A-1Operating manual – Dehumidifier TTR 55 S

B - 1

Table of contens

Unit description............................... B - 1

Installation...................................... B - 1

Safety information........................... B - 2

Commissioning ............................... B - 2

Decommissioning ........................... B - 4

Unit transport.................................. B - 4

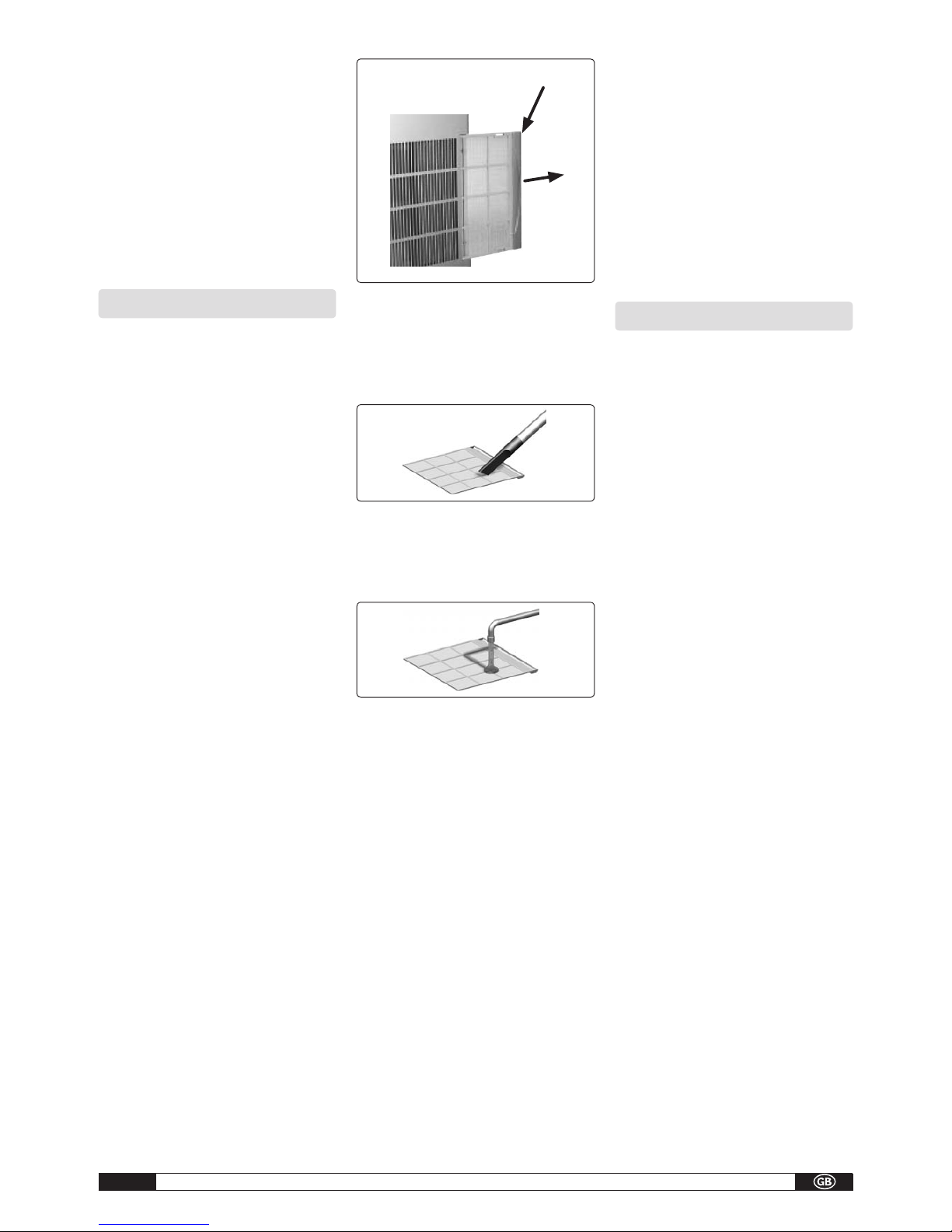

Careandmaintenance.................... B - 5

Troubleshooting .............................. B - 5

Intended use................................... B - 6

Customerserviceandwarrantly...... B - 6

Protection and recycling.................. B - 6

Maintanancereport......................... B - 6

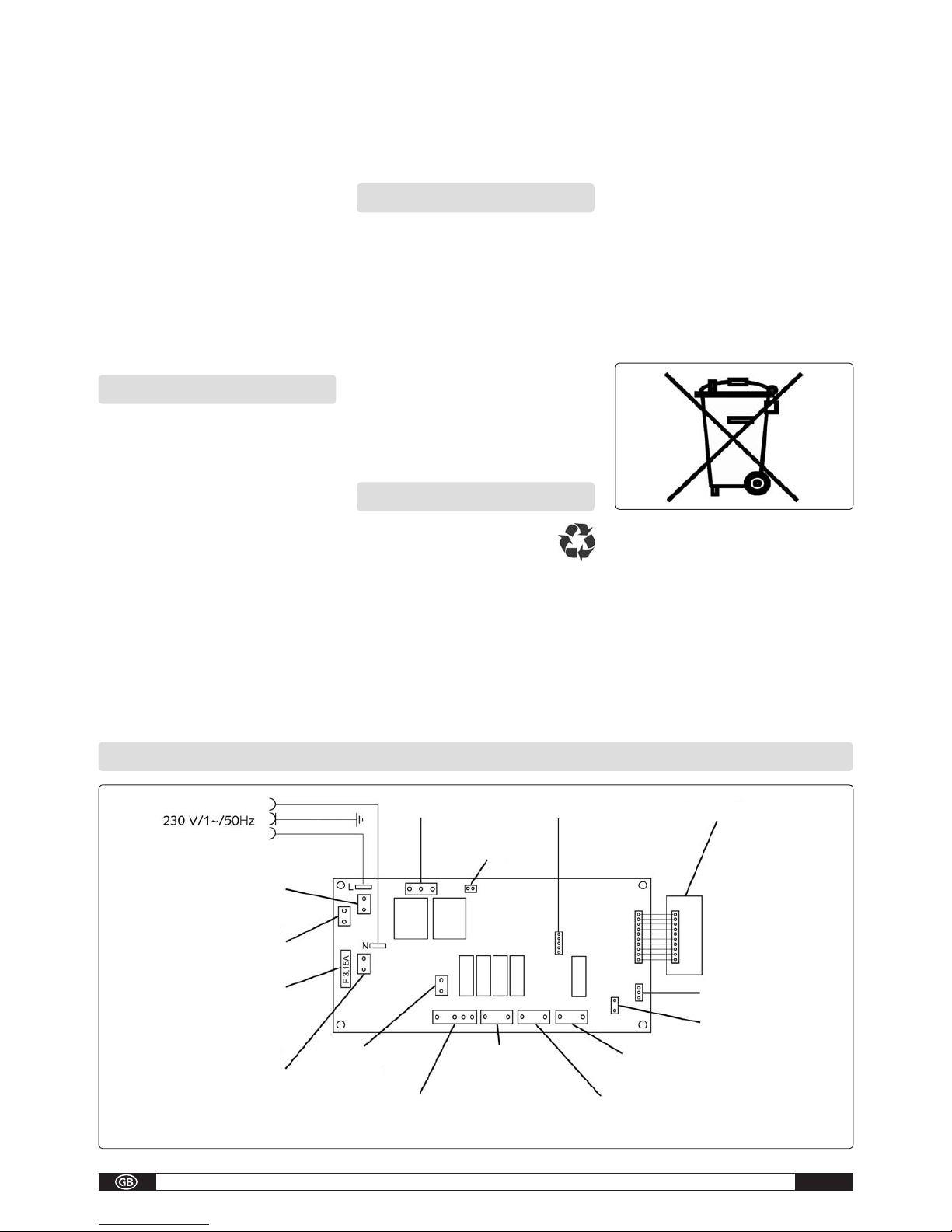

Electrical wiring diagramm.............. B - 7

Capacitygraph................................ B - 7

Technical data................................. B - 8

These operating instructions must be read ca-

refully before commissioning/using the unit!

These instructions are part of the unit and

musst always be kept near to the site of in-

stallation or unit.

The units are designed for universal and pro-

blem-free dehumidification.

Owing to their compact size, they are easy to

transport and install.

The units operate according to the adsorption

principle and are provided with ioniser, low noise

and maintenance recirculation fans as well as

power cord with plug.

The fully automatic control, the condensate con-

tainer with integrated overflow protection and the

drain connection for direct condensate discharge

ensure troublefree operation.

The units comply with the fundamental safety

and health requirements of the pertinent EU di-

rectives.

The units are reliable and easy to operate.

The units are used wherever dehumidification is

necessary and consequential damage (e.g. due

to mould formation) is to be avoided.

Unit description

The units are also suitable for drying and de-

humidification of:

• Living rooms, bedrooms, shower or cellar

rooms, lofts.

• Utilityrooms,weekendhomes,caravans.

• Museums,archives,laboratories.

• Wellness areas, washrooms and changing

rooms, etc..

• Garages, store rooms.

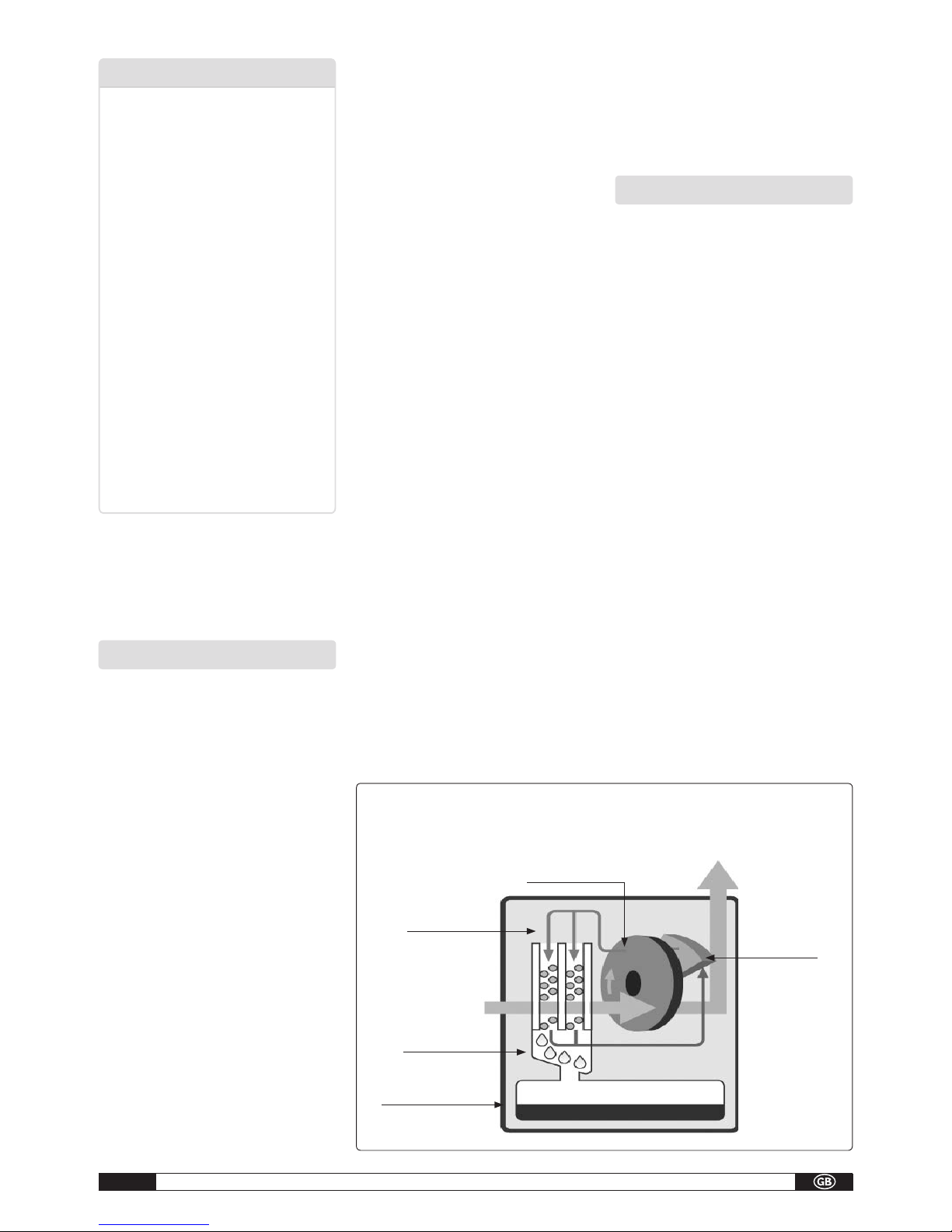

saturated air

condenser

humid room

air

regenerative

heatig element

adsorption rotor

dehumidified

room air

The air flow is cooled on its way through or via the condenser to below the dew point. The water

vapour condenses and is collectes in a condensate trap and discharged.

Operation

The units can be switched on and off with the ON/

OFF button. The LED of the last selected mode

lights up in the control panel. The recirculation

fan draws in the humid room air via the inlet gril-

le with filter, condenser and following adsorption

rotor.

In the internal regeneration circuit, the air flows

across a heating element, dries the adsorption-

rotor and passes the humid air through the con-

denser.

On the colder condenser, heat is removed from

the room air and cooled to below dew-point. The

water vapour contained in the room air deposits

as condensate.

Depending on the room air temperature and re-

lative humidity, the condensed water constantly

drips through the integrated drain connection into

the condensate container located below.

The conditioned drier air continuously mixes with

the room air. Due to the constant circulation of

the room air through the unit, the relative humidi-

ty in the room is gradually reduced to the requi-

red humidity (45% relative humidity).

A float switch in the condensate container inter-

rupts dehumidification via a microswitch when

the container is full. The units switch off with an

audible signal (5x) and the „FULL TANK“ indicator

light illuminates on the control panel. This does

not extinguish until the emptied condensate is re-

fitted. The units return to the previously selected

mode.

In an unsupervised continuous mode with exter-

nal conensate connection, the produced conden-

sate is continuously drained via a hose connec-

tion on the condensate container.

Installation

For optimal and reliable unit operation, the follo-

wing information must be observed in any event:

• Theunitsmustbeinstalledstableandupright

to ensure unhindered condensate drainage.

• The units should be placed in the centre of the

room if possible to ensure optimal air circula-

tion.

• Itmustbeensuredthattheroomaircanbe

sucked in and blown out freely.

• Aminimumdistanceof40cmtowallsand60

cm free space above the unit must be maintai-

ned in any event.

• Theunitsmustnotbeinstalledintheimmedi-

ate vicinity of radiators or other heat sources.

• Optimalroomaircirculationisachievedwhen

the units are installed about 1m above the

ground.

• Theroomtobe driedorratherdehumidied

must always be closed from the ambient at-

mosphere.

• Open windows, doors, etc., as well as fre-

quently entering and leaving the room should

be avoided as far as possible.

• Theunitsmustnotbeusedindusty,chlorine

or ammoniacontaining atmospheres.

condensate container

B - 1