Table of contents

1INTRODUCTION..........................................................................................................................................3

1.1 Disclaimer..................................................................................................................................................................3

1.2 Output waveform.......................................................................................................................................................3

2FRONT PANEL / REAR PANEL & REMOTE CONTROL....................................................................4

2.1 Front panel (E1000)...................................................................................................................................................4

2.2 Front panel (E1500 - E2000).....................................................................................................................................4

2.3 Front panel (E2000GF / With Ground Fault Circuit Interrupter).............................................................................4

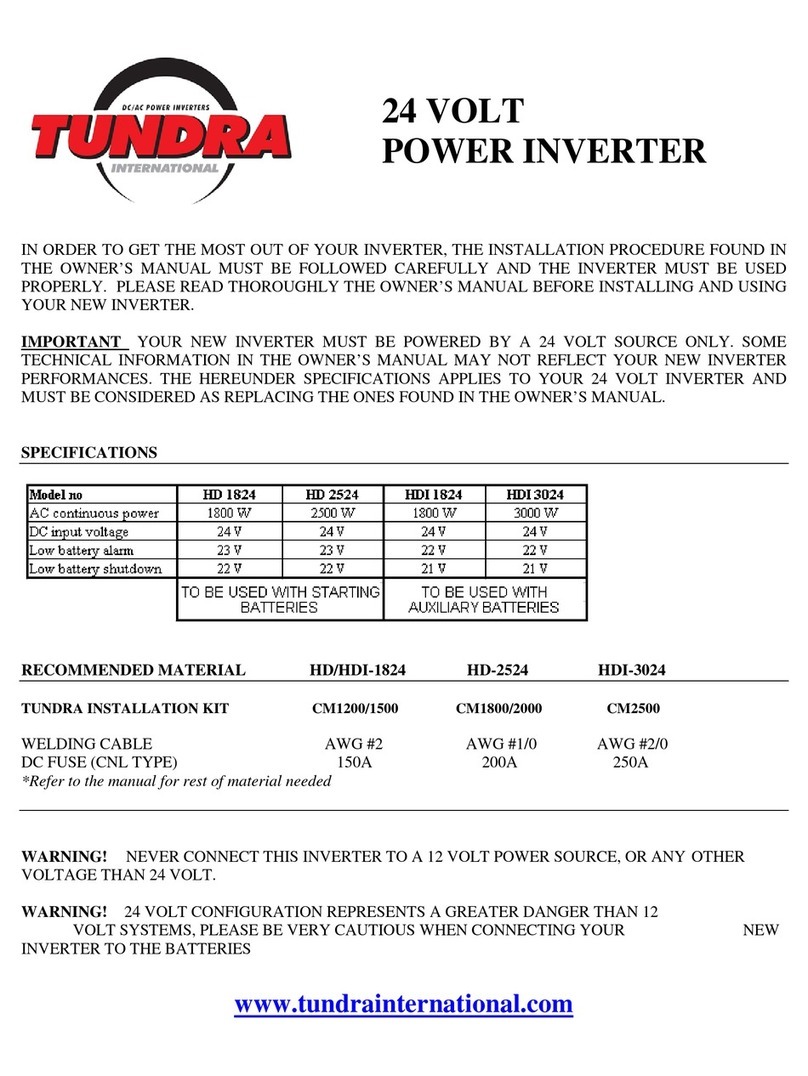

2.4 Front panel (HD1200 –HD1800 –HD2500 –HDi1800 –HDi3000).......................................................................5

2.5 Rear panel (all models)..............................................................................................................................................5

2.6 LCD remote control (all models except E1000)........................................................................................................6

2.6.1 Display................................................................................................................................................................6

2.6.2 Fault codes (you may refer to section 6 for more details):.................................................................................7

3PERMANENT INSTALLATION.................................................................................................................7

3.1 Where to install..........................................................................................................................................................8

3.2 Mounting the inverter ................................................................................................................................................9

3.3 Battery cables.............................................................................................................................................................9

3.4 Strain reliefs installation............................................................................................................................................9

3.5 Ground (not the negative)..........................................................................................................................................9

3.6 Battery cables installation / Inside the cab...............................................................................................................10

3.7 Battery cables installation / Outside the cab............................................................................................................10

3.8 DC fuse installation .................................................................................................................................................11

3.9 Battery connections .................................................................................................................................................11

4OPERATIONS..............................................................................................................................................12

4.1 Operating limits.......................................................................................................................................................12

4.2 Trouble loads - Television & CB radio interference ...............................................................................................12

4.3 Trouble loads - Medical equipment.........................................................................................................................13

4.4 Trouble loads - Microwave......................................................................................................................................13

4.5 Trouble loads - Tools...............................................................................................................................................13

5MAINTENANCE .........................................................................................................................................13

6TROUBLESHOOTING...............................................................................................................................14

7SPECIFICATIONS......................................................................................................................................16

7.1 E SERIES ................................................................................................................................................................16

7.2 HD SERIES.............................................................................................................................................................17

7.3 HDi SERIES............................................................................................................................................................18