WINE AND BEVERAGE CABINET USE AND CARE MANUAL

4

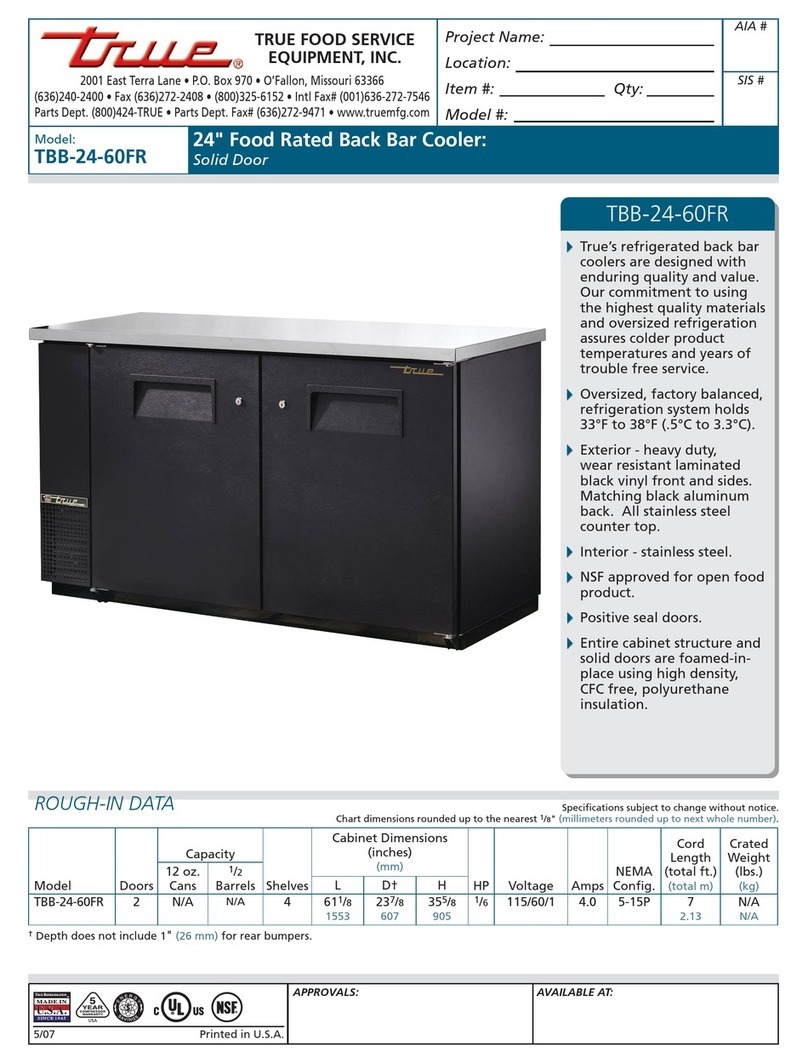

LEVELING REFRIGERATION EQUIPMENT

A. Set unit in its final location. Be sure there is adequate

ventilation in your room.

B. Proper leveling of your True refrigerator is critical to operating

success (for non-mobile models). Effective condensate removal

and door operation will be effected by leveling. Adjust leg

levelers on the front or rear of the cabinet if the unit needs to be

lowered or raised.

C. The refrigerator should be leveled from the interior of the unit

front to back and side to side with a level. (See illustration 1). If

the refrigerator is not level, adjust the stainless steel leg levelers.

The leg levelers can be adjusted by turning to reach the desired

leveling height. (See image 1.)

D. Free plug and cord from back of refrigerator. Do not plug in.

E. The unit should be placed close enough to the electrical

supply so that extension cords are never used.

Warning

Compressor warranties are void if the unit is more than 7 ft.

(2.1m) from plug-in connection or if an extension cord is used.

HOW TO CONNECT TO

ELECTRICITY

Do not, under any circumstances, cut or remove the third

(ground) prong from the power cord. For personal safety, this

appliance must be properly grounded.

Before your new unit is connected to a power supply, check the

incoming voltage with a volt meter. If anything less than 100% of

the rated voltage for operation is noted, correct immediately.

The power cord of this appliance is equipped with a 3-prong

(grounding) plug which mates with a standard 3-prong

(grounding) wall outlet to minimize the possibility of electric shock

hazard from this appliance. A 115V AC, 60 Hz, 15 amp circuit

breaker and electrical supply are required.

Have the wall outlet and circuit checked by a qualified electrician

to make sure the outlet is properly grounded.

If the outlet is a standard 2-prong outlet, it is your personal

responsibility and obligation to have it replaced with the properly

grounded 3 prong wall outlet.

Do not use an extension cord or two prong adaptor. Electrical

ground is required on this appliance.

The refrigerator should always be plugged into its own individual

electrical outlet, which has a voltage rating that matches the

rating plate. This provides the best performance and also

prevents overloading house wiring circuits which could cause a

fire hazard from overheated wires. Never unplug your refrigerator

by pulling on the power cord. Always grip plug firmly and pull

straight out from the outlet.

Repair or replace immediately all power cords that have become

frayed or otherwise damaged. Do not use a cord that shows

cracks or abrasion damage along its length or at either end.

When moving the refrigerator away from the wall, be careful not

to roll over or damage the power cord.

Illustration 1.

Image 1. If the front of the cabinet needs to be lowered or

raised adjust the leg levelers.