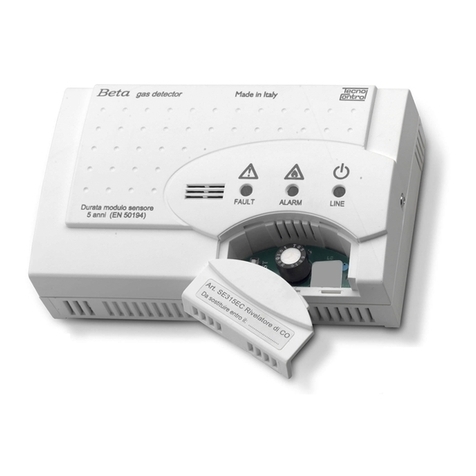

Carbon monoxide detector with

Interchangeable Sensor

series Beta model 752CO

Model Power supply Detected gas

752CO 230Vac-50Hz CO

GENERAL TERMS OF THE GUARANTEE

THIS CERTIFICATE IS THE ONLYDOCUMENT THAT ENTITLES

YOU TO REPAIR OF THE PRODUCT UNDER THE TERMS OF

THE GUARANTEE.

- The product is GUARANTEED for a period of 24 months from the date

of purchase.

- The GUARANTEE does not cover damage caused by tampering,

incorrect or improper use and installation.

- The GUARANTEE is valid only if it is duly compiled.

- In the event of defects covered by the GUARANTEE, the manufacturer

will repair or substitute the product free of charge.

SERVICINGAFTERTHE GUARANTEE PERIOD

Any repairs after the period of the GUARANTEE will be charged on the

basis of the parts substituted and the cost of labour.

Sensor Module

Detected gas

3.752.1634 Carbon monoxide 752CO

Code Beta

Toxic symptoms

When the concentration exceeds one of the alarm thresholds, there

is a slight delay and then the red LED on the front of the device

starts blinking and the internal buzzer is activated. At the same

time, the detector activates any device to which it is connected

(electric extractor, fan, buzzer, electric valve, etc.). The detector

automatically reverts to normal operating mode as soon as the

alarm turns off.

LEDSAND BUZZER

There are three LEDs on the front of the Beta 752/CO gas detector:

- GREEN LED (LINE): indicates the instrument is powered.

When the instrument is turned on, the LED blinks for

about 40 seconds to indicate the sensor is warming up;

the detector is not, therefore, ready for use until the LED stops

blinking.

- YELLOW LED (FAULT) + BUZZER: indicates the sensor

is broken.

- YELLOW LED (FAULT) blinking only: indicates the CO

sensor needs to be replaced.

50 ppm THRESHOLD 1

100ppm THRESHOLD 2

300ppm THRESHOLD 3

The relay and buzzer are activated after the time set for each threshold.

The Beta 752/CO gas detector has a built-in buzzer that warns people

of danger and malfunctioning of the device. The buzzer is sufficiently

loud to be heard in rooms adjacent to the one where the detector is

installed.

LIGHTING DELAYS

After turning on the Beta, it takes about 90 seconds for the CO sensor

in the detector to stabilize (this is the “stabilization time”). In the

meantime, the green LED blinks and the alarm control is disabled.

MALFUNCTIONING

You will need to replace the detector if all three LEDs are still blinking

5 minutes after you turned on the instrument. All three LEDs (RED,

YELLOW and GREEN) blink at the same time whenever the detector

malfunctions.

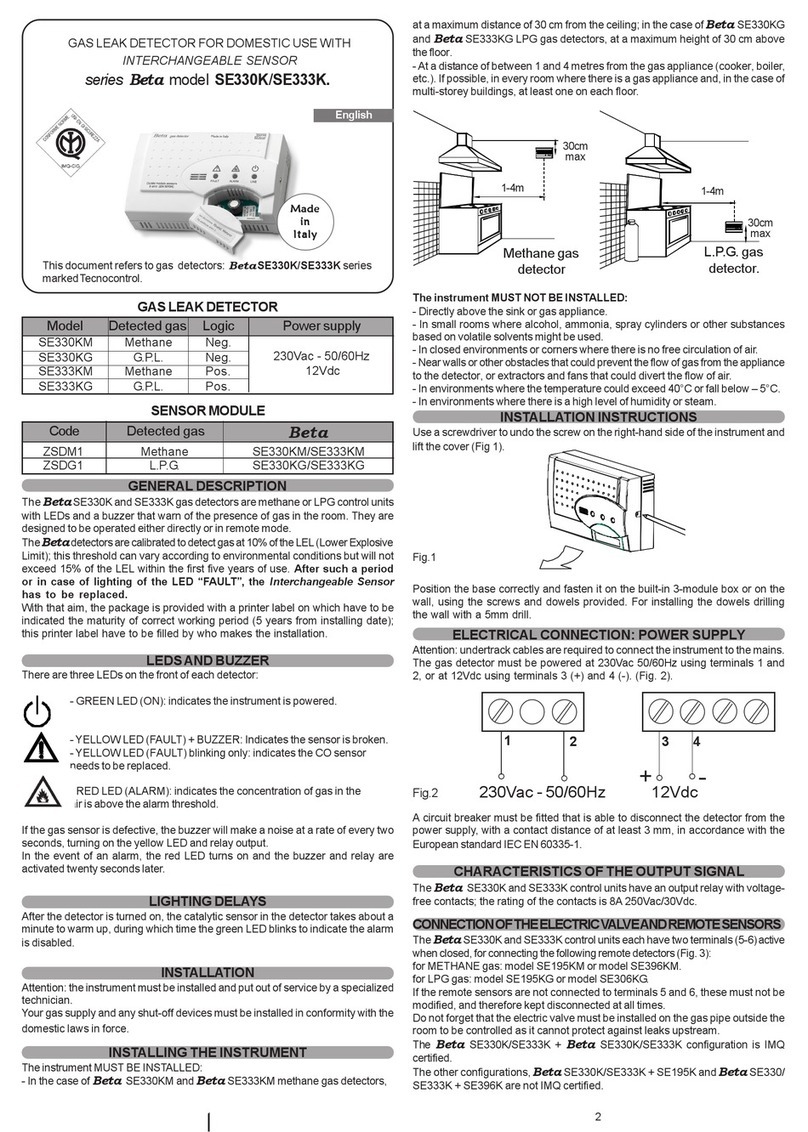

INSTALLATION

Attention: the instrument must be installed and put out of service

by a specialized technician.

Your gas supply and any shut-off devices must be installed in

conformity with the domestic laws in force.

The installation of this instrument does not replace the appropriate

installation, use and maintenance of gas appliances and suitable

ventilation and extractor systems.

- RED LED (ALARM): indicates the detector is in alarm

mode: it has detected a concentration of more than 50 ppm

(1st threshold) within a time-span of 70 minutes, or a

concentration of more than 100ppm (2nd threshold) within

a time span of 20 minutes, or a concentration of 300 ppm in

1 minute.

The red LED blinks at a different rate according to the threshold

concerned:

INTRODUCTION

This instrument is intended solely for the detection of carbon monoxide

(“CO”).

Carbon monoxide is a highly toxic, colourless and odourless gas and

combustion pollutant. The very toxic nature of CO is such that its

presence in air, even in low concentrations, can cause nausea and

cephalea, or loss of conscience in the case of prolonged exposure.

Prolonged exposure to higher concentrations can result in death, as

CO is able to bond with blood much easier than oxygen.

Below is a table illustrating the danger of CO according to level of

concentration and period of exposure:

Concentration of

CO in air

100ppm (0,01%) Slight headache in 2-3 hours

400ppm (0,04%) Slight headache in 1-2 hours, increased after

2-3 hours

1600ppm (0,16%) Headache, giddiness and nausea in 20

minutes, death within 2 hours

6400ppm (0,64%) 6400ppm (0.64%) Headache and giddiness in

1 or 2 minutes, death in 10-15 minutes

12800ppm (1,28%) 12800ppm (1.28%) Death in 1-3 minutes

As the data suggests, the CO detector needs to respond instantly

and even when the concentration of CO is minimal, in order to give

sufficient warning and, therefore, before the amount of CO absorbed

by the human organism reaches a dangerous level. The instrument

is calibrated at the factory to trigger an alarm when the detected

concentration of CO in the air is:

50ppm for 70 minutes

100 ppm for 20 minutes

300 ppm for 1 minute

GECA Srl guarantees these thresholds for a period of 5 years.

The Sensor module must be replaced after these 5 years, or when

the “FAULT” LED turns on.An adhesive label on the front of the detector

indicates the expiry date of the guarantee (5 years from the date of

production).

OPERATION

GENERAL

Beta 752/CO has an element that is sensitive to the concentration of

carbon monoxide in air.