STANDARD FEATURES

Model:

TRUE FOOD SERVICE EQUIPMENT

2001 East Terra Lane • P.O. Box 970 • O’Fallon, Missouri 63366 • (636)240-2400 • Fax (636)272-2408 • (800)325-6152 • Intl. Fax# (001)636-272-7546 • www.truemfg.com

WARRANTY

One year warranty on all parts

& labor and an additional 4 year

warranty on compressor.

(U.S.A. only)

METRIC DIMENSIONS ROUNDED UP TO THE

NEAREST WHOLE MILLIMETER

SPECIFICATIONS SUBJECT TO CHANGE

WITHOUT NOTICE

Model Elevation Right Plan 3D

PLAN VIEW

KCL

TDD-2 TFHY03E TFHY03S TFHY03P TFHY033

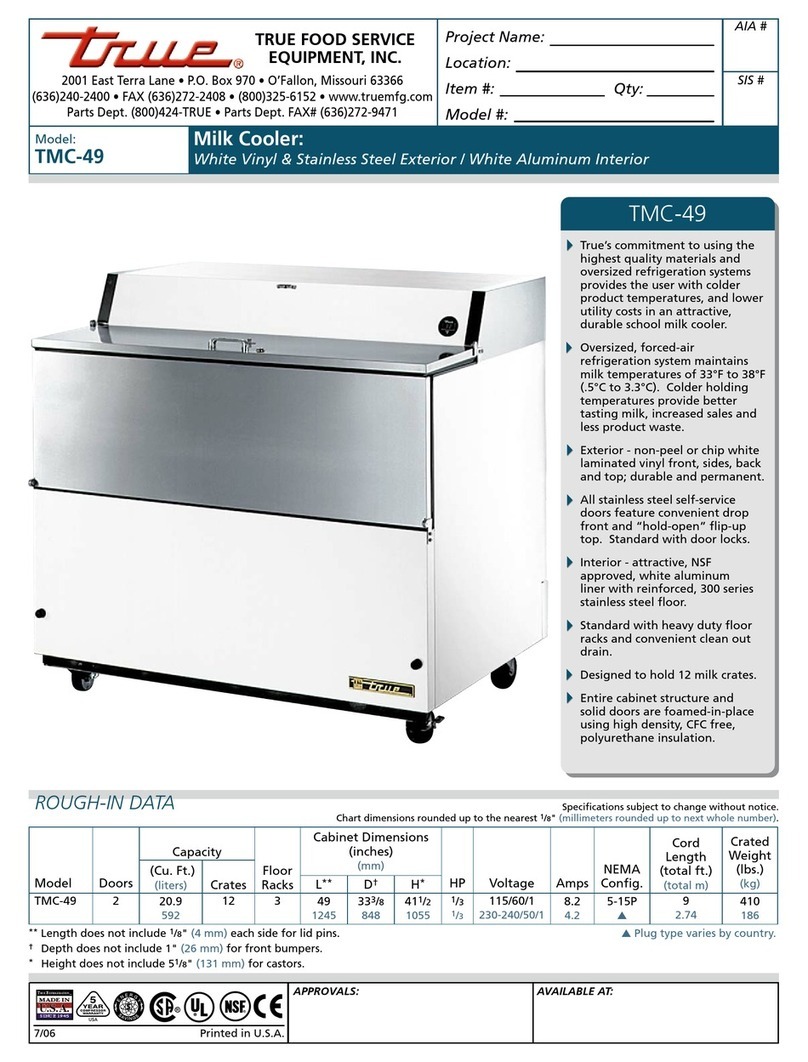

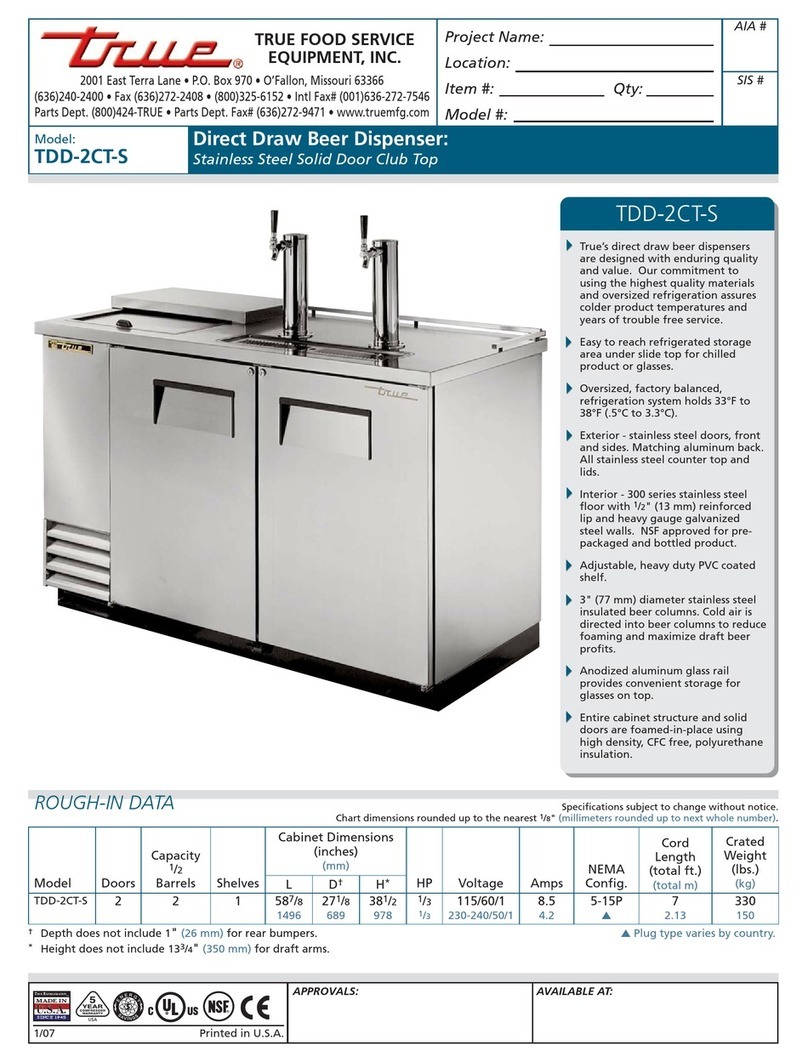

Direct Draw Beer Dispenser:

Solid Door

TDD-2

DESIGN

• True’s direct draw beer dispensers are

designed with enduring quality and

value. Our commitment to using the

highest quality materials and oversized

refrigeration assures colder product

temperatures and years of trouble free

service.

REFRIGERATION SYSTEM

• Factory engineered, self-contained,

capillary tube system using

environmentally friendly (CFC free)

134A refrigerant.

• Extra large evaporator coil balanced

with higher horsepower compressor

and large condenser; maintains cabinet

temperatures of 33°F to 38°F (.5°C to

3.3°C).

• Sealed, cast iron, self-lubricating

evaporator fan motor(s) and larger

fan blades give True merchandisers

a more efficient low velocity, high

volume airflow design. This unique

design ensures faster temperature pull

down of warm product, colder holding

temperatures and faster recovery in

high use situations.

• Condensing unit accessed from behind

front grill of unit for easy cleaning and

maintenance.

CABINET CONSTRUCTION

• Exterior - heavy duty, wear resistant

laminated black vinyl front and sides.

Matching black aluminum back. All

stainless steel counter top.

• Interior - 300 series stainless steel floor

with 1/2" (13 mm) reinforced lip and

heavy gauge galvanized steel walls.

• Insulation - entire cabinet structure and

solid doors are foamed-in-place using

high density, CFC free, polyurethane

insulation.

• Welded, heavy gauge galvanized base

rail dipped in rust inhibiting enamel

paint for corrosion protection inside

and out.

• 3" (77 mm) diameter stainless steel

insulated beer columns. Cold air is

directed into beer columns to reduce

foaming and maximize draft beer

profits.

DOORS

• Wear-resistant laminated black vinyl

exterior with heavy gauge galvanized

steel liner.

• Each door fitted with 12" (305 mm)

long recessed handle that is foamed-

in-place with a sheet metal interlock to

ensure permanent attachment.

• Positive seal doors.

• Magnetic door gaskets of one piece

construction, removable without tools

for ease of cleaning.

• Door locks standard.

LIGHTING

• Incandescent interior lighting.

MODEL FEATURES

• Evaporator is epoxy coated to eliminate

the potential of corrosion.

• Convenient

1/2" (13 mm) barbed T drain

fitting located on front of cooler.

• Designed to accommodate all types of

beer kegs.

• Listed under NSF-7 for the storage

and/or display of packaged or bottled

product.

ELECTRICAL

• Unit completely pre-wired at factory

and ready for final connection to a

115/60/1 phase - 15 amp dedicated

outlet. Cord and plug set included.

OPTIONAL FEATURES/ACCESSORIES

Upcharge and lead times may apply.

❒230 - 240V / 50 Hz.

❒6" (153 mm) standard legs.

❒6" (153 mm) seismic/flanged legs.

❒21/2" (64 mm) diameter castors.

❒4" (102 mm) diameter castors.

❒Double headed draft column.

❒Two-way tapper manifold.

❒Three-way tapper manifold.

❒Draft cap.

❒Remote cabinets (condensing unit

supplied by others; system comes

standard with 404A expansion valve

and requires R404A refrigerant).

Consult factory technical service

department for BTU information.

115/60/1

NEMA-5-15R

ELEVATION PLAN VIEW

57"

(1448 mm)

37"

(940 mm)

3"

(77 mm)

271/16"

(688 mm)

117/32"

(285 mm)

521/4"

(1328 mm)

5813/16"

(1494 mm)

151/4"

(388 mm)

4927/32"

(1267 mm)

2125/32"

(554 mm)

1/2"(13 mm)

Barbed T

Drain Fitting

37/8"

(99 mm)

13"

(331 mm)

2229/32"

(582 mm)

233/16"

(589 mm)

1"

(26 mm)