2

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performinganyintrusivemaintenanceprocedures.Awarranty

maybevoidedif intrusive maintenanceisperformedduring

thewarrantyperiod.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuableguidein determiningthebestmaintenance interval

forairbrakesystemcomponents.At a minimum, theRV-4™

valveshould beinspectedevery6months or1500operating

hours,whichevercomes first, for proper operation. Should

the RV-4™valve not meet the elements of the operational

testsnotedinthisdocument,furtherinvestigationandservice

ofthevalve may berequired.

OPERATING & LEAKAGE TESTS

OPERATING

Connect an accurate test gauge in the supply and delivery

lines of the RV-4™valve. Make certain that supply air

pressureisatthevehiclemanufacturersrecommendedlevel.

Delivery pressure should be within plus or minus 5 p.s.i. of

the delivery pressure specified for the RV-4™valve. If not,

thevalveshouldbe repaired or replaced. Ifthevalvemeets

this operating test, proceed to the leakage tests. Do not

remove the gauges at this time.

LEAKAGE

Withsupplypressureatthelevelrecommendedbythevehicle

manufacturer, apply a soap solution to the 1/4" N.P.T. plug

inthe controlport,aroundthesupplyportandtotheexhaust.

Leakage should not exceed a 1" diameter bubble in 3

seconds (175 SCCM). If leakage is excessive, the valve

shouldberepairedorreplacedandtheoperatingandleakage

testsperformedatthetimeofrepairorreplacement.Proceed

tothe“RemovalandInstallation”instructions.Thisconcludes

theoperationandleakage tests andthetestgaugesshould

beremoved.

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURYOR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

enginebe in operation,EXTREMECAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Useonlythe propertoolsand observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems,make certainto drainthe airpressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS™

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the

electrical system in a manner that safely removes

all electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix®replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

notattemptrepairs requiring machiningorwelding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

REMOVAL & INSTALLATION

REMOVAL

1. Holdthevehicle on a levelsurfacebymeans other than

the air brakes.

2. Removeallair pressure fromallreservoirs.

3. Identify, mark and then disconnect all air lines

attachedtothevalve.

4. Removethevalve.

INSTALLATION

1. Inspectandcleanallairlinesthatconnecttothevalve.

2. Clean the vehicle valve mounting area and mount the

valve.

3. Reconnect the air lines according to the identification

marksmadeduring removal.

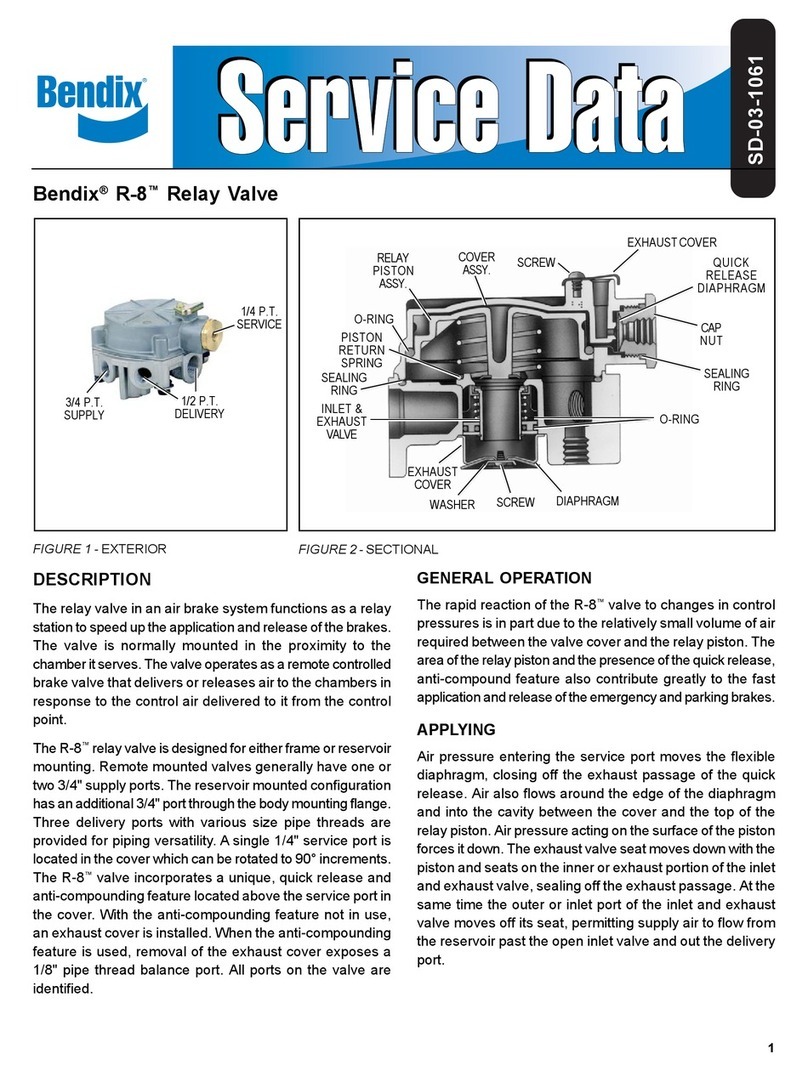

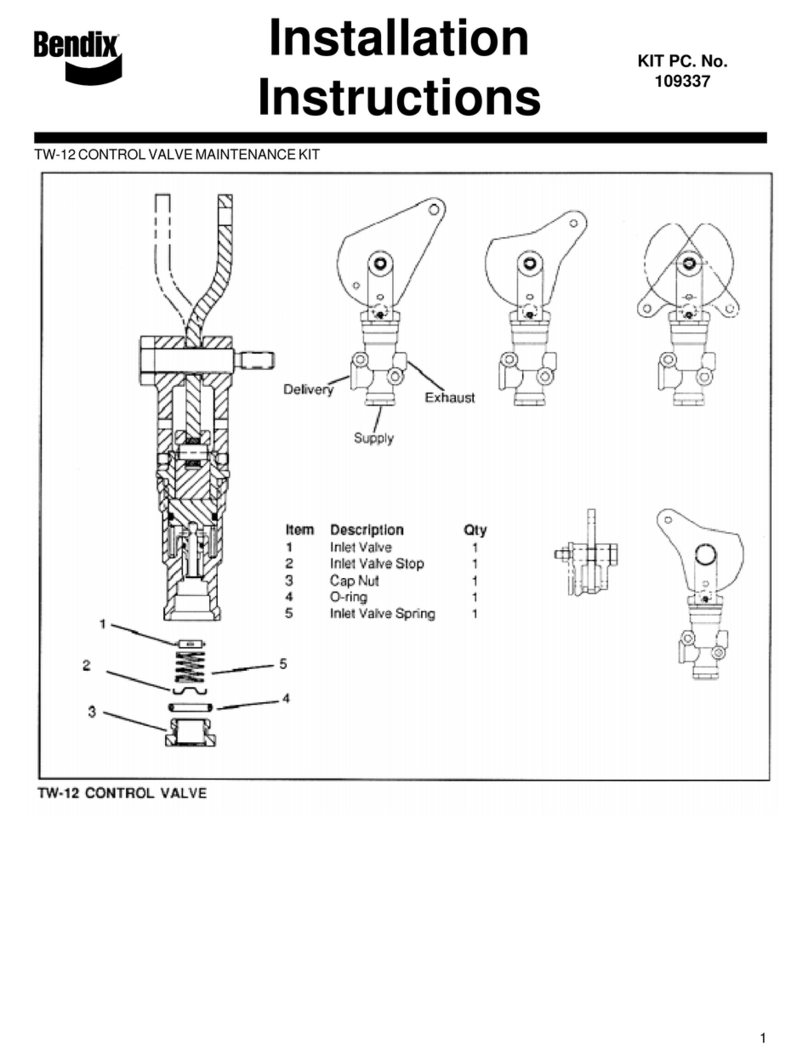

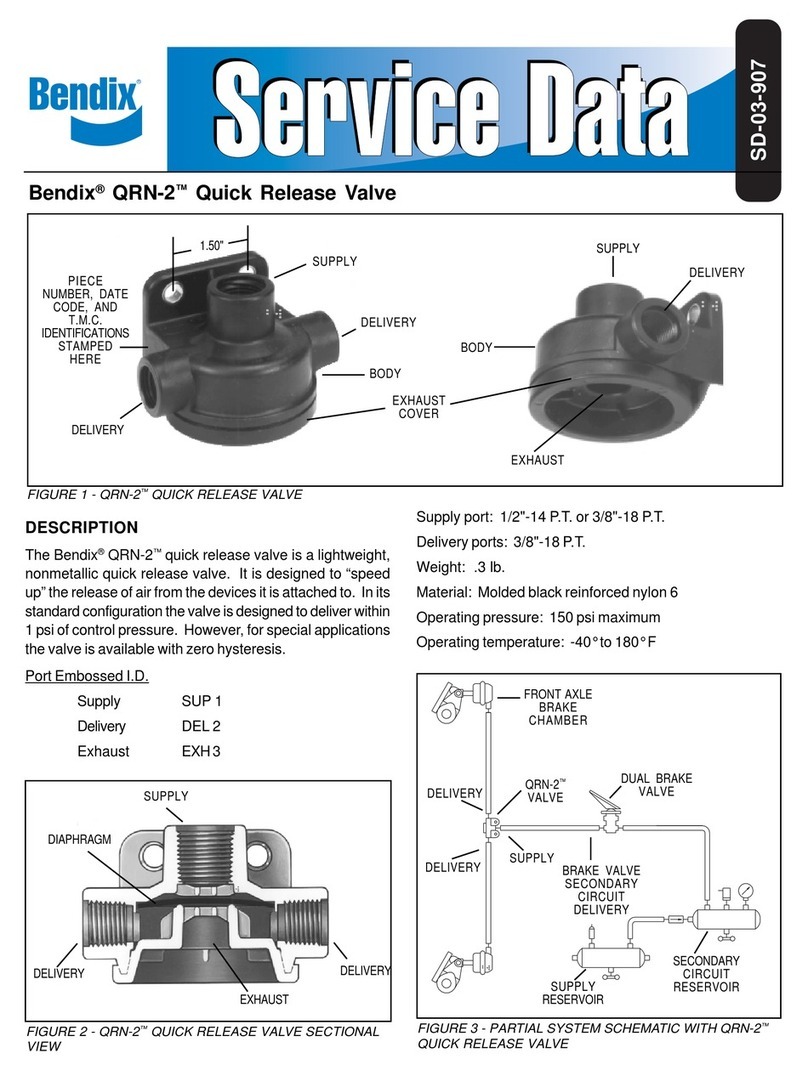

DISASSEMBLY (Refer to Figure 2)

1. Removeexhaustcoverscrew(1),exhaustcover(2),and

exhaustdiaphragm(3).

2. Remove four cap screws (4) with lockwashers (5) and

cover(6).

3. Removecontrolpiston(7).