2. Transportation

1. Jacks that range under the standard capacity of 49.0kN (5tf) are provided with screw covers made of

hard vinyl chloride pipe. Never suspend or carry a jack by its cover.

2. If the Jack has a hanger, use the hanger to lift it. Before lifting, check the packaging, outline drawing or

catalog to confirm the weight of the jack. After the jack has been installed, avoid using the hanger to lift

it and the equipment that is connected to. This may damage the bolts, causing injury or equipment

damage if the equipment drops or the jack turns over.

3. The packaged product has uneven distribution of weight in the longitudinal direction. Be careful when

you carry the product.

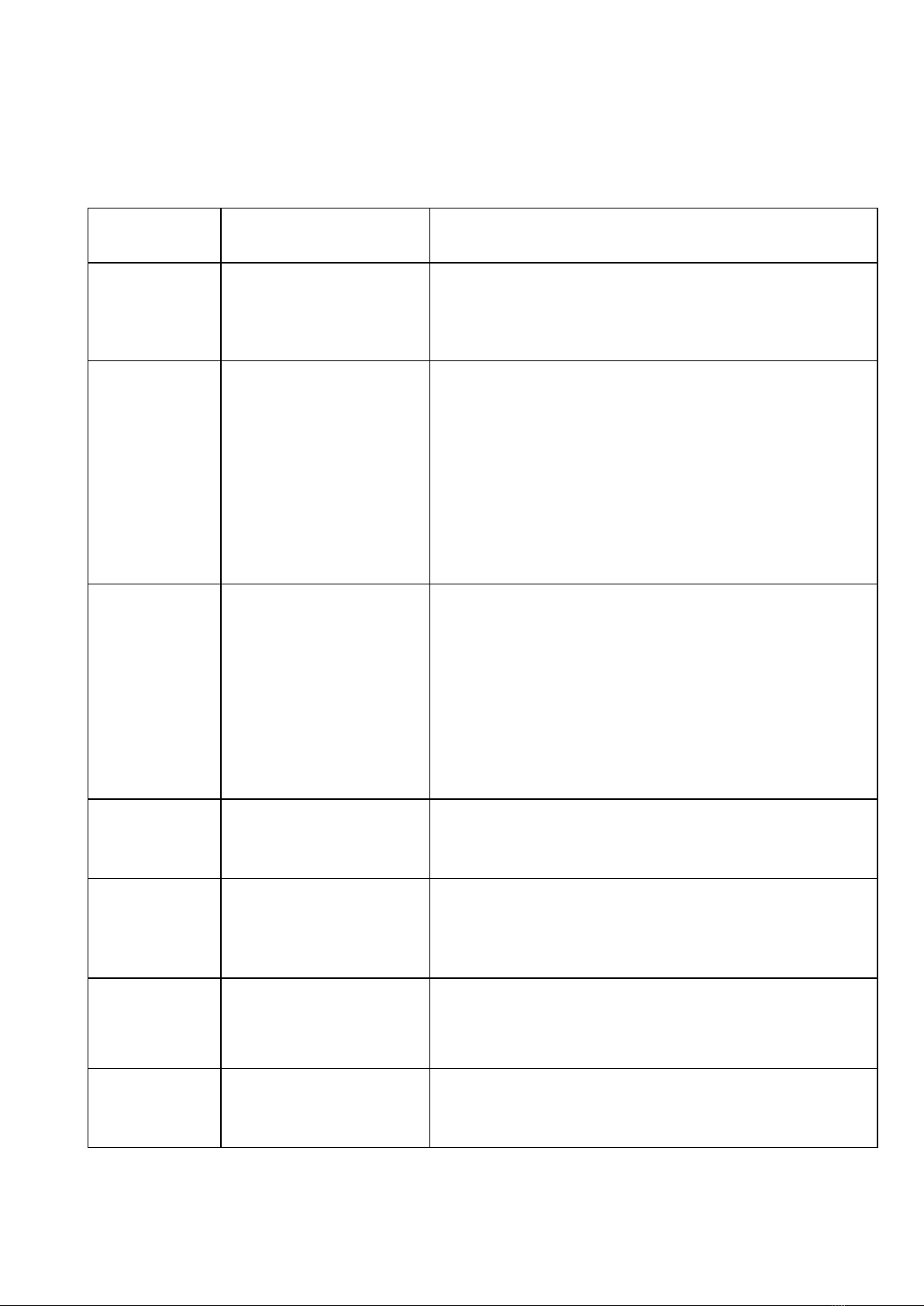

3. Installation

1. Location of installation and atmosphere

Indoor (No rain/water exposure)

Atmosphere ※

Dust level should be that of a

normal factory

Operating

Temperature Range

-15℃to 80℃

※In case of special specification, please confirm the final drawing because use conditions such a use

environment or ambient temperature might be different.

2. Do not place any obstacles that might prevent ventilation around the Jack. They can hinder cooling

resulting in a fire caused by abnormal overheating.

3. Never step or hang on the Jack. This may result in injury.

4. A stopper is not provided on the screw shaft of JWM. If the stroke capacity is exceeded, the shaft may

disengage from the unit or fail to function.

Screw shafts of JWB (Ball Screw Type) and JWH (High Lead Ball Screw Type) rotate and drop by its

own weight. The same is true for the traveling nut of JWB and JWH Travel nut type. Provide

anti-rotation measure to prevent the screw shaft and traveling nut from rotating at the time of

installation.

5. For JWB (Ball Screw Type) and JWH, (High Lead Ball Screw Type), do not operate input shaft

manually while loaded. Load pressure will rotate the shaft.

6. When using equipment that must avoid all contact with oil or grease such as food processing

equipment, make sure a protective device such as an oil receiver is attached to prevent damage from

oil leakage resulting from equipment damage or overuse.

7. When installing a motor and reducer unit in addition to the jack body, prepare a robust counter making

allowance for a safety factor to prevent alignment accuracy at installation from being reduced even if

the maximum load is applied. Make sure that the transmission shaft connected to the input shaft is

aligned accurately (Fig.1).

Fig. 1

8. Using a floating shaft may result in malfunction due to vibration depending on rotation speed,

therefore, sufficiently consider rigidity of the shaft and backlash of the coupling.

※Operating temperature range refers to the

surface temperature of the jack during operation.

To check, measure the surface temperature of the

input shaft unit or travel nut (if used). Be sure all

the rotating parts have completely stopped before

proceeding to

measure.