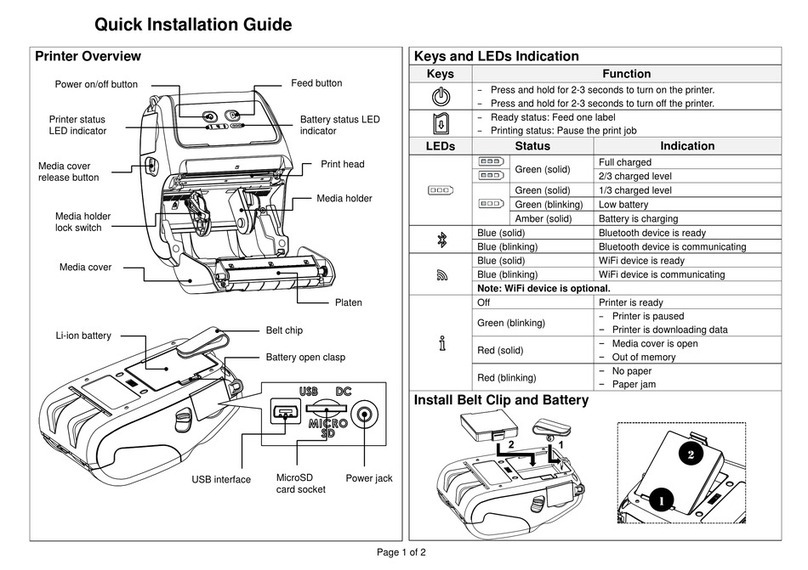

4. LED and Button Functions...............................................................................................................................................................................17

4.1 LED Indication and Key..............................................................................................................................................................................17

4.2 Regular Button Function ............................................................................................................................................................................18

4.3 Power-on Utilities.......................................................................................................................................................................................19

5. TSC Console...................................................................................................................................................................................................20

5.1 Start TSC Console.....................................................................................................................................................................................20

5.2 Setup Ethernet Interface............................................................................................................................................................................22

5.3 Set WiFi and Add to TSC Console Interface ..............................................................................................................................................24

5.4 Initialize the Printer WiFi Setting ................................................................................................................................................................27

5.5 Printer Function .........................................................................................................................................................................................28

5.6 Setting Post-Print Action............................................................................................................................................................................29

6. LCE Menu Function.........................................................................................................................................................................................30

6.3 TSPL..........................................................................................................................................................................................................32

6.4 ZPL2..........................................................................................................................................................................................................34

6.5 Sensor.......................................................................................................................................................................................................37

6.6 Interface.....................................................................................................................................................................................................38

6.6.1 Serial Comm........................................................................................................................................................................................39

6.6.2 Ehernet................................................................................................................................................................................................40

6.7 File Manager..............................................................................................................................................................................................41