Tucson GBPHR/8/CCW User manual

Gas Boiler Pump Head Replacement

Installation, Operation and Maintenance Manual

Warning Prior to installation, read these installation and operating

instructions. Installation must comply with local regulations and

accepted codes of practice.

General Notes - ErP (Ecological Design) Directive

– The benchmark for the most efficient circulators is EEI ≤ 0.20 Part 3

– Information on recycling/disposal: this product should be disposed of

separately from household waste in line with local laws and regulations.

When this product reaches its end of life, dispose of it at your local

waste collection point/recycling centre.

– The separate collection and recycling of your product at the time

of disposal will help conserve natural resources and ensure that it is

recycled in a manner that protects human health and the environment

ISO9001

COMPLIANT

Part 3

High Efficiency

GBPHR/8/CCW GBPHR/8/CW

2

General Information

The Tucson Gas Boiler Pump Head Replacement or GBPHR is available as

a range of Easy to Install, Retro-fit products for Gas Boilers and is available

as both clockwise and counter-clockwise rotating units. These products are

designed as replacement components to be used across an array of market

leading boilers brands. This range of intelligent frequency conversion

circulation pumps incorporate integrated electronic differential pressure

control technology.

The GBPHR range also incorporates PWM / “Pulse Width Modulation”

technology as standard, allowing for intelligent control of the pump as

required by a boiler unit PCB.

Circulating Pumps incorporate a permanent-magnet motor and variable-

pressure control, enabling continuous adjustment of the pumps performance

to the actual system requirements.

Pump Liquids

Clean, non-aggressive and non-explosive liquids, not containing solid

particles, fibres or mineral oil. In heating systems, the water must meet the

requirements of accepted standards for water quality in a heating system.

Warning!

- Please read the instructions fully before carrying out install.

- Pump must be grounded before connecting to power supply.

- Pump must be installed with leakage protection before use.

- Do not touch the pump during operation.

- Pump system must be able to withstand maximum pressure of pump.

Product Code Definition

Pump Model

Maximum Head (metre)

Rotation

GBPHR 8 CCW/CW

3

3

Control Panel

Gas Boiler Pump Head Replacement

Installation, Operation and Maintenance Manual

Pump Head

Replacement CCW

High Eciency

PP CP AUTO

1 2 3

(

(

Elements on the control panel

Fig. 1

Ref. Description

1 Function button

2 LED light field indicating proportional pressure, constant pressure or

auto mode setting

3 QR code linking to tucsonpumps.ie

4 Rotation direction

Table 1

Light fields indicating the pump setting

The Tucson Gas Boiler Pump Head Replacement has three optional settings

which can be selected with the push-button.

Push button when selecting pump setting

Every time the push button is pressed, the pump setting is changed.

A cycle is twelve button presses.

2

1

3

4

GBPHR 8 CCW/CW

4

Control Panel Operation Procedure

Depress Button Function Function Definition Visual Display LED

0 CS III (Factory

Settings)

Constant curve, speed III

1 AUTO Adaptive mode

2 PP I Proportional pressure curve,

speed I

3 PP II Proportional pressure curve,

speed II

4 PP III Proportional pressure curve,

speed III

5 CP I Constant pressure curve,

speed I

6 CP II Constant pressure curve,

speed II

7 CP III Constant pressure curve,

speed III

8 CS I Constant curve, speed I

9 CS II Constant curve, speed II

10 CS III Constant curve, speed III

/ PWM External control of motor

speed

To select the pumps function, depress the “Function Button” on the

interface panel. Fig 1.

5

Gas Boiler Pump Head Replacement

Installation, Operation and Maintenance Manual

5

Automatic Venting Feature

Function Description Operation

Venting Pump venting/purging

is the process of air

removal from within

the system. Removing

this air is vital to ensure

pump’s operation

efficiency & effectivness

are maximised.

Press & hold the function button for 5 seconds until

LED1+LED2+LED3 light up and then release. The

pump will vent automatically for 5 minutes. All LED

lights flash slowly during venting.

After, it will enter into the previous operation mode

and the LED lights will stop flashing.

Manual

Restart

Restart the pump

manually

(after a long idle time in

the summer).

Press & hold the function button for 8 seconds until

LED1+LED2+LED3+LED4+LED5 all light up and

then release. The pump will start and stop contin-

uously for 5 minutes to unlock. All LED lights flash

quickly during this procedure.

If after the start and stop for 5 minutes, the pump

works as normal, then the LED lights will stop flash-

ing. If it does not work as normal, the pump will

stop running and report a fault code.

6

Supply Voltage 230V, 50/60Hz

Ingress Protection Rating IP44

Insulation Class E

Relative Ambient Humidity Max. 95%

Maximum System Pressure 10 bar

Suction Inlet Pressure Liquid Temperature Suction Minimum Inlet Pressure

≤+75°C 0.05 bar

≤+90°C 0.28 bar

≤+110°C 1.08 bar

EMC Standard EN61000-6-1, EN61000-6-3

Decibel Rating 43dB

Operating Environment Temperature 0°C - 40°C

Liquid Temperature +2°C - 110°C

Surface Temperature Maximum 125°C

EEI ≤0.23 Part 3

Technical Data

Performance GBPHR/8/CCW & GBPHR/8/CW

7

Gas Boiler Pump Head Replacement

Installation, Operation and Maintenance Manual

Fig. 2

1

2

35

4

7

6

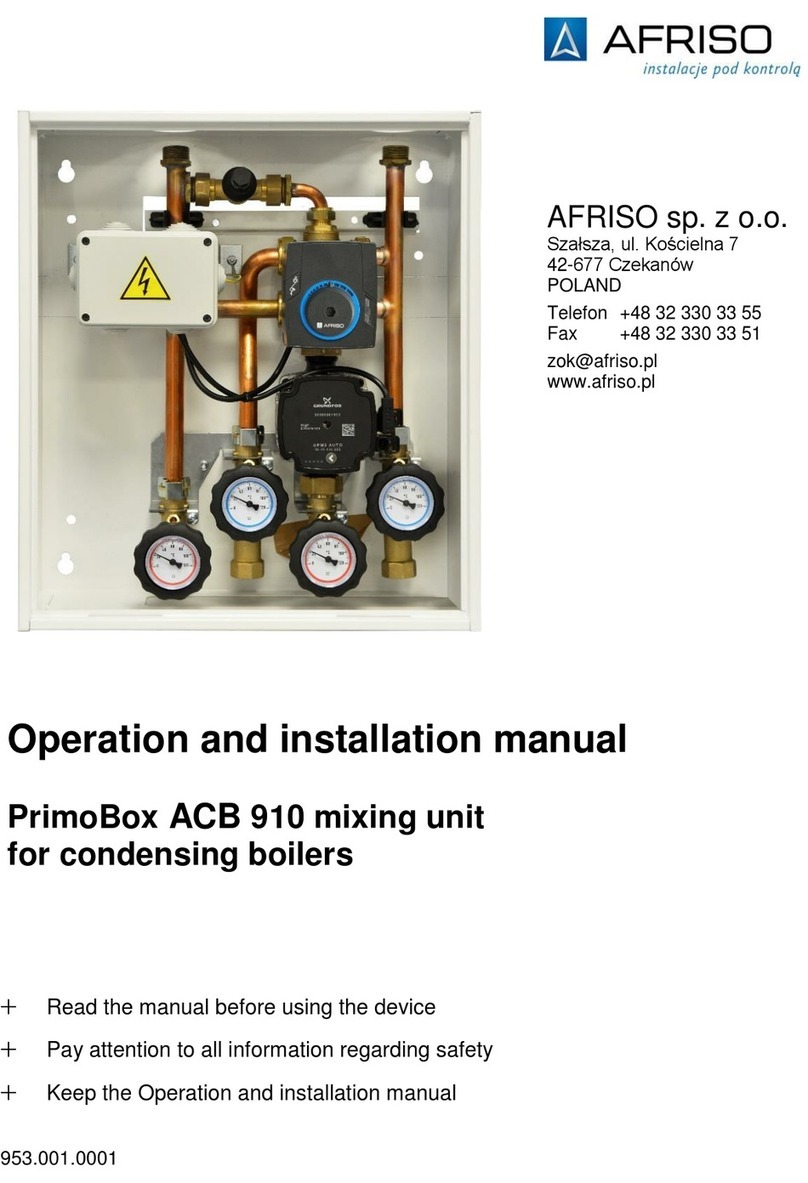

Product Components (Fig. 2 & 3)

1. Pump body model

2. Wet rotor motor

3. Body fixing screws

4. Electronic control board

5. Pump identification plate

6. Function button

7. LED light field

8. PWM control cable (optional) (Fig. 3)

9. Mains power supply (Fig. 3)

8

Fig. 3

9

8

Fig. 4

Fig. 5

AC Power Cable: 230 Vac Brown

Yellow

Blue

Brown: (L) Live

Yellow/Green: Earth

Blue: (N) Neutral

PWM Control Cable

Red

Yellow

Black

Yellow: PWM output (from pump)

Red: PWM imput (from controller)

Black: Ground cable (GND)

9

Gas Boiler Pump Head Replacement

Installation, Operation and Maintenance Manual

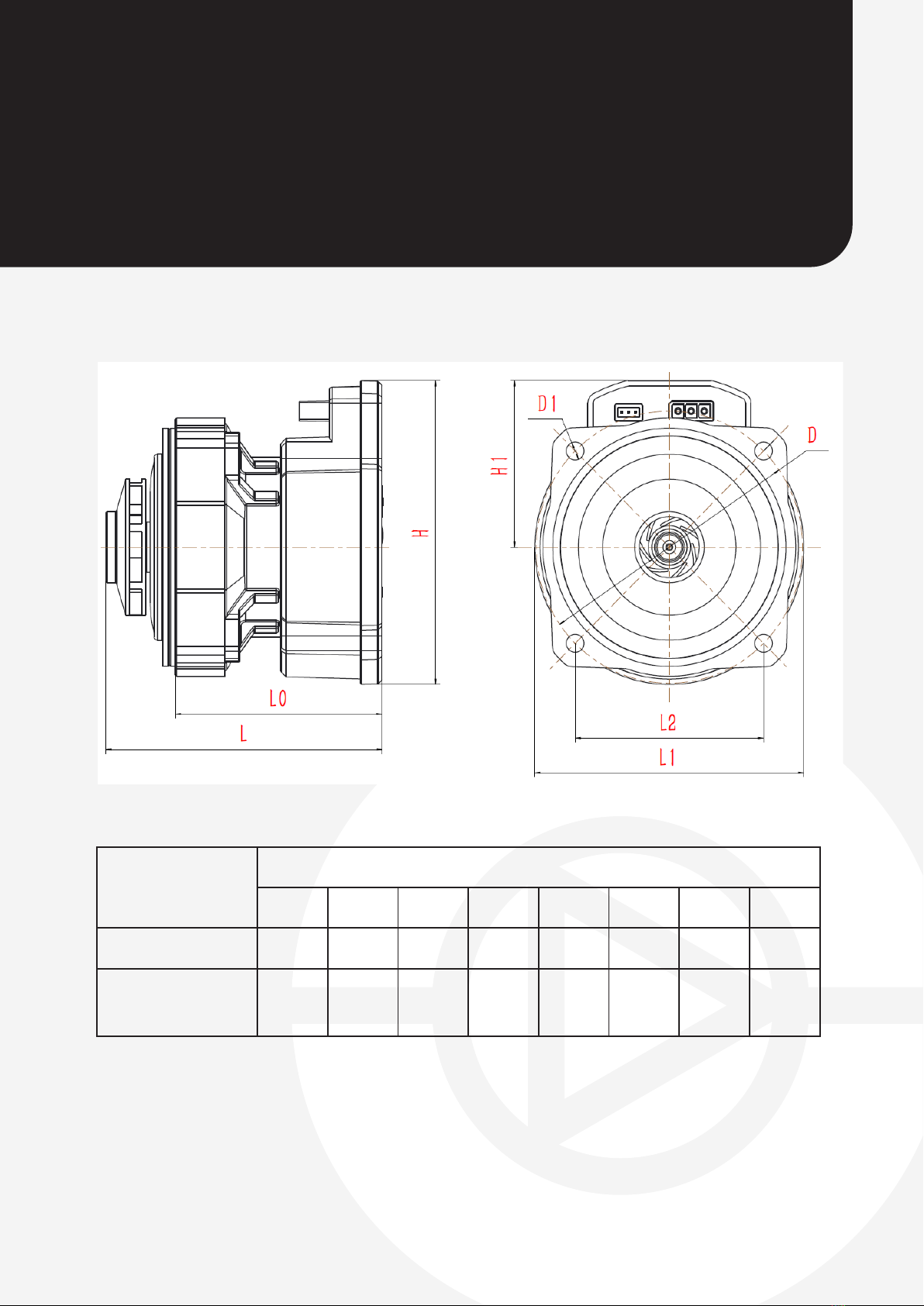

Pump Dimensions

Model Dimension (mm)

H H1 L L0 L1 L2 D D1

GBPHR/8/CW 109 60 102 76 99 69 98 6.5

GBPHR/8/

CCW 109 60 102 76 99 68 96 5.5

Fig. 6

10

Electrical Connection

Electrical

connection

Connection

signal PWM

1. Installation position 2. Position the AC

& PWM cable plugs

towards the control box

sockets and firmly insert

3. Completed assembly

The Tucson GBPHR/8/CCW is compatible and interchangable with the

following pump models:

PWM

- Grundfos®UPM3

- Grundfos®UPM2

- Grundfos®ALFA2

- Grundfos®UPS

- Grundfos®UPS2

(The Tucson GBPHR/8/CCW is compatible

as a replacement head on a PWM

controlled or non-PWM controlled pump)

68mm

This manual suits for next models

1

Table of contents