Chapter 1 Overview of the CPS System.............................................8

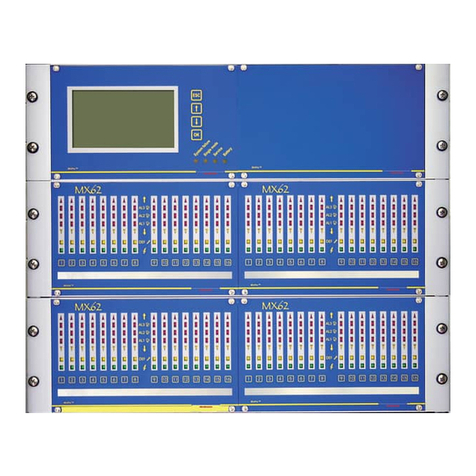

The CPS central controller..........................................................................................................10

Digital addressable modules.......................................................................................................10

Digital linking...............................................................................................................................11

The COM_CPS software application..........................................................................................12

System Architecture....................................................................................................................13

Chapter 2 Assembly / Installation.....................................................14

Installation of the CPS central controller................................................................................14

Mounting the metal wall casing...................................................................................................14

Mounting the 19" 4U rack ...........................................................................................................14

Installing digital modules.........................................................................................................15

Mounting the CPS 10 sensor module.........................................................................................15

Mounting the other modules .......................................................................................................15

Connection of modules in a line..................................................................................................15

Chapter 3 The CPS Central Measuring Controller...........................16

View of rack–mounted CPS........................................................................................................16

View of wall-mounted CPS .........................................................................................................16

Central controller electrical connections ...............................................................................17

Main power supply......................................................................................................................17

Grounding the central controller..................................................................................................17

Digital lines .................................................................................................................................17

Internal relay dry contacts...........................................................................................................17

RS-485 serial link out..................................................................................................................17

Overview of the Motherboard......................................................................................................19

Inspecting the digital buses.........................................................................................................20

Mini-switches..............................................................................................................................20

Internal relay and buzzer ............................................................................................................20

USB / RS-232 serial connectors.................................................................................................21

RS-485 serial connection (3) ......................................................................................................21

Printer (Optional feature) ............................................................................................................22

The front panel circuit..............................................................................................................23

Display Screen............................................................................................................................23

Keys............................................................................................................................................23

Lights..........................................................................................................................................23

Alarm thresholds ......................................................................................................................24

Alarm acknowledgement..........................................................................................................24

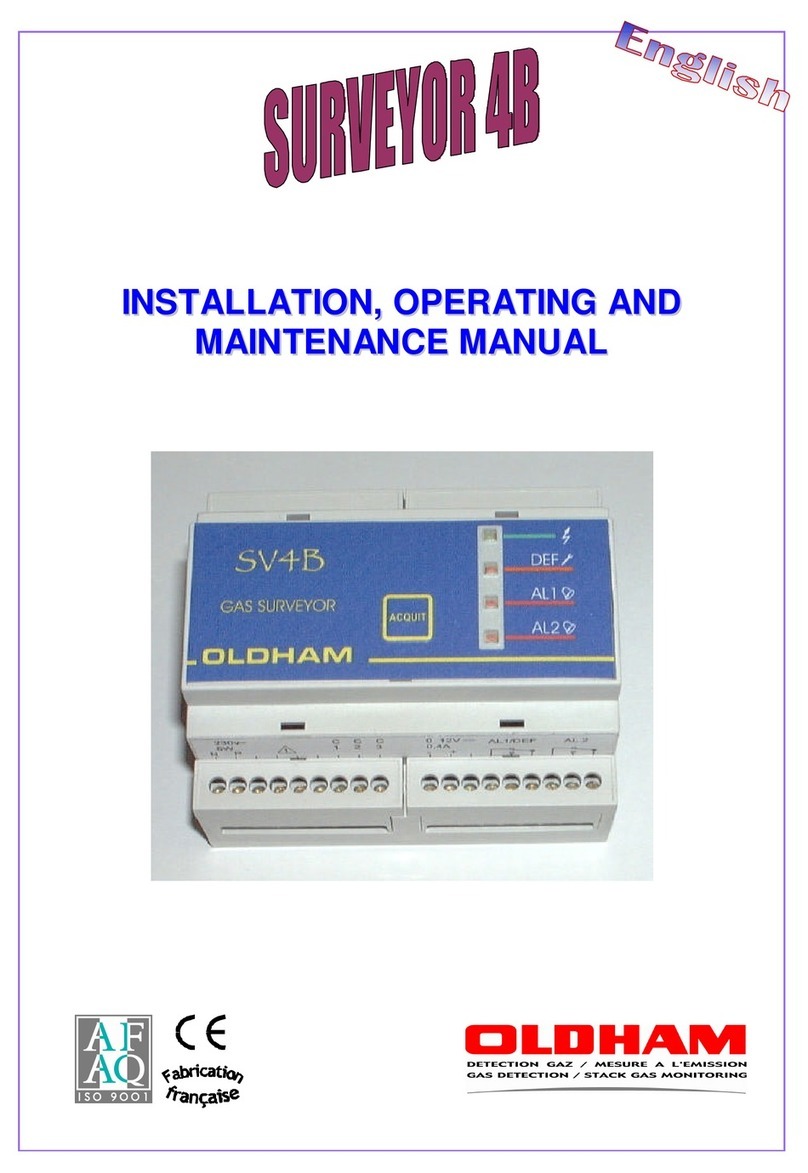

Chapter 4 Digital Modules............................................................26

View of Digital Modules............................................................................................................26

Connecting Digital Modules.....................................................................................................27

General topology of the RS-485 network....................................................................................27

Wiring the digital network............................................................................................................27

Configuring the communication settings...............................................................................28

Slave address.............................................................................................................................28

End of line resistor......................................................................................................................28

CPS 10 Detector Module ..........................................................................................................29

Available Detector Types............................................................................................................29

Detector settings.........................................................................................................................29

External relay module ..............................................................................................................30

Relay status lights.......................................................................................................................30

“Positive/negative” relay security ................................................................................................30

Relay configuration.....................................................................................................................31

Logic Input Module...................................................................................................................33