

Lift the cutter assembly and place it centrally on

the locating brackets. The larger cutters are

heavy and this will require two people.

Remove the clear stretch wrap and gently

manoeuvre the assembly until it is located

properly on each of the brackets. Slide the

assembly left or right so that the holes in the fixed

arms line up with holes in the support brackets

fitted to the table. Insert the four button head

screws and nuts (included with the table) at this

point but do not tighten.

Loosen by one full turn anti clock-wise, the four

hexagon screws (two at each end) joining the

fixed arms to the cutter base (see 4.2). Now

tighten the four button head screws fully insert

the two wood screws.

Tighten the grub screws at the back of each

bracket (see 4.1 picture 1) by 8 full turns and then

tighten the front grub screws (see 4.1 picture 2)

up fully (approx 7-8 turns).

The cutter bar is guaranteed to be straight to

within 0.4mm (.016”) along its full length. If you

need to adjust the cutting groove in the base to

match this, follow the instructions in 4.1

7.1 FITTING TO THE ATLAS TABLE 7.1

This manual suits for next models

6

Table of contents

Other TRIMALCO Cutter manuals