Tronic TR10250 User manual

Residential ESS Battery Cabinet

TR10250 | TR20450 | TR30750| TR40950

Quick Guide

TRONIC ESS CO., LTD

1

Pr

o

duct Ov

e

rv

ie

w

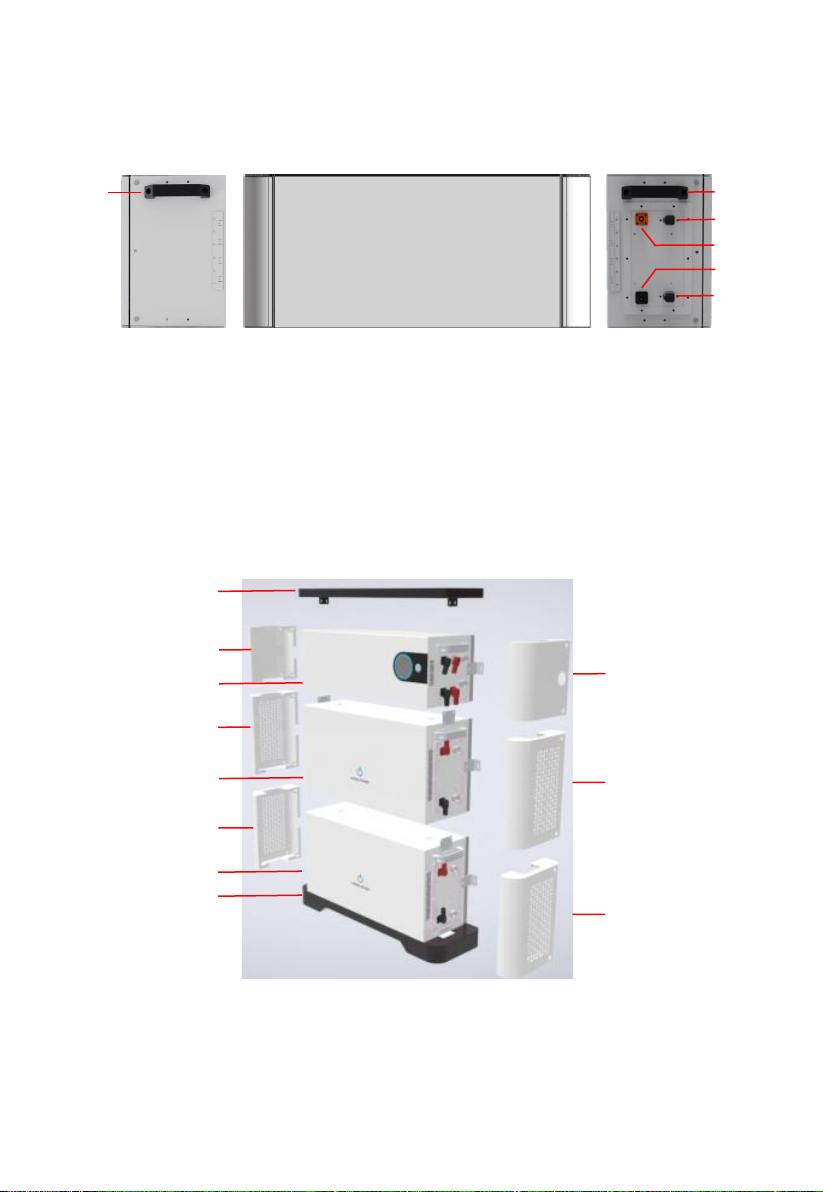

1.1 ESS Battery Cabinet Product Appearance

ESS Battery Cabinet is applicable to the grid-tied or off-grid systems. It

can store and release electric energy based on service requirements.

Note: The TR20450 ( 10 kWh) model is used as an example.

ESS Battery Cabinet consists of a power control module and battery expansion

modules. Each power control module is 5.12 kW, and can expanded to 4

power control modules. (total 20.48kWh).

Power control module

(1)Mounting handle (2)Disconnecting switch (3)Debugging port

(4)Power display (5)Start switch (6)Inverter COM port

(7) Inverter cascading terminals (8) Internal COM port

(9) Battery cascading terminals

Top Cover

Base

Battery expansion module

(5.12kWh)

Battery expansion module

(5.12kWh)

Power control module

DC Switch

Left View

9

2

Front View

Right View

8

7

6

5

4

1

3

1

Power control module

(1)Mounting handle (2)Internal COM port 1

(3)Battery cascading terminal(+) (4)Battery cascading terminal(-)

(5)Internal COM port 2

Product diagram

(1)Top cover (2)Protective cover (3)Power control module

(4)Battery expansion module (5)Bottom cover

1

2

3

2

4

2

4

5

2

2

2

Right View

Front View

2

3

4

1

5

1

Left View

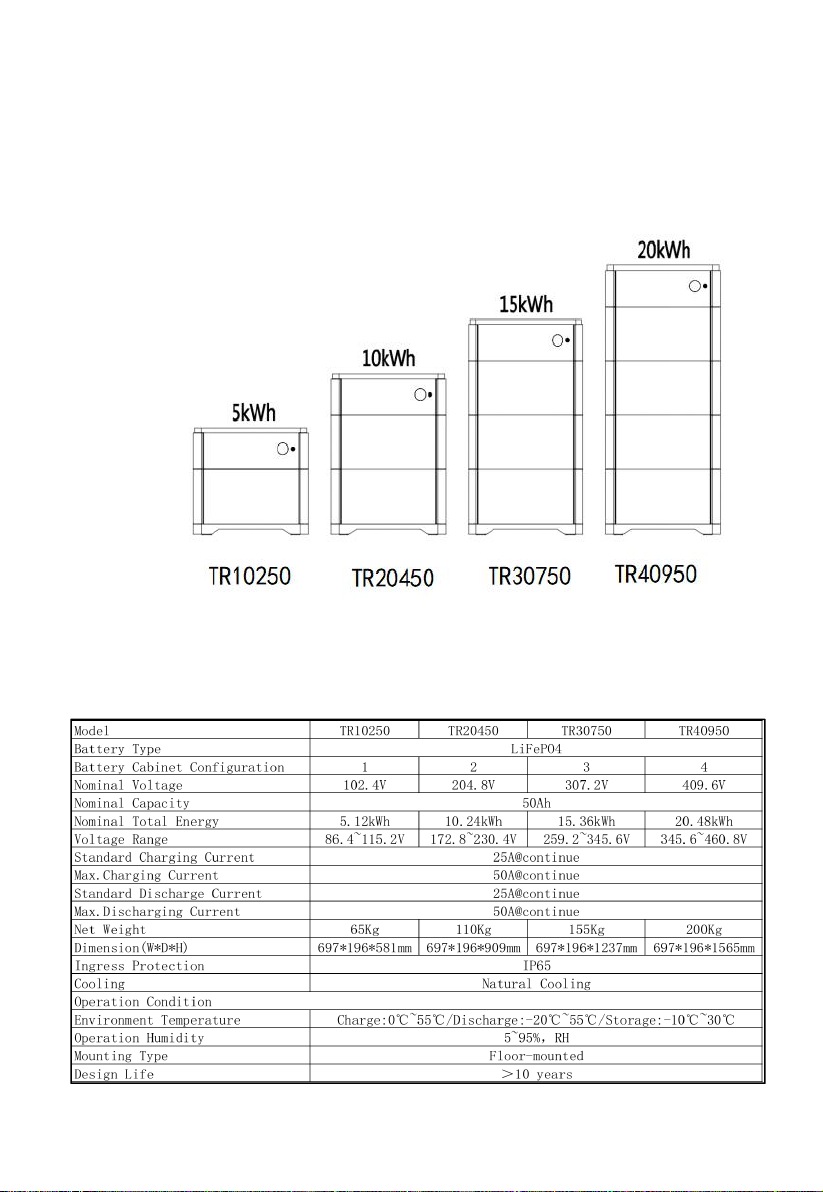

1.2 ESS Battery Cabinet Model

TRONIC ESS has different electricity products to meet user’s needs, such

as TR10250、TR20450、TR30750、TR40950.

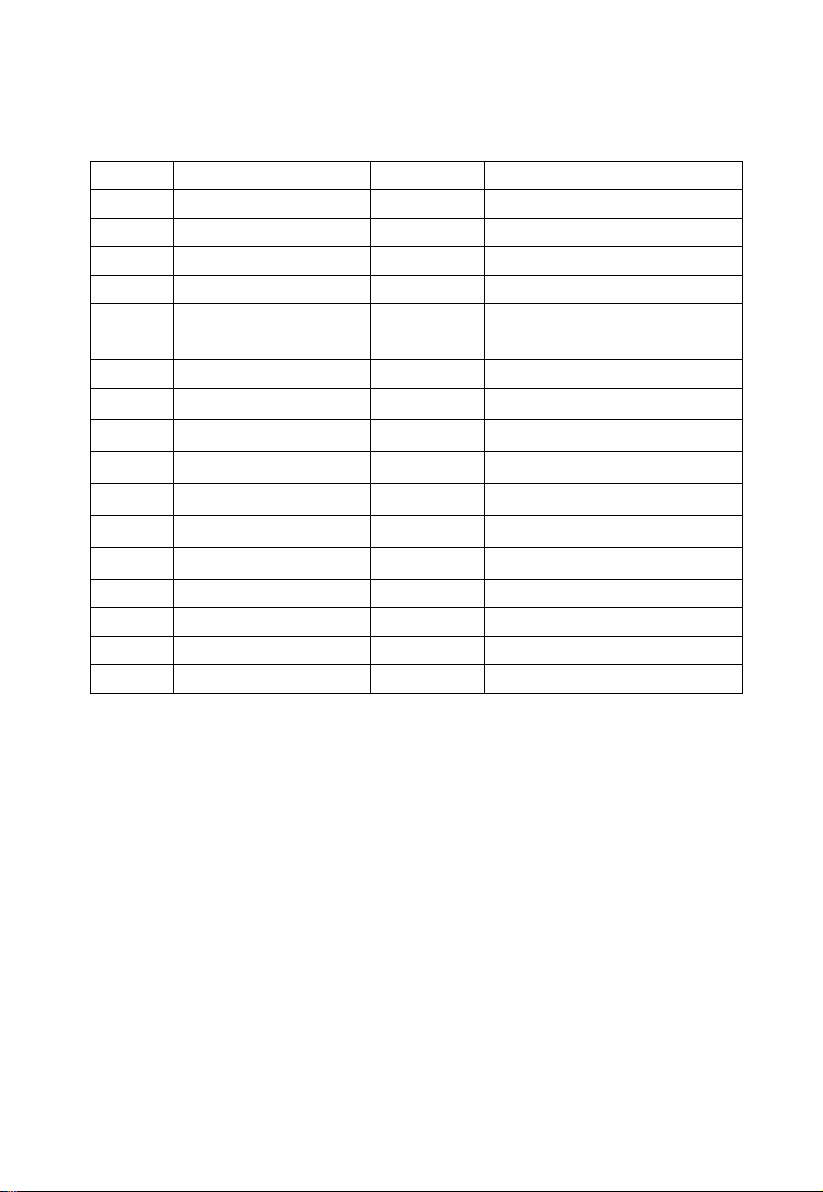

1.3 Technical data

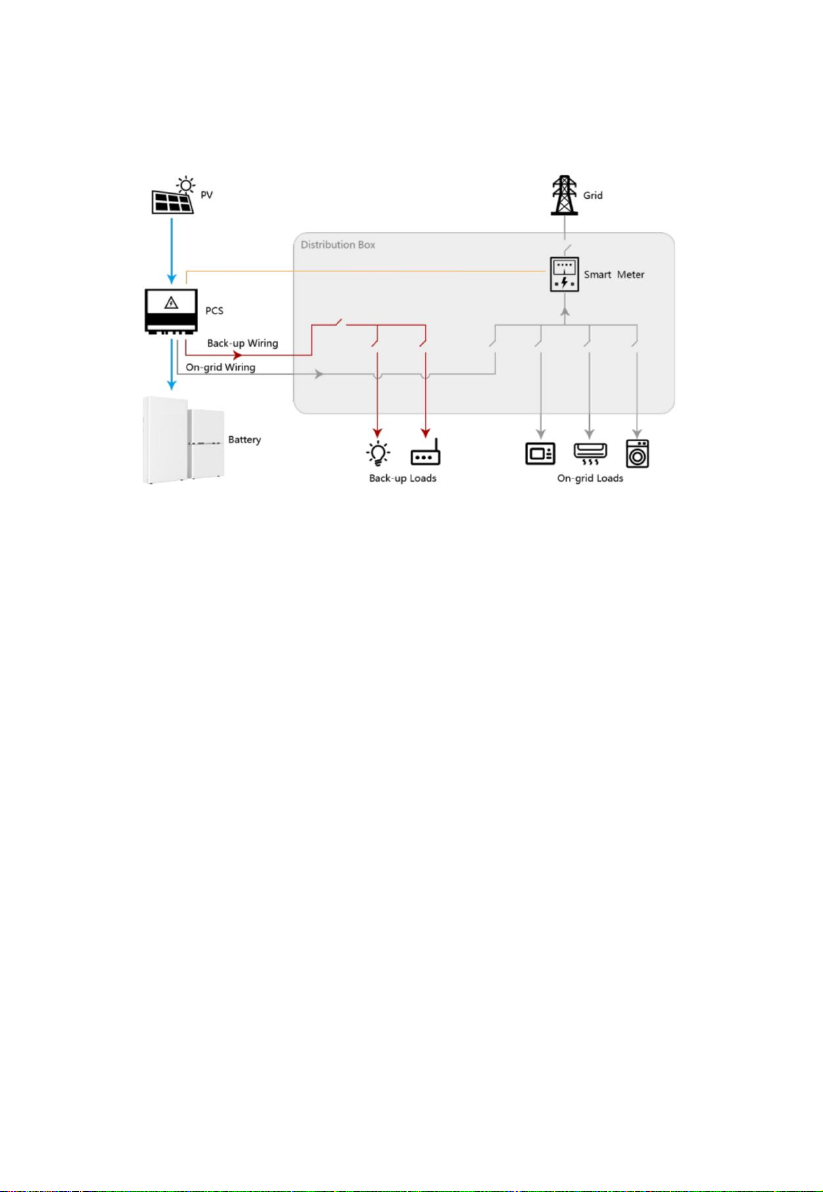

1.4 System Schematic

2

Device Installation

2.1 Installation Requirements

2.1.1 Installation Environment

2.1.2 Installation Space

inverter

front≥1000mm

unit:mm

2.1.3 Mounting Hole Dimensions

unit:mm

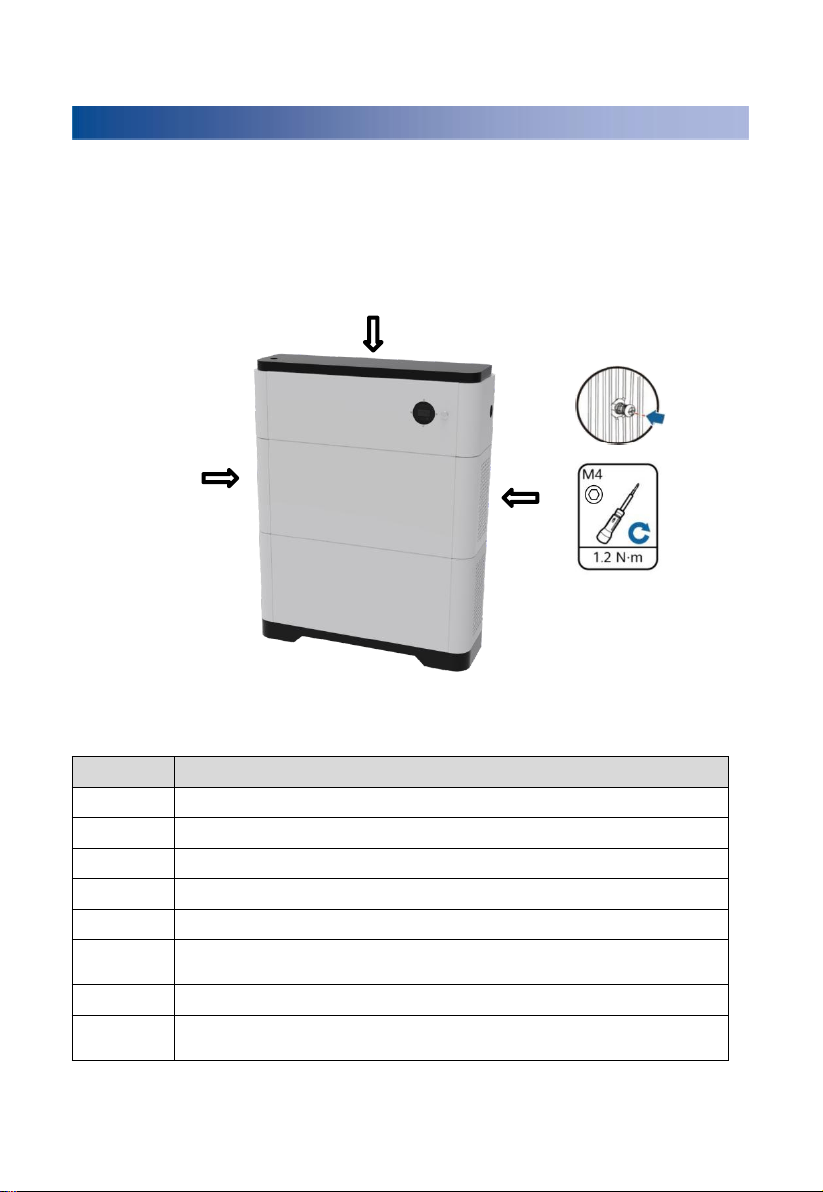

2.2 Installation and fixation

1. Place the base in a horizontal position, then put the battery unit on the base.

(Note: pay attention to the red circle mark in the figure, the battery unit and the

base should be completely consistent to prevent dislocation).

2. Using a fixing piece to fix the battery unit with the base.

(Note: when fixing, the torque shall not exceed 1.2N. M to prevent equipment

damage.)

3. Place the remaining battery units and power control units respectively.

(Note: when fixing the component unit, the torque shall not exceed 1.2N. M

to prevent equipment damage. When fixing the wall, the torque shall not

exceed 1.2N. M; The power control unit is placed on the battery unit. The

legend is jk20450 product. There are two battery units, each 5kwh, the

battery unit parameters are the same, and the installation sequence is not

divided).

M6

5

3

Inte

rna

l

Electric

al

C

o

nn

ect

io

ns

o

f

the

Bat

t

e

ry

Note:

A. The internal connecting wires are packed in the box;

B. Before connecting cables, ensure that the switches of the devices are

turned off. Otherwise, high voltage electric shock and equipment

damage may be caused.

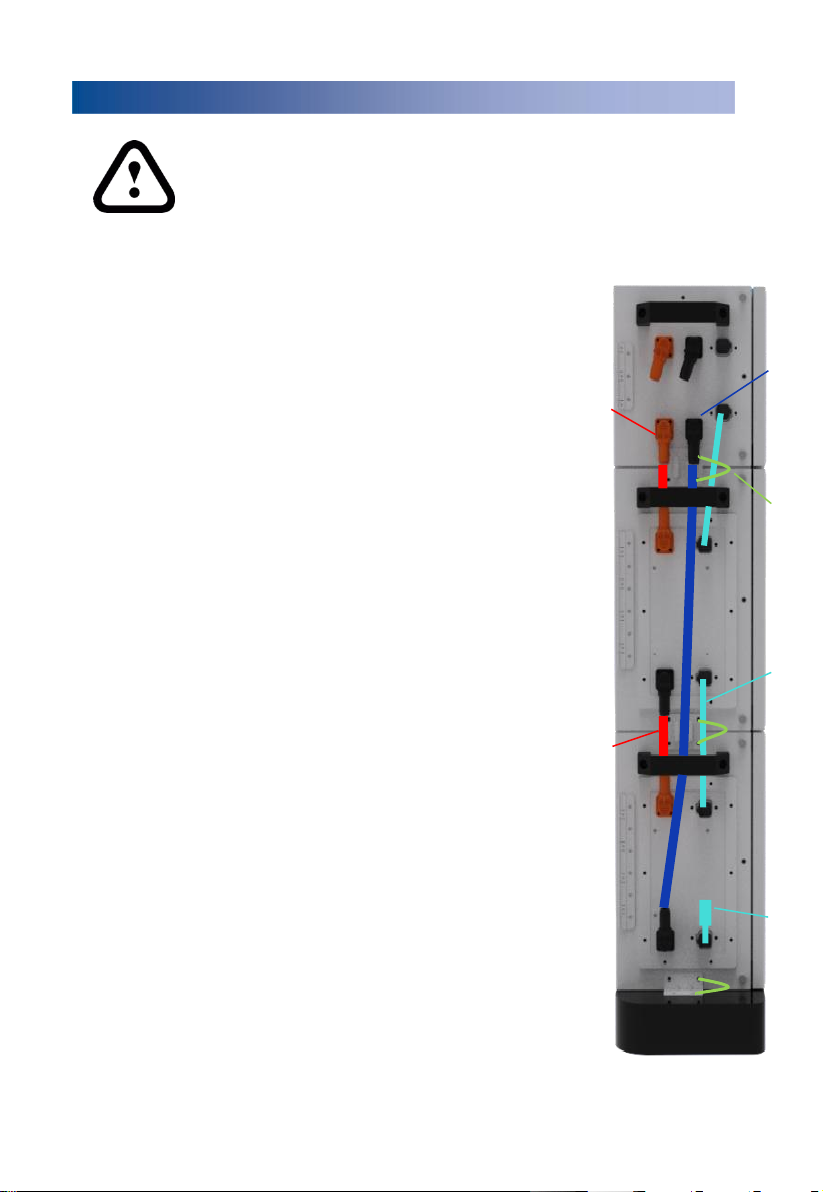

3.1 Connection of Battery Cable

The battery expansion modules in the ESS battery cabinet are

connected in series.

The top battery expansion module "+" is connected by

the power control module "battery cascading terminal

+", the top battery expansion module "-" is connected

to the next battery expansion module "+", and so on.

The lowest battery expansion module "-" is connected by the

"battery cascading terminal" of the power control module- .

3.2 Connection of Communication Cables

The ESS Battery Cabinet uses Daisy chain for internal

communication.

As shown in the figure, the battery expansion modules are

connected one by one.

The battery expansion module at the top is connected with the

power control module internal communication interface

the bottom battery expansion module’s internal COM port is

connected to a terminal resistance.

3.3 Connection of Internal Ground Cable

For the internal ground cable of the ESS Battery Cabinet,

connecting each component unit one by one as shown in right

picture.

-

+

-

+

Battery Cascading

Terminal -

Ground

Cable

Internal

Communication

Cable

Battery

cable

Battery Cascading

Terminal +

Terminal

Resistance

4

Ex

tern

al

Electric

al

C

o

nn

ect

io

ns

o

f

the

Bat

t

e

ry

Note:

A. The internal connecting wires are packed in the box;

B. Before connecting cables, ensure that the switches of the devices

are turned off. Otherwise, high voltage electric shock and equipment

damage may be caused.

4.1 cable specification

No.

Cable

Type

ConductorCross-

Sectional Area Range

1

Ground cable

Single-core outdoor

copper-core cable

4-6 mm2

2

DC input power cable

(inverter to battery

and battery to

Common outdoorPV

cable in the industry

10 mm2

3

Signal cable (inverter

to battery and

battery to battery)

Outdoor shielded

twisted pair cable (8

cores)

0.20–0.35 mm2

4.2 External Cable Connection

As shown in the following figure, external cables are routed through

cable holes on the side panel and connected to ports on the PDU side.

Inverter cascading terminal+

Inverter communication cable

Ground cable

Inverter cascading terminal-

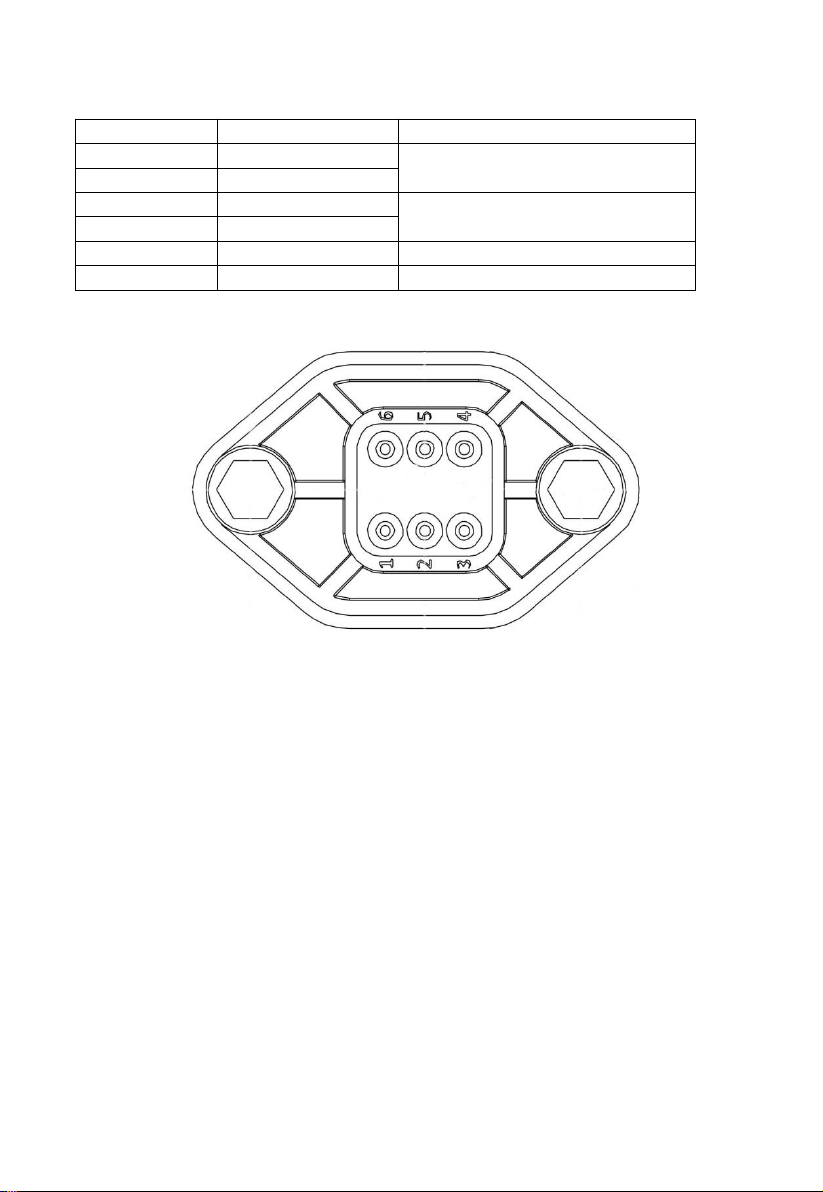

4.3 COM Port Pin Definitions

PIN

Definition

note

1

External CANH

Communicate with inverter CAN

2

External CANL

3

RS485-A

Communicate with inverter 485

4

RS485-B

5

NC

6

NC

5

Ve

rifying

the

Insta

lla

tion

5.1 Installing Cover

After electrical connections are complete, check that cables are

correctly and securely connected, install the external protective cover, and

secure it using screws.

No.

AcceptanceCriterion

1

The battery is installed correctly and securely.

2

The cables are routed properly as required by the customer.

3

Cable ties are secured evenly and no burr exists.

4

The ground cable is connected correctly and securely.

5

The battery switch and all switches connected to the battery are OFF.

6

The DC input power cables and signal cables are connected correctly and

securely.

7

Idle terminals and ports are locked by watertight caps.

8

The installation space is proper, and the installation environment is clean

and tidy.

6 Power-On Commissioning

1. Confirm the connection between ESS battery cabinet and inverter before power on

for the first time starting. Turn the isolation switch of ESS battery cabinet and

inverter switch to "on"

(refer to inverter manual for specific inverter operation).

2. Press the start button. The equipment will be self-checked and started. If there is

no fault, the equipment can be used normally.

3. If the device is not used for a short time, press the start button and the device will

go to sleep mode. If the equipment is not used for a long time (two weeks), in

addition to the above steps, turn the equipment disconnector to "off".

OFF

ON

ALM

RUN

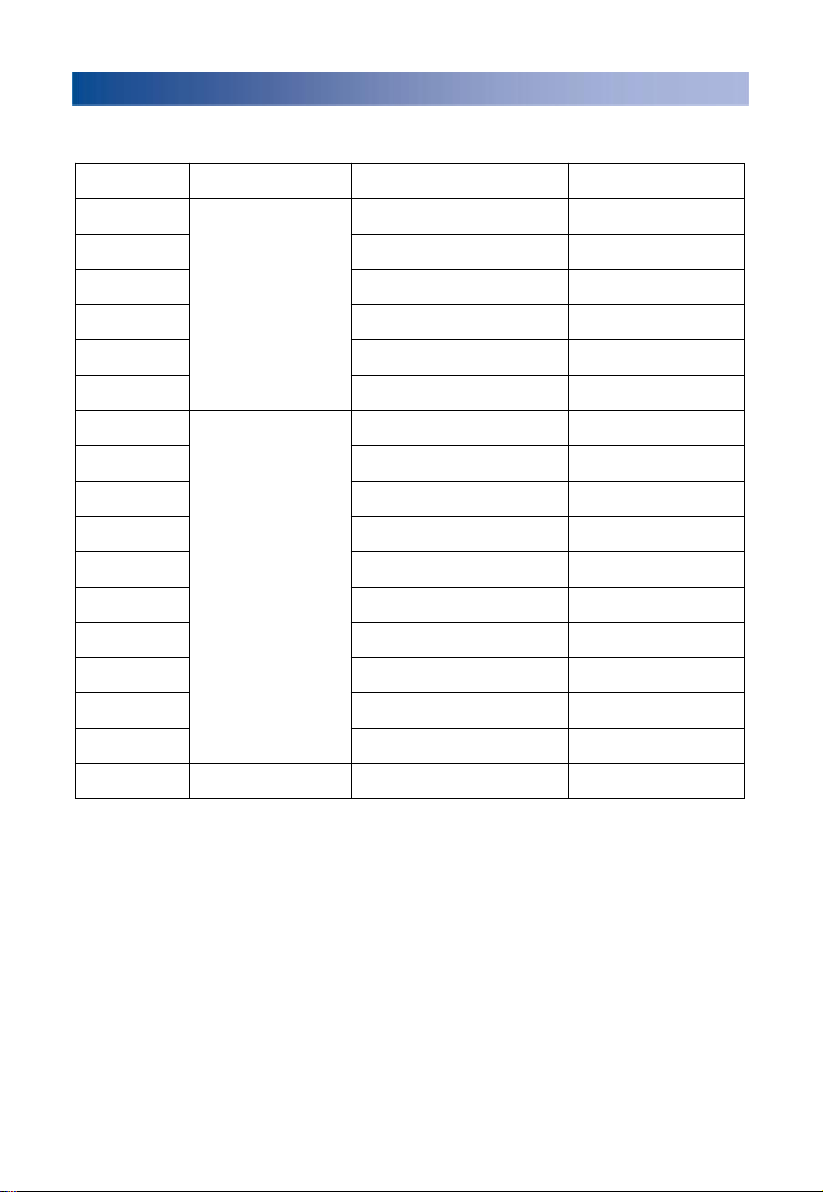

See the table below for status indication

System

state

Abnormal

event

RUN

ALM

SOC

Note

Off

/

Lights out

Lights out

Lights out

Standby

Normal

Light on

Lights out

Light on / display

percentage

according to

electric quantity

Alarm

Light on

Twinkle

Discharge

protection

Lights out

Light on

Lights out

Floating

charge

Normal

Light on

Lights out

Light on / display

percentage

according to

electric quantity

Alarm

Light on

Twinkle

Charging

protection

Twinkle

Light on

Charge

Normal

Twinkle

Lights out

Light on / display

percentage

according to

electric quantity

Alarm

Twinkle

Twinkle

Discharge

Normal

Light on

Lights out

Light on / display

percentage

according to

electric quantity

Alarm

Light on

Twinkle

RUN

7 Tool & safety gears required

1. Tools

The following tools are required to install the battery pack:

Precision screwdriver Drill Pencil or Marker

2. Safety gears for personal protection

It is recommended to wear the following safety gears when handling the

battery pack.

Insulated gloves Safety goggles Safety shoes

8 Inverter

Matched inverter brand and model

No.

Brand

Type

Note

1

GOODWE

GW3600-EH

2

GW5000-EH

3

GW6000-EH

4

GW5K-ET

5

GW8K-ET

6

GW10K-ET

7

SUNWAYS

STH-3KTL-HSS

8

STH-3.6KTL-HSS

9

STH-3KTL-HS

10

STH-3.6KTL-HS

11

STH-4.2KTL-HS

12

STH-4.6KTL-HS

13

STH-5KTL-HS

14

STH-6KTL-HS

15

STH-7KTL-HS

16

STH-8KTL-HS

17

KOYOE

KY-1Hybrid-5K0-H

9 Packing list

1.The outer packing box size of power control module is 820 * 400 * 495mm.

The details of accessories contained in the packing box are shown in the table below:

※ the number of power lines configured for Mint-JKE5, Mint-JKE10, Mint-

JKE15, and Mint-JKE20 is 0, 1, 2 and 3 respectively.

No.

Material name

Quantity

Note

1

Power control unit

1

2

Protective cover

1

left

3

Protective cover

1

right

4

cover

1

5

base

1

6

Power line

1

PDU“+”~PACK“+”

7

Power line

1

PDU“-”~PACK“-”

8

Power line

1/2/3

※ PACK “+”~PACK“-”

9

Power line

1

Connect inverter "+"

10

Power line

1

Connect inverter "-"

11

Communication line

1

Internal communication

12

Communication line

1

Inverter communication

13

RJ45 wiring converter

1

14

Screw M8*40L

4

15

Screw M4*12L

14

16

Screw M6*12L

4

17

Screw M5*10L

6

18

Base connecting piece

2

19

Wall connecting piece

2

20

Ground wire

1

21

Tie

5

22

user 's manua

1

23

Shipment report

1

24

certificate

1

25

Quality assurance card

1

2. The outer packing box size of battery expansion module is 760 * 425 * 420mm.

The details of accessories contained in the packing box are shown in the table below:

No.

Material name

Quantity

Note

1

Battery pack

1

2

Protective cover

1

left

3

Protective cover

1

right

4

Wire

1

COM port to COM port

5

Connecting piece

between boxes

2

6

Wall connecting piece

2

7

Screw M8*40L

4

8

Screw M4*12L

10

9

Screw M6*12L

4

10

Screw M5*10L

6

11

Ground wire

1

12

Tie

5

13

user 's manual

1

user 's manual

14

Shipment report

1

Shipment report

15

certificate

1

certificate

16

Quality assurance card

1

Quality assurance card

TRONIC ESS CO., LTD

Add: Room 401-1, Gaorong Building, High-speed Railway New Town,

Xiangcheng District, Suzhou City, Jiangsu Province, China

Web: http://www.tronic-te.com

Tel:+86-512-66101116

E-mail:jswzs@tronic-te.com

This manual suits for next models

3

Table of contents