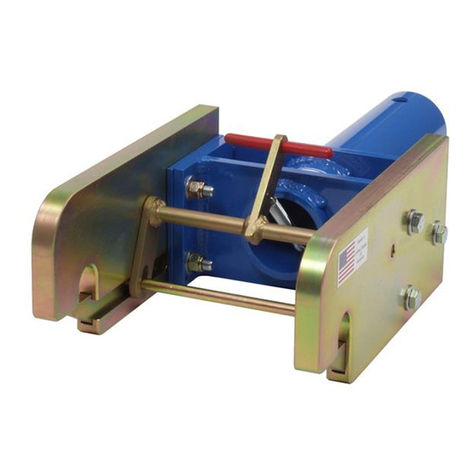

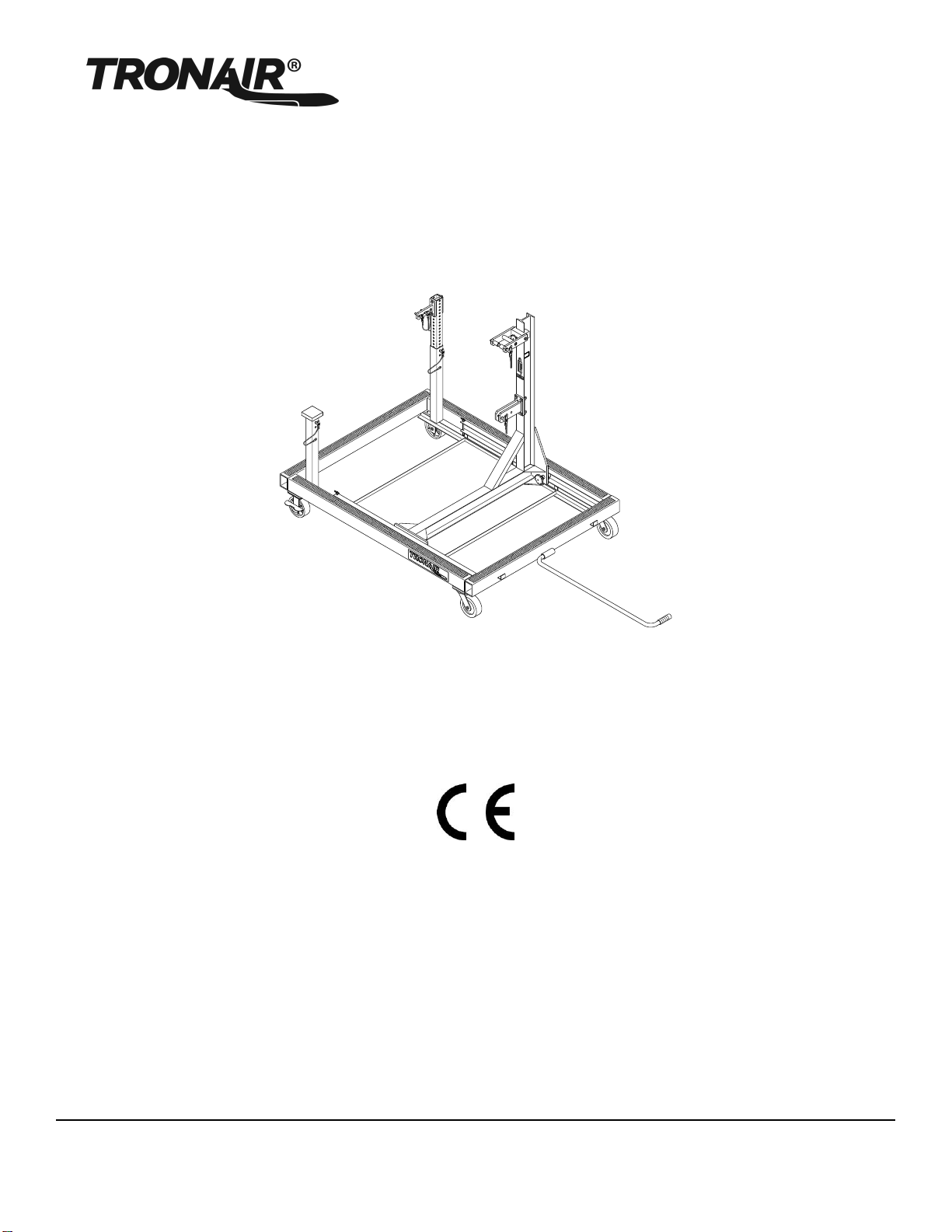

Model: 08-2030-0000

Engine Work Stand

05/2007 | Rev. 03

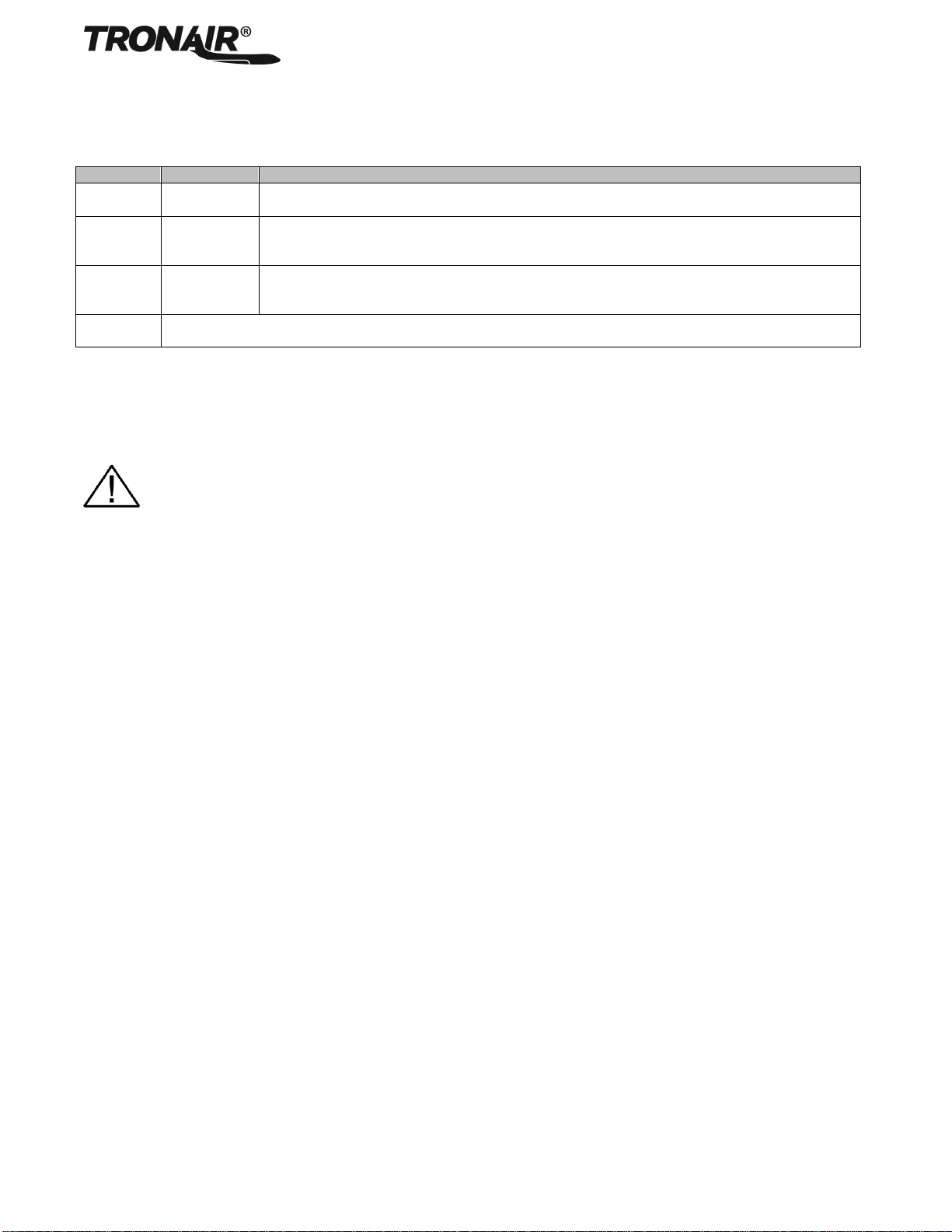

TABLE OF CONTENTS PAGE

1.0 PRODUCT INFORMATION ..............................................................................................................................................1

1.1 DESCRIPTION....................................................................................................................................................1

1.2 MODEL & SERIAL NUMBER..............................................................................................................................1

1.3 MANUFACTURER..............................................................................................................................................1

1.4 USAGE ...............................................................................................................................................................1

1.5 SPECIFICATIONS..............................................................................................................................................1

2.0 ASSEMBLY INSTRUCTIONS...........................................................................................................................................2

2.1 ASSEMBLY STEPS............................................................................................................................................2

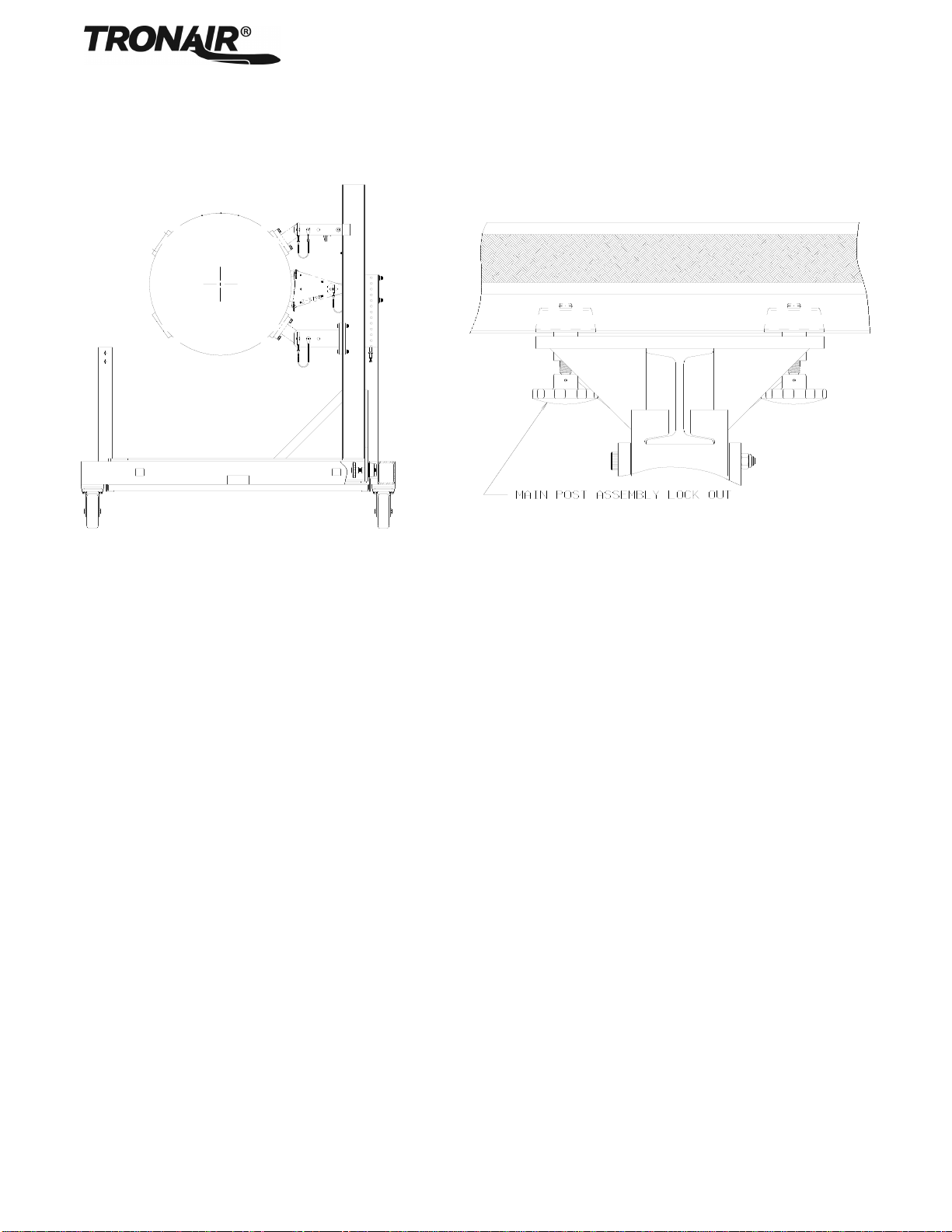

2.1.1 Install Main Post Assembly .................................................................................................................................2

2.1.2 Install Rear Engine Support Post........................................................................................................................2

2.2 PRE-USE CHECKS............................................................................................................................................2

3.0 TRAINING.........................................................................................................................................................................2

3.1 TRAINING REQUIREMENTS.............................................................................................................................2

3.2 TRAINING PROGRAM .......................................................................................................................................2

3.3 OPERATOR TRAINING......................................................................................................................................2

4.0 OPERATION.....................................................................................................................................................................3

5.0 MAINTENANCE................................................................................................................................................................4

5.1 PERIODIC INSPECTION....................................................................................................................................4

5.2 LOAD TEST........................................................................................................................................................4

6.0 PROVISION OF SPARES.................................................................................................................................................4

6.1 SOURCE OF SPARE PARTS.............................................................................................................................4

6.2 RECOMMENDED SPARE PARTS LISTS ..........................................................................................................4

7.0 GUARANTEES/LIMITATION OF LIABILITY....................................................................................................................5