II Table of Contents - Nitro

Table of Contents

Operator’s Manual I

Warranty and Limitation of Liability ............................................................I

Nitro Apron Chain Warranty..................................................................I

Manuals.................................................................................I

Serial Number ............................................................................I

Principals of Operation ....................................................................IV

Intended Use ............................................................................IV

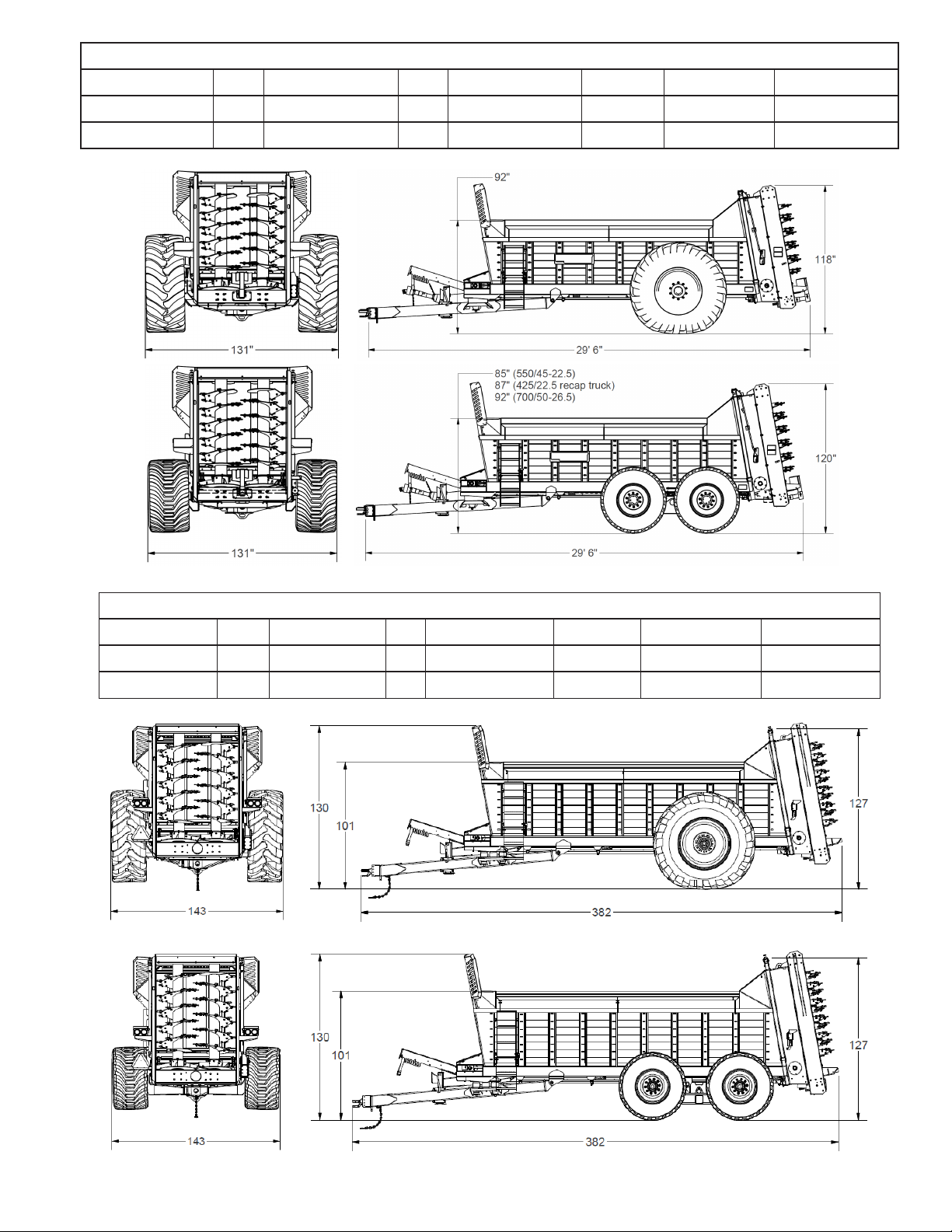

Section 1 - Specications 1-1

Terminology ............................................................................1-4

Hydraulic Requirements ..................................................................1-5

PTO / Horsepower Requirements ...........................................................1-5

Tire Load Index Charts ...................................................................1-5

425/65 R22.5 Recap Truck ................................................................1-5

480/70 R30 R-1W .......................................................................1-5

550/45-22.5 I-3 .........................................................................1-5

600/65R34 R-1W........................................................................1-6

700/50-26.5 I-3 .........................................................................1-6

710/50R26.5 CargoXBIB 170D TL HF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

710/70R38 R-1W........................................................................1-8

710/70R38 R-1W VF .....................................................................1-8

710/70R42 R-1W........................................................................1-9

Section 2 - Safety 2-1

Safety Symbol ..........................................................................2-1

Safety Signal Words .....................................................................2-1

General Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Personal Protection Equipment (PPE) .......................................................2-2

Operation Safety ........................................................................2-2

Tire Safety .............................................................................2-3

Hydraulic Safety ........................................................................2-3

Maintenance Safety......................................................................2-4

Lighting & Clearance Marking ..............................................................2-5

Safety Signs ...........................................................................2-5

Installing Safety Signs ....................................................................2-6

Safety Sign Locations ....................................................................2-6

Safety Decals ..........................................................................2-7

ISO Safety Decal Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

ISO Safety Decals .......................................................................2-9

Section 3 - Operation 3-1

Tractor Preparation ......................................................................3-1

Spreader Preparation ....................................................................3-1

Hook-up / Unhooking.....................................................................3-2

Loading ...............................................................................3-3

Spreading .............................................................................3-3

Unplugging ............................................................................3-3

Reversing Apron Chain ...................................................................3-4

After operating for 2 hours: ................................................................3-4

After operating for 10 hours: ...............................................................3-4