Pre-Installation Instructions

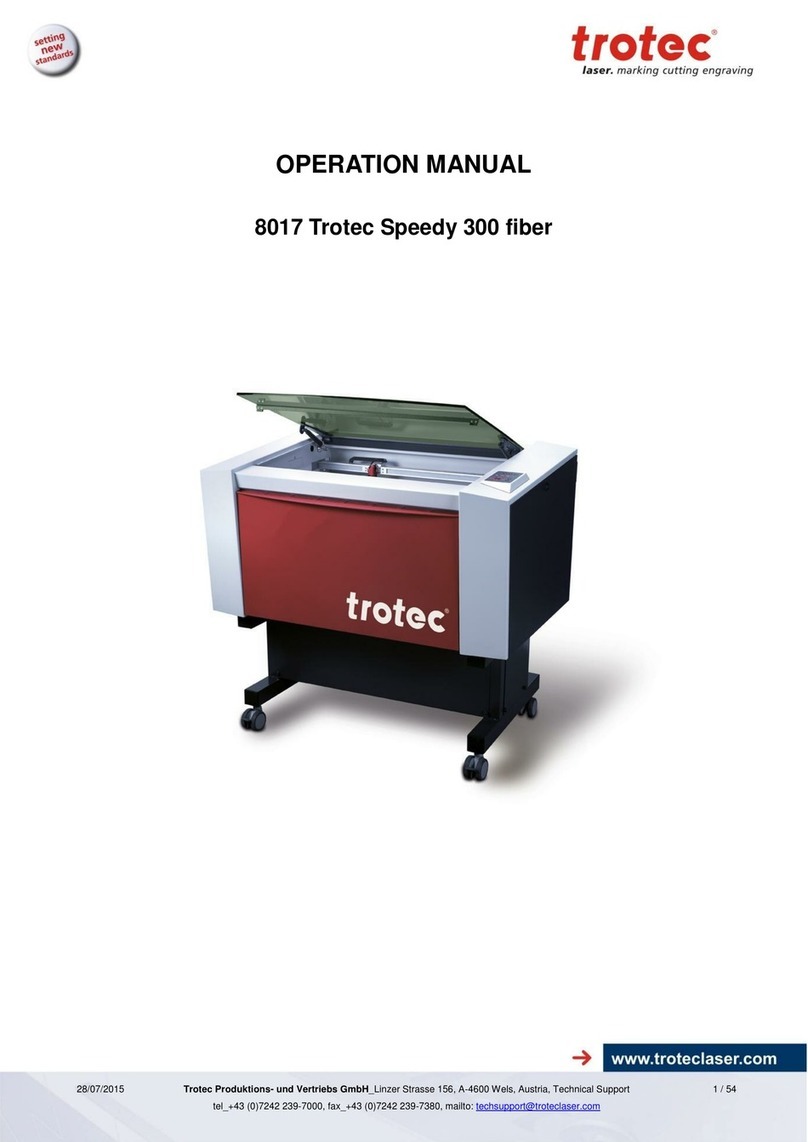

8014 Trotec Speedy 500

Laser Machine Requirements

13/12/2011 Trotec Produktions- und Vertriebs GmbH_Linzer Strasse 156, A-4600 Wels, Austria, Technical Support 6 / 15

tel_+43 (0)7242 239-7000, fax_+43 (0)7242 239-7380, mailto: techsupport@troteclaser.com

1.5 Operating Environment and Safety

Laser safety class Class 2

Class 4 with pass through option

Wavelength of the laser radiation 10.6 µm

Ambient room temperature

Humidity

MUST be between 15 and 25°C (59 and 77°F);

40% - 70%, not condensing

Follow the local laws and regulations regarding operation of laser machines.

It is important that the machine is installed in an appropriate operating environment. This will reduce

the risk of possible downtime plus increase performance and quality of output.

Operating outside of this temperature range can have a detrimental effect to the working life and/or

performance of the system, particularly the laser tube. If transporting the laser system from a very

cold or very hot environment to the proper operating environment, the laser system must not be

turned on before it has adjusted to the temperature conditions. Therefore, once the system has

been moved to the desired area it must be allowed to stand for 24 hours before use. Rapid

changes of temperature during operation can risk condensation forming within the laser tube and/or

electronics and increases the potential risk of electronic failure.

These guidelines must be followed to ensure a proper operating environment for the laser system.

Although conforming to these guidelines will greatly reduce the chance of a problem occurring, it

does not guarantee it. It is your responsibility to provide a proper operating environment.

•Dusty or dirty air environments can damage the laser system. Keep the laser system isolated

from any type of sandblasting, sanding equipment, or any other machinery or processes that

produce airborne particles.

•Avoid small, enclosed, non-ventilated areas. Some materials, after laser engraving or cutting,

continue emitting fumes for several minutes after processing. Having these materials present in

a confined, unventilated room can contaminate the room.

We recommend installing the laser system on a concrete floor. The floor underneath the laser

system should be flat within 3mm from wheel to wheel. An uneven surface may cause a twisting of

the main enclosure. This can cause motion system binding as well as engraving problems.