Model: K-3864

2 ¼" Load Alarm Kit

06/2004 −Rev. OR

TABLE OF CONTENTS PAGE

1.0

Product Information............................................................................................................................................................1

2.0

Safety Information..............................................................................................................................................................1

2.1

Alarm And Warning Systems..................................................................................................................................1

2.2

Warning And Danger Signs ....................................................................................................................................1

2.3

Component Safety Features...................................................................................................................................1

2.4

Functional Safety Features.....................................................................................................................................1

2.5

Features For Operator Safety.................................................................................................................................1

2.6

Environmental Safety Features...............................................................................................................................1

2.7

Protection Systems.................................................................................................................................................1

2.8

Closed Circuits........................................................................................................................................................1

2.9

Interlocking .............................................................................................................................................................1

2.10

Necessary Personal Protective Equipment.............................................................................................................1

2.11

Safety Guidelines....................................................................................................................................................1

2.12

Conditions For Safe Use.........................................................................................................................................2

2.13

Operator Qualifications...........................................................................................................................................2

2.14

Additional Safety Measures....................................................................................................................................2

3.0

Packaging And Storage......................................................................................................................................................2

3.1

Packaging Requirements........................................................................................................................................2

3.2

Handling..................................................................................................................................................................2

3.3

Strapping ................................................................................................................................................................2

3.4

Packaging Protection..............................................................................................................................................2

3.5

Labeling Of Packaging............................................................................................................................................2

3.6

Storage Compatibility..............................................................................................................................................2

3.7

Storage Environment..............................................................................................................................................2

3.8

Storage Space And Handling Facilities:..................................................................................................................2

4.0

Transporting Requirements................................................................................................................................................2

5.0

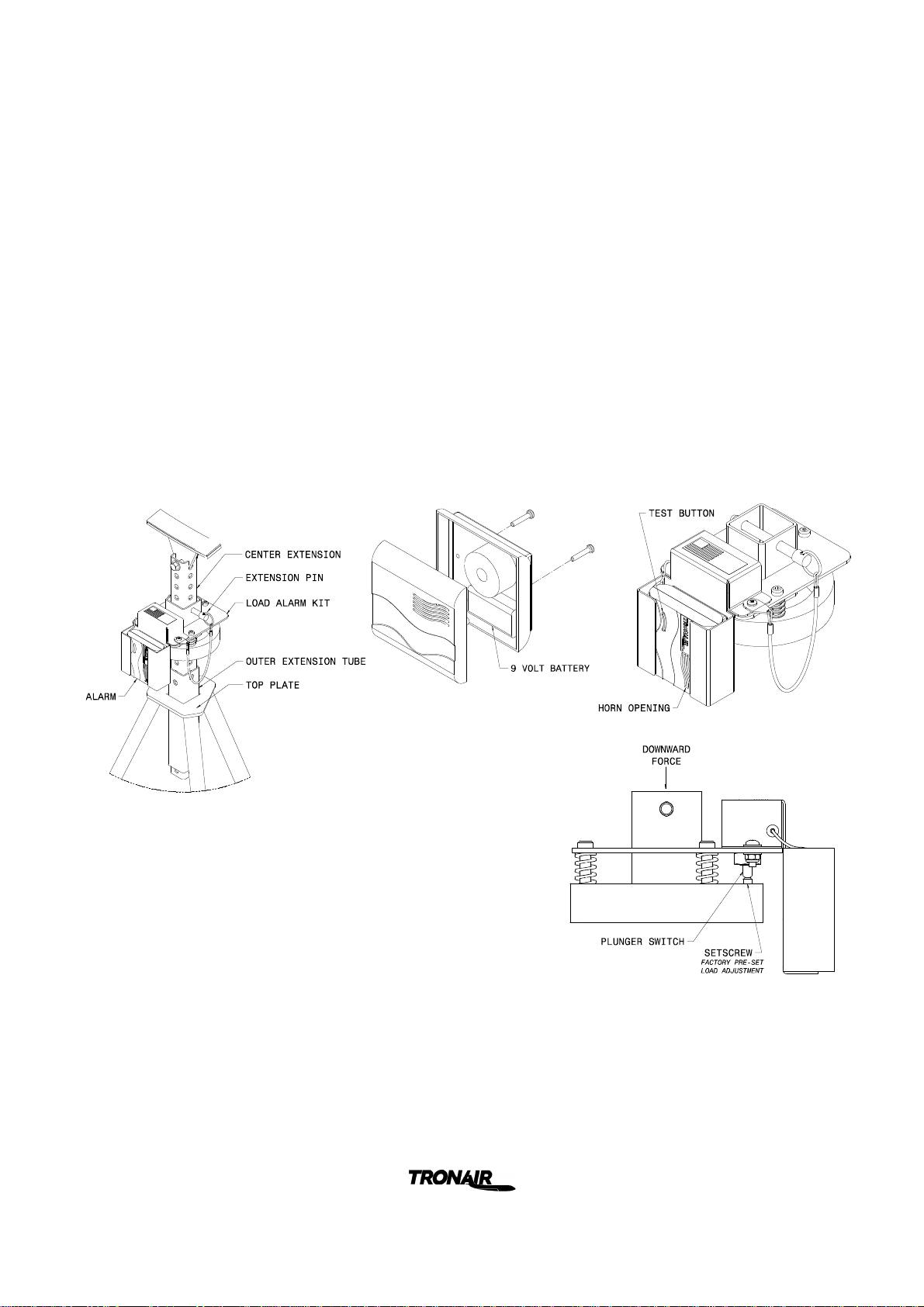

Assembly............................................................................................................................................................................3

5.1

General Instructions................................................................................................................................................3

5.2

Pre-Use Checks......................................................................................................................................................3

5.3

Personnel Requirements ........................................................................................................................................3

5.4

Assembly Steps......................................................................................................................................................3

5.5

Inspection And Test Procedures.............................................................................................................................3

6.0

Installation..........................................................................................................................................................................3

7.0

Operation ...........................................................................................................................................................................4

7.1

Operating Parameters.............................................................................................................................................4

7.2

Numerical Values....................................................................................................................................................4

7.3

Operator Controls ...................................................................................................................................................4

7.4

Operating Instructions.............................................................................................................................................4

7.4.1

Rules For Operating.................................................................................................................................4

7.4.2

Alarm Operation And Test........................................................................................................................4

8.0

Training..............................................................................................................................................................................4

9.0

Maintenance.......................................................................................................................................................................5

General ..............................................................................................................................................................................5

9.1

Maintenance Schedule ...........................................................................................................................................5

9.2

Cleaning Alarm.......................................................................................................................................................5

10.0

Troubleshooting .................................................................................................................................................................5

11.0

Provision Of Spares ...........................................................................................................................................................5

11.1

Recommended Spares To Be Kept On Hand.........................................................................................................5

11.2

Parts List.................................................................................................................................................................5

12.0

In-Service Support..............................................................................................................................................................7

13.0

Guarantees/Limitation Of Liability ......................................................................................................................................7