MAINTENANCE

General Care

Keep ball free of dust and grit. Do not attempt to disassemble the

BPC-16.

Clamp Maintenance

Our clamp delivers a lifetime of wear. However, from time to time,

we recommend placing a drop of lubricant on the shaft to prevent

binding. If you find that your clamp is not closing as smoothly as it

used to, unscrew the knob to fully open the clamp and turn it upside

down. Blow out any dirt or grit, and place a drop of lubricant on the

threads.

GUARANTEE

ALL REALLY RIGHT STUFF BRAND PRODUCTS ARE GUARANTEED

TO THE ORIGINAL PURCHASER TO BE FREE OF DEFECTS IN

MATERIALS OR WORKMANSHIP FOR FIVE (5) YEARS FROM THE

DATE OF PURCHASE. PRODUCTS WILL BE REPAIRED OR REPLACED

AT OUR OPTION.

® , ™, © 1990-2018 Really Right Stu, LLC. All rights reserved. Comes with ¼”-20 stud, ” hex key, T8 Torx

BPC-16

PANNING MICRO BALL

PATENT PENDING

1146 Farmhouse Lane, San Luis Obispo, CA 93401 USA

1-805-528-6321 | 1-888-777-5557

www.ReallyRightStu.com

MAINTENANCE

General Care

Keep ball free of dust and grit. Do not attempt to disassemble the

BPC-16.

Clamp Maintenance

Our clamp delivers a lifetime of wear. However, from time to time,

we recommend placing a drop of lubricant on the shaft to prevent

binding. If you find that your clamp is not closing as smoothly as it

used to, unscrew the knob to fully open the clamp and turn it upside

down. Blow out any dirt or grit, and place a drop of lubricant on the

threads.

GUARANTEE

ALL REALLY RIGHT STUFF BRAND PRODUCTS ARE GUARANTEED

TO THE ORIGINAL PURCHASER TO BE FREE OF DEFECTS IN

MATERIALS OR WORKMANSHIP FOR FIVE (5) YEARS FROM THE

DATE OF PURCHASE. PRODUCTS WILL BE REPAIRED OR REPLACED

AT OUR OPTION.

® , ™, © 1990-2018 Really Right Stu, LLC. All rights reserved. Comes with ¼”-20 stud, ” hex key, T8 Torx

BPC-16

PANNING MICRO BALL

PATENT PENDING

1146 Farmhouse Lane, San Luis Obispo, CA 93401 USA

1-805-528-6321 | 1-888-777-5557

www.ReallyRightStu.com

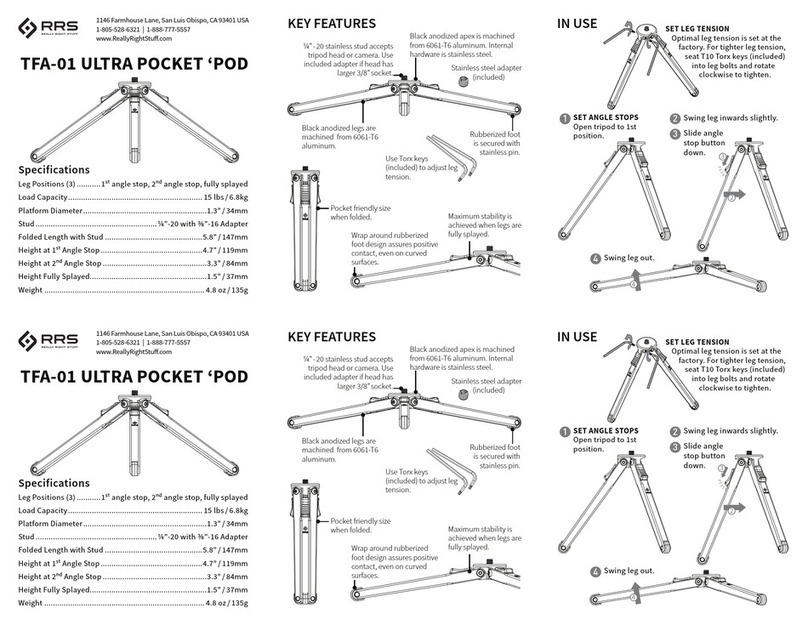

SPECIFICATIONS:

Weight: ............................................................................4.4 ounces (125g)

Height:........................................................2” overall, 1.85” added height

Load Capacity:................................................................. 5 pounds (2.3kg)

Tripod Mount:............................................................female ¼”-20 socket

Ball Articulation: ................................................................ ±45°, 90° notch

Panning Base:................................................ 5° increments, zero to 360°

Optional Mount Stud:...........................................................1/4”-20 x 1/2”

Ball Diameter:.................................................................................... 16mm

Stem Base Diameter: ........................................................................ 0.725”

Tension Adjustment:.................................................. via ball clamp lever

Locking Mechanism:..................................nested jaw & pan lock knobs

PATENT PENDING

SPECIFICATIONS:

Weight: ............................................................................4.4 ounces (125g)

Height:........................................................2” overall, 1.85” added height

Load Capacity:................................................................. 5 pounds (2.3kg)

Tripod Mount:............................................................female ¼”-20 socket

Ball Articulation: ................................................................ ±45°, 90° notch

Panning Base:................................................ 5° increments, zero to 360°

Optional Mount Stud:...........................................................1/4”-20 x 1/2”

Ball Diameter:.................................................................................... 16mm

Stem Base Diameter: ........................................................................ 0.725”

Tension Adjustment:.................................................. via ball clamp lever

Locking Mechanism:..................................nested jaw & pan lock knobs

PATENT PENDING