26SCD_IOM_1.4_Mar22_6

6

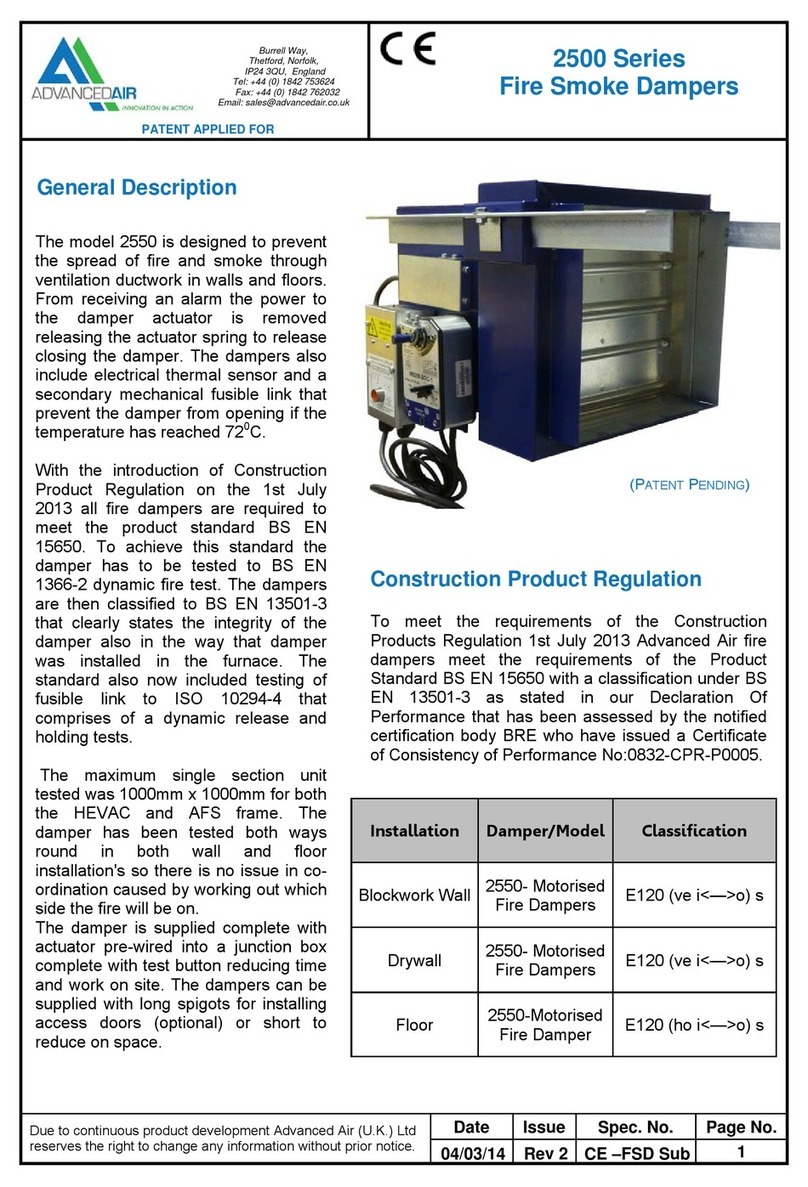

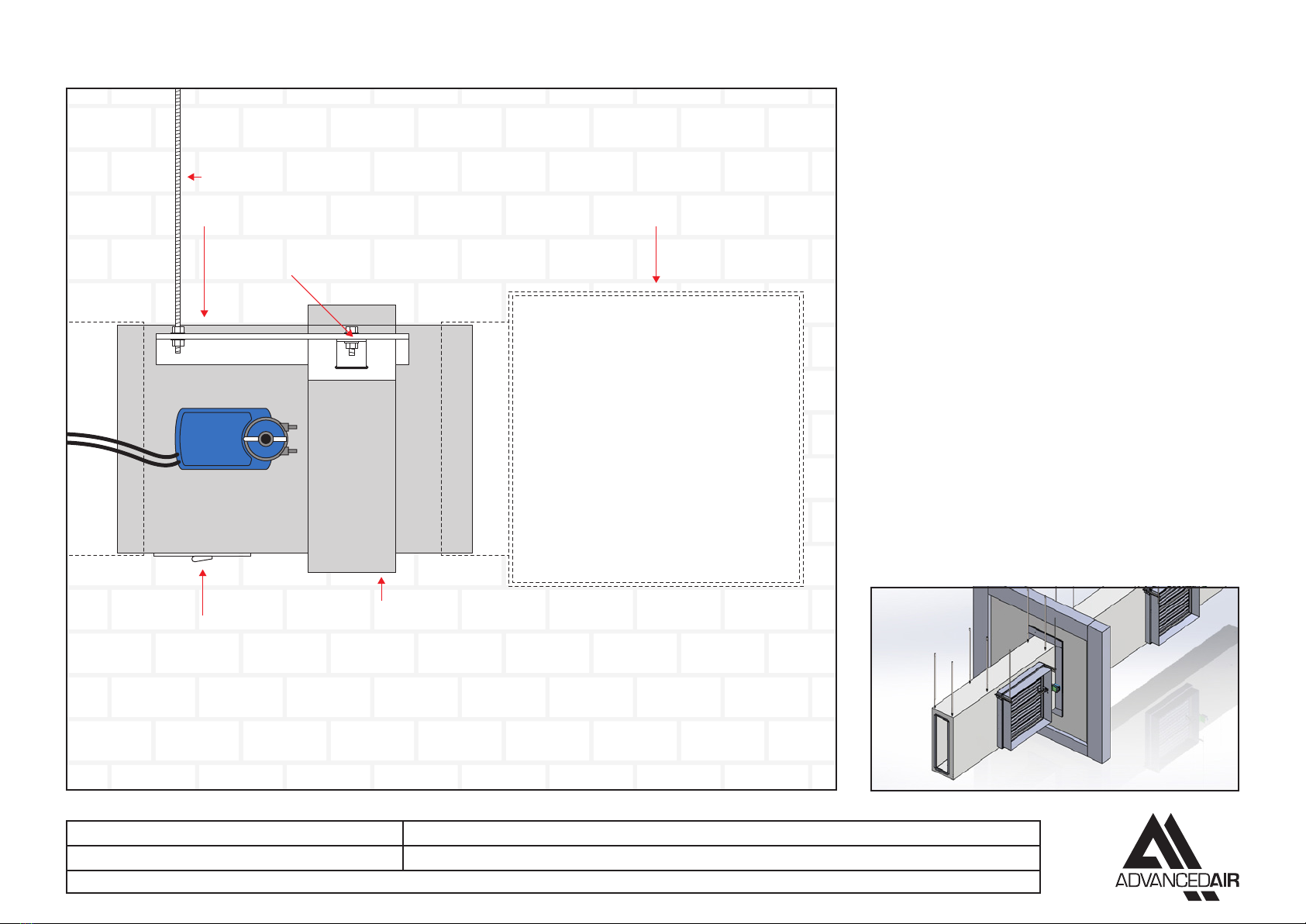

PRODUCT 26SCD W/AFS APPLICATION DUCT MOUNTED, IN-LINE, TWO HOUR REMOTE FROM WALL

CLASSIFICATION REPORT NO. EFR-20-002148 REV1 RC CLASSIFICATION E120 (Vew i o) S500 C 10000 AA multi • E120 (Vew i o) S500 C mod AA multi

TESTED INSTALLATION METHOD SHOWN. DIFFERING INSTALLATION METHODS TO THIS MUST BE APPROVED BY THE BUILDING CONTROL AUTHORITY (BCA) BEFORE PROCEEDING.

SMOKE CONTROL 26SCD TWO HOUR REMOTE FROM WALL INLINE

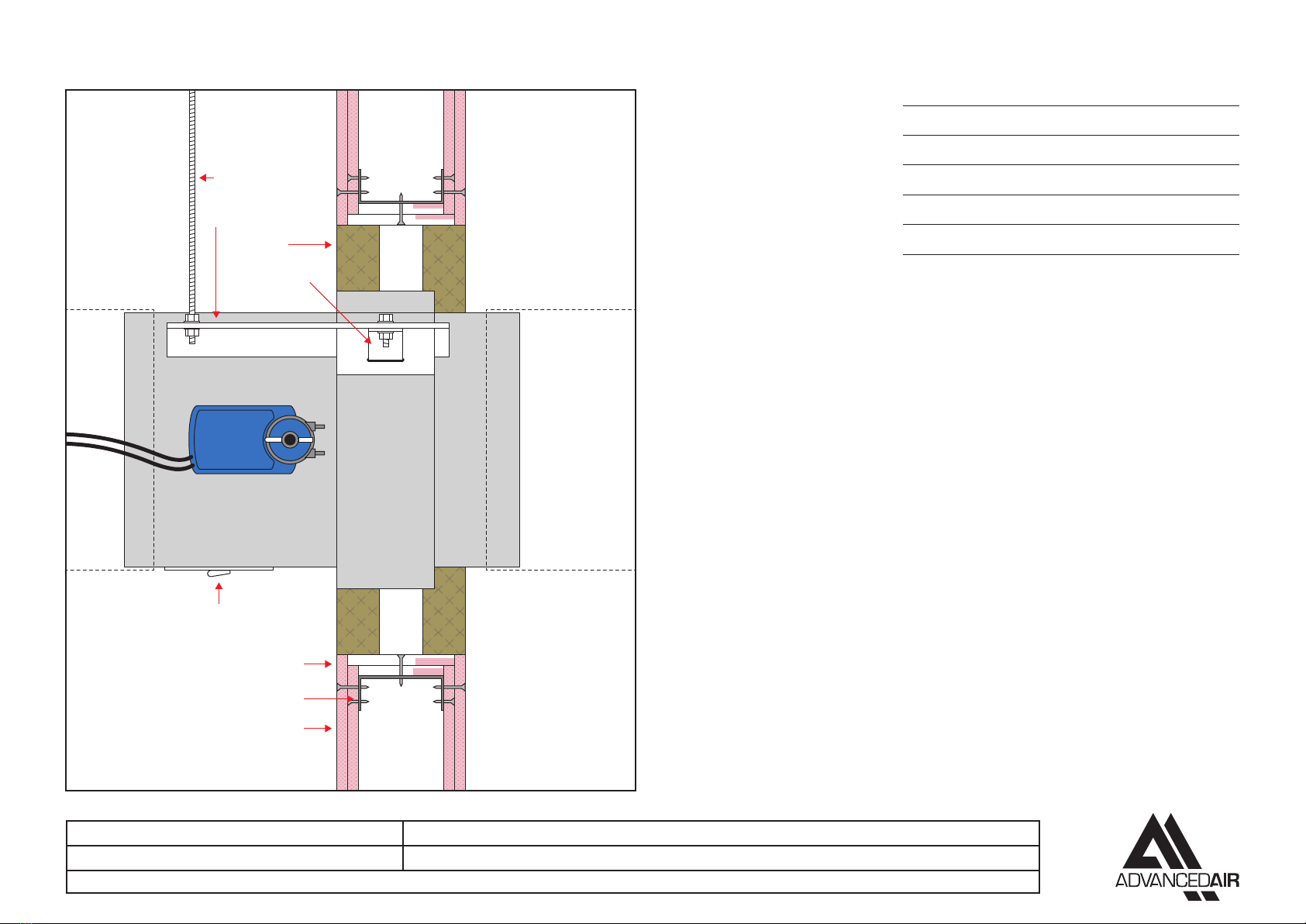

Preparation

1 Work out the opening size to be cut 120mm larger than the

nominal duct width/height, at a tolerance of ±5mm (for example

a 1,000 x 1,000mm duct requires a 1,120 x 1,120mm opening).

Installation sequence

2 Drill and rivet at 150mm centres, the 50x50x5mm stiening flange

to the galvanised mild steel galvanised mild steel ductwork.

3 Pass the duct through the opening, so that the flange is

centralised in the wall.

4 Drop rod anchor points, and M10 drop rods to support the

galvanised mild steel galvanised mild steel ductwork, should be

positioned within 350mm of the wall, on both sides.

5 Install Unistrut to the drop rods with M10 fixings, and adjust to

that they fully support the weight of the galvanised mild steel

galvanised mild steel ductwork, using a spreader plate. The

position of the duct should be adjusted so that the stiening

flange is centralised in every axis.

6 Fill the wall opening around the duct with 85-115kg/m2mineral

wool insulation, on both sides of the wall.

7 Fit two layers of 200mm wide, 12.5mm thick plasterboard around

the damper, overlapping the joints, to form a pattress around

the galvanised mild steel galvanised mild steel ductwork on

both sides of the wall. The pattress must be axed with drywall

screws which bite into the steel stud channel at 150mm centres,

and sealed with a bead of intumescent acrylic sealant to BS EN

13501-2, which shall be applied to back of each pattress section

before it is fitted.

8 The damper is mounted to the duct using self tapping fixings, at

150mm centres. When the duct is slid over the damper spigot,

an overlap of up to 40mm is permitted, allowing for 10mm for

duct expansion.

9 Support the damper case using a single piece of Unistrut, hung

on M10 drop rods.

10 Galvanised mild steel ductwork and sealing of the duct should

be in accordance with DW144.

11 The damper operation should be checked to ensure that it fully

opens and closes.

12 When the damper installation has been completed, checks

should be made to ensure the installation is secure, and there is

no movement.

13 Complete DW145 Fire Damper Checklist.

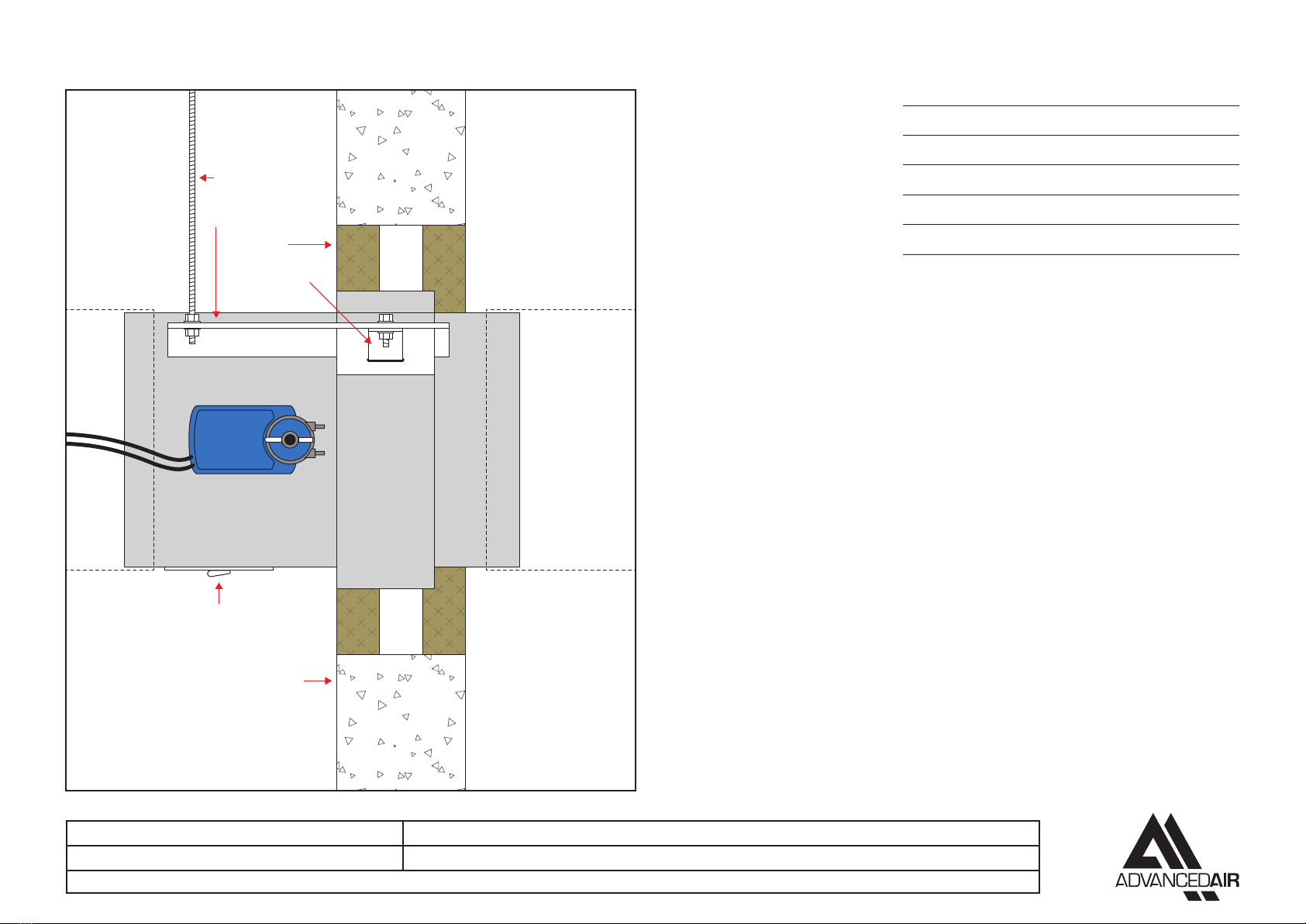

Fire-rated ductwork tested to BS EN 1366-8

Insulation on damper is optional.

Leave actuator uncovered for maintenance.

M10 drop rods

AFS bracket, bracket slot and Z-piece

Ductwork insulation tested to BS EN 1366-8

This is an example illustration –

installations through the wall may

vary and should be carried out in

accordance with BS EN 1366-8.

Wall construction must be in

accordance with the ductwork

manufacturer’s specifications

Mineral wool insulation 85-115 kg/m

15mm thick gypsum boards

2x 12.5mm thick gypsum boards, forming pattress

Access door

50x50x5mm

stiening angle

Group A 122mm (or thicker) two hour rated flexible

supporting construction to BS EN 1363-1:2020

Steel stud